When performing welding work, from the very beginning to the end, an inspection is necessary to confirm the quality of the result. Over time, the structure on which the weld was applied may need to be re-examined to ensure that the connection is intact and the product is safe to use. For this purpose, visual and measuring inspection of welded joints is used. Its parameters are determined by GOST 23479-79. What is the essence of the method? What defects can they identify? When and how is it carried out?

Advantages and disadvantages of the method

Visual and measuring inspection of welded joints is a simple control method that does not require special knowledge, skills and equipment. Its main advantages include:

- the cheapest method, so its implementation does not affect the final cost of the structure;

- no need to use highly specialized reagents and other consumables;

- high accuracy and the ability to identify almost any defective connection;

- no special skills required, just basic knowledge about welds;

- the highest possible speed of assessment;

- visual inspection of welded joints is performed before any other inspection method or independently.

Despite the obvious advantages of application, these methods also have a number of disadvantages. The main one is the ability to find only external defects. In this case, internal defects may be hidden and over time will cause the destruction of the connection. In addition, inspection results are recorded manually, which can cause difficulties if a quality report is required.

Interesting video

Sources

- https://gs16.ru/svarka/vik-svarnyh-shvov.html

- https://osvarka.com/shvy-i-soedineniy/vizualno-izmeritelnyy-kontrol-svarnykh-soedineniy-vik

- https://elsvarkin.ru/texnologiya/texnologiya-vizualno-izmeritelnyx-metodov-ispytaniya-svarnyx-shvov/

- https://svarkaed.ru/svarka/shvy-i-soedineniya/vizualno-izmeritelnyj-kontrol-svarnyh-soedinenij.html

- https://svarkaprosto.ru/tehnologii/vizualnyj-i-izmeritelnyj-kontrol

- https://electrod-svel.ru/tehnika-svarki/vizual-no-izmeritel-nyy-kontrol-svarnyh-shvov.html

Tools

Visual measurement control of welds includes not only a visual assessment of joints, but also the use of special equipment. The most convenient and popular tools for quality control of seams include:

- Dipstick _ It is a scaleless measuring device. To work with them, plates of different sizes are used, which make it possible to determine whether the workpiece meets the required parameters.

- Vernier caliper . This tool allows you to measure connection parameters, including its diameter, depth of cracks and pores.

- Magnifier . Allows multiplicity for external assessment of seams. Using a magnifying glass with varying degrees of magnification allows you to detect even small defects in seams.

- Goniometer . Allows you to identify at what angle the parts are located relative to each other. This parameter allows you to determine how strong and reliable the seam will be during its operation.

- Ruler . It is most convenient to carry out visual inspection of welds using metal rulers of various lengths.

Additionally, various templates, micrometers, calibration plates, gauges and other tools can be used. It is possible to detect the presence of seam defects without the use of special tools only if they are large and clearly visible. Otherwise, you cannot do without additional measurements.

Basic requirements for welds

After manufacturing structures by welding joints of elements, an assessment of the finished product is required. After the inspection of welded joints, a report is issued, which is filled out on the basis of inspection and changes in the main elements of the weld. The width and height of the roller must be within the specified limits, and the seam must be uniform, without depressions or protruding parts. The seam should have a uniform structure without scales. In addition, there should be no cracks, burns, unwelded areas or other defects.

When is visual inspection carried out?

VIC can be carried out at any stage of welding work in relation to the elements that are used in the joint. At the same time, the conformity of the markings of the workpieces themselves and their integrity are revealed.

The next stage is to control the assembly of elements for application with a seam and assess whether the surfaces are properly cleaned of foreign materials. Particular attention is paid to the cutting of the edge, which must be in accordance with the thickness of the material, the type of joint and the welding current.

Upon completion of welding of parts, each seam is examined for a list of all types of defects that can be detected visually:

- sink;

- undercut;

- lack of penetration;

- it's time;

- crack, etc.;

In cases where the technical specifications talk about multi-layer surfacing on a worn element, a separate examination should be carried out for each layer. Upon completion of the entire scope of work, the products are handed over accompanied by an inspection report.

Important! VIC can be used on existing structures in cases where the specified service life of the welded joint will soon end. Any suspicion of a decrease in the quality characteristics of the seam must be accompanied by an examination.

Check procedure

VIC inspection of welded joints includes the following stages of the procedure:

- Preparation . Includes removal of slag, metal spatter and surface cleaning. Correct and thorough preparation of the welded joint allows you to identify even minor defects.

- Visual inspection . To begin with, the seam is inspected with the naked eye. This inspection stage makes it possible to identify only obvious defects.

- Using tools . The main stage of checking the quality of welded joints. It may include illumination of welded joints, measurement of the height and width of the seam, determination of the angle and through defects.

- Conclusion . The final stage is drawing up a report, which may indicate the high quality and reliability of the seams or the presence of defects. If the welded joint has many defects and is of insufficient quality, this information, along with a list of defects, is entered into the report.

VIR welding allows you to determine the quality of the seams and minimize the risk of damage in the future.

Results

Based on the results of the control, the expert draws up a conclusion. In the document, the specialist reflects the nature of the non-compliance, refers to the points of the violated standards, accompanies the report with relevant photographs, and provides recommendations on ways to eliminate defects.

The expert certifies the conclusion with a personal signature and affixes his own stamp. The report is signed by the head and stamped by the expert organization.

You can order a check of the condition of metal structures using a visual measuring control method. Qualified laboratory experts, within the timeframe agreed with the customer, will assess the quality of welding, provide a detailed description of the identified violations, and give recommendations on the possibility of further operation of the facility or the necessary measures to restore the defects.

Scope of application

This method is the simplest and most popular method for assessing their quality and reliability. It can be used to identify pores, cracks, undercuts and other defects that may affect the reliability of welded joints.

This control method is used in various fields:

- ship repair, automobile and shipbuilding factories;

- metallurgical industry;

- during various construction works;

- in the manufacture of pipelines and metal structures;

- after any work that involves the use of welding.

Control is necessary at all stages of production. During the welding process, only visual control is used, and after completion of the work, a measuring stage is used.

Visual measurement control of pipeline welded joints is one of the most critical and labor-intensive work processes. In some cases, time, labor and material costs for quality control can reach 30%. This is due to the fact that visual and measuring control of pipeline welded joints has a small dose of automation, and therefore requires a careful approach from an experienced craftsman and time investment.

Areas of implementation of this technique

External inspection of the weld is carried out before the cleaning procedure, thermal or chemical treatment, as well as after its implementation.

When assessing the quality of a weld, VIC is used:

- As an informative method of describing the general external state.

- As a theoretical method for assessing the internal condition of a seam and as a reason for recommending a more accurate inspection.

- As an evaluation method of the operating conditions of a given seam, structure, system and the entire product.

- As a monitoring method for identifying gross violations of the technological process.

- As a method for preliminary conclusion during decommissioning or recording an emergency situation.

- As a predictive method of possible locations of structural failure for a specific set of visible defects found.

- As a final method for assessing and concluding on the correctness, safety and stability of the technological process of manufacturing or repairing a structure.

Visual and measurement control is a very effective method of checking and double-checking the quality of industrial materials and welded joints when performing construction work and when receiving a certificate of completion of construction, a certificate of commissioning, as well as various other technical certificates.

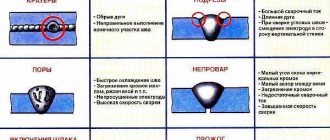

Defects that can be detected

Inspection of seams with the naked eye already makes it possible to identify a number of significant defects in welded joints:

- scaliness of the welded joint;

- uneven seam width and height;

- the presence of influxes;

- strengthening or weakening of the connection in certain areas;

- cracks of various origins;

- burns;

- undercuts.

With the additional use of various tools, other defects can be detected:

- deep pores that affect the performance characteristics of the seam;

- lack of penetration;

- corrosion damage;

- delamination;

- defects in paint or polymer coating;

- axial displacement of the seam or the presence of fractures;

- hairline;

- risks of damage;

- open sinks.

An external inspection of the seam is carried out during the process of making the welded joint, as well as during the process of cleaning it. Visual and measuring control of welded joints is one of the simplest and most effective ways to check their quality. It is recommended for pipe welding, construction and many industries.

These checks are required for the certificate of commissioning, completion of construction and other technical documentation. The use of this method guarantees high quality connections with minimal time and labor costs, and without the use of special reagents or expensive equipment.

What does VIC reveal?

Specialists of the TPE Atom laboratory, conducting visual inspection, identify the following defects:

- longitudinal and transverse cracks;

- metal splashes;

- axle fracture;

- burns;

- violation of seam geometry;

- uncooked areas;

- surface pores;

- surges;

- undercuts;

- fistulas;

- open craters of the weld pool, sinks.

Thanks to the use of magnifying devices, the possibilities of visual inspection are significantly expanded. Such tools make it possible to identify corrosion areas, seam displacement, various cracks, unwanted inclusions in the alloy, open pores, and nicks. If you have a construction site with welded elements, your organization will require a VIC. The TPE Atom laboratory will provide the entire necessary range of services, acting on the basis of a special technical documentation. Our specialists carry out non-destructive testing using visual inspections, as well as additional tools (lenses, endoscope, microscope, probes, tape measures, magnifiers, calipers, etc.). Prices can be found via this link