Features of the three-phase welding machine

380-volt welding machines are common in manufacturing and construction because of their power and ease of use.

The use of three-phase devices allows you to work with electrodes of large diameters and metals of maximum thickness. Welding is softer compared to single-phase machines. When working as part of production lines, three-phase equipment is also used.

Types of three-phase devices

Three-phase welding machines come in three types:

- transformer;

- rectifying;

- inverter

Welding equipment of the first type is based on a three-phase transformer. The primary winding consists of three windings connected in a star, and the secondary step-down winding is connected in a delta.

If alternating current is used for welding, then a reduced voltage is supplied from each phase of the secondary winding via a separate wire to the electrode through an inductor. Compared to a single-phase welding transformer, the welding is softer, the electric arc becomes more stable, and the voltage drop is less.

The rectifiers at the output of the secondary winding have three half-bridge circuits assembled from powerful diodes. As in the first case, current is supplied from each rectifier to the welding electrode.

Compared to a rectifier in one phase, pulsations are significantly less; accordingly, the welding current is more stable, which affects the quality of welding.

In three-phase inverters with the same welding power, you can use less powerful diodes and transistors, but this is practically not done. On the contrary, the use of three-phase voltage makes it possible to obtain high-power devices with small dimensions and weight.

Advantages and disadvantages

All three-phase welding equipment belongs to the category of professional devices. Many of them are capable of welding in continuous mode, that is, the duty cycle is 100%. In construction, three-phase transformer and rectifier welding machines still have no alternatives.

They are not afraid of dust, dirt, and operate at low temperatures, which is contraindicated for inverters. Single-phase transformer-type devices can also operate under the same conditions, but they have less power and more current ripple.

Accordingly, they cannot compare with three-phase devices in terms of welding quality, electrode diameter and thickness of the metal being welded.

The use of three-phase current in inverters also has its advantages. By using the same element base, a more powerful device with higher welding currents is obtained, which allows you to work with almost any product.

The device circuit differs slightly. The same pulse width modulator is used. The conversion of high to low voltage occurs at a frequency of about 40-100 kHz.

The only drawback of these devices is that it is not always and not everywhere possible to connect to a three-phase 380 V power source, and their price is much higher than that of single-phase devices.

Popular models

The 380 V semi-automatic welding inverter is the most common device among professional devices. Unlike transformer devices, they have small dimensions and weight.

The Czech-made TESLA MIG 350 semi-automatic welding machine has proven itself when working in difficult conditions. In case of unstable or reduced supply voltage, it provides a stable welding arc, operates at a voltage of 380 V, and the maximum welding current is 350 A.

The welding wire feeding mechanism of the device has two rollers, the power consumption is 11.9 kW. The power reserve allows the use of long cables up to 20 m. Bayonet plugs ensure reliable and quick connection of the torch to the device. The manufacturer provides a three-year warranty on the equipment.

Another example of a professional three-phase inverter is Svarog ARCTIC ARC 315 (R14). It works in harsh conditions, allows you to weld in intensive manual mode and perform surfacing. Thanks to the use of the latest inverter technology, the device can operate at temperatures down to -30 ⁰С. There is a “hot start” function.

Separate installation of power transistors increases the maintainability of the device. With a maximum welding current of 315 A, the inverter can use electrodes with a diameter of 6 mm. This allows you to weld metals up to 17 mm thick. With a power of 12 kW it weighs 22 kg.

The three-phase inverter welding machine "Resanta SAI-315 380V" has approximately the same characteristics as the "Svarog", but fewer additional functions. It is simpler, therefore cheaper and weighs only 10 kg.

Connection

Unlike single-phase welding equipment, three-phase welding equipment has a four or five-pin plug at the end of the power cable. If the room has an appropriate outlet, you just need to connect the welding machine through it.

But, sometimes, especially in construction conditions, when there are no appropriate sockets, the ends of the cable are connected through a bolted connection to the phases of a diesel generator or transformer substation.

When choosing equipment for welding in a home workshop and the presence of a three-phase power supply at the site, it is worth choosing a three-phase welding machine . At the same time, it must provide manual arc welding and shielded gas welding modes (MMA, MAG/MIG).

Then it will provide almost unlimited possibilities in welding. Since they are intended for professionals, they have many additional functions and settings.

As you acquire skills, you can master new capabilities of the device, which will undoubtedly be very useful for the owner. Unlike a single-phase device, it will not sag voltage during operation, distributing the load across all phases, and accordingly there will be no complaints from neighbors.

Homemade welding machine: single-phase inverter SVAROG to three-phase. Part 2.

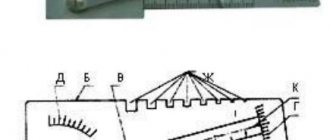

Connection diagram of a 3-phase network to the Svarog TIG 200P AC_DC inverter

The operating algorithm will be as follows: 1. If you plug a standard plug into 220v, then the starter K1 (25A per contact) is triggered, which with one pair of contacts restores the wire we cut that goes to the ON/OFF switch of the welding machine.

And its second pair of contacts will close the cuts we made in the tracks on the printed circuit board, which supply power voltage to the standard single-phase full-wave rectifier.

ALL!

K1 is not needed for anything else. It only restores the original power circuit of the welding machine after cutting two wires and two tracks. (although there is one more function - K1 does not allow the standard swarApp plug to be energized when it is connected to three-phase power. This is very good!)

2. Starter K2 (10A per contact) is used to connect the three-phase power supply to the device circuit. It is smaller and cheaper, since it requires the short circuit of only two wires, which we will pass through paired 10A contact groups. Actually, that's all. First, I bought three-phase sockets 3p+N+E, which means four phase and neutral contacts and a fifth ground. I bought a four-core wire with a diameter of 2.5 mm per core. I planned to place the rectifier diodes on the radiator inside the svarApp. However, as I worked, I came up with a more elegant and secure solution.

The idea was that I would place a 3-phase rectifier in a separate box directly next to the input panel, and send the already rectified voltage to the welding unit through one wire, through the second any of the phases to the SwarApp electronics startup circuit (without this there is no way), through the third NULL, and I still have a fourth wire left, through which I will attach a real honest GROUND from the input panel to the body of the device (I actually have it in the input panel).

This way I can provide all types of security for the user and svarAppa, plugs and sockets can be supplied with four pins, i.e. 3p+E. I found this more convenient.

To prevent the diodes from being energized “day and night” in the panel, and for convenience, of course, I connected them through a cheap 40A load switch. This is not an automatic machine, they are enough together with the RCD in the main panel, it is just a three-pin switch. The diodes are suitable “for every taste and color,” I had D242B from one batch in the trash, I paralleled them and screwed them onto a radiator from some old computer processor. I took copper wires, also collected scraps from around the house, folded the thinner ones in pairs - put one end into a screwdriver and twisted them: it came out in a nice, stiff braid. The total cross-section of copper is 2mm2. Doesn't make much sense anymore. It is very convenient to take copper with one thick core. It will immediately serve as a rigid structure and will be clamped more correctly into the terminal blocks. Yes, and prepare a soldering iron of 60-100 watts so that you can do the assembly efficiently wherever necessary, we are not Chinese. Now, we call upon all our attentiveness to help and do as I said: (for those who are still swimming in our topic and have forgotten the rules of sapper equipment)

STEP 1.

Upgrade STEP 1

Homemade three-phase welding machine: STEP 1

We place the 25A starter in a place convenient for it (we don’t even fasten it if the wires are rigid), estimate by eye at what distance it is better to cut off the phase and neutral in the condom that go to the ON/OFF switch and... feel free to cut it off with a saber! We clean the resulting stumps from the braid, beautifully tin them and clamp them into the two upper terminal blocks K1 in the photo.

Homemade three-phase welding machine: STEP 1

Hint - before step 1, prepare and screw a suitable wire to the K1 coil and immediately solder it to the ends of the neutral and phase coming from the RF interference filter (this is the lower cut piece in the photo). Feel free to clamp these ends to the starter coil terminals in any

ok. If you have done step 1, then you can plug the welder's wire into the socket and make sure that it continues to work as before, the only thing that pisses us off at first is that when the wire is plugged into the socket, the starter clicks. This makes you flinch at first, but then you get used to it.

Upgrade STEP 2

Homemade three-phase welding machine: STEP 2

We take a hacksaw blade in our hands and carefully, with a width of at least 1.5 mm, deeper into the textolite, we cut the tracks that go to a pair of fours of yellow wires in the connectors. Here, closer, pay attention - there is a small yellow circle around the varistor contact, which we cut (the black line indicates the former track). And the red stripe is a jumper that you need to remember to solder later! Otherwise, transient pulse voltage surges will not be suppressed. On the right, the contacts of the relay (white) are circled in an oval, which closes with some delay after power is supplied to the svarApp. These, in fact, are all the control points to which our attention will be drawn in further manipulations. And then we lay out the wires from K1 to close the cut we made with its contacts. Without completely turning off our heads, we trust our straight hands...

That's where we laid it out, and here we soldered the ends. (NOT FORGETING ABOUT THE JUMPER FROM THE VARISTOR! Not visible in the photo?)

Homemade three-phase welding machine: STEP 2

We turn on the device again and make sure that it is fully operational from a single-phase network.

And now, a simple but very important moment. We solder to the ends of the cut tracks (the ones on the left most in the photo, going to the rectifier) a two-core, thin wire that goes to the K2 coil. We connect the K2 contacts in pairs with four short (orange) jumpers.

Homemade three-phase welding machine: STEP 2

In the photo, we twist the right contacts of K2 with short wires and clamp them together with the contacts of K1, going to the same place from where the wire was thrown onto the K2 coil.

The wire that in “ordinary life” first goes to the “white switch” is black; we will connect it (in a three-phase connection) to any phase we choose to power the SwarApp starting electronics. And we solder the wire that goes without a break from ON/OFF (thick red) to the standard rectifier through the yellow leads in the white connectors to the NULL-left wire from our three-phase socket.

Homemade three-phase welding machine: STEP 2

We carefully look at the diagram and, with a smart expression on our face, poke the tester into the terminals, checking that the wiring matches the diagram.

If you are completely convinced that “everything is according to the scheme”, then assemble\neatly bend the reins from K1 and K2, place the SwarAppa inside, admire and once again make sure that it still works from one phase! There's no need to be lazy...

Upgrade STEP 3

Homemade three-phase welding machine: STEP 3

STEP 3. The most interesting and exciting. I first did it right on the operating table. The blue braided wire, trimmed by the frame, is soldered to the yellow/blue braided wire and screwed to the radiator (plus) of the three-phase rectifier (it is temporary). This power plus goes to the paired contacts of the K2 starter (clearly visible in the photo). On K1 from a 3-phase socket there is a phase/zero pair and a power zero.

ATTENTION! Let me remind you that in this PHOTO there is a socket with 5 contacts; later, when I move the rectifier into the panel, the socket will be four-pin. (see diagram)

Homemade three-phase welding machine: STEP 3

SO, we supply three phases to a homemade welding machine, and switch ON/OFF to ON! The starters clicked... And everything worked!!

Upgrade STEP 4

We plug in the power cables, unscrew...

Homemade three-phase welding machine: STEP 4

Wow! on the 202A current handle, in the barn we find the thickest and oldest electrode. My 4 turned out to be rotten with mold since perestroika.

Homemade three-phase welding machine: STEP 4 - Homemade welding

We grab a black piece of iron, where it is 10mm thick, shamelessly push it and press the electrode... In the first moment it sticks, water and mushrooms boil out of it with a hiss (really, it smells like soup!) and...... with full pressure for three to four seconds Let's burn the through hole! We experience our first joy/pride, and over the next couple of evenings we thoughtfully and slowly experiment with our beauty in different poses and modes…..

Upgrade STEP 5 (Cleaning and packaging the assembled circuit)

We carefully and finally lay out the wires and starters. Sparing no effort, we pull in different directions, simulating a hard fall of the SwarApp from the roof. If no starter touches the surrounding pieces of iron with its contacts, then everything is reliable.

Homemade three-phase welding machine: STEP 5 Cleaning and packaging the assembled circuit

The final touch is to tighten it where possible, with tourniquets (I had green ones, I don’t remember where I expropriated them). We admire it and get to work designing the wire output for the three-phase socket.

We bring out four wires approximately to the center of the top of a homemade three-phase inverter. This is a +250v wire from a three-phase rectifier, NULL, any one phase, and we screw the yellow wire with a green stripe to the device body, this will be our “honest ground”. We remove a small piece of braid from the power cable and wrap it around all the cables in the place where they will pass through the hole in the inverter cover, and wrap it with insulation.

Below is a photo of new four-pin sockets/plugs, a 40A load switch and a cozy house for a radiator with rectifier diodes from MAKEL (by the way, with a poetic name - “siva-ostyu-sigorta-kutushu”). In Russian, everything is more prosaic - Electrical panel of the Invoice.

Using a 14th drill, we drill a hole in the svarApp cover for the output of our power leads, screw one of the sockets, screw the ends of the wires, etc. and so on…

Homemade three-phase welding machine: Final stage

Homemade three-phase welding machine: Final stage

Here's what happened:

Homemade three-phase welding machine: What happened...

Homemade three-phase inverter from Svarog

We make preliminary preparations for the connection of the second socket and the panel with the rectifier and load switch, use a tester to check that there are no tangled wires in the sockets and go to screw the panel onto the wall.

Preparing the connection of the second socket and panel with the rectifier and load breaker

Panel

This is what happened in the “panel room”.

Left connector for homemade welder

The right connector - there is a 3ph + N + E socket - this is for connecting ordinary 3-phase devices. But the left one is exclusively for our delight. That's all, actually. Currently, I burned an argon cylinder while playing with SwarApp in 3 phases. Works flawlessly.

Beginning of the article: Upgrade: single-phase SVAROG inverter to three-phase. Part 1

Similar

svarka-master.ru

Welding inverters 380 V

Products and servicesCompanies

By ratingBy price (cheaper first)By price (higher first)

Pages: previousnext

Products and servicesCompanies

By ratingBy price (cheaper first)By price (higher first)

Pages: previousnext

Page 3

Inverter device KEDR Ultra mm A 200 in case 8009728

Mains voltage, V: 220 Frequency, Hz: 50/60 Operating mode, PV%: 60 Open circuit voltage, V: 70 Welding current range, A: 10-200

Page 4

Universal welding inverter CT 416 (R40)

Country of origin: Spain Maximum power (kW) : 0.4 Maximum productivity (l/min) : 550 Total pressure (m) : 3.3 Maximum operating pressure (bar) : 10 Mains voltage (V) : 380 Protection level: IP44 Class

Page 5

Welding inverter FoxWeld Summer resident 210

Can operate at reduced voltage, which is important when used in places where the voltage is unstable and drops to 140V; it features a simple control panel on which you can easily set the required welding current value

Page 6

Air plasma cutting inverter CUT 40

Manufacturer: Mealer (China) We offer a wide range of welding, construction, pumping equipment, power plants, stabilizers, air conditioners, metal furniture.

Page 7

Products and servicesCompanies

By ratingBy price (cheaper first)By price (higher first)

Page 8

Capacitor 6.3UF, 400V KEMPPI

We truly have the widest range of products. All items are located in warehouses in Krasnoyarsk and Moscow, delivery of TC to any city in the shortest possible time. For those who have questions about our products, we offer specialist consultation.

Page 9

Products and servicesCompanies

By ratingBy price (cheaper first)By price (higher first)

Page 10

Products and servicesCompanies

By ratingBy price (cheaper first)By price (higher first)

Page 11

Welding inverter (TIG) REDBO PulseTig-250 AC/DC

Mains voltage: 380±15%V, PN TIG/MMA-35%, no-load voltage 42V, purge before/after welding 0-2/1-10s., welding modes 2/4-stroke, high-frequency arc ignition , frequency 50/60 Hz, protection class IP21S,

Page 12

Welding inverter, BISON, MASTER, ZAS-M1-170

-Welding type: MMA -Transistor type: IGBT -Power: 5.7 kVA-Max. current consumption: 26 A - Welding current type: constant - Electrode diameter: 1.6-4.0 mm - Open circuit voltage: 82 V - Operating voltage: 26 V - Min. supply voltage: 160 V-

Page 13

Welding inverter Fubag IN 206 LVP

Confident operation at reduced voltage in the range of 130 - 265 V in a very compact package and light weight of 5.5 kg. Microprocessor intuitive control, high arc stability, operation from a 16A network in intensive operating mode, including

Page 14

Products and servicesCompanies

By ratingBy price (cheaper first)By price (higher first)

Page 15

Welding inverter TSS SAI-400PROF

Country of origin: Spain Maximum power (kW) : 1.26 Maximum productivity (l/min) : 434 Total head (m) : 18 Maximum operating pressure (bar) : 10 Mains voltage (V) : 380 Protection degree: IP44 Class

Page 16

Welding inverter REAL TIG 200 (W223)

Afalina Chelyabinsk is a company offering traditional and technically new construction equipment to Russian organizations. We offer not only equipment, but also modern high-tech solutions. The range of equipment is dynamically expanding

Page 17

Semi-automatic welding inverter 10-200A + torch, FUBAG INMIG 200SYN LCD

current in MIG/MAG mode 25-200Ak at duty cycle 60% and t=40 degrees. C, 165% Digital display Coil diameter, 200 mm / weight 5 Wire diameter 0.6-1.0 mm Welding current range 10-200 AN Open circuit voltage 67 V Voltage 150-260 VPV at max current 40%

Page 18

Inverter welding machine SAI 140 Resanta

Protection degree IP: 21 Weight: 4.3 Load duration: 70.0 No-load voltage: 75.0 Maximum current consumption, A: 20 Maximum electrode diameter, mm: 3.2 Operating voltage range, V: 140 - 260 Arc voltage, V: 25

Page 19

Products and servicesCompanies

By ratingBy price (cheaper first)By price (higher first)

0

Welding inverter (TIG) REDBO PulseTig-200 AC/DC

Mains voltage: 220±15%V, PN TIG/MMA-35%, no-load voltage 65V, purge before/after welding 0-2/1-10s., welding modes 2/4-stroke, high-frequency arc ignition , frequency 50/60 Hz, protection class IP21S

1

Industrial MIG/MAG welding machines | buy in Moscow with delivery throughout Russia

Nutrition:

220V

Welding current:

20-185A

Synergic:

stainless steel, steel, aluminum, copper soldering.

Pulse mode in the basic version!

Certified for car manufacturers. Country of origin: Italy. 24 month warranty.

Cebora EVO SPEED STAR 520 TS PROMOTION! Pulse and Double Pulse functions as a gift! Industrial semi-automatic Power supply:

380V

Welding current:

10-520A

Synergic:

stainless steel, aluminum, steel.

Pulse, Double Pulse

Country of origin: Italy. 24 month warranty.

Cebora Synstar 270T SRS Edition Industrial welding machine

MIG/MAG, TIG DC, MMA

Power:

380V

Welding current:

10-270A

Synergic:

stainless steel, aluminum, copper, steel.

Full functionality already in the basic version: Pulse, Double Pulse, SRS (coolArc), TIG DC.

Country of origin: Italy. 24 month warranty.

Nutrition:

220V

Welding current:

20-200A

Synergic:

stainless steel, aluminum, steel, copper and galvanized soldering.

Certified for car manufacturers

Country of origin: Italy.

24 month warranty. Power:

380V

Welding current:

20-200A

Synergic:

stainless steel, aluminum, steel, copper and galvanized soldering.

Certified for car manufacturers

Country of origin: Italy.

24 month warranty. Power:

220V

Welding current:

20-250A

Synergic:

stainless steel, aluminum, steel, copper and galvanized soldering.

Certified for car manufacturers

Country of origin: Italy. 24 month warranty.

Nutrition

: 380V

Welding current

: 20-270A

Synergic

: stainless steel, aluminum, copper, steel.

Pulse mode.

Country of origin: Italy.

24 month warranty. Industrial welding machine

MIG/MAG, TIG DC, MMA

Power:

380V

Welding current:

15-330A

Synergic:

stainless steel, aluminum, copper, steel.

Pulse, Double Pulse in the database!

Country of origin: Italy.

24 month warranty. Industrial welding machine

MIG/MAG, TIG DC, MMA

Power

: 380V

Welding current

: 15-330A

Synergic:

stainless steel, aluminum, copper, steel.

Pulse, Double Pulse in the database!

Country of origin: Italy. 24 month warranty.

Industrial welding machine

MIG/MAG, TIG DC, MMA

Power:

380V

Welding current:

10-400A

Synergic:

stainless steel, aluminum, copper, steel.

Pulse, Pulse HD, Double Pulse, Doble Pulse HD, SRS (coolArc), WEB control, FULL TIG (TIG XP, APC,EVO START)

Country of origin: Italy. 24 month warranty.

Industrial welding machine

MIG/MAG, TIG DC, MMA

Power:

380V

Welding current:

10-520A

Synergic:

stainless steel, aluminum, copper, steel, powder.

Pulse, Pulse HD, Double Pulse, Doble Pulse HD, SRS (coolArc), WEB control, FULL TIG (TIG XP, APC,EVO START)

Country of origin: Italy. 24 month warranty.

Cebora Synstar TWIN 270 T Power

: 380V

Welding current

: 20-270A

2 spools with Synergic

: stainless steel, aluminum, steel.

Certified for VAG (Volkswagen).

Country of origin: Italy. 24 month warranty. Cebora Sound MIG 2060/MD Star Double Pulse

Nutrition:

2200V

Welding current:

15-200A

Synergic:

stainless steel, aluminum, copper, steel.

Pulse, Double Pulse OEM certified;

Country of origin: Italy. 24 month warranty.

Cebora EVO 350 TC Synergic Power:

380V

Welding current:

35-400A

Synergic:

stainless steel, aluminum, copper, steel.

Country of origin: Italy. 24 month warranty. Cebora EVO 350 TS Synergic Industrial semi-automatic Power:

380V

Welding current:

35-400A

Synergic:

stainless steel, aluminum, steel.

Country of origin: Italy. 24 month warranty. Cebora EVO 450 TS Synergic Industrial semi-automatic Power supply:

380V

Welding current:

40-500A

Synergic:

stainless steel, aluminum, steel.

Country of origin: Italy. 24 month warranty. Power:

220V

Welding current:

20-200A

Synergic:

stainless steel, aluminum, steel.

Country of origin: Italy. 24 month warranty. Are you looking for modern, reliable, and most importantly high-quality welding equipment? The Italian company Cebora, which produces welding machines using advanced welding technology and supplies its products to 120 countries around the world, !

"Cebora - Russia" offers to buy professional and industrial semi-automatic welding MIG-MAG with synergetic control, optimizing welding processes of various metals: steel, stainless steel, aluminum, copper and various alloys. In particular, they significantly simplify the welder’s work and improve the quality of welds. Welding work is performed faster and with better quality than with conventional machines with manual settings. The welder does not waste time selecting parameters, because the synergic control does this independently. The experience accumulated by Cebora over more than 65 years of operation allows it to be one of the world leaders in the field of electric welding. Today, Italian Cebora welding machines are well known in Europe and other regions, including Russia, where they have proven themselves to be the best. The use of the most effective synergistic technologies, the widespread introduction of innovations and strict product quality control - all this, combined with its very reasonable cost (compared to competitors), have become powerful arguments in favor of purchasing Cebora equipment. In addition, our industrial welding machines and semi-automatic machines have high technical and operational characteristics, but at the same time they are very easy to operate. Each semi-automatic welding machine from Cebora has a set of synergetic programs for almost perfect welding of stainless steel, aluminum and its alloys. Setting is carried out only by selecting the wire and the thickness of the workpiece being welded. The device selects the remaining parameters independently! Need quality seams? Then buy Cebora and we will not disappoint you!

MIG/MAG welding equipment is divided into 2 types: inverter semi-automatic welding machines with synergetic technology and transformer machines also with synergic control.

Each Cebora welding machine, be it the professional Pocket Pulse, Synstar 200/270/330 or the industrial KING STAR 400/520, does an excellent job of welding stainless steel, black steel and aluminum.

Buying welding machines in Moscow from Cebora means providing your enterprise with reliable and modern welding equipment for many years.

The main advantages of CEBORA welding equipment

Having purchased a mig-mag semi-automatic welding machine from a European manufacturer, you will appreciate its manufacturability. Unique functionality and welding technologies, as well as performance characteristics:

- Cost:

the price of Cebora inverter-type welding machines compares favorably in cost with other brands. - Reference quality welding of aluminum and stainless steel.

You can buy semi-automatic welding machines for stainless steel and aluminum, specially adapted for these types of materials, which allows you to obtain standard quality seams, in Moscow and the regions of Russia. Other, more specific types of devices are also available. For example, it will not be a problem to find and buy from us a welding machine for welding aluminum with two spools and wire feed mechanisms, ideal for the high standards of modern car service, as well as the consumables, welding torches, tools and accessories necessary for their operation.

- Synergetic technologies.

All semi-automatic welding machines have advanced MIG-MAG welding technology using synergetic programs. Settings take place in 2-3 clicks on the display or joystick. The digital intelligence of each model contains programs for welding stainless steel, steel, aluminum, as well as for soldering copper and various alloys. - Advanced welding technologies.

The new line of multifunctional MIG-TIG-MMA welding machines CEBORA King Star series has the most advanced technologies for welding various metals. For example, the Pulse HD and Double Pulse functions can significantly improve the quality of seams. Buy a semi-automatic welding machine and you can quickly adjust the process to the characteristics of the material and production. For example, minimize splashing thanks to SRS technology. - WEB interface and remote management:

the new hardware architecture allows the implementation of a web server, which, through LAN and Wi-Fi connections in addition to two USB ports, provides useful functions for remote maintenance, information system diagnostics, backup and recovery data, firmware updates and etc. and for all those activities that require data collection and processing. - Convenient delivery method throughout Russia

. You can buy a semi-automatic welding machine or a multifunctional welding machine both from us at Chebora-Trading LLC and from our regional dealers in Moscow, St. Petersburg, Nizhny Novgorod and other cities of Russia. Most devices are in stock. Delivery and commissioning is carried out up to 10 days. - Professional consultation.

When ordering a professional and industrial series of welding machines, our company’s specialists will provide advice and help with choosing a specific model based on the customer’s requirements. By purchasing welding equipment from us, you are guaranteed high professionalism, prompt service and an individual approach to each customer, without exception. - Long warranty.

All Cebora welding equipment is provided with a factory warranty of 24 months (2 years). An on-site warranty service is available. Therefore, having purchased industrial and powerful welding machines, you can be sure that any possible problems with them will be resolved as quickly as possible.

Where to buy professional and industrial Cebora welding machines?

You can buy semi-automatic welding machines manufactured by CEBORA from the official representative of Chebora-Trading LLC in Moscow, Moscow region, Rostov-on-Don.

And also from our regional dealers in Moscow, Moscow region, St. Petersburg, Vladimir, Voronezh, Nizhny Novgorod, Rostov-on-Don, Volgograd, Yekaterinburg, Kazan, Komsomolsk-on-Amur, Krasnodar, Krasnoyarsk, Norilsk, Novosibirsk, Perm, Ryazan, Simferopol, Smolensk, Tver, Tula, Ufa, Yakutsk, Yaroslavl and other cities of Russia.

Where is it used?

The scope of application of three-phase inverters is quite large, and in some cases it is simply impossible to do without them. Motor control will be much more efficient when modified modern three-phase inverter devices are used. They are included in the general circuit with single- and three-phase asynchronous motors, commutator units, as well as three-phase DC motors.

To control different types of engines, their own modes are used, supported by appropriate software. This makes it possible to connect almost any motors whose windings have from 1 to 3 phases. As an exception, we can note the design of bipolar two-phase stepper motors equipped with two independent windings.

The components of such an inverter include the main control board, power inputs and outputs, as well as an interface for entering the necessary data and displaying current readings on a display or scoreboard. Quite often, control is carried out using a computer. The inverter is connected through a special connector installed on the board.

Modern control inverters have a demonstration mode, in which the main functions are shown one by one - start and stop, speed change and reverse. To switch between functions there are 4 buttons located on the board.

Industrial welding machine 380V: what are its advantages, characteristics, where to use

What should you pay attention to when choosing welding equipment? As a rule, when buying a welding unit for the home, they take into account the power, size, additional settings, and also the price tag.

Speaking about industrial units, the voltage of the electrical network they request plays a big role here.

Residential buildings are supplied with 220V voltage as standard. But providing constant 380V power in factories is a completely solvable task. Therefore, three-phase devices can be easily installed and used in workshops.

This article will discuss the industrial welding machines themselves, their varieties and parts that you should know about when choosing.

General information

What is the difference between welding machines and household ones? The first, three-phase, operate at a voltage of 380V. Such units can be repaired and are unpretentious in operation, so they are often used in new industries.

Working with an industrial welding machine, it is possible to connect parts of any thickness and use electrodes of any diameter.

The advantage of such units is that we get more power without increasing the current. Therefore, the welding process is much smoother and the result is a higher-quality three-phase device than a single-phase one.

Variations

Transformers, rectifiers, inverters and semi-automatic machines are all types of three-phase welding devices.

We will introduce you to each of them.

Transformer

The transformer (380V) is classified as a type of classic industrial welding equipment. This device received the name three-phase because of the three coils at its base.

Receiving three phases, which in turn ensures stable arc burning and voltage during the welding process. The simple design of the unit is easy to repair, and not expensive.

It must be taken into account that the transformer produces only alternating current. For this reason, you will not be able to use direct current in your work.

A trolley is used to transport the transformer; it is heavy and of impressive size. At the same time, it has a good price tag.

Rectifier

A rectifier is a type of industrial transformer, and it is distinguished by a built-in rectification unit. The unit is built into the housing, its function is to convert alternating current into direct current.

Since these devices allow you to cook on any type of current, they are more versatile than transformers. Due to the rectifier, the arc burns more stable and is easier to ignite, repeatedly.

Often, beginners are faced with the difficulty of igniting an arc using an industrial welding transformer. There are no big differences between a transformer and a rectifier, except that the latter simplifies this task a little.

Inverter and semi-automatic

Semiautomatic welding machines and inverters are industrial devices of a new generation. Built-in microcircuits and additional functions complicate the structure of devices. They are lighter and smaller than transformers and rectifiers.

Which makes them significantly more expensive than other industrial units. Inverter and semi-automatic devices are used in different fields.

The former is used for manual arc welding with electrodes, and the latter for welding with the participation of shielding gas and filler wire.

The name of the semi-automatic machine comes from the fact that it has a mechanism for supplying filler material in a semi-automatic mode.

Working with these industrial models, you get the best quality seam, while they are easier to operate, they are lightweight and sometimes offer a large number of additional functions that simplify the welding process.

The only difficulty here is the expensive maintenance and repair of a high-tech unit. Often this factor becomes decisive for small industries to abandon their use.

Three-phase welding transformers and rectifiers withstand operating conditions well, that is, even if they are stored incorrectly or left in dust, they will still perform their task properly.

Inverters and semi-automatic machines are less stable due to built-in microcircuits. The latter can work in any conditions if they have a dust- and moisture-proof housing.

The objection of professionals that an ordinary single-phase transformer is also unpretentious is true.

Only the quality of the welds is noticeably worse due to the high frequency of current pulsation on a single-phase device compared to a three-phase transformer, of course.

Three-phase models are universal and are used for welding of any complexity. But a stationary single-phase industrial transformer or rectifier is not capable of welding metals of any thickness and using thick electrodes.

Nuances of connection and selection

Before connecting a 380 V welding unit, you need to consider a number of features. Three-phase welders come with four and sometimes five pins. Please pay attention to this when purchasing a power cable for a welding machine.

In cases where the production does not have sockets of the required voltage, or the work is carried out on site, you need to think in advance about how to connect a three-phase device to a generator or substation.

When choosing an industrial three-phase welding machine, you should choose universal equipment that operates in different modes, such as RDS and MMA (or MIG/MAG).

Using such devices, you can carry out welding work of any complexity, whether in a shielding gas environment, or using only electrodes.

If at home welding it is possible to connect to a 380 volt network, we advise you to acquire a three-phase welding machine.

Because it does not cause overvoltage and power outages, evenly distributing the load on the network, and working much more stable than single-phase ones.

Homemade welding machine: single-phase inverter SVAROG to three-phase. Part 1.

Svarog TIG 200P AC/DC

I had to tidy up an old house in the village. Without welding to a man - you know what. A phase on the edge of the village failed on an ordinary welding transformer so that the neighbors came and warned “in a good way” in a restrained tone. I bought myself a nice TIG 200P AC_DC... or rather, at first there was a TIG 160 AC_DC, but it was quickly taken out along with the linoleum, so we won’t talk about it...

Well, the neighbors are happy, I'm happy, because... from 40 to 90 amperes for three electrodes and TIG stainless steel is quite enough. Together with the new wiring in the house, I agreed with the power grid to connect 3 phases - it became generally kosher, thickness planer and all that... wow!

Welding inverter Svarog photo inside

However, the need came to cook the aluminum a couple of times... This is where I became sad. There was no way I could pump out a current of more than 90 A from one village phase of the TIG 200P AC_DC. The protection crackled, the light blinked, the UPS on the OGV, after unsuccessful attempts to understand what was happening with the phase, went out and was reanimated only after a complete ON/OFF. I had to overcome my laziness and turn on my brain about whether it was possible to take a little from the three phases so that my SvarApp would have enough for a shirt (I note that Google disdained to help me in this topic)...

So, autopsy of the patient:

Responsibly, without personal emotions, we can say that the Chinese modules are assembled quite well. The parts are straight, the boards are varnished, full-fledged radiators, almost all the screws/bolts are tightened and marked with red varnish, the wires are tied into bundles, hidden where necessary in non-flammable condoms, honest copper busbars carry high currents, that is, if you don’t know that dad is Chinese - the patient looks like a normal person. Right away, in order to perform the operation without complications, we disperse the spiders with a brush and blow off the dust with a lung compressor...

Photo of welding inverter Svarog inside: 1-block of pulse transformers and 2-Power transistors

We draw attention to the standard, for the declared performance characteristics, module configuration - that is, a decent surge noise filter (the cardboard at the bottom at the back where the 220v wire enters) then to the ON/OFF switch, after which the wires go to the board with a relay, which supplies power with a slight delay change to power rectifier diodes (two chocolate bars in each, apparently two independent diodes) a battery of capacitors at 400v, and from them the rectified and smoothed power goes to a block of pulse transformers (1) hidden between the radiators in the left module in the photo. The right module, along the way, deals with current pulses and turning it from constant back to variable when necessary. We’re too lazy to figure it out further, because we only need to dissect the part of the circuit that goes up to the capacitor bank.

Almost immediately I found a bolt (2) that had begun to burn, to which a copper busbar was screwed, going to the right module.

Here in the photo, after restoration, a new nut was tightened onto the busbar heated with a soldering iron from below; at the same time, the board from below was also soldered to the busbar.

Power transistors (3) are neatly pressed into a heap against massive radiators - babble.

In the next photo you can see two identical connectors (5) one after the other, each with four yellow wires in parallel - these are two variable ends for a full-wave diode rectifier made of two chocolates (4). A pair of pairs of red wires is a plus from the rectifier bridge and a pair of pairs of black ones is a minus.

Photo welding inverter Svarog inside: 4-diode rectifier, 5-connectors, 6-capacitor bank

If you measure the voltage between the red and black ones and a bank of capacitors (6) is also connected to them, then approximately 240-260v of constant voltage runs up from one phase. We unscrew a couple of nuts from our side and lift the board (7).

Photo of welding machine inside

Yes, that’s right, the change goes to the yellow ones, and the rectified plus and minus goes to the capacitors. This is where we should stick our plus and minus from the straightened three phases! By the way, (12) is just the restored and soldered burnt contact mentioned above. The red wire (9) comes from the ON/OFF switch, and the black wire is tied together with it. This is the second alternating wire and it also goes to the board, BUT, do you see the white switch behind it? It is triggered a little later than the svarApp’s power is turned on and supplies power from the black wire to 4 yellow ones in the connector and then to the rectifier…. Let's take note of this moment! In the white condom (8) we see two red wires going to the ON/OFF switch. This is 220v that you plug into the outlet. We see the beginning of this wire (11) coming out of the RF network filter board (its inductor is visible there behind 11). Note the black varistor (10). Below is a red oval, there is a barely noticeable track on the board; it will later be cut and the freed contact will be soldered slightly to the side with a jumper. The photo will be below... plynn, am I the only one who sees tulips or who else?! To summarize, examination of the patient inspires hope for a positive outcome from the implantation of grafts and expansion of functional capabilities.

Surgery can be planned.

Now let’s figure out what and how.

How to straighten 3 phases and what it is in general. Again, Google gives pictures that only gurus can understand, stars and triangles and effective voltages, we don’t even know such words... now I’ll draw them myself so that “all the hedgehogs” understand... Look, who is not yet in the subject, everything is as simple as two fingers.

Now, a short associative series: Let’s imagine that on the left there are three testers with apartments on the same landing. In the common riser there are three wires of “three-phase voltage 360V” (marked L1, L2, L3 in different colors) and a fourth, common\ground\neutral wire (we won’t go into detail). You can touch the neutral wire (NULL) with your hand, it is screwed to the frame/door of the metal cover of the common panel on the landing, and it is one/common not only on your floor, but for everyone in the whole house…. And even in your socket, one of the two contacts has exactly this neutral wire. In the figure it is indicated in black and is common to the three left testers. So, if you measure the voltage between the NULL wire and any of L1, L2, L3, then the testers will show 220V. And just like that, all three apartments on the landing have one of L1, L2, L3 and one common NULL. There is NO 360V there!, it seems….

At each phase (L1, L2, L3) relative to NULL, in the form of a sinusoid with a swing of plus and minus, there is an EMF that strains/presses the electrons, forcing them to move “back and forth” if the circuit from the phase closes to NULL through which or load. This EMF is called “voltage” among ordinary people and is conventionally measured in Volts. For us, it is 220v on the network. In total, the socket of each apartment receives one NULL and one phase Lx, on which, either in one direction or in the opposite direction, pressure appears on the electrons with a force/voltage of 220V.

THE MOST MYSTERIOUS thing about “3-phase” is - where is 360 volts? The fact is that the sinusoids on L1, L, and L3 (see the image in the previous part) are shifted from each other in the voltage form by 120 degrees, and if so far we have measured the voltage on a phase relative to the NULL wire, then measuring the voltage of one phase relatively the other will give us a surprise - look at the fourth tester at the bottom of the picture. If you draw a line on the graph at any point in time, you can immediately understand - “so this is what they are like!” 360v" I marked with dots what the tester shows, measuring the voltage between L1 and L2. Now we understand the phenomenon when refrigerators and televisions burn in our house because of an electrician who mixed up the wires. It’s just that instead of NULL, the electrician forwarded the adjacent phase and a two-phase voltage occurred in the socket, which, after rectification in the household appliance, instead of 250V on the capacitors of the power supplies, gives all 400V with a tail, which in turn breaks the electrolytic capacitors, which are not designed for such mockery. In the refrigerator and in the light bulb, after a short struggle, the windings and spirals burn out. However, don't be so quick to blame the electrician. Much more often, the problem is man-made. Somewhere in the tangle of power wires at a substation near your house, or maybe even in a common riser, a rat or simply erosion of the insulating winding on any phase shorts the phase to NULL. The EMF joyfully accelerates electrons along the resulting circuit into the depths of our planet, tightly welding the contact point. After some time, if the EMF has enough strength, the NULL wire towards the planet’s core heats up and melts…. the circuit to the ground opens and... voila! Through the welding of the phase with the NULL wire, which burned off in the direction of the ground, but remained intact in the direction of the apartments (there was almost no current there), we get TWO phases in the socket! You already know the consequences. Only those who were hanging on the same phase that was welded to NULL will be lucky. They will simply turn everything off without consequences (despite the fact that the same phase will move on both contacts of the sockets, and if you touch it with your hand, it will be very unpleasant!).

There is also a third version of the consequences, simply with “burnout of the neutral wire” and “phase imbalance due to load differences,” but it is a little more difficult to understand and we will not go into it.

So, now after theory, let's start practice. On the right side of the picture with testers, comparative results of rectification of 3 phases according to the Mitkevich circuit (we will use it for a number of reasons) and rectified single-phase voltage according to the full-bridge circuit, which is used in our welding machine, are shown. Schematically, such a rectifier is on the right.

What can you say about them? The first thing is that a three-phase rectifier, unlike a single-phase one, gives a ripple of 150Hz instead of 100Hz, and this is good for us, because The power capacitive battery is charged 50 times per second more often (by the way, it will last longer). Secondly, the load from the swarApp is divided into three parts, which reduces line sagging, and this also gives us a gain. The third, most interesting thing is the shaded area of the effective voltage. In a rectified single-phase circuit there is a complete dip to zero, but in a three-phase circuit there is none at all. Because of this situation, the SwarApp’s containers are charged at least 1.3 times more efficiently, but in reality the efficiency will be even higher!

Now, we know that with the most pessimistic forecast, we will be able to raise, in my case, the permissible welding current from 90A to 120A. And this is already nice.

Read the continuation in “Upgrade: single-phase inverter SVAROG to three-phase. Part 2"

Similar

svarka-master.ru