In what state and form is carbon found in gray cast iron?

What is cast iron?

Cast iron is an alloy of iron and carbon obtained by smelting iron ore in blast furnaces. Cast iron contains from 2 to 5% carbon. How are blast furnace cast irons divided depending on their chemical composition and purpose? Depending on the chemical composition and purpose, blast furnace cast iron is divided into pig iron, foundry cast iron and special cast iron.

How are cast irons separated depending on the nature of the carbon-iron compound?

Promotional offers based on your interests:

Depending on the nature of the combination of carbon with iron, cast iron is divided into white and gray.

What is characteristic of white cast iron?

The carbon in white cast iron is present in the form of cementite (FeO), so it is very hard and is practically not processed, but is used for conversion into steel and for other purposes. The fracture of white cast iron has a matte white color.

What is the state of carbon in gray cast iron?

In gray cast iron, all or part of the carbon is in a free state in the form of graphite, which gives it a gray or dark gray color when broken. Gray cast iron is the main foundry material; it has quite satisfactory mechanical properties, is cheap, has high casting properties and is well processed by cutting tools.

What is the designation for gray cast iron?

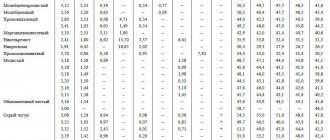

Gray cast iron is designated by two letters and two two-digit numbers separated by a dash. The letters SCH mean gray cast iron, the first two-digit number is the tensile strength, the second is the bending strength. For example, SCh 18-36 is gray cast iron, the tensile strength is 18, and the bending strength is 36.

How is modified cast iron different from regular gray cast iron?

Modified cast iron differs from ordinary gray cast iron in that it has improved mechanical and casting properties. It is obtained by adding graphitizing additives (ferrosilicon, elico-calcium or silicoaluminum) to liquid gray cast iron. Grades of modified cast iron: SCh 28-48, SCh 32-52, etc.

How is high-strength cast iron produced?

Ductile iron is produced from gray cast iron by ladle addition before casting into magnesium molds. The result is nodular cast iron, which has high mechanical and casting properties.

Grades of high-strength cast iron according to GOST 7293-54: VCh 45-0, VCh 45-5, VCh 40-10, VCh 50-1.5, VCh 60-2. The letters VCh mean high-strength cast iron, the first two digits indicate tensile strength , and the latter - the value of relative elongation during tension.

How is malleable cast iron obtained?

Malleable cast iron is produced by long-term annealing of white cast iron in special furnaces, after which graphite is formed in the cast iron instead of free cementite.

Grades of malleable cast iron according to GOST 1215-59: KCh 30-6, KCh 33-8, KCh 35-10, KCh 37-12, etc. The letters KCh mean malleable cast iron, the first two digits are the tensile strength, and the last are relative tensile elongation.

What parts are made from gray cast iron in crane construction?

Source

What is

Cast iron is an iron-based alloy.

Belongs to the group of ferrous metals. Ferrous metals are iron, alloys based on it (steel, cast iron, ferroalloys), manganese. According to some classifications, chromium is included in the group.

In terms of composition, cast iron is a conglomerate of iron, carbon, plus other metals. The steel formula could contain the same basic components.

The difference between these alloys is the amount of carbon. If it is less than 2.14%, it is steel. More - cast iron.

Other components are alloys and impurities (sulfur, silicon, phosphorus, manganese).

Carbon in the structure of cast iron is represented by inclusions of graphite or cementite (iron carbide, formula – Fe3C).

You can distinguish cast iron from steel visually. Steel is lighter and shiny, cast iron is dark matte.

Advantages and disadvantages

Cast iron, like any material, has positive and negative sides.

The advantages of cast iron include:

- Carbon in cast iron can be in different states. Therefore, this material can be of two types (gray and white).

- Certain types of cast iron have increased strength, so cast iron is sometimes placed on the same line as steel.

- Cast iron can maintain temperature for quite a long time. That is, when heated, the heat is evenly distributed throughout the material and remains in it for a long time.

- In terms of environmental friendliness, cast iron is a clean material. Therefore, it is often used to make dishes in which food is subsequently prepared.

- Cast iron is resistant to acid-base conditions.

- Cast iron has good hygiene.

- The material has a fairly long service life. It has been noticed that the longer cast iron is used, the better its quality.

- Cast iron is a durable material.

- Cast iron is a harmless material. It is not capable of causing even slight harm to the body.

The disadvantages of cast iron include:

- Cast iron will rust if it is exposed to water for a short time.

- Cast iron is an expensive material. However, this minus is justified. Cast iron is very high quality, practical and reliable. Items made from it are also high quality and durable.

- Gray cast iron is characterized by low ductility.

- White cast iron is characterized by brittleness. It is mainly used for smelting.

Chemical composition of cast iron

Cast iron is an alloy of iron and carbon, in which the percentage of carbon is not less than 2.14% but not more than 4.5%. Carbon is part of cast iron in the form of cementite or graphite. If the percentage of carbon content is less than 2.14%, the alloy is called steel.

It is known that cast iron alloy was first produced in China in the 6th century. The secret of its production came to Europe in the 14th century, and in Russia its composition was brought to perfection only in the 17th century. Over all this long time, the formula of cast iron has not changed.

The highest quality material was produced at the Demidov brothers foundry, located in the Urals.

Over the centuries, it not only has not lost its relevance, but has also acquired an even wider range of applications.

Story

The documented history of cast iron starts from the 1st millennium BC:

- Smelting was mastered by the Chinese and their neighbors.

- From the 5th century BC, the period of decorative iron casting began.

- 600 years later, coins appeared in China.

The appearance of the alloy in Europe dates back to the 14th century, in Russia – two hundred years later. Interest increased due to the suitability of cast iron as a material for cannons and cannonballs.

Eglinton Tournament Bridge (completed c. 1845), North Ayrshire, Scotland, built of cast iron

Since the time of Queen Victoria, fireplaces have become the most popular product in the “civil segment” among the British.

Cast iron coal iron

The heyday of the cast iron industry in Russia dates back to the 18th century:

- Bridges and rails appeared.

- Cast iron pots were invented in the Urals - the number one cookware for the Russian stove. Later they were supplemented with frying pans.

- By the end of the century, Russia had become the world leader in the production of cast iron.

The original bridge across the Tey from the north (finished in 1878)

The openwork products of Kasli craftsmen have gained world fame.

The method of molding for casting artistic castings of complex shapes, invented by the Kasli people, is still in demand by machine builders today.

Alloy features

The main feature of cast iron is hidden in the process of its manufacture. The fact is that for different types of this alloy the melting point reaches 1200ºC, while for steel it is 1500ºC. This factor is affected by too high a carbon content. Iron and carbon atoms do not have very close bonds with each other.

When smelting occurs, the carbon atoms cannot be completely embedded in the molecular lattice of the iron, causing the cast iron alloy to become brittle. In this regard, it is not used in the production of parts that will be constantly subject to load.

This material belongs to the ferrous metallurgy industry and its characteristics are similar to steel. Products made of cast iron and steel are widely used in everyday life, and it is entirely justified.

If we compare the characteristics of these metals, we can draw the following conclusions:

Industry challenges

Today, cast iron casting has dubious prospects. The fact is that due to high costs and large amounts of waste, industrialists are increasingly abandoning cast iron in favor of cheap substitutes. Thanks to the rapid development of science, it has long been possible to obtain higher quality materials at lower costs. Environmental protection plays a major role in this issue and does not accept the use of blast furnaces. It will take years, if not decades, to completely convert iron smelting to electric furnaces. Why so long? Because it is very expensive, and not every state can afford it. Therefore, all that remains is to wait until mass production of new alloys is established. Of course, it will not be possible to completely stop the industrial use of cast iron in the near future. But it is obvious that the scale of its production will fall every year. This trend began 5-7 years ago.

Metal composition and structure

Cast iron as a structural material is represented by a metal cavity with graphite inclusions. Its main components are pearlite, ledeburite and plastic graphite. It is interesting that in different types of alloys these elements are present in different proportions or may be completely absent.

According to its structure, cast iron alloy is divided into the following varieties:

In this case, graphite may be present in it in one of the following forms:

Manufacturing technologies

As you know, cast iron is produced in special blast furnaces. The main raw material for its production is iron ore. The manufacturing process consists of the reduction of iron ore oxides and the resulting production of another material - cast iron. For its production, fuels such as coke, thermoanthracite, and natural gas are used.

To produce one ton of pig iron, about 550 kilograms of coke and approximately a ton of water are required. The volume of ore loaded into the furnace will depend on the iron content in it. As a rule, ore is used, which contains at least 70% iron. The thing is that it is not economically feasible to use a lower concentration.

The first stage in the production of cast iron is its smelting. Ore is poured into the blast furnace, and then coking coal, which is necessary to pump and maintain the required temperature inside the furnace shaft. During combustion, these components take an active part in the ongoing chemical reactions as iron reducers.

Meanwhile, flux is immersed in the furnace, which acts as a catalyst. By accelerating the melting of rocks, it thereby supports the rapid release of iron. It is important to know that before loading into the furnace, the ore undergoes the necessary pre-treatment. It is crushed in a crushing plant because smaller particles melt faster. It is then washed to remove non-metal particles. Next, the raw material is fired, as a result of which sulfur and other foreign components are extracted from it.

At the second stage of production, natural gas is supplied through special burners into the filled and ready-to-use furnace. Coke is involved in heating the raw materials. Carbon is released, which combines with oxygen to form an oxide. It, in turn, promotes the recovery of iron from ore.

As the volume of gas in the furnace increases, the rate of the chemical reaction decreases. It may even stop completely when a certain gas ratio is reached. Carbon penetrates the alloy and combines with iron to form cast iron. Unmelted elements remain on the surface and are soon removed. Such waste is called slag. It is used to make other materials.

Scope of use

This metal is used in various industries. For example, it is widely used in mechanical engineering for the production of various parts.

Most often this material is used in the production of engine blocks and crankshafts. To manufacture the latter, an improved alloy with the addition of special graphite impurities is required. This metal is resistant to friction, so high quality brake pads are made from it.

In harsh climatic conditions, cast iron alloy is indispensable, as it allows machine parts made from it to operate smoothly even at the lowest temperatures.

It has also proven itself excellent in the metallurgical industry. Its excellent casting properties and relatively low price are highly valued. Products made from it are characterized by very high strength and wear resistance.

A great variety of plumbing products are made from cast iron alloy. These are radiators, sinks, various sinks and pipes. Cast iron bathtubs and heating radiators are widely popular. Their service life is very long. Many apartments still use these products to this day, because they retain their original appearance for a long time and rarely need restoration.

It is also important that the excellent casting properties of cast iron make it possible to make entire works of art from it: such as openwork forged gates and all kinds of architectural monuments.

It is noteworthy that the price for 1 kilogram of cast iron is determined by the amount of carbon in its composition, as well as the presence of various impurities and alloying components. The price of a ton of cast iron is about 8,000 rubles.

Today there is not a single area where this metal is used. Its castings and alloys form the basis of many components, mechanisms and parts. Sometimes it is used as an independent product, perfectly coping with the functions assigned to it. This iron-containing compound is unique in its kind. It remains indispensable to this day.

Source

Gray cast iron

Gray cast iron is an alloy of iron and carbon, which, when the metal cools, forms in the form of flake-like or plate-like inclusions. The carbon content of the alloy exceeds 2.14%, which is higher than normal solubility. This is what distinguishes the alloy from steel, in which carbon is completely dissolved and is absent in the form of separate inclusions, the structure of which defines them as graphite.

Main characteristics

Gray cast iron is the basis of ferrous metallurgy, as it is obtained from the reduction of iron ores using carbon fuel (coke). As a result, in addition to the chemical reaction of reduction of iron oxides, the alloy is additionally saturated with free carbon.

The high free carbon content determines the mechanical properties of gray cast iron. One of the main qualities that allow gray cast iron to be used not only as a pigment metal is its high casting qualities and low shrinkage during solidification. Molten metal has high fluidity, so it can be used to make castings of complex shapes.

Gray cast iron plates

The restriction on the use of products made of gray cast iron is due to the fact that it has low bending strength and high fragility. At the same time, the compressive strength of gray cast iron is very high.

Despite its high fragility, such a characteristic as the wear resistance of cast iron allows it to be used in products operating under friction conditions. Under these conditions, the antifriction properties of the alloy have a strong influence.

Due to the presence of carbon inclusions, welding gray cast iron is practically impossible. There are welding technologies under certain conditions. This is preheating of parts, the use of special high-carbon electrodes, but still, the structure of the weld metal is very different from the base material. The parts to be welded must be cooled slowly to eliminate stress in the weld area.

Classification

Cast iron is classified on several grounds:

- According to the dimensions and shape of graphite inclusions. Layered, spheroidal, vermicular, flakes.

- By type of carbon. Graphite, cementite.

- According to production technology. Grey, white, reworked.

- Based on the presence of additives. Ordinary and alloyed. Alloyed are alloys of cast iron with metals (molybdenum, nickel, chromium, titanium, etc.). Alloys with such metals give products ductility, resistance to wear, destruction, and corrosion.

Microstructure of white cast iron

Product characteristics are established at the production stage.

Varieties

There are white and gray cast iron.

- The carbon in white cast iron is in the form of iron carbide. If you break it, you can see a white tint. White cast iron is not used in its pure form. It is added to the process of producing malleable iron.

- At a fracture, gray cast iron has a silvery tint. This type of cast iron has a wide range of uses. It lends itself well to processing with cutters.

In addition, cast irons are high-strength, malleable and with special properties.

- High-strength cast iron is used to increase the strength of the product. The mechanical properties of such cast iron allow this to be done perfectly. High-strength cast iron is obtained from gray cast iron by adding magnesium to the mass.

- Ductile iron is a type of gray iron. The name does not mean that this cast iron is easily forged. It has increased plasticity properties. It is obtained by annealing white cast iron.

- There is also a distinction between half cast iron. Some of the carbon in it is in the form of graphite, and the remaining part is in the form of cementite.

Composition and types of white cast iron

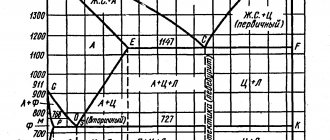

White cast iron consists of the so-called cementite eutectic. In this regard, it is divided into three categories:

- Hypoeutectic. These are alloys in which carbon does not exceed 4.3% of the total composition. It is obtained after complete cooling. As a result, it acquires the characteristic structure of such elements as pearlite, secondary cementite and ledeburite.

- Eutectic. Their carbon content is 4.3%.

- Hypereutectic white cast iron. The content exceeds 4.35% and can reach 6.67%.

In addition to the above classification, it is divided into ordinary, bleached and alloyed.

The internal structure of white cast iron is an alloy of two elements: iron and carbon. Despite high-temperature production, it retains a fine-grained structure. Therefore, if you break a part made of such metal, a characteristic white color will be observed. In addition, in the structure of a hypoeutectic alloy, for example, hard grades, in addition to pearlite and secondary cementite, cementite is always present. Its percentage can approach 100%. This is typical for a eutectic metal. For the third type, the structure is a composition of eutectic (Ep) and primary cementite.

One of the varieties of such alloys is the so-called bleached cast iron. Its basis, that is, the core, is gray or high-strength cast iron. The surface layer contains a high percentage of elements such as ledeburite and perlite. The whitening effect up to 30 mm deep is achieved using the rapid cooling method. As a result, the surface layer is white, and then the casting consists of an ordinary gray alloy.

White cast iron structure

Depending on the percentage of alloyed additives, the following types of metal are distinguished:

- low-alloyed (they contain no more than 2.5% alloying elements);

- moderately alloyed (the percentage of such elements reaches 10%);

- highly alloyed (in them the amount of alloying additives exceeds 10%).

Quite common elements are used as alloying additives. The alloyed white cast iron obtained in this way acquires new, predetermined properties.

Properties of white cast iron

Any cast iron alloy, on the one hand, is very strong, but at the same time it is quite brittle. Therefore, the main positive properties of white cast iron include:

- High hardness. This greatly complicates the processing of parts, in particular cutting.

- Very high resistivity.

- Excellent wear resistance.

- Good resistance to increased heat.

- Sufficient corrosion resistance, including to various acids.

White cast irons, with a reduced percentage of carbon, are more resistant to high temperatures. This property is used to reduce the number of cracks in castings.

Appearance of white cast iron

The disadvantages include:

- Low casting properties. It has poor mold filling. During pouring, internal cracks may form.

- Increased fragility.

- Poor machinability of castings and parts made of white cast iron.

- Large shrinkage, which can reach 2%.

- Low impact resistance.

Another disadvantage is poor weldability. Problems in welding parts made of this material are caused by the fact that during welding, cracks form, both during heating and cooling.

Marking of white cast iron

To mark white cast iron, letters of the Russian alphabet and numbers are used. If it contains impurities, then the marking begins with the letter “H”. The composition of the available alloying additives can be determined by the following letters P, PL, PF, PVK. They indicate the presence of silicon. If the resulting metal has increased wear resistance, then its marking will begin with the letter “I”, for example ICHH, ICH. For example, the presence of the designation “Ш” in the marking means that the alloy structure contains spherical graphite.

The numbers indicate the amount of additional substances present in white cast iron.

Brand CHN20D2ХШ is deciphered as follows. This is a heat-resistant high-alloy metal. It contains the following elements: nickel - 20%, copper - 2%, chromium - 1%. The remaining elements are iron, carbon, and spherical graphite.

Chemical composition and structure

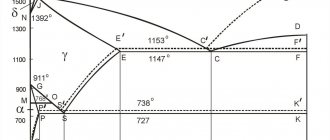

The chemical composition of the alloy, in addition to iron and carbon, also includes some silicon content. The properties of the alloy depend on the cooling conditions, since the time of temperature change affects the formation of the internal structure of the material.

With slow cooling, large iron crystals are formed, and metal-carbon compounds acquire a pearlite base. Slow cooling causes an increase in the geometric dimensions of not only iron crystals, but also carbon inclusions, therefore, pearlite metal has high strength, but increased fragility.

Microstructure of gray cast iron

Under conditions of rapid cooling, carbon does not have time to form large graphite inclusions, so the alloy acquires a ferritic structure.

Ferritic gray cast iron is slightly less brittle than pearlitic.

By choosing a cooling mode for a cast workpiece, you can influence the final properties of the material in a certain way, depending on the requirements.

How to distinguish cast iron from steel

At scrap metal collection points, cast iron is accepted at a low price, since it is fragile, difficult to process, and removing harmful impurities from it is not an easy task. Experts shared with us tips on how to independently distinguish cast iron from other metals:

- by sound (if you hit steel with any object, the sound comes out very loud);

- by strength;

- on magnetic properties.

Cast iron can be easily distinguished from iron. Iron rusts quickly, it is light silver in color and ductile. But it is more difficult to distinguish cast iron from steel, due to their similar composition; they are externally similar to each other, but the characteristics of the alloys are different from each other.

Steel is easier to process and is not afraid of impacts. There is an opinion that a magnet will help distinguish cast iron from steel. This is correct to some extent, because the magnetic properties of the alloy depend on its composition.

Application

Gray cast iron is widely used in casting products for which high compressive strength is important. This property is important mainly in the manufacture of cast tool beds. The use of the material is limited by the increased fragility of products in the presence of significant bending forces.

Gray cast iron product

Previously, the good casting properties of the material were widely used in the manufacture of various products for household and industrial purposes. A variety of kitchen and household utensils - cast iron pots, frying pans, irons - made by casting with minimal subsequent processing had low cost and ease of production.

Currently, casting is also used to produce highly loaded machine elements where they are not subjected to bending loads. These are pistons and cylinders of internal combustion engines.

High-strength parts cast from gray cast iron have minimal cost and long service life. Without exaggeration, we can say that cast beds and machine bodies are almost eternal compared to other elements of the device.

Source