In systems with pumping equipment, various types of devices with microswitches and sensors are often used. They help to automatically start and turn off equipment without constantly monitoring the condition inside the water supply or in the tank as a whole. Let's consider one of such devices - a flow sensor. Let's get acquainted with the types of relays and their operating principles. Read to the end, and you will learn about the features of connecting and setting up the classic model.

Example of a water flow switch Source prom.st

Relevance of device installation

Virtually all pumps used in the private sector are equipped with a cooling system that interacts with the working environment. As a rule, this is water from a well or well, sewage, or the contents of flooded areas, natural/artificial reservoirs. In the absence of this kind of “coolant,” the equipment quickly overheats, which leads to a decrease in the efficiency of the unit and its breakdown.

In the case of circulation pumps that operate in heating systems, the cause of failure may be low pressure in the pipeline. Surface units “suffer” from damage to the hose connected to the inlet pipe. Other causes include blockages, unacceptable levels of impurities, and violations of the rules of operation and installation of equipment.

Circulation pump in an autonomous heating system Source eco-kotly.ru

In order to prevent engine overheating due to lack of liquid medium or low pressure in the serviced system, various measures are taken. The simplest thing is to install a low-power pump. The second solution is to exercise constant personal control over the situation as a whole. The third option is to connect special sensors to the network for automatic control of equipment operation.

Visual fluid flow indicators

Fluid flow indicators are simple and reliable instruments for determining the presence, absence and direction of flow.

They are also used to determine the transparency (purity) of liquids and gases. Visual indicators MIDWEST SFI SFI-100, 300, 400, 700 are used in those processes where indication without flow measurement is required. Depending on the contacting medium, they are made of bronze or stainless steel. Depending on the installation location, you can choose with one or several viewing windows. The turbine type is ideal for 360 degree viewing.

Indicators of the series, SF-2, SFI-100T, SFI-800 provide the ability to indicate not only at the installation site. These devices have a relay output signal and a pulse output signal proportional to the flow rate. They are successfully used in automated control systems and are used for water, lubricating oils, fuels, aggressive liquids, paints, and gases.

Types of sensors

The water flow switch for the pump is a compact device. It is configured to measure flow parameters. The device allows the owner to control and maintain it at the same level without personal presence. Among the disadvantages, users highlight only the need for periodic replacement or repair of devices due to the gradual weakening of the springs in the mechanism. On trading platforms, sensors are presented in three versions, which differ in their operating principle. Let's take a closer look at each of them.

Petal

Here the working elements are a valve (petal) and a reed switch isolated from direct contact with water. The moving parts are magnets, which are turned towards each other with identical poles. This is necessary to create a repellent effect to start or stop the equipment.

Example of a water flow sensor with replaceable petals Source yandex.net

The operating principle of a classic water flow sensor is as follows:

- when the pump chamber is filled with water, the petal begins to rotate around its axis;

- valve movements lead to a displacement of the magnet towards the reed switch;

- inside the sealed reed switch bulb, the built-in contact plates come together;

- from the closure, the impulse is transmitted to the pumping equipment in order to turn it on;

- when the water level inside the pump chamber decreases, the rotation of the petal slows down;

- the magnet is removed from the reed switch;

- the repulsive force between the magnetic parts weakens;

- inside the switch bulb, the contacts open;

- If there is no impulse from the sensor, the pump automatically turns off.

There are samples in which the return magnet is replaced by springs. But here the craftsmen note less stability in their work. This is justified by the false activation of the water flow sensor for the pump due to pressure surges. However, a common advantage for petal-type relays is the timely shutdown of equipment.

Press control

Devices of this kind are used, as a rule, to service pumping stations.

Example of press control for a pump Source ebayimg.com

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

The devices are installed on the outlet pipe of the surface pump to control water pressure. The limit values for operation are in the range from 1 to 2 bar. When the pressure is below the limit, the sensor contacts open and the pump turns off. The response time is 5-10 seconds.

The main disadvantage of using such a sensor is the delay in turning off the equipment. In particular, the accumulator is emptied and the next start of the pump will lead to its “idling”. The solution here is two approaches. Either you will have to manually fill the container with water, or install additional check valves on the system. True, masters do not consider the latter the best option.

Thermal relay

Technically, this is the most complex device, which is reflected in the final cost. Here, a pump with a water flow sensor depends on the correct setting of the sensor to the temperature of the contents in the well (more precisely, in the chamber of the submerged unit).

Example of a surface-mounted thermostat for a pump Source pkfst.ru

The control element is heated by electricity. The degree of heating is several degrees Celsius higher than the working environment. As long as water acts as a refrigerant, that is, it is present, the pump operates. As soon as the flow stops, the contacts open and the equipment turns off.

The thermal relay is considered the optimal solution for protecting the circulation pump, which is connected to the home heating system. Additionally, the user gets the opportunity to save on energy bills from this solution. In accordance with the settings, the sensors automatically turn off the equipment when the system reaches the required degree of heating of the coolant. The contacts are also open when the water is cold. Some circulation pumps are prudently equipped with similar sensors at the factory. But this does not apply to the budget category.

Float switch

Here, the flow switch for the pump replaces the float with sensors connected to it.

Example of a float switch Source prom.st

A similar device refers to sensors for monitoring the water level in a particular tank. At the same time, control of submersible equipment for startup and shutdown is also performed automatically.

The sealed float is immersed together with the pump into the container. It is located outside the equipment with a distance of 200-250 mm from the inlet pipe (above). If this gap becomes smaller, the connected sensor is triggered and the pumping unit is subsequently turned off. This solution does not allow working with narrow well channels, but is optimal for a well or other wide reservoir. Another disadvantage of the water level switch is the need to properly adjust the cable to suspend the pump.

Operating principle

The sensor operates on the phenomenon of reflection of ultrasonic waves from the boundary of liquid and gaseous media. The device emits sound vibrations with a frequency of more than 20,000 hertz, receives echoes and measures the signal's travel time. The distance to the boundary of the media is calculated by the formula: R= tV/2, where t is the time from the start of radiation to the reception of the echo, V is the speed of sound. It is necessary to divide by 2 because sound waves travel twice the distance between the surface of the liquid and the emitter.

The speed of sound in air is 331 m/sec. When the temperature changes, this indicator also changes. Therefore, ultrasonic level sensors have a thermometer in their design, the indicators of which are taken into account by the electronic circuit of the device when calculating the liquid level.

Relay selection criteria

First, you need to consider options so that the pump and flow sensor are compatible in terms of the type of thread and the diameter of the node connections. If this is a direct connection, then the experts recommend abandoning various types of adapters. In such units, the likelihood of leaks increases due to several obstacles to the flow of water under pressure.

Size range of water flow sensors Source solar-dom.com

When choosing a device for automatic pump control, it is also necessary to take into account such technical characteristics as:

- permissible limits of temperature and pressure (in the case of circulation equipment it must correspond to its power) for effective use of the relay;

- indicators of the acceptable depth of the water reservoir for submersible systems;

- protection class and other recommendations on the operating conditions of specific samples.

Equally important is what material this or that sensor of water movement in the pipe, temperature or pressure is made of. According to experts, the best options are stainless steel, brass and alloys with a high aluminum content. Such devices exhibit low sensitivity to so-called hydraulic shocks.

Typical configuration of the protective system

The standard circuit includes:

- Ball valves with electric drive, designed to block pipeline lines in case of threat of an accident. In the configuration of such popular systems as Neptune or Aquaguard, ball elements with a valve are used, the size of which can be ½, ¾ and 1″. Devices installed after the inlet valves not only shut them off, but also report an emergency situation. The disadvantage is the need to install them for both cold and hot water.

- The controller is a control module that closes the ball valves after receiving and converting the sensor pulse, and also informs owners about the presence of leaks. The device panel displays information about the status of the meters and the charge level of their batteries. The block is mounted in any accessible place.

- Autonomous and volatile sensors. Install them where there is a risk of water leakage.

Elements included in the structure of the water leakage protection system.

A few words about installation and configuration of the relay

Pumping equipment often lacks various types of sensors, in particular water flow switches. Therefore, the installation of the attachment has to be done separately. Installation is carried out on horizontal sections of the water supply system in order to position the valve in a vertical position.

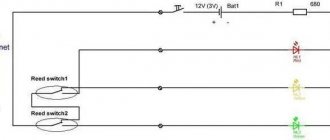

Example of parallel connection of two pressure sensors and “dry running”

How to choose the right one

When choosing an ultrasonic level meter, you must consider:

- liquid properties;

- the material from which the tank is made, its effect on the accuracy of measurements;

- the used circuit for processing measurement information;

- equipping the sensor with a display for displaying data and changing settings;

- availability of certificates;

- influence of temperature changes and other external factors on measurement accuracy;

- the material from which the device is made.

Substances

The great advantage of ultrasonic level sensors is that the measurement accuracy does not depend on the physical and chemical properties of the liquid: density, chemical activity, electrical conductivity, etc. The device will work with water, milk, sulfuric acid, oil. However, in some cases they do not apply:

- for monitoring the level of boiling liquids. The air bubbles formed during boiling have different parameters for reflecting acoustic waves than the liquid - the measurement results are distorted;

- when foam forms on the surface of the liquid, which scatters and absorbs the ultrasonic signal;

- when controlling liquids that require constant stirring. The resulting cavitation and vortex-shaped funnels distort the reflected signal, and the measurement accuracy decreases.

Tank material

The material of the tank inside which the acoustic sensor is installed does not affect the measurement accuracy of the device. The strongest reflected signal comes from the boundary of the media, and the secondary echo from the walls of the container is weak and is not detected by the calibrated device.

When, due to technological factors, compliance with safety measures, etc., the sensor cannot be installed inside the container, the method of repeated reflection of sound vibrations from the internal walls is used to measure the liquid level. The method involves installing the sensor outside. Measurements are possible if the tank is made of metal, fiberglass, glass, plastic. These materials reflect ultrasound well, so the level measurement will be accurate.

Features of application

The use of ultrasonic meters has a number of features. For example, to eliminate measurement errors, you must follow the algorithm:

- carry out calibration of the device when the composition of the gaseous medium changes to establish the actual speed of sound;

- carry out calibration at each significant change in temperature, recording the speed values;

- In the future operation of the device when temperature changes occur, do not carry out calibration, but use previously recorded speed indicators.

The process of setting up the sensor is quite labor-intensive. A situation is possible when changes in the gas environment in the tank are not associated with changes in temperature. In this case, you will have to recalibrate the device.

Source

How to make it yourself

To create a simple level meter, you will need an HC-SR04 ultrasonic module and an 8051 microcontroller. The device allows you to control the liquid level in a tank up to 2 meters deep. To operate the device, you need to isolate the NS-SR04 from moisture.

HC-SR04 is installed at the top of the tank, with the emitter facing the liquid. Ultrasonic vibrations emitted by the module are reflected from the surface of the water. The receiver receives the echo signal, calculates the time delay and transmits the generated signal about the measurement results to the microcontroller.

The microcontroller reads the signal and calculates the distance.

When you enter the required program, the microcontroller will turn on the pump when the water level drops to the minimum set value, and turn it off when the maximum level is reached.

Care

To avoid silting of the drain pipe, preventive maintenance must be carried out periodically. If there are two pipes connected to the aquarium - for topping up and for draining, to clean the drain pipe it is enough to connect them together and turn on the water. You can also make several strong “pumps” into the drain pipe with a car pump. If the sewer drain has a sufficient diameter, it is enough to do this once a year.

The mesh or sponge covering the drain hole should be inspected weekly and, if necessary, cleaned and rinsed.

Products sold

For ease of installation of the sensor and its further regulation, NPP Proma suggests choosing the following types of installations:

- a mechanical sensor is a membrane with contacts that react to changes in pressure and activate the pump;

- An electronic water pressure sensor not only starts the water supply system, but also regulates the pressure automatically.

The advantage of mechanical converters is their price and ease of installation; by tightening the springs, the maximum and minimum operating pressure threshold is set. Electronic devices reduce the number of equipment startups, extending its service life, and inhibit the occurrence of water hammer.

The presented products are suitable for household pumps:

- circulation;

- high blood pressure;

- direct flow

Popular models

The modern market offers many models of alarms. The most popular of them:

- DE-1 (capacitive sensor). Most often, this alarm is used in aggressive environments in the chemical and metallurgical industries. It allows you to control the temperature and level of bulk and liquid substances. Often used in emergency protection installations.

- ESU-1 (electronic level switch). The body of this model is made of high quality steel and fluoroplastic. Most often, ESU-1 is installed in explosive and aggressive environments. The power source is located outside the process environment. The sensor measures the level of oil, alcohol and water. The power supply is made of durable aluminum alloy.

- RU-305 (level relay). This device is designed to monitor the condition of liquid media. Its body is made of special material and can easily withstand temperatures from -50 to +50 degrees Celsius. However, RU-305 must not be used in aggressive chemical environments. Among the disadvantages of this level gauge, consumers note only that it works only in one position, without tilt. Level measurement is carried out by moving a magnet with a float and triggering a reed switch. Measurements have an accuracy of no more than 5 mm.

- SU-100 (level alarm). Sensor for measuring the level of bulk and liquid substances. The SU-100 design contains an electromagnetic relay.

- Rosemount 5600 This radar level sensor allows non-contact measurement of any type of substance. To achieve the most accurate readings, the level gauge must be installed correctly. The device's reading accuracy may be degraded by exposure to electromagnetic radiation. The housing has an explosion-proof design and a display that displays all the necessary information. The Rosemount 5600 can be used to measure tank temperatures. To fully evaluate the capabilities of this equipment, it requires qualified adjustment taking into account the diameter of the pipeline, the length of the level gauge and the distance between the level and the reference point.

It is advisable to purchase complex models only for industrial use. The simplest versions of level meters are suitable for domestic purposes.

Previous Instrumentation and equipment (instruments and equipment) DIY circuit diagram of an electronic thermometer with a remote sensor Next Instrumentation and equipment (instruments and equipment) Methods for measuring power in electrical circuits

I like it I don't like it