Material that does not rust

Various alloying additives are added to low-carbon steel: chromium - at least 12%, nickel, etc. Chromium, when interacting with oxygen from the air, forms a very thin oxide film on the surface, which prevents the rusting process and the action of a chemically aggressive environment. The surface anti-corrosion layer is restored if damaged. Stainless steel has its own characteristics:

- Low thermal conductivity prevents heat removal from the welding site. As a result, overheating and burning of the metal occurs, and alloying elements burn out.

- Low melting point reduces energy costs.

- Low electrical conductivity leads to a decrease in voltage on the metal of the workpiece, which causes overheating and the formation of burns, especially on thin parts

- Large thermal expansion deforms parts when heated.

A material with such properties is difficult to weld. There are several methods, one of which is welding using a semi-automatic machine. A beginner can learn how to semi-automatically cook stainless steel on the website mrmetall.ru.

Which gas to choose

To protect the weld pool from the negative influence of air, gas is used. It improves the burning of the wire and its adhesion to the workpiece without reacting with the molten metal.

There are two methods: MIG – welding with protection with inert gases: argon, helium; MAG – with active gases: nitrogen, oxygen, carbon monoxide.

The main gases used are argon (Ar), carbon dioxide (CO2) - carbon dioxide, nitrogen (N2) and their mixtures.

In a carbon dioxide environment, semi-automatic welding of stainless steel is a frequently encountered option, as it is more economically accessible. In this case, the seam turns out to be clumsy due to the strong splashing of metal.

When using argon, you get a reliable seam that has a beautiful shape. The high cost of gas requires its use for products where the appearance of the connection is important. Semi-automatic welding of stainless steel with argon is most used in industry.

Each gas in its pure form has positive and negative qualities. Therefore, for a more efficient process, gas mixtures in various proportions are used. Based on the complexity of the work, the required result and material costs, one or another gas mixture is chosen.

The most commonly used composition is Ar+CO2 in the proportions of 98% to 2%, 95% to 5%, respectively. Without increased requirements for the type of seam, an increase in carbon dioxide up to 32% is allowed. The percentage depends on the thickness of the material, its type and other parameters. Welding stainless steel in such a protective mixture promotes good spreading of the molten metal and improves the structure of the seam.

Sometimes 1-5% oxygen is added to argon - Ar+O2 . This helps to reduce the porosity of the treated surface and small-droplet transfer of metal, and stabilizes the arc.

What wire should I use to weld stainless steel semi-automatically?

This article will provide all the basic information about stainless steel welding wire. You will learn the features of its marking, the requirements that a quality product must meet, and what you need to pay attention to when choosing.

The features of semi-automatic welding technology with wire will also be analyzed, and the current state of the market for these materials will be analyzed for the main manufacturers and their pricing policy.

Wire welding

The wire is an element that, when welding semi-automatically, takes on the functions of an electrode and transmits current to the surfaces being welded. In addition to this, the knitting wire acts as a filler material, when melted, a welding seam is formed.

Marking of stainless wire for welding

Below is a standard type of wire marking and an explanation of its meaning.

Explanation of standard welding wire markings

- Diameter of metal thread. Stainless steel threads with a diameter of 1.6 mm, 1.2 mm, 1 mm, 0.8 mm and 0.6 mm for semi-automatic welding

- Product brand.

Cell No. 2 – purpose: SV – welding, or NP – surfacing; cell No. 3 – carbon concentration in the raw material, which is indicated in hundredths of a percent. For example: CB09 is a product for welding with a carbon content of 0.09%. Cells No. 4, No. 5, No. 6 and No. 7 indicate the concentration of additional alloying impurities.

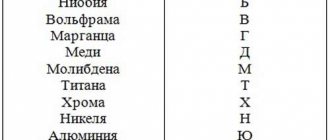

The marking features are as follows: Y - aluminum, D - Copper, T - titanium, G - manganese, C - zirconium, M - molybdenum, X - chromium, N - Nickel, S - silicon. In the cell next after the indicated letter there is a number , which indicates the concentration of a given element, but if the content of the element is within one percent, then, as a rule, the number is not given.

For example: stainless steel knitting wire for semi-automatic welding SV09N5X21T contains 0.9% carbon, 5% nickel, 21% chromium, and 1 percent titanium.

Cell No. 8 - marking in this cell is placed if the welding thread meets the increased requirements for harmful sulfur and phosphorus impurities.

Depending on the standard of the wire, two indicators can be placed in this cell: A - indicating that the product is manufactured according to high cleaning standards, AA - the principle of maximum cleaning was used in the production process, this is how the highest quality stainless steel welding wire is usually marked;

- Production technology (smelting method): Ш – electroslag smelting, VI – smelting in vacuum-induction furnaces (the most preferable option in terms of the final quality of the product), VD – smelting in vacuum-arc furnaces;

- In the case where electrodes can be made from this thread, the marking contains the indicator E;

- O – marking element highlighting copper-coated wire;

- Product compliance with the State Quality Standard.

About making wire

The current standard, according to the requirements of which stainless steel welding wire is produced, is GOST of the Russian Federation 2246-70 “Welding wire made of high-alloy, heat-resistant and corrosion-resistant steel.”

Coils of stainless wire for semi-automatic machines

Since the efficiency of semi-automatic welding directly depends on the quality of the welding wire used, this GOST puts forward strict requirements for the raw materials used to create it.

According to the requirements of GOST 2246, the presence of the following materials in the product is strictly standardized:

The amount of carbon contained in raw materials directly affects the quality of the final product.

If the carbon concentration is sufficient, which is extremely important for a welding thread, then the stainless threads will have good ductility, which has a positive effect on the ease of use in the welding process, and, at the same time, high strength and wear resistance, as a result of which wire consumption will be reduced.

- Manganese and silicon impurities.

These elements are used to deoxidize raw materials during the smelting process. The optimal concentration of manganese and silicon gives the stainless thread high resistance to abrasion, resulting in increased wear resistance and elasticity.

However, it is extremely important that phosphorus and silicon impurities are evenly dissolved in stainless steel, since accumulations of oxides in which silicon molecules can accumulate negatively affect the elasticity of the welded wire.

These elements belong to the category of harmful impurities, therefore their quantity in the raw materials for the manufacture of stainless steel products for semi-automatic welding is strictly standardized.

Stainless Welding Wire Production Process

According to the current GOST 2246, the total concentration of sulfur and phosphorus in stainless steel should not exceed 0.05%; when this norm is increased, stainless steel acquires the property of “red brittleness” - increased brittleness under the influence of high temperature, which makes it difficult to use during welding.

data-ad-client=»ca-pub-8514915293567855″ data-ad-slot=»1955705077″>

Chromium is a foreign element that enters stainless steel blanks during their smelting in blast furnaces. The presence of chromium negatively affects the strength characteristics of the final product, so manufacturers are taking various measures to reduce its concentration, which, according to GOST, should not exceed 0.1%.

The presence of nitrogen impurities in stainless steel has virtually no effect on the strength and elasticity of fresh thread. However, over time, nitrogen provokes an increase in the properties of strain aging - loss of performance characteristics of the product, such as elasticity, strength and fragility.

- The rest (non-metallic impurities).

Any non-metallic impurities in the composition of stainless thread for semi-automatic welding are defects and indicate low quality of the product.

Features of use

There are two main technologies for semi-automatic welding using stainless wire: welding using a short arc, and the pulse method. There is also jet transfer welding; this method does not necessarily require the use of gas, but flux-cored binding wire is better suited for its implementation.

Welding using a short arc (jet transfer) - used in most semi-automatic welding machines. This technology requires the device to maintain a constant output voltage with a high current density.

What wire to weld stainless steel with semi-automatically

[The process of welding stainless steel] semi-automatically in a carbon dioxide environment is not an easy task even for experienced welders.

Due to the special properties of stainless steel, its processing is specific and requires careful preparation, the correct choice of operating mode and consumables.

What is stainless steel?

Stainless steel is low-carbon steel with the addition of chromium. It is chromium, interacting with oxygen, that creates an oxide film, which ensures the corrosion resistance of the metal.

For steel to become stainless, 12% chromium in its composition is sufficient. In this case, the thickness of the chromium oxide film is equal to several atoms.

If the surface of a stainless steel is scratched, the protective anti-corrosion layer is destroyed, but after a while it is restored again.

Modern stainless steel contains not only chromium and carbon, but also a small part of nickel or niobium, titanium or molybdenum.

All these elements also help to increase corrosion resistance, thereby improving the physical and mechanical properties of steel.

Depending on the type of microstructure, stainless steel is divided into classes with different properties:

- Austenitic - contains chromium and nickel. It is characterized by high corrosion resistance, strength and ductility, non-magnetic;

- Ferritic – contains iron and chromium. Resistant to thermal hardening. Used in aggressive environments;

- Martensitic - contains chromium and carbon. Despite its high hardness, it is brittle. Used in slightly aggressive environments.

Special properties of stainless steel that a welder needs to know about

Due to its physical and chemical properties, stainless steel is considered a difficult material to weld. Therefore, when welding, the following parameters must be taken into account.

Low thermal conductivity of stainless steel. Compared to other types of low-carbon steel, the thermal conductivity of stainless steel is 2 times lower.

This factor can contribute to the concentration of heat and more powerful penetration of the metal. At the same time, the anti-corrosion properties of the metal deteriorate.

To avoid unwanted effects, welders resort to reducing the current by 20% and additionally cooling the seam.

Low melting point.

Maintaining the correct thermal regime is the only way to avoid loss of the anti-corrosion quality of steel.

Intergranular corrosion appears as a result of the formation of a carbide compound of iron and chromium. This occurs if the welding temperature exceeds 500 °C.

Subsequently, carbides provoke cracking, which leads to corrosion.

Wire selection

When welding, the wire is both an additive and, together with the molten metal, fills the seam. Two types are used: powder and solid with a very low carbon content and high silicon content, resistant to an oxidizing environment.

The diameter varies from 0.13 to 6-10mm. For household use, wire with a cross-section of 0.6 and 0.8 mm is usually taken; for production, where they work with powerful semi-automatic systems, wire with a cross-section of over 1.0 mm is used.

To weld stainless steel semi-automatically without gas, use flux-cored (self-shielding) wire. It is a thin steel tube filled with flux. When the top layer melts, the flux is released and also protects the welding zone from oxidation. A lot of slag is formed that must be removed.

Solid wire is used to carry out the process in a gas environment and submerged arc, and it must be identical to the metal being processed, i.e. made of stainless steel. It is better to take wire with a slightly higher content of alloying elements, due to their burnout at high temperatures.

Some brands of welding wire:

- 0.8x20n9g7t – contains chromium, nickel and manganese;

- 0.6x19n9t – high quality, corrosion resistant;

- 0.4x19n11m3 – chrome-nickel with the addition of silicon and molybdenum for resistance to intercrystalline corrosion.

To reduce the formation of splashes from molten metal, a wire of smaller diameter than the electrode is used. The seam is neat, but at the same time its consumption increases.

Some devices are equipped with a cable hose, inside which wire, gas, and current pass separately from each other to deliver it to the welding zone - the so-called welding hose.

Types of welding wire for semi-automatic machines

Under normal conditions, just over a dozen types of welding wire are used, out of more than seventy types produced. This is explained by the industrial specifics of using most types of welding machines, and the high cost of some of them. The most popular types are products with a diameter from 0.6 mm to 2 mm, weighing from 1 kg to 5 kg. Products are divided into solid wire and tubular wire with fillers, which have different purposes. According to the chemical composition, it can be aluminum, copper-coated, with titanium impurities and alloying.

The wire for semi-automatic welding of stainless steel is selected with particular care because it should be as close as possible in composition to the material being welded. Current parameters are also important, since overheating when welding stainless steel leads to a loss of the physical properties of this material.

When joining different grades of stainless metal, the following types of stainless welding wire should be selected:

- for chromium-nickel steels 12Х18Н9Т and 08Х18Н10Т, use grades SV-06Х19Н9Т, SV-01Х18Н10 or an analogue OK Autrod 347 Si in an argon environment;

- steel types 03Х17Н14М2 and 08Х18Н10Т are welded using grades SV-01Х18Н10, SV-06Х19Н9Т and OK Autrod 308LSi in inert gas;

- Stainless steel of chromium-nickel-molybdenum composition is welded with wire SV-06Х20Н11М3ТБ, SV-08Х19Н10М3Б and OK Autrod 318 in an argon environment.

These types of wire correspond to grades of stainless steel and provide high levels of strength, elongation, toughness and yield, making the weld strong and elastic after cooling and deslag removal. When working with high-frequency inverter or direct current, the metal in the weld pool does not overheat, which means that the corrosion resistance at the junction of the parts is not impaired.

The parameters and composition of the wire are regulated by GOST 18143-72, which determines the quality assessment criteria and the production method.

Also, flux-cored wire with rutile filler is used to connect stainless materials and dissimilar steels. It is used for welding difficult-to-weld, carbon-manganese and stainless steels in a gas mixture of 80% argon and 20% carbon dioxide. Powder products make it possible to work in any position, and are alloyed with molybdenum, which gives the weld high physical and chemical properties.

For steel grade E 2209, OK Tubrod 14.27 wire is used, for stainless steel 317 and 317L OK Tubrod 14.25 is used, and for grade 309 OK Tubrod 14.22 is suitable. For welding other metals, you can use self-protecting powder products with flux (for example, SV-000009283), which do not require an inert gas atmosphere.

Preparatory work

Before cooking stainless steel with a semi-automatic machine, careful preparation is required:

- Clean work surfaces until shiny;

- degrease parts with acetone or any organic solvent;

- if the metal thickness is more than 4 mm, process the ends so that a small space is formed between them for filling with metal;

- warming up the parts to 100, remove excess moisture;

- heat the metal to 200 to relieve internal stress.

In production, to remove surface contaminants: carbon deposits, traces of grease, rust, parts and wires are etched with a solution of hydrochloric or sulfuric acid. After this, rinse with hot and cold water and dry.

The flow rate of the gas mixture at an operating pressure of 0.2 atmospheres using a reducer is set within the range of 6-12 m3/min. Failure to comply with these indicators reduces the quality of the seam.

Adjustment of current and voltage depends on the power of the device.

The penetration depth, arc length, and weld shape depend on these parameters. As the current increases, the deposited weld becomes wider, and the welding depth decreases.

Some settings for a semi-automatic welding machine:

| Metal thickness, mm | Wire diameter, mm | Gap when butt welding parts, mm | Current strength, A | Welding voltage, V |

| 1 | 0,8 | 0 | 65 | 17 |

| 1,5 | 0,8 | 0 | 115 | 17 |

| 2 | 0,8 | 0,5 | 130 | 17,5 |

| 3 | 1 | 1 | 210 –215 | 18 |

| 4 | 1 – 1,2 | 1,5 – 2,5 | 220 – 280 | 20 |

| 5 | 1,2 | 2,5 | 190 – 300 | 21 |

| 6 | 1,2 | 2,5 | 300 | 22 |

Each machine is supplied with a table of welding modes. The master selects the semi-automatic operating mode, depending on the welding parameters. After setting up the machine, weld on a test piece. If necessary, adjust the settings.

Welding fluxes: functions, classification, general requirements

Welding flux is one of the most important elements that determine the quality of the weld metal and the conditions for the welding process. The composition of the liquid slag and gas atmosphere depends on the composition of the flux. The interaction of slag with metal determines the specific chemical composition of the weld metal. The composition of the weld metal determines its structure and resistance to cracking. The composition of the gas atmosphere determines the stability of the arc, resistance to the appearance of pores and the amount of harmful gases released during welding.

Functions of welding fluxes

Fluxes perform the following functions:

- physical isolation of the weld pool from the atmosphere;

- arc discharge stabilization;

- chemical interaction with liquid metal;

- weld metal alloying;

- formation of the seam surface.

The best insulating ability is found in fluxes with a dense structure of finely granulated particles. However, when flux particles are densely packed, the formation of the weld surface deteriorates. Sufficiently effective protection of the weld pool from atmospheric influences is provided at a certain thickness of the flux layer.

The required flux layer height for welding low-carbon and low-alloy steels in various modes is as follows:

| Welding current, A | 200 — 400 | 600 — 800 | 1000 — 1200 |

| Flux layer height, mm | 25 — 35 | 35 — 40 | 45 — 60 |

Stabilizing elements are introduced into the flux to increase the stability of the arc. The introduction of these elements makes it possible to use alternating current for welding and to vary welding modes more widely.

The chemical composition of the weld metal is formed by the base and electrode metals. The composition of the flux can also lead to changes in the chemical composition of the weld metal. However, these changes are possible, as a rule, only within fractions of a percent. Ceramic fluxes are used to alloy the weld metal.

The forming ability of fluxes is determined by the viscosity of the slag, the nature of its dependence on temperature, interfacial tension at the metal-slag interface, etc. The forming ability largely depends on the arc power. When welding with a powerful arc (current over 1000 A), good formation is ensured by “long” fluxes, the viscosity of which monotonically decreases with increasing temperature. When welding circumferential welds of small diameter, to prevent slag swelling, “short” fluxes should be used, the viscosity of which sharply decreases with increasing temperature.

The gas permeability of the flux, which is determined by the particle size and bulk mass of the flux, has a significant influence on the formation of the weld. The recommended particle sizes of glassy flux depending on the arc power to ensure satisfactory weld formation are given below.

| Welding current, A | 200 — 600 | 600 — 1200 |

| Particle granulation, mm | 0,25 – 1,6 | 0,4 – 2,5 |

Classification of fluxes

Fluxes can be classified according to:

- manufacturing method;

- chemical composition;

- structure and size of particles;

- purpose.

According to the manufacturing method, fluxes are divided into:

- fused;

- ceramic;

- mechanical mixtures.

Fused fluxes are produced by fusing the components of the charge in electric or flame furnaces.

Ceramic fluxes are made from mixtures of powdered materials held together with adhesives, mainly liquid glass. Sintered fluxes are produced by sintering the components of the charge at elevated temperatures without fusing them. The resulting lumps are then crushed to the required size.

Flux mixtures are made by mechanically mixing grains of various materials or fluxes. A big disadvantage of mechanical mixtures is their tendency to separate into components during transportation and during the welding process due to differences in density, shape and size of the grains. Therefore, mechanical mixtures do not have constant compositions and welding properties and do not reliably provide stable quality welds.

Depending on the chemical composition, fluxes are classified according to their content:

- silicon;

- manganese

Low-silicon fluxes contain less than 35% silicon oxide (SiO2). When the content is more than 1% manganese oxide (MnO), the flux is called manganese. High-silicon fluxes contain more than 35% SiO2; Manganese-free fluxes contain less than 1% MnO. Oxygen-free fluxes occupy a special group when classifying fluxes by chemical composition.

according to the degree of alloying :

- passive (practically no alloying of the weld metal);

- lightly alloyed (fused);

- and alloying (ceramic).

Based on the particle structure, fused fluxes are divided into:

- glassy (transparent grains)

- pumice-like (grains of foamy material white or light shades of yellow, green, brown and other colors).

Pumice-like fluxes have a lower bulk density (0.7-1.0 kg/dm3) than glassy ones (1.1-1.8 kg/dm3). Fused fluxes have found the greatest application.

Depending on the purpose and primary use , fluxes are distinguished for electric arc and electroslag welding, as well as for mechanized welding and surfacing of carbon steels, alloy steels, non-ferrous metals and alloys. This division is to a certain extent arbitrary, since fluxes, primarily used for welding and surfacing of metals or alloys of one group, can be successfully used for welding and surfacing of metals of another group. At the same time, fluxes intended for welding some non-ferrous metals or some grades of alloy steels may be unsuitable for welding other non-ferrous metals or other grades of alloy steels.

General requirements for flux

Fluxes for mechanized welding must ensure a stable welding process, the absence of crystallization cracks and pores in the weld metal, the required mechanical properties of the weld metal and the welded joint as a whole, good formation of the weld, easy separation of the slag crust, minimal release of toxic gases during welding, and also have low cost and the possibility of mass industrial production.

According to EN 760, welding fluxes are classified according to their chemical composition as shown in the table below.

Classification (types) of fluxes by chemical composition

| Symbol | Main components | Flux type | Basicity index |

| MS | MnO + SiO2 > 60%; CaO 15%; ZrO2 | Manganese silicate | 0,8 |

| C.S. | CaO + MgO + SiO2 > 60%; CaO > 15% | Calcium silicate | 0,7-1,2 |

| AR | Al2O3 + TiO2 > 45% | Aluminate-rutile | 0,7-1,4 |

| AB | Al2O3 + CaO + MgO + CaF2 > 55%; Al2O3 > 20%; CaF2 (total fluorine content) 20% | Aluminate-basic | 1,0-2,0 |

| FB | CaO + MgO + MnO + CaF2 > 50%; SiO 2 20%; CaF2 (total fluorine content) > 15% | Fluorite-basic | > 2,0 |

| W | Fluxes whose composition does not fall under any of the specified types | Others |

Sequence of work progress

Stainless steel welding can be carried out in three main ways:

- Using a short arc - semi-automatic gas welding, especially suitable for working with thin workpieces;

- with jet transfer - cored wire is used;

- The pulse method is the most accurate and efficient, when the wire is fed into the welding zone by pulses in the form of small drops.

Before cooking stainless steel semi-automatically in carbon dioxide, you need to take into account the general provisions:

- Set reverse polarity - turn on the burner in the positive terminal, and the workpiece in the negative terminal;

- the current should be approximately 20% lower than for conventional welding;

- departure, i.e. distance from tip to tip of wire, no more than 12mm;

- To remove water vapor, the gas passes through a dryer located before or after the reducer.

- fill the device with a coil of wire. Using the broaching mechanism, its tension is adjusted.

Semi-automatic welding of stainless steel in a carbon dioxide environment

Stainless steel is a material that is low carbon steel with the addition of chromium. The resulting alloy has high resistance to acidic environments and increased anti-corrosion resistance.

Despite all the advantages, this composition has one drawback - to obtain high-quality welds, you must comply with all technical requirements for the selection of materials and welding technology. Welding stainless steel can be simplified by using semi-automatic welding and wire suitable for this purpose.

In this article you will learn how to cook stainless steel with a semi-automatic machine. We will look at what materials you need to choose, the technical design, setting up the device and other nuances.

Stainless steel welding technology in a carbon dioxide environment

Next, we will consider the principles of operation of the bundle - semi-automatic, stainless wire and carbon dioxide, as the most common option that exists. The process consists of several stages: preliminary preparation, the welding process itself and post-processing.

Welding process

Once the equipment is set up and all recommendations are taken into account, you can proceed directly to welding.

To avoid the appearance of deformation and cracks, a gap is left between the parts along the entire length for expansion. The parts are secured in a vice or other way and clamped in several places.

You need to start with minimal consumption of shielding gas. Turn off the wire feed and adjust the gas flow rate to operating mode using the valve on the reducer. Then direct the gas flow to the workpiece and blow through its surface in literally 3-5 seconds.

At the beginning of welding, you need to look at the seam. If pores form, increase the gas supply until they no longer appear. Gas consumption must be adjusted to economical mode. So that the quality of the seam does not suffer.

You need to start cooking 5-6mm away from the edge to prevent cracks from forming. The torch nozzle should be angled slightly back in the direction of the seam and at a height of 10-12mm above the welding joint.

If the angle is tilted forward, the weld width increases and the penetration of the welding arc decreases, which is good for thin sheets.

Welding speed

The speed at which the electric arc moves along the welding site is controlled by the welder. Too high - it can cause a lot of splashes and melting of the metal, while the protective gas does not have time to escape and pores form. Insufficient speed is the reason for changes in the penetration of the welding arc into the parts being welded.

You need to cook with a short arc - this is when the distance between the end of the wire and the surface of the molten metal is 0.5-1.5 mm. Boiled in this way, the seam has the correct outline, a smooth and convex surface.

Another method of welding thin parts is pull-off welding, i.e. short circuits of the arc gap. Press the trigger and release, and gradually fill the joint with a thread seam (rollers).

If the device has a pulse function, then it is better to work on it. Pulses generated by a short circuit in the welding machine are used to melt the metal.

When welding thin (up to 3mm) stainless steel with a semi-automatic machine, guide the torch nozzle along the seam, avoiding transverse movements. Otherwise, there is a possibility of molten metal leaving the protective environment zone. It is better to weld thin parts in a vertical position, moving from top to bottom.

If two workpieces are of different thickness, then keep the nozzle on the thick one. With an instant movement, move the torch to the thin workpiece and return to the thick one again. Otherwise, the thin metal will burn out.

To avoid serious defects during welding, it is worth using ceramic pads, which are self-adhesive tape. They are most suitable for working with thin parts, as well as in awkward spatial positions.

Features and Benefits

The advantages of semi-automatic and automatic welding under a protective layer of flux allow this type of permanent connection to occupy one of the leading places.

High level of performance

According to this characteristic, the advantage over manual welding is at least 6 times, some experts believe that it is much more. But this is not the limit; by increasing the operating coefficient of the welding machine, the amount of labor productivity increases. Another reason for achieving such results is the use of high current values during welding.

A dense layer of flux material does not allow the metal to spread, while good weld formation occurs. At higher current values, this equipment can reliably provide penetration of even thick metal without extensive cutting of edges. Therefore, productivity increases even more. The time required to clean up splashes and heavy metal spreading is reduced.

Improved seam quality

The quality of the connection increases due to the fact that the molten metal is not exposed to oxygen and other atmospheric substances.

There is a wide choice of welding wire material available. By using the brand that is best suited for welding, you can obtain a weld with a homogeneous composition.

It becomes possible to give the seam an excellent shape, with the required seam leg. Thanks to the protective film that forms when the flux burns, there are no undercuts, lack of penetration, pores or cracks in the seams. Finally, there is no need to replace electrodes, so the seam is smooth and without tears.

Economical consumption of materials and improved working conditions for the welder

When welding with submerged arcs, wire consumption is reduced by up to 35%, when compared with welding with electrodes. The material is not wasted in the form of cinders and metal spattering.

With this method, carbon monoxide is released in smaller quantities; the specialist’s eyes and face are not exposed to strong ultraviolet radiation, as with electric welding.

Connection of stainless steel and black steel

Welding of such materials is carried out at direct current. The position of the wire is strictly perpendicular to the working area.

Stainless steel wire must contain manganese and nickel, for example, ESAB OK, Autrod. A special transition wire deposits a buffer layer, which connects the parts.

When welding St40 steel to stainless steel, you can use 08G2S wire. This strengthens the seam between two dissimilar metals after cooling. The most important thing in the process is that the stainless steel does not become too fluid, and the ferrous metal does not remain solid. The seam is made as wide and as deep as possible.

Advantages and disadvantages

The undoubted advantages of semi-automatic welding of stainless steel:

- High performance combined with high-quality connection;

- low smoke emission, which protects health and the environment;

- slight metal spattering due to automatic wire feeding;

- versatility - you can weld workpieces of different thicknesses, as well as dissimilar metals.

One significant drawback is the bulky gas cylinder. These are additional costs for its acquisition and inconvenient movement.

The spread of the method became possible with the development of technology and process automation. Mainly used in industry for large-scale production. Working with a semi-automatic welding machine, although it requires certain knowledge and skills, still remains one of the popular types of metal processing. You can learn more about how to operate a semi-automatic welding machine in our article.

Application area

It is necessary to understand where submerged arc welding is used, which is rightfully considered one of the main methods for obtaining a permanent connection. Welding is performed in the lower position, for connecting parts end-to-end, overlapping, for corner connection methods.

Previously, the method was used only for welding metal structures made of structural steels. With the development of new technologies, it became possible to weld all types of steel and nickel alloys. For this purpose, a wire suitable in its composition is used.

Titanium and its alloys, copper and copper-based alloys, aluminum alloys and pure metal - these materials are successfully and reliably joined using submerged arc welding.

Using the submerged arc method, complex building structures, bridges, pipes, tanks, sea and river vessels are welded. It is economically profitable to use this method for sheets with a thickness of 6 mm or more.

It is important to choose the right operating mode, wire material and type of flux . The seam will be able to withstand large temperature changes and exposure to aggressive environments. A joint made by a professional will withstand very high pressure and will be reliable in conditions of complete vacuum.