The ability to read the electrode markings will help a novice welder choose the right consumables. This skill is necessary for suppliers to select goods purchased for production. The quality of the seam and the cost of the product depend on the correct choice. Let's consider what each letter or number in the marking means, what types of electrodes are available and other details that will be useful in the selection.

- Types of electrodes

- Electrode brands

- Electrode diameter

- Purpose of electrodes

- Coating thickness coefficient

- Index group

- Coverage type

- Spatial position

- Welding current characteristics

Where to find the markings

Marking is necessary to indicate the properties and characteristics of the metal rod and its coating, which affect the arc burning process and the formation of the welding joint. The electrodes themselves are produced in accordance with GOST 9466-75 and GOST 9467-75 and are necessarily marked so that the user can look at the designation and understand how best to use welding materials.

Labeling must be applied to the packaging. The inscription is placed on a white or blue field, free from the decorative design of the pack. Markings are also applied to the melting coating, closer to the end of the electrode inserted into the holder. Some manufacturers additionally indicate data on the side of the pack, but this is not a requirement.

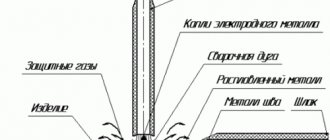

The essence of manual arc welding

Before we talk about electrodes, let's understand what manual arc welding is. An arc is a flow of particles formed during the ionization of the anode and cathode. The ionization process itself is formed by the interaction of current and short circuit. At the same time, the welding process is also influenced by the composition of the electrode coating and oxygen obtained from the atmosphere. Together, these processes lead to heating of the arc and the release of a large amount of heat, sufficient to melt the edges of the parts being welded. The edges then cool, forming a strong and reliable seam.

The key element in this process is the electrode. Without it, it is impossible to ignite the arc and keep it burning. Welding can be done using one or more arc welding electrodes. There is no single classification of rods, since the types of electrodes for manual welding can be divided into many small categories: from purpose to materials of manufacture. By the way, the electrodes themselves for electric arc welding can be made not only from metal, and we will talk about this later.

Types of electrodes

E42A

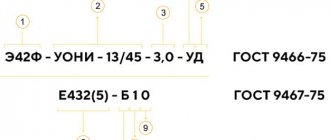

-UONI-13/45-3.0-UD ———————————— E432(5)-B 1 0

The marking consists of a group of letters and numbers, behind which there are certain characteristics. For clarity of explanation, let’s take as an example common electrodes with the following markings:

The first indices E42A indicate the type of consumable element. There are several of them and they explain to the welder which metal is best welded with certain electrodes.

| Surfacing of the surface layer of metal | E-10, E-10G3, E-12G4, E-15G5, E-16G2ХМ, E-30G2ХМ - in total there are 38 types of this group |

| Welding structural carbon and low alloy steel | E38, E42, E46, E50, E55, E60 |

| Welding of carbon and low-alloy steels with increased requirements for impact strength and weld ductility | E42A, E46A, E50A |

| Welding of alloy structural steels | E70, E85, E100, E125, E150 |

| Welding of high-alloy structural steels | E-12X13, E-06X13N, E-10X17T, E-12X11NMF, E-12X11NVMF |

| Welding heat resistant steel | E-09M, E-09MH, E-09X1M, E-05X2M, E-09X2M1, E-09X1MF, E-10X1MNBF, E-10X3M1BF, E10X5MF |

In our example, type E42A is indicated, where:

- E - electrodes for RDS.

- The number 42 is the tensile strength, measured in kg per mm?.

- A - the weld metal will have increased ductility and impact strength.

Thanks to knowledge of this part of the marking, you can easily select electrodes based on the strength of the seam - the higher the number, the stronger the connection. For example, in our case, 42 means that the welded seam will withstand a load of 42 kg per 1 square millimeter. When resistance to sudden loads is required, choose consumables with the prefix “A” in the type.

Welding wire

Solid welding wire is used as an additive in manual argon-arc welding with a W-electrode and gas-oxygen-acetylene welding. The surface of the wire must be clean, free of scale, rust, oil and dirt.

Wires Sv-08MH, Sv-08KhM and Sv-09KhMFA are used for argon arc welding only of alloy steels with a silicon content of no more than 0.25%.

Wires Sv-08MH, Sv-08KhM and Sv-09KhMFA are used for welding pipelines with ambient temperatures up to 510°C inclusive, as well as for root weld welding, regardless of the parameters of the working environment.

For manual argon arc welding of the root seam of pipelines with a wall thickness of more than 10 mm made of chrome-molybdenum and chrome-molybdenum-vanadium steels, Sv-08G2S or Sv-08GS wire is used.

Application area

| Type and grade of steel | Wire grade | ||

| Manual argon arc welding with W-electrode | Manual gas welding with oxy-acetylene flame | ||

| Carbon St2; St3; St4; St3G; 08; 10; 20; 15L; 20L; 25L | Sv-08GA-2; Sv-08G2S; Sv-08GS | Sv-08; Sv-08A; Sv-08GA; Sv-08GS; Sv-08G2S; Sv-08MH | |

| Low alloy structural 15GS; 16GS; 17GS; 14GN; 16GN; 09G2S; 10G2S1; 14HGS; 20GSL; 17G1S; 17G1SU | Sv-08GS; Sv-08G2S | Sv-08GS; Sv-08G2S | |

| Alloy heat resistant | 12MX; 15ХМ; 20HML; 12Х2М1 | Sv-08MH; Sv-08KhMA-2; Sv-08ХМ; Sv-08HGSMA | Sv-08MH; Sv-08ХМ; Sv-08HMFA |

| 12Х1МФ | Sv-08KhGSMFA; Sv-08ХМ; Sv-08HMFA; Sv-08MH; Sv-08KhMA-2 | Sv-08MH; Sv-08ХМ; Sv-08HMFA | |

| 15Х1М1Ф; 20ХМФЛ; 15Х1М1ФЛ; 12X2MFSR; 15Х1М1Ф-ЦЛ; 12Х2МФБ | Sv-08HMFA; Sv-08KhGSMFA; Sv-08KhGSMFA2; Sv-08HMFA2 | — | |

| High alloy corrosion resistant, heat resistant and heat resistant | 08X18H10T; 12X18H12T; 12X18H10T; | Sv-04Х19Н11МЗ; Sv-08Х19Н10Г2Б; Sv-04Х20Н10Г2Б; Sv-01Х19Н9; Sv-04Х19Н9; Sv-06Х19Н9Т | — |

| 12Х11В2МФ | Sv-10Х11НВМФ; Sv-12Х11НМФ | ||

Electrode brands

E42A- UONI-13/45

-3.0-UD ———————————— E432(5)-B 1 0

The brand is determined by GOST or patented separately by the manufacturer if its designation differs from generally accepted standards. Indicates the purpose of the consumables. Among the standard brands according to GOST there are the following:

- ANO-4, -6, -17, -21, -24, -36, -37, -27, UONI 13/45, 13/55, MR-3, -5, TMU-21U, VN-48 - for welding low-alloy and carbon steels.

- OZL-6, -8, -17U, -9A, -25B, ZIO-8, ANZHR-3U, -13, NII-48G - for welding high-alloy steel.

- TsCh-4, MNCh-2 - for welding cast iron.

- T-590, -620, -6L, -12M, EN-60M, OZN-400 - for surfacing the surface layer.

- TsM-7S, OK-46, ANO-1, OZS-3, OZS-12 - for underwater welding.

Some manufacturers have created their own brands of electrodes for all these processes and patented the designations. The most common is OK from ESAB.

Which brand of welding electrode should I choose?

Products from both foreign and Russian companies show high performance. The most common brands of welding electrodes have a large number of positive reviews among professional and novice welders. The most popular companies producing electrodes with basic and rutile coating:

- SSSI. The product UONI 13/55 has a basic coating, has an affordable price, and provides a reliable seam. Moreover, it is affordable and popular, so it can be easily purchased from any relevant store.

- Kobelco. Products from this company also have a base coating and require pre-calcination to remove excess moisture. Suitable for welding pipes and serious structures.

- ESAB-SVEL. The equipment of this company does not require serious calcination, since it is not highly sensitive to moisture. Work can be carried out at a minimum current, which allows you to work with thin-walled steel.

- Lincoln Electric. The electrodes from this company are inexpensive, have fast ignition, and form a high-strength seam.

- OZL-8. Electrodes for welding stainless steel, as well as metals containing chromium and nickel. They are distinguished by their high cost.

- Resanta MP-3. If this product becomes damp, prolonged calcination at medium temperature will be required, otherwise the quality of the seam will noticeably drop.

In addition to popular brands of electrodes, there is a variety of welding elements that have a narrow scope and are not used in everyday life.

In general, it is worth noting that the quality of the seam formed, the speed of the process, safety and comfort of work depend on the parameters and characteristics of the selected welding electrodes. Reliable equipment guarantees reliable work results, which is why it is necessary to select it carefully and responsibly.

Electrode diameter

E42A-UONI-13/45-3.0

-UD ———————————— E432(5)-B 1 0

The next thing in the marking is the diameter of the metal rod. The value is indicated in millimeters with tenths, separated by commas. The electrode cross-section is selected based on the thickness of the workpieces being welded and the welding current. Electrodes that are too thin will quickly burn and spatter the filler metal, while electrodes that are too thick will create additional resistance and make the welding poor due to the shallow penetration depth.

Purpose of electrodes

E42A-UONI-13/45-3.0- U

D ———————————— E432(5)-B 1 0

This is another element that indicates the suitability of certain metals and alloys for welding, as is the case with the type of electrodes:

- B - welding of high-alloy steels.

- T - welding of heat-resistant alloys.

- L - welding of structural steels containing alloying elements.

- N - used only for surfacing.

- U - welding of low-alloy and carbon steels.

Coating thickness coefficient

E42A-UONI-13/45-3.0-U D

———————————— E432(5)-B 1 0

Coating is necessary to protect the liquid metal of the weld pool from interaction with the external environment. The coating melts as the arc burns and the rod melts. The thicker the coating, the more protective gas is released. The coating thickness level is indicated in the electrode marking with the letter:

- M - thin.

- C - average.

- G - very thick (maximum possible).

- D - thick.

Gases

Argon of the highest and first grades in accordance with GOST 10157-79 is used as a shielding gas for manual argon arc welding with a W-electrode. Argon gas or liquid is acceptable.

Shielding gas must be tested before use. A control bead 100-150 mm long is fused onto the plate or pipe and the quality of protection is determined by the appearance of the surfacing surface. If pores are found in the deposited weld metal, the gas is rejected.

For gas welding, technical acetylene is used in accordance with GOST 5457-75, supplied in cylinders or produced in gas generators from calcium carbide in accordance with GOST 1460-81.

Calcium carbide CaC2 is a dark gray or brown solid that, when reacted with water, produces acetylene C2H2. Depending on the granulation of calcium carbide, the yield of acetylene varies.

It is allowed to use gaseous oxygen only of the first or second grade according to GOST 5583-78.

| Approximate dimensions of calcium carbide pieces, mm × mm | Acetylene output, l/min | |

| I grade | II grade | |

| 2 × 8 | 255 | 235 |

| 8 × 15 | 265 | 245 |

| 15 × 25 | 275 | 255 |

| 25 × 80 | 285 | 265 |

Index group

Sometimes the marking contains an additional designation written under the horizontal line.

E42A-UONI-13/45-3.0-UD ———————————— E432(5)

-B 1 0

Digit 4

indicates the resistance of the weld to corrosion. There are five levels in total (0/2/3/4/5) - the higher the number, the better. In our example, the number is 4, which indicates high protection of the seam from rust during subsequent use.

Digit 3

refers to the maximum temperature at which the heat resistance of a joint is maintained. There are 9 options in total, where 1 is 500 degrees, and 9 is over 850 degrees. In our case 3 - the seam will withstand heating up to 560-600? With no loss of properties.

Digit 2

— limit of working temperature of the seam. It also has 9 levels with an indicator from 600 to 1100 degrees. In our example, 2 indicates a limit of 650? C, after which changes will begin in the metal.

The value taken in brackets (5) is the amount of ferrite phase in the weld. The index is divided into 8 levels with percentages from 0.5-4.0% to 10-20%. With our indicator 5, the content of the ferrite phase ranges from 2.0 to 8.0%.

Such a group of indices does not indicate several characteristics at once. Usually, it is written on the packaging of electrodes intended for working with low-alloy and alloyed metals.

Coverage type

E42A-UONI-13/45-3.0-UD ———————————— E

432(5)-

B

1 0

The letter E at the beginning of the second line of marking indicates a consumable electrode, the coating of which burns out from the temperature of the electric arc. But the type of coating is indicated by the letter B. There are four main options, as well as their mixing with each other:

- A - this is the designation for acidic coating. Electrodes with this marking are manufactured for work in all spatial positions on direct and alternating current. But they cook poorly from top to bottom. Not suitable for joining metals with a high carbon and sulfur content; they promote splashing of droplets and may cause cracks in the seam.

- B is the main coating designed for welding with direct current of reverse polarity. Suitable for joining thick workpieces.

- P - designation for rutile coating. Electrodes can work on alternating or direct current in any spatial position, but verticals from top to bottom are difficult.

- C - cellulose coating. Consumables are used for the installation of metal structures; they are excellent for welding in all positions in space on direct and alternating current. But there are increased losses due to splashing.

- RB, AC - mixed coating options. Optimal for welding in the lower and vertical positions of pipelines. Provide low consumption.

In order for the electrode to correspond to the markings, its coating must contain chemicals in certain proportions. These can be: quartz sand, kaolin, marble, manganese ore, titanium concentrate, chalk, etc. It is the gas from the molten coating that reacts with the weld pool and gives the seam certain characteristics. This process occurs during the burning of the arc and after its extinction, while a new crystal lattice is formed.

Welding with electrodes with basic coating

When using electrodes with a basic coating for welding, several nuances need to be taken into account:

- Do not extend the welding arc. In this case, the metal is saturated with nitrogen, which significantly reduces the strength of the weld. May cause cracks.

- The working surface must be completely dry. Otherwise, pores may form in the seam.

- Mandatory requirements for storing electrodes must be observed. Store only in a dry place at a temperature not lower than 15°C. Some manufacturers pack electrodes in vacuum packaging. This significantly extends their shelf life without the need for re-calcination.

Spatial position

Indicates for which positions in space the electrodes are intended. Ignoring this part of the marking leads to poor weld penetration, burn-throughs, and increased metal consumption due to splashing and dripping. There are four index options in total:

E42A-UONI-13/45-3.0-UD ———————————— E432(5)-B 1

0

- universal for all positions (as in our example).

- for all positions except vertical top-down.

- optimally cooked horizontally on a vertical surface. Not intended for ceiling welding.

- for bottom corner, tee and regular connections.