If you want to know how much oxygen cylinders weigh, what types they come in, their volumes and sizes. You will find all this in our article, and also learn how to find out the amount of oxygen in a cylinder and the features of cylinder inspection.

Oxygen is used in various fields of activity: construction, industry and medicine. Stored and transported in special oxygen vessels, the weight of which is a key parameter.

All characteristics of oxygen containers are usually written on the body of the product, where there is information about the weight of the tank in kilograms, a special trademark of the manufacturer, its own unique number, the number of further maintenance, maximum pressure and displacement.

Characteristics of an oxygen cylinder.

Oxygen-containing containers are needed for containing and transporting gas. The tank is painted with blue indelible paint with the signature “OXYGEN”. The vessel has a volume of 40 liters and is made of steel. The normal pressure of a gas cylinder is from 9.8 to 9.6 MPascal. The container has a total diameter of 219 mm and a length of 1350 mm.

The weight of a 40 liter oxygen cylinder can reach up to 51 kilograms without valves, caps and other devices. The neck thread complies with the standards, and the valve is installed using a special seal.

Containers must undergo timely inspection. The main condition is that it must be manufactured with a strength of 65 kilograms per millimeter squared and the surface of the cylinder must be smooth without foreign defects.

Useful article - How to check your NAKS certificate using the register of welders - find yourself by last name on the official website

Maximum oxygen cylinder pressure.

Container pressure is a parameter that is responsible for the volume of gas that the container can withstand. In a tank with a volume of 40 liters, the highest pressure indicator is 150 kilograms per centimeter cubed. Such a tank holds 6 thousand liters or 6 cubic meters. The pressure of a 50 liter oxygen cylinder puts 200 kilograms per centimeter cubed, which is 10 cubic meters of gas.

The oxygen tank pressure may deviate due to increased or decreased temperature. The standard indicator for a gas container is +20 degrees, and at +40 degrees the pressure can rise by 10 Pascal. In turn, at 0 temperature it will decrease by 10, and at -40 it will decrease by 30 Pascal.

When refilling the container, it is important to pay attention to this parameter. It is necessary to use a special formula that allows you to correctly determine the required pressure, and when calculating, take into account all the characteristics of the container model.

Weight of a full and empty oxygen cylinder.

Oxygen-containing containers are manufactured in different volumes, on which, first of all, the weight of oxygen in the cylinder depends.

Empty cylinder weight.

To determine the mass of the remaining gas, you need to know the weight of the container without and with contents. It is impossible to say exactly what the weight of the container is because it can come in different sizes. The weight of an empty 40 liter oxygen cylinder varies depending on the size and substance from which the product is made. The weight of the container, which is made from forty-five d steel, is 58.5 kilograms with parameters of 1370 millimeters and 76.5 kilograms with dimensions of 1430 millimeters. The gas container is made of 30KhGSA steel, has a length of 1350 millimeters, and weighs fifty kg.

Elements that come with a gas cylinder. The weight of an empty oxygen-containing vessel consists of the following elements:

- The gas vessel itself;

- Fan made of brass (0.5 kilograms);

- A cap made of aluminum or plastic (1.8 kilograms);

- Ring for putting on a cap, (0.3 kilograms);

- The shoe is made from steel tape (5.2 kilograms).

The latest equipment gives the structure greater stability.

When producing containers, solid drawn metal tubes are used. The wall size reaches 7 millimeters. A tube of the required length is pressed into a rounded shape and a neck is created, which is needed to install the valve.

A ring is put on the other neck, which is necessary to secure the gearbox. The cap is necessary to protect against technical damage. The components may have a lot of weight, which must be calculated during use.

Useful article - How to properly prepare welding documentation and submit work on time

Weight of a full oxygen cylinder.

To calculate the weight of a full oxygen cylinder, use various special calculations for gas or look at table values. The weight of a full oxygen cylinder is the sum of the capacity and gas pressure. The weight of an empty container from a filled one usually differs by ten kg, and the pressure does not exceed 14.7 MPascal.

An ordinary oxygen-containing container, which is made in accordance with GOST, can hold 40 liters of oxygen. It weighs about 70 kg, and the pressure reaches 19.6 MPascal or 193 atmospheres.

This vessel can hold about 11.5 kg of gas. When adding up all the indicators, the total weight of the cylinder filled with oxygen is from 76 to 86 kg.

Useful article - Certification of welders and specialists: what is it for, how does it happen, types of certification

Oxygen cylinder volumes.

The volume of oxygen in the cylinder varies depending on the purpose and the amount of content that was filled into it. It may depend on the type of gas transportation. Each volatile substance has its own standards for filling containers.

Oxygen cylinder, the volume of which may vary. This depends on the material from which the container is made. Metal containers made of steel can reach a volume of 5 to 50 liters. There are small disposable containers that cannot be refilled.

They are also called cartridges. They are made in the form of steel containers and can hold up to 450 grams of gas.

Dimensions of oxygen cylinders.

The dimensions of steel containers are determined by:

- Gas cylinder volume;

- The thickness of the walls of the vessel;

- Container diameter;

- Container lengths.

All characteristics are measured in millimeters or liters.

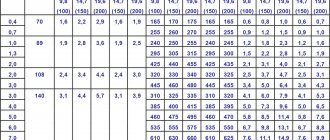

The weight of a standard oxygen-containing cylinder ranges from 9.8 to 93 kg, and may contain dimensions: 70x165, 89x240, 108x310, 140x460, 140x495, 140x610, 219x770, 219x1775 millimeters, where the first number is the diameter and the second is the length.

4. TEST METHODS

4.1. Pneumatic and hydraulic pressure tests are carried out in accordance with the “Rules for the design and safe operation of pressure vessels.” Test duration is at least 1 minute. Pneumatic tests of cylinders intended for filling with gases, the penetrating ability of which is higher than that of air, must be carried out in accordance with regulatory and technical documentation. (Changed edition, Amendment No. 4).

4.2; 4.3. (Excluded, Amendment No. 4).

4.4. Cylinders equipped with a chlorine valve are tested with a pneumatic pressure equal to 2.94 (30 kgf/cm2).

4.5. Tensile test according to GOST 10006-80. The test speed up to the yield point and during its passage is no more than 10 mm/min, beyond the yield point is no more than 40 mm/min. It is allowed to control the mechanical properties of carbon steel cylinders using a non-destructive method according to the regulatory and technical documentation. In controversial cases, tests are carried out in accordance with GOST 10006-80.

4.6. Impact bending test - according to GOST 9454-78 on longitudinal samples of type 3.

4.7. If the test results do not comply with the requirements of this standard, tests are carried out on twice the number of samples. If the results of repeated tests are unsatisfactory, the entire batch of cylinders is sent a second time for heat treatment. No more than two repeated heat treatments are allowed. Additional tempering is not considered repeated heat treatment. (Changed edition, Amendment No. 4).

4.8. The volume of the cylinder must be controlled by limiting templates along the length; in this case, the volume of the cylinder should not be lower than the nominal one. The volume of two cylinders from a batch is checked by filling with water and determining the volume or mass of water.

Note. From 01/01/89, determination of the volume of all medium-volume cylinders is introduced. (Changed edition, Amendment No. 1, 2).

Inspection of gas containers.

Inspection is a process that allows you to determine how long it is possible to use a gas container and under what circumstances use should occur. When a container is accepted for diagnostics, an internal inspection is carried out, the weight is measured, valves and adapters are made, after which cleaning and degassing occurs.

All walls inside and out are checked for unevenness, rust, cracks and other mechanical damage. After which the gas cylinder is again washed, disinfected, painted, and the weight and capacity of the cylinder are checked.

This is necessary in order to see damage to the walls and decide on the further use of the gas cylinder. If the capacity increases by 1.5 percent or more, and the weight decreases by 5 percent, then the container can be used, but with little pressure. If the indicators have changed in the opposite direction, it is prohibited to use such a cylinder.

Next, during the inspection, hydraulic tests are carried out. The vessel is connected to a pressure many times greater than the operating limits. This allows you to check the walls for wear. After which the vessel is dried. At the end, the gas cylinder must be branded.

Useful article - Metal welding: methods, types, types, classification and scope of application

Causes of gearbox failures

Like any technical device, the oxygen reducer is susceptible to problems that arise during operation. Thus, oxygen leakage may occur due to the fact that the seal between the valve and the chambers is broken. This may be because the hard rubber seat seal has worn out, or because foreign particles have entered the valve mechanism.

When operating in winter, the oxygen reducer may freeze. To prevent this phenomenon, the valve of the cylinder must be closed and blown with warm air. This will remove both ice and excess moisture. By the way, it is strictly prohibited to use fire to heat the gearbox.

There are frequent cases when the gearbox becomes clogged with foreign particles. To prevent this, the filter must be periodically blown or washed.

How to find out the volume of a gas cylinder and how much oxygen is in cubic meters

Often, all the characteristics and material about the company that manufactured the product are indicated on a steel label attached to the top of the container, which contains data on the volume. It is written in a standard unit - liter, but the mass of gas per meter cubed can vary depending on the type of gas.

Oxygen-containing containers can be of medium or small capacity.

In order to find out the remaining mass of gas in cubic meters, it is necessary to find out the initial pressure of the gas cylinder, the readings of which are on the pressure gauge. It is necessary to calculate an indicator for measuring volume based on the data from the pressure gauge and tables.

By multiplying the value of the standard volume, which is measured in cubic decimeters. The weight of the full cylinder volume is indicated on the label.

How to find out the amount of oxygen in a cylinder and how many kilograms are in an oxygen cylinder

This gas is mainly needed for welding work. Gas welding allows you to create neat and high-quality seams.

For a full container of oxygen, there is no need to calculate when the contents will run out. And if the container has been used, it will be problematic to determine the amount of oxygen in the remaining gas cylinder. Often the definition is based on the fact that one liter of oxygen weighs 1.13 kg. Therefore, to calculate the mass of a gas, you need to multiply the volume by a factor of 1.13. However, there are special tables for welding.

LABELING, PACKAGING, TRANSPORTATION AND STORAGE

5.1. Cylinders are marked in accordance with the requirements of the “Rules for the Design and Safe Operation of Pressure Vessels”. Additionally, data on the type of heat treatment is applied:

- N - normalization;

- V - hardening and tempering.

Note. Until 01/01/89, the nominal volume of the cylinder is indicated.

5.2. The inscriptions on the cylinders and their painting are carried out in accordance with the “Rules for the design and safe operation of pressure vessels” and Table. 5.

5.3. Cylinders transported without valves must be protected from contamination with polyethylene or nylon plugs.

5.4.

Small volume cylinders are transported in containers made according to GOST 18477-79, without packaging. When shipped by carload in covered wagons, small-volume cylinders are transported packed in boxes in accordance with GOST 2991-85 (type III-1) with a cargo weight of no more than 200 kg or stacked up to the full capacity of the wagon. Dimensions of boxes according to regulatory and technical documentation in accordance with the requirements of GOST 21140-88; Medium-volume cylinders are transported without packaging. covered cars, gondola cars or containers manufactured in accordance with GOST 18477-79. It is allowed to transport cylinders in multi-turn packaging means in gondola cars or in packages in special cars. Table 5

| Name of gas | Coloring of cylinders | Inscription text | Lettering color | Stripe color |

| Nitrogen | Black | Nitrogen | Yellow | Brown |

| Ammonia | Yellow | Ammonia | Black | — |

| Argon raw | Black | Argon raw | White | White |

| Argon technical | Black | Argon technical | Blue | Blue |

| Argon pure | Gray | Argon pure | Green | Green |

| Acetylene | White | Acetylene | Red | — |

| Butane | Red | Butane | White | — |

| Butylene | Red | Butylene | Yellow | Black |

| Hydrogen | Dark green | Hydrogen | Red | — |

| Air | Black | Compressed air | White | — |

| Helium | Brown | Helium | White | — |

| Nitrous oxide | Gray | Nitrous oxide | Black | — |

| Oxygen | Blue | Oxygen | Black | -=- |

| Medical oxygen | Blue | Medical oxygen | Black | — |

| Oil and Gas | Gray | Oil and Gas | Red | — |

| Hydrogen sulfide | White | Hydrogen sulfide | Red | Red |

| Sulfur dioxide | Black | Sulfur dioxide | White | Yellow |

| Carbon dioxide | Black | Carbon dioxide | Yellow | — |

| Phosgene | Protective | — | — | Red |

| Freon | Aluminum or light gray | R (indicating its number) | Black | — |

| Chlorine | Protective | — | Green | |

| Cyclopropane | Orange | Cyclopropane | Black | — |

| Ethylene | Purple | Ethylene | Red | — |

| All other flammable gases | Red | Name of gas | White | — |

| All other non-flammable gases | Black | Name of gas | Yellow | — |

5.1; 5.2. (Changed edition, Amendment No. 4).

The arrangement and fastening of cylinders on vehicles must comply with the requirements of the “Technical conditions for loading and securing cargo” approved by the Ministry of Railways. (Changed edition, Amendment No. 4).

5.4a. Transport markings must be applied to one of the sides of each box, including main, additional and informational inscriptions in accordance with GOST 14192-77. (Introduced additionally, Amendment No. 4).

5.5. Cylinders are transported by all types of transport in accordance with the rules in force for each type.

5.6. Each batch of cylinders must be accompanied by a quality document certifying the cylinders’ compliance with the requirements of this standard, which must indicate:

- name of the manufacturer and its location (city or conventional address);

- product designation;

- number of cylinders and their numbers;

- results of hydraulic and pneumatic tests;

- designation of this standard.

5.5; 5.6. (Changed edition, Rev. N4).

5.7. Storage of cylinders according to group Zh2 GOST 15150-69.

5.8. Each cylinder that has been assigned the state Quality Mark in the prescribed manner and the certificate must be marked with an image of the state Quality Mark. in the manner established by Gosstandart. (Introduced additionally, Amendment No. 3).