Make an order

Steel rope GOST 2688-80 double lay type LK-R design 6x19 (1+6+6/6)+1 o.s.

Rope construction:

6x19 (1+6+6/6)+1 o.s. — 6 strands of 19 wires each (wires of increased diameter in the outer layer of the strands).

Application of metal rope GOST 2688-80:

- manufacturing (production) of rope slings;

- cargo rope for a truck crane;

- hoisting rope for tower crane;

- rope for an overhead crane (rope for a hoist);

- grab rope;

- cargo rope for winch;

- scraper ropes for earthmoving and mining machines;

- rope for drilling rig;

- rope for cable cars;

Load rope for truck crane: Galichanin, Ivanovets, Klintsy, Masheka, Chelyabinets, Ulyanovets.

Has an organic core (OC). More rigid, compared to GOST 7668-80 rope;

Possible alternative product: GOST 2688-80 (14954-80) and GOST 3077-80 (3081-80) are interchangeable

GOST 2688-80 is used on construction and metallurgical cranes, mine lifting installations, excavators, scrapers, cable cranes, lifting mechanisms as the main load-bearing ones. GOST 3077 - 80 is used where reliable descent of people is carried out (elevators, shafts) and high-intensity work.

Advantages:

- increased breaking force of ropes in general;

- non-rotating;

- high wear resistance of wires in strands and strands in a rope;

- large contact surface of the rope with pulleys and blocks;

- The service life of ropes with plastically compressed strands is 1.5 times longer than that of conventional ropes.

Catalog of steel ropes GOST 2688-80

| Naming | Unit |

| 3.6 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 3.6 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 4.1 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 4.5 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 4.5 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 4.8 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 5.1 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 5.1 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 5.6 mm steel rope GOST 2688-80 G-VK-N-R-T | linear meters |

| 5.6 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 6.2 mm steel rope GOST 2688-80 G-V-N-R | linear meters |

| 6.2 mm steel rope GOST 2688-80 G-VK-N-R-T | linear meters |

| 6.2 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 6.9 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 6.9 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 7.6 mm steel rope GOST 2688-80 G-V-N-R | linear meters |

| 7.6 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 8.3 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 8.3 mm steel rope GOST 2688-80 G-VK-N-R-T | linear meters |

| 8.3 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 9.1 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 9.1 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 9.6 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 9.6 mm steel rope GOST 2688-80 G-VK-N-R-T | linear meters |

| 9.6 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 11.0 mm steel rope GOST 2688-80 G-VK-N-R-T | linear meters |

| 11.0 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 11.0 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 12.0 mm steel rope GOST 2688-80 G-VK-N-R-T | linear meters |

| 12.0 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 13.0 mm steel rope GOST 2688-80 G-VK-N-R-T | linear meters |

| 13.0 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 13.0 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 14.0 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 14.0 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 15.0 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 15.0 mm steel rope GOST 2688-80 G-VK-N-R-T | linear meters |

| 15.0 mm steel rope G-V-L-O-MK-N-R-1770 TU 14-173-030-2015 PK MS lubricant (A1) | linear meters |

| 15.0 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 15.0 mm steel rope GOST 2688-80 galvanized (G) lubricant (A) | linear meters |

| 16.5 mm steel rope GOST 2688-80 G-VK-N-R-T | linear meters |

| 16.5 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 16.5 mm steel rope GOST 2688-80 galvanized (C) lubricant (A) | linear meters |

| 18.0 mm steel rope GOST 2688-80 G-VK-N-R-T | linear meters |

| 18.0 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 18.0 mm steel rope GOST 2688-80 galvanized (C) lubricant (A1) | linear meters |

| 19.5 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 19.5 mm steel rope GOST 2688-80 G-VK-N-R-T | linear meters |

| 19.5 mm steel rope GOST 2688-80 galvanized (C) lubricant (A1) | linear meters |

| 21.0 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 21.0 mm steel rope GOST 2688-80 galvanized (C) lubricant (A1) | linear meters |

| 22.5 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 22.5 mm steel rope GOST 2688-80 G-VK-N-R-T | linear meters |

| 22.5 mm steel rope GOST 2688-80 galvanized (C) lubricant (A1) | linear meters |

| 24.0 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 24.0 mm steel rope GOST 2688-80 galvanized (C) lubricant (A1) | linear meters |

| 25.5 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 27.0 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

| 28.0 mm steel rope GOST 2688-80 G-V-N-R-T | linear meters |

Additional payments for additional specifications for ropes (custom)

- GL - + 15%

- F — + 30%

- Coolant + 45%

- Certificates МР and РР + 5%

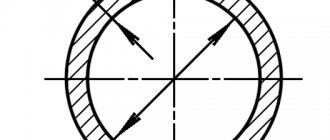

How to determine the diameter of the rope?

Measurements should be taken in two cross sections located at a distance of at least one meter from each other. At each of these points, measurements are taken in two planes perpendicular to each other. After receiving all four results, their arithmetic mean is calculated. For a new rope, the resulting figure should be located within the tolerance field of the “nominal” diameter.

Example of a symbol:

Steel rope GOST 2688-80 12-GL-V-L-O-N-T-1770 (180): steel rope GOST 2688-80 with a diameter of 12 mm, for cargo purposes, made of uncoated wire, grade B, left one-sided lay, non-rotating, non-straightened, increased accuracy, marking group 1770 N/mm² (180 kgf/mm²).

Travel rope GOST 16853-88

GOST 16853-88 applies to steel traveling ropes used on drilling rigs for production and deep exploration drilling of oil and gas wells. Requirements paragraphs. 1.1, 1.3, 2.4, 2.5, 2.6, 2.7, 2.14, 4.2, 4.4 are mandatory.

(Changed edition, Amendment No. 1).

1. MAIN PARAMETERS AND DIMENSIONS

1.1. The traveling rope must be made of the LK-RO type, design 6 31 (1 + 6 + 6 / 6 + 12) with a metal core of design 7 7 (m.s.) or an organic core (o.s.).

1.2. The GOST 16853-88 rope must be made with a right-hand cross lay. The lay direction of the wires in the rope strands must be opposite to the direction of the rope lay.

It is allowed to produce left-hand cross lay ropes.

1.3. The main parameters and dimensions of the ropes must correspond to the drawings. 1, 2 and table. 1, 2. The diameters of the wires in the ropes are calculated and can be specified within ± 0.1 mm, while the diameters of the ropes should not go beyond the permissible deviations given in clause 2.4.

Six-strand tackle rope 6 31 + 1 m.s.; 6 31 = 186 wires with a metal core of the structure 7 7 = 49 wires (rope strand 1 + 6 + 6 / 6 + 12; core strand 1 + 6).

Crap. 1

Six-strand tackle rope 6 31 + 1 o. With.; 6 31 = 186 organic core wires (rope strand 1 + 6 + 6 / 6 + 12).

Crap. 2

Table 1

| Diameter, mm | Calculated cross-sectional area of all wires, mm2 | Approximate mass of 1000 m of lubricated rope, kg | Marking group for tensile strength, N/mm2 (kgf/mm2) | ||||||||||||

| rope | wire | 1570 (160) | 1670 (170) | 1770 (180) | |||||||||||

| central core | central in the strand | 1st layer (6 wires) | 2nd layer | 3rd layer (12 wires) | Design breaking force, N (kgf), not less | ||||||||||

| central in the strand | in a layer of strands (6 wires) | large size (6 wires) | small size (6 wires) | total of all wires in the rope | the rope as a whole | total of all wires in the rope | the rope as a whole | total of all wires in the rope | the rope as a whole | ||||||

| 25 | 1,1 | 1,0 | 1,35 | 1,30 | 1,20 | 0,85 | 1,60 | 300,64 | 2660 | 471500 (48100) | 400500 (40850) | 501000 (51100) | 426000 (43400) | 530500 (54100) | 451000 (45950) |

| 28 | 1,2 | 1,10 | 1,55 | 1,45 | 1,30 | 1,00 | 1,80 | 376,50 | 3380 | 590500 (60200) | 502000 (51200) | 627500 (64000) | 533000 (54400) | 664500 (67750) | 564500 (57600) |

| 32 | 1,4 | 1,30 | 1,70 | 1,60 | 1,50 | 1,10 | 2,00 | 475,75 | 4200 | 746000 (76100) | 634500 (64700) | 792500 (80850) | 673500 (68700) | 839000 (85600) | 713000 (72750) |

| 35 | 1,4 | 1,35 | 1,85 | 1,75 | 1,65 | 1,20 | 2,20 | 564,13 | 5050 | 885000 (90250) | 752000 (76700) | 940500 (95900) | 799000 (81500) | 995500 (101500) | 846000 (86300) |

| 38 | 1,6 | 1,50 | 2,00 | 1,90 | 1,80 | 1,30 | 2,40 | 672,50 | 5980 | 1055000 (107500) | 896500 (91450) | 1121000 (114000) | 952500 (97150) | 1185000 (121000) | 1009000 (102500) |

table 2

| Diameter, mm | Estimated cross-sectional area of all wires, mm2 | Approximate weight of 1000 m of lubricated rope, kg | Marking group for tensile strength, N/mm2 (kgf/mm2) | ||||||||||

| rope | wire | 1570 (160) | 1670 (170) | 1770 (180) | |||||||||

| central in the strand | 1st layer (6 wires) | 2nd layer | 3rd layer (12 wires) | Design breaking force, N (kgf), not less | |||||||||

| large size (6 wires) | small size (6 wires) | total of all wires in the rope | the rope as a whole | total of all wires in the rope | the rope as a whole | total of all wires in the rope | the rope as a whole | ||||||

| 25 | 1,35 | 1,30 | 1,20 | 0,85 | 1,60 | 262,18 | 2450 | 411000 (41900) | 349000 (35650) | 437000 (44550) | 371000 (37850) | 462500 (47150) | 393000 (40100) |

| 28 | 1,55 | 1,45 | 1,30 | 1,00 | 1,80 | 329,95 | 3000 | 517500 (52750) | 439500 (44850) | 550000 (56050) | 467500 (47650) | 582000 (59350) | 494500 (50450) |

| 32 | 1,70 | 1,60 | 1,50 | 1,10 | 2,00 | 409,94 | 3800 | 643000 (65550) | 546500 (55750) | 683000 (69650) | 580500 (59200) | 723500 (73750) | 615000 (62700) |

| 35 | 1,85 | 1,75 | 1,65 | 1,20 | 2,20 | 494,01 | 5640 | 775000 (79000) | 658500 (67150) | 823500 (83950) | 700000 (71350) | 872000 (88900) | 741000 (75550) |

| 38 | 2,0 | 1,90 | 1,80 | 1,30 | 2,40 | 585,92 | 5450 | 919000 (93750) | 781000 (79650) | 976500 (99600) | 830000 (84650) | 1030000 (105000) | 878500 (89650) |

Examples of symbols:

Travel rope with a metal core, diameter 32 mm, grade B, right-hand cross lay, increased manufacturing accuracy T, marking group for tensile strength 1570 N/mm2 (16 kgf/mm2):

Rope MS-32-V-T-1570 GOST 16853-88

Tackling rope, grade 1, left-hand cross lay, normal manufacturing accuracy:

Rope MS-32-1-L-1570 GOST 16853-88

Rope 16853 with an organic core, diameter 32 mm, grade B, right cross lay, increased manufacturing accuracy T, marking group for tensile strength 1770 N/mm2 (180 kgf/mm2):

Rope OS-32-V-T-1770 GOST 16853-88

Rope 16853 grade 1, left cross lay, normal manufacturing accuracy:

Rope OS-32-1-L-1770 GOST 16853-88.

2. TECHNICAL REQUIREMENTS

2.1. Strands of ropes must be made from uncoated wire grade B or 1 according to GOST 7372 in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

2.2. Rope cores must be manufactured:

metal - from uncoated wire grade B or 1 according to GOST 7372;

organic - from sisal according to normative and technical documentation, from hemp fiber according to GOST 5269, from polypropylene film thread according to normative and technical documentation.

It is allowed to add individual cables to the twisted organic core in an amount not exceeding the number of cables, the linear density of which is equal to the difference in the linear density of adjacent diameters of the cores.

2.2.1. Cores made of hemp fiber and sisal must be impregnated with lubricant in accordance with GOST 15037 or other lubricant according to regulatory and technical documentation.

2.2.2. The lay of the metal core in the rope must be one-sided.

The strands and core are twisted in one direction: left - for right lay ropes and right - for left lay ropes.

2.2.3. Separate sections of organic cores are spliced, and the diameter of the ropes should not exceed the maximum deviations in diameter.

2.3. The wires in the layers should not sink, protrude, cross, and also not be bent or flattened; The ends of the wires are connected by electric butt welding with tempering.

At the welding site, the thickening of the wire diameter should not exceed the maximum deviation in diameter.

In grade 1 ropes, no more than two connections of wires in different cross sections are allowed per meter of rope; in grade B ropes, no more than one connection per 10 m.

2.4. The permissible variation in the tensile strength of wires of each diameter taken from the finished rope, with the exception of the central wire of the strand, should not exceed the values given in Table. 3.

Table 3

N/mm2 (kgf/mm2)

| Rope marking group for tensile strength | Allowable variation in tensile strength of wires of each diameter taken from finished rope grades | |

| B | I | |

| 1570 (160) 1670 (170) 1770 (180) | 250 (26) | 310 (32) 330 (34) 360 (37) |

2.5. The number of bends and twists of wires taken from the finished rope must comply with GOST 7372–79.

It is allowed to reduce the number of bends and twists of wires by one in relation to the requirements specified in GOST 7372–79.

2.6. The maximum deviations of the rope diameter must be:

- for high precision ropes with a metal core;

- with organic core;

- with a metal core;

2.7. The total breaking force of all wires in the rope and the breaking force of the rope as a whole must be no less than those given in table. 1 and 2.

2.8. The length of ropes of various diameters must correspond to those given in table. 4.

Shortened length ropes used for the operational needs of the consumer should not exceed 2% of the lot weight.

The permissible deviation in length should not be more than ±1%. The ends of the ropes must have at least two dressings with a length of at least 40 mm at a distance of no more than 50 mm from each other.

Table 4

| Rope diameter, mm | Nominal rope length, m, not less | |

| normal | shortened | |

| 25,0 | 1000 | 450 |

| 28,0 | 1200 | 570 |

| 32,0 | 1500 | 850 |

| 35,0 | 1500 | 850 |

| 38,0 | 1500 | 850 |

2.9. The GOST 16853-88 rope must be non-unwinding and straightened.

2.10. The traveling rope must have a uniform pitch of lay of all elements along its entire length. The pitch length of the wires in the strands of the rope and the core should not exceed 8.5 times the diameter of the strands, and the pitch length of the strands in the rope and its metal core should not exceed 6.5 times the diameter of each.

2.11. Rope 16853 is coated with lubricant over its entire section.

The following lubricants should be used: Torsiol-35, BOZ-1 and other rope lubricants according to regulatory and technical documentation.

2.12. The GOST 16853-88 rope must be wound in one piece on wooden drums in accordance with GOST 11127–78, metal drums according to technical documentation, or on return drums using them in the prescribed manner.

At the consumer's request, drums with ropes are covered with boards. A layer of paper is placed under the sheathing in accordance with GOST 8828–75 or GOST 9569–79.

2.12.1. Packaging of ropes shipped to the Far North and hard-to-reach areas, as well as ropes transported by sea, according to group 123 GOST 15846–79. When transporting by air, drums must be packed in plank crates.

2.12.2. The diameter of the drum neck must be at least 15 times the diameter of the rope. The drum cheeks must protrude above the outer layer of the wound rope by at least 50 mm.

2.12.3. The ends of the rope must be firmly attached to the drum: the rope must be laid in dense, untangled rows to ensure that it can be unrolled freely from the drum.

2.13. Transport marking - according to GOST 14192–77.

2.14. Rope markings are in accordance with GOST 3241–80.

2.15. Other technical requirements are in accordance with GOST 3241–80.

3. Acceptance rules

3.1. Ropes are accepted in batches. The batch must consist of a rope of the same standard size, in one unit of packaging and documented in one quality document containing:

trademark or name and trademark of the manufacturer;

name of the organization in whose system the manufacturer is included;

rope number according to the manufacturer’s numbering system;

symbol of the rope;

rope length;

gross weight of the rope;

the total breaking force of all wires in the rope or the breaking force of the rope as a whole;

core material;

date of manufacture of the rope;

type of lubricant;

drum number.

3.2. The appearance, dimensions and mechanical properties of the wires are checked on each rope.

3.3. Other acceptance rules are in accordance with GOST 3241–80.

4. Test methods

4.1. To check the mechanical properties of the wires and the diameter of the wires, the presence of lubricant in the rope and core, a piece of rope at least 1 m long is taken from each rope.

46 main wires from the strands (including 27 wires of the outer layer of the strands, 18 wires of the inner layers and 1 central wire) are taken from a section of rope for tensile, twisting and bending tests, and 12 wires of the metal core are taken from the rope with a metal core.

4.2. The mechanical properties of the wires and the marking group of the rope are determined by testing the breaking force of the rope wires.

If the total breaking force of all wires of the rope is lower than the breaking force given in table. 1 and 2, then a repeat test is carried out, the results of which are final.

When testing the breaking force of grade I ropes, it is generally allowed to evaluate the rope grade based on the results of testing the mechanical properties of 10% of wires of each diameter, but not less than three. The number of wires obtained by calculation is rounded up to a whole number.

4.3. The presence of lubricant in the rope and core is checked by visual inspection.

4.4. Other requirements for test methods are in accordance with GOST 3241–80.

5. Transportation and storage

5.1. Drums with wound ropes are transported by all types of transport in accordance with the rules for the carriage of goods in force for this type of transport. The placement and securing of cargo during rail transportation is carried out in accordance with the technical conditions for loading and securing cargo, approved by the Ministry of Railways of the USSR. Transportation of ropes by rail is carried out by carload, low-tonnage or small shipments.

Conditions for transportation in covered vehicles - according to groups 5, 6 GOST 15150–69, open vehicles - according to groups 8, 9 GOST 15150–69.

5.2. A drum with a wound rope weighing more than 10 tons must be transported in a horizontal position (the axis of rotation is horizontal), and a weight of 10 tons or less can be transported with the drum axis vertical.

5.3. Under the anti-corrosion metal plate or in a metal envelope nailed to the drum, a copy of the quality document and a hoist rope performance form must be enclosed, which the consumer must fill out and send to the manufacturer (see appendix).

When transporting by air, the metal plate must be placed inside the drum and secured in two places.

5.3. Storage of ropes - in accordance with GOST 3241–80.

6. Operating instructions

6.1. The diameter of the rope used must correspond to the size of the traveling system on which it will be used.

6.1.1. It is not allowed to operate the rope without a stabilizer and to contaminate parts of the rope with drilling fluid and abrasives.

6.1.2. The rope is threaded onto the hoisting system using a cross-type rig. In some cases, the use of parallel equipment is allowed.

6.1.3. The rope should be worked out periodically with a bypass during the process of drilling the well according to a system approved by the management of the consumer enterprise.

6.1.4. When installing and transferring ropes with a metal core, separation of the rope strands from the core is not allowed. A core with one twisted strand should be used to make a loop at the end of the rope.

6.1.5. The enterprise-consumer of ropes must keep systematic records of the operating time and re-runs of ropes. The rope operating time form must be sent to the manufacturer.

7. Manufacturer's warranty

7.1. The manufacturer must ensure that steel ropes comply with the requirements of this standard, subject to the conditions of transportation, storage, installation and operation.

7.2. The guaranteed shelf life of grade B ropes is 12 months from the date of their manufacture.

7.3. Warranty operating time of grade B ropes per 1 m, not less than:

15 tkm – for a diameter of 25 mm;

19 tkm – for diameter 28 mm;

20 tkm – for diameter 32 mm;

20 tkm – for diameter 35 mm;

20 tkm – for a diameter of 38 mm.

Examples of symbols for steel ropes

NOTES:

Ropes are manufactured:

- by purpose - cargo (G); (GL)

- according to the mechanical properties of the wire: grade VK - high quality, grade B - increased quality, grade 1 - normal quality;

- by type of wire coating : “-” – without coating.

- C – with zinc coating for medium aggressive operating conditions.

- F – with zinc coating for harsh aggressive working conditions.

- Coolant – zinc coated for particularly harsh aggressive operating conditions.

- in the direction of lay - right, left (L);

- according to the laying method - non-unwinding (N), unwinding;

- in terms of manufacturing accuracy - normal, increased (G).

If you have a need to select (replace) a rope (cable) on a Galician truck crane, then there is a simple algorithm:

- View the passport of the truck crane (all information on the rope is indicated).

- If there is no passport: - determine the crane model; — correctly measure the diameter of the rope; — determine the lay of the rope (right or left).

- Call us. We will select the right rope for you.

How to choose a steel rope

- Where is it used? Application.

- Construction of steel ropes

- Classification. Types of lay

- Decoding

- Characteristics Load capacity of steel ropes

- Dimensions

- Weight

- Diameter

- Tension

- Margin of safety

- Breaking forces

Where is it used? Application.

Speaking about where steel ropes are used, we can point to the following areas:

- For lifting and moving loads and people;

- As load-bearing elements of structures (reinforcement, load-bearing elements, braces);

- As lightly loaded elements (fences, lightning protection elements, etc.);

- To transfer forces between controls and actuators in various mechanisms.

The use of steel ropes is not limited to lifting and transport equipment, but is quite wide and varied

Construction of steel ropes

Structurally, a steel rope is a product twisted from steel wires of small diameter. There are two main parts in it:

- The core is the central part, acts as a support for the outer layers and a shock absorber;

- The outer layer (layers) takes on the load and provides the necessary strength.

The following types of cable structures exist:

- General purpose – made of round wires;

- Closed - made of round wires, but with one or more outer layers of shaped wire (wedge-shaped, z-shaped, x-shaped). They, pressing against each other, form a protective shell;

- Made from round wires followed by plastic compression - the wires are deformed and pressed against each other, creating a kind of protective shell;

- Made from round wires and plastically compressed with an outer polymer sheath.

Steel cables can be woven from individual wires or whole strands; in the latter case, an increase in the diameter of the product is achieved with an increase in its tensile strength. A strand of steel wire or organic material (natural or synthetic) can be used as a core. In order to protect against corrosion, the finished product is coated with a special grease.

What types of steel ropes are there? Lay types.

The classification of steel ropes is based on design features, parameters and application:

- Construction – made of round wires and with a sheath of shaped wires (closed);

- Purpose – cargo and cargo-carrying vehicles;

- Cross-sectional shape – round and flat;

- The cross-sectional shape of the strands is round and shaped-stranded (triangular);

- Laying of strands - TK (point contact of wires of different layers, layers are wound at different angles), LK (linear contact of wires of different layers, layers are wound at the same angle), LK-O (lay of LC from wires of the same diameter), LK-R (lay of LK, the outer layer of a strand of wires of different diameters), LK-Z (LK lay with filling wires), LK-RO (LK lay, there are layers of wires of both the same and different diameters), TLC (combined point-linear tangency wires), PC (strip contact of wires);

- Laying method – untwisting (wires are not subject to preliminary deformation) and non-unwinding (wires are pre-deformed) strands;

- Degree of balance – straightened (straightens when unwinding) and unstraightened (lose straightness);

- Lay direction – right and left;

- The direction of lay of double and triple lay rope elements is cross, one-sided and combined lay;

- Mechanical properties – VK (high quality), B (increased quality), 1 (ordinary quality);

- Manufacturing accuracy - normal and increased accuracy;

- Wire coating – uncoated and galvanizing types C (for medium aggressive conditions), Zh (severe aggressive conditions), OZh (especially severe aggressive conditions);

- Rope coating – uncoated and with polymer coating;

- Core material – with a metal core, with an organic core of natural or synthetic fibers, with an organic core of solid polymer, with a combined metal-organic core.

The design, types of lay and features of various grades of steel cables are prescribed in the relevant GOST

Interpretation of steel ropes

The marking of steel ropes produced in Russia is established by the corresponding GOST, it consists of a number of symbols:

- The word “Rope” is the designation of the product;

- Rope diameter in mm;

- Purpose (G – cargo, GL – cargo);

- Mechanical properties (grade VK, B or 1);

- Type of coating of the wires in the rope or the entire rope (no designation - without coating, S, Zh, OZH - with zinc coating for various conditions, P - with polymer coating);

- Direction of lay (L – left, no designation – right);

- Combination of lay directions (O – single-sided, K – combined, no designation – cross);

- Laying method (N – non-unwinding, no designation – unwinding);

- Degree of balance (P – straightened, no designation – unstraightened);

- Manufacturing accuracy (T - increased accuracy, no designation - normal accuracy);

- Marking group (in N/mm2);

- GOST to which the product corresponds.

For example, the designation Rope 6.5-G-V-S-N-T-1860 GOST 3070-88 has a steel rope with a diameter of 6.5 mm for cargo purposes of high quality made of zinc-coated wires according to group C, right-hand cross lay, non-unwinding, unstraightened, increased strength, marking group 1860 N/mm2 (190 kgf/mm2), manufactured according to GOST 3070-88.

Characteristics

The main characteristics of steel ropes include:

- Design;

- Coating;

- Direction and type of lay;

- Core type;

- Diameter;

- Wire diameter in layers;

- Core wire diameter;

- The cross-sectional area of all wires and the rope as a whole;

- Weight;

- Breaking force (breaking load) - usually indicated separately for all wires and the product as a whole.

These parameters are indicated in GOST for a specific type of product and accompanying documents. Other characteristics, including permissible load, are calculated when selecting a cable for equipment.

Load capacity of steel ropes

The load capacity of steel ropes and the equipment in which they are used directly depends on their design breaking force and permissible load. According to current regulatory documents, the permissible load to which a cable can be subjected must be 2-7 or more times lower than its breaking force (this number is the safety factor). The carrying capacity of steel ropes generally corresponds to the permissible load, but is often underestimated in order to increase reliability and safety.

Manufacturers of steel rope products usually offer a table of load capacity depending on the diameter, which helps to find the sling, cable for hoists, etc. needed to solve specific problems.

Dimensions

The main dimensions of steel ropes depend on the type, design and purpose of the product:

- Length;

- For round ropes without a polymer sheath - diameter;

- For flat ropes - width and thickness;

- For round cables with a polymer sheath - nominal diameter and sheath diameter.

Round ropes are available in diameters from 0.65 to 72 mm or more. Cables in a polymer sheath have a minimum sheath thickness of 0.5 to 3.0 mm or more (only the nominal diameter is indicated in the product labeling). Flat ropes have a width to height ratio of approximately 6:1; in accordance with GOST 3091-80, with a height of 11.5 to 19.5 mm, they can have a width of 72 to 119 mm.

The length can be arbitrary according to customer requirements.

Most often products are supplied in lengths of 50, 100, 200, 400, 500 and 1000 m

Weight

The total weight of a steel rope depends on its dimensions, design, materials used and the presence of lubricant. At similar diameters, cables with an organic core are 10–15% lighter than similar products with a metal core, and closed ropes are 50–55% heavier than cables of other types of similar diameters.

For each type of product, the relevant GOST provides a weight table, according to which the calculated or approximate weight of the steel rope is determined. Usually the weight is indicated for 1000 m of lubricated cable (less often - for 100 m), which allows you to quickly calculate the weight of the segment. The gross weight of the product according to GOST 3241-91 is indicated on the label.

Diameter of steel ropes

In Russia and abroad, steel ropes with a diameter of 0.65 to 72 mm or more are produced. The most popular cables have the following diameters:

- GOST 2688-80 – from 3.6 to 56.0 mm;

- GOST 3077-80 – from 4.6 to 46.0 mm;

- GOST 3090-73 – from 30.5 to 35.5 mm;

- GOST 7668-80 – from 6.3 to 72.0 mm;

- GOST 7669-80 – from 5.9 to 72.0 mm;

- Group of standards DIN EN 12385-4 – from 1.5 to 40.0 mm depending on the standard (DIN 3055 – from 1.5 to 8.0 mm, DIN 3060 – from 2.5 to 20.0 mm, DIN 3064 – from 12.0 to 40.0 mm, etc.)

Depending on the type, the diameter of steel ropes is measured along equally spaced wires or strands, along the protective sheath, or anywhere (for closed-type ropes).

Tension

During operation, the steel rope must experience loads that do not lead to its destruction - they are called permissible or working. To ensure safety, the permissible load of steel edges should be 2 to 7 times less than the breaking load. The permissible load of steel ropes is indicated in the equipment passport, the breaking load is indicated in the documents for the cable, and the safety factor is regulated by general industrial and industry documents.

When performing individual operations, it is necessary to control the tension of the steel ropes so as not to exceed the permissible load. This is done both by tapping the cable or slings, and using dynamometers.

What is the safety factor of steel ropes?

One of the main parameters of a rope is its breaking load, however, in order to avoid accidents, the maximum load on the rope must be several times less than the breaking load. The number showing how many times the tension of the cable during operation is less than the breaking load determined for it is the safety factor of the steel rope.

When selecting components for lifting equipment, it is necessary to determine what the safety factor of steel ropes is and whether it meets the requirements. This coefficient depends on the application:

- Hoisting ropes must have a safety factor of 2.5 - 3;

- In some cases, a double safety margin is allowed;

- Rope slings must have a safety factor of up to 6 - 7 and higher.

Specific values are determined in accordance with regulations, equipment operating instructions and other documents.

Breaking forces

One of the main operational characteristics of a steel rope is its breaking force - it shows how much force must be applied to the product to break it. The breaking strength of steel ropes depends primarily on their diameter, but the design, type of wire used, etc. also contribute. This parameter is established for each type of cable, it is specified in the relevant GOST - the documents present a table of the breaking force of steel ropes depending on the diameter and marking groups.

It is the breaking force that is one of the main starting points when selecting a rope for specific equipment or equipment.

Operating rules

Rules for the operation of steel ropes are established by general technical and industry standards. The rules may differ slightly for different types of cables, but there are several general requirements:

- Ropes must be regularly inspected and rejected;

- The cables of lifting and transport machines must be lubricated regularly;

- It is necessary to protect ropes from exposure to aggressive environments, welding equipment, excessive loads, etc.;

- Bending, torsion and other deformations of ropes in excess of established standards are not allowed;

- For each type of equipment or operation performed, it is necessary to use the type, brand and diameter of the rope that is specified in the instructions or relevant documents.

If the operating rules are followed, steel ropes will operate reliably and safely throughout their entire service life.

Requirements for steel ropes

The following requirements apply to steel ropes:

- Technical – establish the design features of products, their production, characteristics, mechanical properties, tolerances and deviations, as well as markings and transportation features;

- Operational - establish the procedure for operating ropes, safety requirements, methods for monitoring the condition of products, etc.

Technical requirements for steel ropes are specified in GOST 3241-91 (for ordinary ones), GOST 18899-73 (for closed ones), GOST R 58386-2019 (for reinforcing ones in a polymer sheath), etc.

Operational requirements are specified in general industrial and sectoral documents. In particular, the requirements for ropes operated at facilities with lifting equipment are established by Order of Rostekhnadzor dated November 12, 2013 N 533; for elevator equipment ropes - document PB 10-06-92; for ropes used in the oil and gas industry - document RD 08-200-98, etc.

Fastening steel ropes

Depending on the application and operating conditions of the rope, various fastening methods are selected:

- By means of a loop formed at the end onto a finger or anchor;

- Direct fixation in a drum or other elements of lifting and transport machines;

- Temporary fixation using knots and loops.

In the first case, the fastening of steel ropes is carried out with a loop, which is made at the end of the cable using clamps, braiding, wedge and sleeve-wedge bushings, and filled bushings. To protect against wear, a thimble is inserted into the loop. In the second case, wedges or clamping bars are used, which firmly press the end of the cable to the drum. In the third, special knots or loops are knitted and secured with clamps.

Rejection standards

Slings must be regularly inspected to ensure that damaged or unusable products are rejected.

The inspection is carried out:

- By slingers - before each use;

- Persons responsible for the safety of work – once every 10 days;

- If the equipment is rarely used - immediately before issuance and use.

There are the following signs of rejection of steel rope slings:

- The presence of kinks, kinks, twists and knots on the cables;

- The tag is damaged or lost;

- The number of visually observed cable wire breaks is higher than the established standards (control is carried out according to the rejection tables of specific types of slings);

- Cable wear due to corrosion by 7%;

- Cable wear due to damage to the core by 10%;

- Wear of wires of outer layers by 40%;

- Breaking strands (even one);

- Core extrusion;

- High temperature damage to the cable (melting, welding);

- Deformation and damage to the thimble, bushings, hook;

- Lack of safety locks.

If damage, deformation or excessive wear is detected, the slings are removed in accordance with the rejection rules and sent for repair or disposal.

Storage

Cables can be stored in conditions corresponding to category 5 according to GOST 15150. According to this document, as well as GOST 3241-91, steel rope storage is possible under the following conditions:

- In unheated rooms with high humidity;

- In mines and soil;

- In ship holds and rooms where water may remain for a long time.

In this case, it is necessary to observe several measures to ensure reliable safety of products:

- A cable sent for storage must be inspected and areas that have lost their protective lubricant must be lubricated;

- If the product is stored on a drum, its axis should be parallel to the floor;

- During long-term storage, products must be inspected at least once every six months and, if necessary, lubricated.

Compliance with the requirements of the standards ensures reliable storage of steel cable for many years without loss of its characteristics.

Technical and road conditions

Technical specifications for steel cables manufactured in Russia are specified in a number of documents:

- GOST 3241-91 – general purpose;

- GOST 18899-73 – closed type load-bearing structures;

- GOST R 53772-2010 – reinforcement;

- GOST R 58386-2019 – protected reinforcement in a shell;

- And others.

The same documents also indicate the road conditions under which the transportation of ropes is permitted. For general purpose products, transportation conditions are simple: they can be transported by any open or closed type transport. In this case, it is necessary to comply with the loading and securing standards provided for the specific type of vehicle.

What marking group should steel ropes be?

The marking group of a steel rope is determined by two factors:

- Cable tension during operation;

- A specified safety margin for a specific equipment or application.

For example, a single lay steel rope of type LK-O (structure 1+6) with a diameter of 10.5 mm, marking group 1370 (140) has a breaking force of 81.55 kN (about 8.3 t) - it can be used for the manufacture of slings with the tension of one branch is 13.6 kN (about 1.38 t), which meets the requirement for a six-fold safety factor. At the same time, this rope can be used in hoists with a load capacity of up to 2.8 tons, which corresponds to a threefold safety factor.

Selection of steel ropes

When choosing steel ropes, you must be guided by:

- Requirements for the cable in the instructions or equipment passport, standards and other documents;

- Characteristics of a particular rope;

- Occupational health and safety standards.

In case of replacing a damaged or worn rope, the new one should not differ in type, brand and characteristics from the old one (unless otherwise stated in the instructions). It is also not allowed to use cables with a smaller diameter or a different type, with a lower breaking force and other parameters.

If difficulties arise with the selection of steel rope, our specialists will come to the rescue. You can ask questions about products by phone, in instant messengers or through the feedback form - we will answer you and help you make the right purchase.

Buy steel rope

Packaging, transportation and storage

The ropes are wound into coils and wound onto wooden or metal drums. A metal tag is attached to the end. The marking on the label must contain:

- Symbol.

- Factory number.

- Trademark or name of the manufacturer.

- Date of manufacture.

- The length of the rope or each of its segments.

- Weight.

Products are transported in accordance with the rules established for the transportation of goods in open and closed modes of transport.

Steel ropes are stored in accordance with the requirements of GOST 15150 for group Zh2. Coils and coils are allowed to be placed in unheated rooms and under canopies.

During storage at the consumer's place, the products are inspected along the outer wire layer and lubricated at least once every 6 months. The axis of the drum on which the cable is wound must be parallel to the floor during storage.

Unwind ropes from a coil or reel, holding them under tension. This avoids the formation of loops and creases. Cut the desired piece using a circular saw.

Compliance with the rules of transportation and storage allows you to preserve the original structure of the rope and protect it from corrosion and mechanical damage.

Currently manufactured ropes are classified according to GOST 7372-79 “Steel ropes. Technical specifications” according to the following characteristics: BY DESIGN:

- single lay (spiral) - consisting of one, two or three concentric layers of wire twisted in a spiral;

- double lay - consisting of six strands twisted into one concentric layer;

- triple lay - consisting of twisted double lay ropes.

BY MECHANICAL PROPERTIES OF THE WIRE:

- VK – high quality;

- B – improved quality;

- 1 – normal quality.

BY TYPE OF WIRE SURFACE COATING:

- without cover;

- with zinc coating for various environments - coolant, liquid and wet.

BY PURPOSE:

- cargo-human (GL);

- cargo (G).

BY CORE MATERIAL:

- with an organic core made of natural or synthetic materials - OS;

- with a metal core - MS.

IN THE DIRECTION OF LAYING THE ROPE ELEMENTS:

- right lay;

- left lay (L).

BY COMBINATION OF LAY DIRECTIONS OF THE ROPE AND ITS ELEMENTS:

- cross lay, in which the direction of lay of the strands in the rope is opposite;

- the direction of laying of wires in strands;

- one-sided lay, in which the direction of lay of the wires in the strands and the strands in the rope is the same (right or left).

BY DEGREE OF STRONGNESS:

- twisting - with the same direction of lay of all strands along the layers of the rope, these are, as a rule, six- and eight-strand ropes with an organic or metal core;

- low-twist (MC) - with the opposite direction of lay of rope strands in layers in multi-layer, multi-strand and single lay ropes.

BY ROLLING METHOD:

- non-unwinding (N) - rope elements retain their position after removing the ties from the ends of the rope and removing the end welding;

- unwinding.

BY DEGREE OF BALANCE:

- unstraightened;

- straightened (R).

BY TYPE OF LAYING STRANS AND ROPES OF ORDINARY LAYING:

- with point contact of wires between layers (TC);

- with linear contact of wires between layers (LC);

- with a combined point-linear contact of wires between layers (TLC).

BY MANUFACTURING PRECISION:

- normal accuracy;

- increased accuracy (T);

- with stricter maximum deviations for the rope diameter.

BY STRENGTH CHARACTERISTICS:

The classification is based on the value of tensile strength:

- 1370 N/mm2 (140 kgf/mm2);

- 1470 N/mm2 (150 kgf/mm2);

- and then after 100N to 2160N/mm.

| Double lay rope type LK-RO Design 6x36(1+7+7/7+14)+1 o.s. GOST 7668-80 |

| Double lay rope type LK-R Design 6x19x(1+6+6/6)+1 o.s. GOST 2688-80 (DIN 3059-72, JIS G 2525-88, PR-W-410D-84, UNI 7265-7) |

| Double lay rope type LK-PO Designs 6x36(1+7+7/7+14)+7x7(1+6) GOST 7669-80 (DIN 3064-72, ISO 2408-85, BS 302-8742, JIS G 3525-88, NFA 47-200-83, UNI 7297-74) |

| Double lay rope type LK-3 Design 6x25(1+6; 6+12)+7x7(1+6) GOST 7667-80 (DIN 3057-72, ISO 2408-85, GIS G 3525-88, NFA 47-200 -83, UNI 7295-74) |

| Double lay rope type LK-O, design 6x19(1+9+9)+1 o.s. GOST 3077-80 (DIN 3051-72, ISO 2408-85, BS 302-8742, PR-W-410D-84) |

| Double lay rope type TLK-O design 6x37(1+6+15+15)+1 o.s. GOST 3079-80 |

| Double lay rope type LK-3, design 6x25(1+6; 6+12)+1 o.s. GOST 7665-80 |

| Double lay rope type LK-O, design 6x7(1+6)+1 o.s. GOST 3069-80 (DIN 3055-72, ISO 2408-85, BS 302-87 4.2, NFA 47-200-83) |

| Double lay rope type LK-O design 6x19(1+6)+1x7(1+6) GOST 3066-80 (DIN 3055-72, ISO 2408-85, BS 302-87, NFA 47-200-83, UNI 7293-74) |

| Single lay rope type TK design 1x37(1+6+12+18) GOST 3064-80 |

PromKomplektCenter

Example of a symbol:

rope 3.6-G-V-N-R-T-1860 GOST 2688-80 rope diameter - additional characteristics - GOST

Price from: 17 RUR/m*

Double lay rope Type LK-R, design 6´19(1+6+6/6)+1 o.s.

- Great structural strength.

- Resistant to aggressive environments.

- Wide range of diameters.

- Applications in various industries.

* Price excluding cutting

The production of modern ropes is strictly regulated and monitored without fail. This is due to safety issues when performing work using cables. Naturally, developers and manufacturers pay a lot of attention to this aspect.

, the GOST 2688-80 rope has earned wide distribution . This product has a double lay, which significantly increases the strength characteristics. The rope design is designated in the literature and documentation as follows: 6x19 (1+6+6/6)+1 o.s. The type of core used in the product is organic. Cable type – LK-R. This type of rope has proven itself when used in various types of aggressive environments, including outdoors with significant temperature changes. In this case we are talking about both annual and daily changes in this parameter.

As a result, steel rope 2688-80 has become quite widespread in the following areas of human activity, mechanisms and units:

- in lifting mechanisms of various cranes. Among them are pavements, ships, automobiles, towers, and so on;

- grab, table options;

- as mechanisms in systems on installations for drilling operations;

- widely used on cable cars in the design of the traction mechanism; they are often used in load-bearing structures;

- in elevator structures of various load capacities;

- since this product is structurally quite resistant to abrasion, it is often used for drum-type winches and friction pulleys;

- as a lifting mechanism for hydraulic elevators;

- trawl equipment;

- and in many other systems, units and mechanisms.

The diameter of the product can vary over a fairly wide range, from 3.6 mm to 56 mm for heavy machines and loads with a breaking force of 1.4 million N. The weight of 1000 meters of cable made in accordance with GOST 2688-80 ranges from 48 kg for the thinnest products up to 11650 kg. for the most powerful options. Naturally, for transportation and operation of this kind of ropes, different sizes of drums are required. And they lie in the range of numbers 6-20. Moreover, the length of the rope when sold on one drum can be 1-4 km, depending on the type of cable.

Thus, this type of rope can be used in various areas of human activity and production.

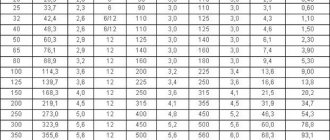

| Steel rope GOST 2688-80 | d rope, mm | Breaking force of the rope as a whole, H 1770/180 | weight 1000 m, kg |

| 3,6 | 7465 | 48 | |

| 3,8 | 8400 | 55 | |

| 4,1 | 9750 | 64 | |

| 4,5 | 11250 | 73 | |

| 4,8 | 12850 | 84 | |

| 5,1 | 14600 | 95 | |

| 5,6 | 17800 | 116 | |

| 6,2 | 21100 | 141 | |

| 6,9 | 26300 | 176 | |

| 7,6 | 32300 | 211 | |

| 8,3 | 38150 | 256 | |

| 9,1 | 45450 | 305 | |

| 9,6 | 53450 | 358 | |

| 11,0 | 68800 | 461 | |

| 12,0 | 78550 | 527 | |

| 13,0 | 8900 | 596 | |

| 14,0 | 108000 | 728 | |

| 15,0 | 125500 | 844 | |

| 16,5 | 152000 | 1025 | |

| 18,0 | 181500 | 1220 | |

| 19,5 | 209000 | 1405 | |

| 21,0 | 243500 | 1635 | |

| 22,5 | 275000 | 1850 | |

| 24,0 | 314000 | 2110 | |

| 25,5 | 356000 | 2390 | |

| 27,0 | 399500 | 2685 | |

| 28,0 | 434000 | 2910 | |

| 30,5 | 520000 | 3490 | |

| 32,0 | 573000 | 3845 | |

| 33,5 | 629000 | 4220 | |

| 37,0 | 748000 | 5015 | |

| 39,5 | 629000 | 4220 | |

| 42,0 | 975000 | 6535 | |

| 44,5 | 1075000 | 7385 | |

| 47,5 | 1230000 | 8430 | |

| 51,0 | 1395000 | 9545 | |

| 56,0 | 1705000 | 11650 |

Print Email

Technical requirements

Steel cables GOST 2688 are manufactured for industrial equipment and lifting devices that move loads and people. The design and materials provide the specified properties depending on the purpose and operating conditions.

General design requirements

The outer sheath of the cable consists of six wire strands, twisted in one technological step. Technology and equipment ensure linear contact of the strand elements. Each strand contains 19 round steel wires. They are arranged in three layers:

- Central axis - 1 pc.

- Middle layer - 6 pcs.

- Top layer - 12 pcs.

In the upper rows, half of the wires have a different diameter from the rest , which ensures roundness of the strands and a more even surface of the bundle.

There is a non-metallic core inside. It is made from various natural and artificial materials, depending on the purpose of the cable. The organic core provides higher elasticity and mobility of the rope than twisted steel wire.

Requirements for the product and materials

Steel wire can be galvanized and uncoated, but must meet the requirements of GOST 7372–79. Any zinc coating must be free of rust and microcracks and cannot contain foreign impurities.

The presence of sunken, protruding and broken wires on the surface of the product is unacceptable. The laying pitch of the wires in the outer layer of the strands should not exceed nine strand diameters.

To lubricate ropes, it is recommended to use Torsiol-55 or other oils manufactured in accordance with regulatory documentation. Cores are not impregnated only at the request of the consumer.

The length of the product is determined during its manufacturing process using a counter. The ends at the cutting line should be tightly tied or welded . The surface of the cable may contain lint from the organic core and a gap between the strands. The gap size must be within the tolerance range for each type of product.

Acceptance and technical control

Each batch of the product is subject to control. A batch is considered to be ropes of the same type and size in packaging provided with one quality document. The quality document, certified by the stamp of the technical control department, must present the test results and indicate the breaking force of the rope or the total value of the breaking forces of all the wires from which the sheath is twisted. The product batch document contains complete information about the composition of the core material and the type of lubricant. It indicates the number and designation of the product, length, weight, drum number and date of manufacture.

Products for cargo purposes undergo more careful selection and testing than those used in industry for moving cargo. In a cargo rope, 25% of the wires are tested for bending and stretching, and in a cargo rope - 100%.

For all galvanized cables, ten percent of the wires are tested for the adhesion strength of the zinc to the base. Visually check the presence of lubricant and the absence of defects on the surface. For ropes of all types, control measurements of the diameter and lay pitch are carried out.