- Designation - Al (Aluminum);

- Period - III;

- Group - 13 (IIIa);

- Atomic mass - 26.981538;

- Atomic number - 13;

- Atomic radius = 143 pm;

- Covalent radius = 121 pm;

- Electron distribution - 1s22s22p63s23p1;

- melting temperature = 660°C;

- boiling point = 2518°C;

- Electronegativity (according to Pauling/according to Alpred and Rochow) = 1.61/1.47;

- Oxidation state: +3.0;

- Density (no.) = 2.7 g/cm3;

- Molar volume = 10.0 cm3/mol.

Aluminum (alum) was first obtained in 1825 by the Dane G. K. Ørsted.

Initially, before the discovery of an industrial method of production, aluminum was more expensive than gold. Aluminum is the most abundant metal in the earth's crust (mass fraction is 7-8%), and the third most abundant of all elements after oxygen and silicon. Aluminum is not found in free form in proirod.

The most important natural aluminum compounds:

- aluminosilicates - Na2O Al2O3 2SiO2; K2O Al2O3 2SiO2

- bauxite – Al2O3 nH2O

- corundum - Al2O3

- cryolite – 3NaF AlF3

Aluminum in D.I. Mendeleev’s Periodic Table of Chemical Elements is numbered “13” and belongs to group 13(IIIa) (See Atoms of group 13(IIIa).

Rice. Structure of the aluminum atom.

Aluminum is a chemically active metal - at its outer electronic level there are three electrons that participate in the formation of covalent bonds when aluminum interacts with other chemical elements (see Covalent bond). Aluminum is a strong reducing agent and exhibits an oxidation state of +3 in all compounds.

At room temperature, aluminum reacts with oxygen contained in the atmospheric air to form a strong oxide film, which reliably prevents the process of further oxidation (corrosion) of the metal, as a result of which the chemical activity of aluminum decreases.

Thanks to the oxide film, aluminum does not react with nitric acid at room temperature, therefore, aluminum cookware is a reliable container for storing and transporting nitric acid.

Physical properties of aluminum:

- silver-white metal;

- solid;

- lasting;

- easy;

- plastic (stretched into thin wire and foil);

- has high electrical and thermal conductivity;

- melting point 660°C

- natural aluminum consists of one isotope 2713Al

Chemical properties of aluminum:

- when removing the oxide film, aluminum reacts with water: 2Al + 6H2O = 2Al(OH)3 + 3H2;

- at room temperature it reacts with bromine and chlorine to form salts: 2Al + 3Br2 = 2AlCl3;

- at high temperatures, aluminum reacts with oxygen and sulfur (the reaction is accompanied by the release of a large amount of heat): 4Al + 3O2 = 2Al2O3 + Q; 2Al + 3S = Al2S3 + Q;

- at t=800°C reacts with nitrogen: 2Al + N2 = 2AlN;

- at t=2000°C reacts with carbon: 2Al + 3C = Al4C3;

- reduces many metals from their oxides - by aluminothermy (at temperatures up to 3000°C) tungsten, vanadium, titanium, calcium, chromium, iron, manganese are produced industrially: 8Al + 3Fe3O4 = 4Al2O3 + 9Fe;

- reacts with hydrochloric and dilute sulfuric acid to release hydrogen: 2Al + 6HCl = 2AlCl3 + 3H2; 2Al + 3H2SO4 = Al2(SO4)3 + 3H2;

- reacts with concentrated sulfuric acid at high temperature: 2Al + 6H2SO4 = Al2(SO4)3 + 3SO2 + 6H2O;

- reacts with alkalis with the release of hydrogen and the formation of complex salts - the reaction occurs in several stages: when aluminum is immersed in an alkali solution, the durable protective oxide film that is on the surface of the metal dissolves; after dissolving the film, aluminum, as an active metal, reacts with water to form aluminum hydroxide, which interacts with alkali as an amphoteric hydroxide: Al2O3+2NaOH = 2NaAlO2+H2O - dissolution of the oxide film;

- 2Al+6H2O = 2Al(OH)3+3H2↑ - interaction of aluminum with water to form aluminum hydroxide;

- NaOH+Al(OH)3 = NaAlO2+2H2O - interaction of aluminum hydroxide with alkali

- 2Al+2NaOH+2H2O = 2NaAlO2+3H2↑ - the overall equation for the reaction of aluminum with alkali.

Iron: Impurity and Alloying Element

Iron is the main and most dangerous impurity in most industrial cast and wrought aluminum alloys. Therefore, the iron content in aluminum alloys is strictly limited, in some alloys - up to 0.05%.

On the other hand, iron is the main component in aluminum-based materials that are produced using new technologies. For example, in amorphous and nanocrystalline alloys the iron content is more than 10%. These materials have a record level of strength up to 1500 MPa.

Manufacturing

The alloy is created from waste duralumin, aluminum and iron by aluminizing. In a heat-resistant container (electric arc furnace), pieces of steel, free of scale and dirt, are poured (purification degree 99%), a 49% mixture of Al or aluminum alloy containing 2% ammonium chloride, and then sintered in an argon atmosphere. The heat treatment temperature can range from +9000C to +15000C.

The container is heated by supplying current to the heating elements or through the structure itself, provided that it has a high ohmic resistance.

After heating, the optimal annealing method is selected, depending on the composition of the components, followed by natural cooling.

Sources of impurities in aluminum

Ordinary aluminum and its alloys inevitably contain impurities, that is, chemical elements that are not specifically introduced into the alloy. Impurities, including iron, have various origins. They can come from the ore, can enter the metal during electrolysis, and are not always completely removed during the production and refining of primary aluminum. Impurities can arise during the melting and casting process due to contamination of the charge, interaction of the metal with the lining and fluxes, as well as due to the dissolution of elements of foundry equipment and foundry tools. In addition, large amounts of impurities can be introduced during the melting of aluminum waste.

Welding aluminum to steel using the argon arc method

Before starting the welding process, it is recommended to clean the metal edges and apply a protective coating to them. The most affordable of them is zinc.

The filler material in this case is AD1 grade aluminum wire with a silicon additive (it has a good effect on the formation of a diffusion layer of stable quality) or AK-5 alloy wire.

Important! AMg-6 is not recommended for use, since this additive gives low weld strength.

To prepare a steel piece for welding, the butt joint should be beveled at a 70° angle for maximum joint strength.

The edges must be thoroughly sandblasted or mechanically treated, then a surface coat must be applied.

Argon arc welding of aluminum and steel is distinguished by the location of the arc : at the beginning of the welding of the first pass, it is held on the filler rod, and during the welding of subsequent passes - on the filler rod and the resulting bead. This will protect the coating from premature fading.

During the welding process, it is important to apply weld beads sequentially (depending on the type of connection).

Current selection:

- MIG welding - occurs with a constant welding current of reverse polarity;

- TIG welding - can be used with both alternating welding current and direct current of straight polarity.

The magnitude of the welding current should depend on the thickness of the metal being welded:

- up to 3 mm : 110-130 A;

- 6-8 mm : 130-160 A;

- 9-10 mm : 180-250 A.

Non-metallic impurities in aluminum

The main non-metallic impurities in aluminum are oxygen and hydrogen. Oxygen has low solubility in liquid and solid aluminum, and hydrogen has high solubility in liquid aluminum and extremely low solubility in solid aluminum. Oxygen forms oxides. Hydrogen dissolved in liquid aluminum is released during its solidification and leads to the formation of shrinkage porosity.

In practice, the harmful effects of gas impurities are suppressed by removing hydrogen from the melt (usually by blowing with inert gases or chlorine) and by filtering it to remove oxide particles.

Mendeleev

“Biography of Dmitry Mendeleev” - Meniscus height. Medal of H. Davy. Cover of the first publication. In 1880 he put forward the idea of underground gasification of coal. Research in the field of gases. Naturalist. Founders of the Russian Chemical Society. Periodic law. Heidelberg period. Definitions of physical constants. Takes part in the first International Chemical Congress.

“Chemistry of Mendeleev” - Ivan Pavlovich Mendeleev - father of D.I. Mendeleev. Gold medal of the USSR Academy of Sciences (now RAS) named after D. I. Mendeleev. Academy and Society Awards. Aeronautics. Suitcases of D. I. Mendeleev. Development of the Far North. A monument installed on the facade of the Faculty of Food and Chemical Technology in Bratislava.

“Mendeleev biography” - Sculptor Petin V.P. Marble, granite. Mendeleev D.I. The doctrine of industry by D. Mendeleev. Members of the commission for the inspection of the Ural mining plants. USSR 1 ruble 1984 (D.I. Mendeleev). Author of the famous textbook “Fundamentals of Chemistry”. Dmitry Ivanovich Mendeleev (left) and Clemens Wiikler. Monuments to the great scientist D.I. Mendeleev.

“Mendeleev Dmitry Ivanovich” - D.I. Mendeleev with his children – Vladimir and Olga. “He worked hard and became a genius!” said Dmitry Ivanovich. The structure of the atom (1911. E. Rutherford). Since 1861, Dmitry Ivanovich taught in St. Petersburg. Only what you acquire through your own labor is lasting and fruitful. Lyubov Mendeleeva (“Beautiful Lady”) and Alexander Blok.

“The Life of Mendeleev” - “If you don’t know names, then the knowledge of things will die” K. Liney. Life and work of D.I. Mendeleev. Discovery of the periodic law. On July 18, D.I. Mendeleev graduated from the Tobolsk gymnasium. Family. Maria Dmitrievna Mendeleeva (1793 - 1830), mother of the scientist. 1834, January 27 (February 6) - D.I. Mendeleev was born in the city of Tobolsk, in Siberia.

“Mendeleev and environmental protection” - Chemistry of the hydrosphere. Selection of combustible material. Using "substances all over the place" Requirements for production processes. Reduce losses in the production process. DI. Mendeleev. Works of a scientist in atmospheric chemistry. DI. Mendeleev on the problems of nature conservation. Offers. Atmospheric chemistry. The greatest Russian scientist.

Insoluble impurities in aluminum

The negative effect of impurities with low solubility is associated with the formation of phases and/or eutectics with a low melting point. Phase particles that are insoluble during homogenizing annealing usually have low plasticity and are often elongated in shape. Such particles significantly reduce the technological ductility, elongation and strength of the aluminum alloy. In addition, it is necessary to take into account the possibility of combining the main alloying elements into insoluble phases. Such phases can lead to a decrease in, for example, the effect of age hardening.

Insoluble phases often have an electrode potential that is very different from that of the aluminum matrix, which reduces the corrosion resistance of the alloy. On the other hand, low-soluble metals have almost no effect on electrical conductivity, which makes it possible to use them as alloying additives in electrical alloys: aluminum grades and aluminum alloys.

History of discovery

The first attempts to use aluminum and iron alloys were made by Faraday in 1820. There have been attempts to use aluminum alloy as an alloying element to produce high-strength steel, but these have proven ineffective.

Thorough research was resumed after 1918 in the USSR, Germany, and England. It has been shown that the addition of Al increases the heat-resistant properties of cast iron. The samples have increased strength and fragility, withstand contact with acidic environments, and are not prone to the formation of scale.

It was found that the appearance of scale depends on the thickness of the oxide film on the samples: the thicker and more uniform it is, the higher the surface protection. It is important that the oxides do not form a eutectic phase and do not undergo sublimation, and their ionic conductivity is minimal.

The condition for heat resistance of a sample is loss with scale in the range of 2-10-3–4-10-3 g/cm2/h.

Many studies of Fe and Al alloys have resulted in the determination of their chemical and physical properties. This is due to problems with gas saturation of samples, aluminum waste, the formation of internal oxide films, and destruction of samples under normal conditions.

The most promising were alloys containing from 16 to 20% Al and 3% carbon, called “chugal”. They began to be smelted in the USSR.

Later, a group of inventors led by Z. Eminger developed a technology for the production of high-quality castings of iron-aluminum samples. Thanks to this, new data was obtained.

Reducing the harmful effects of impurities in aluminum

However, technological operations are not always able to reduce the impurity content to an acceptable level, and in some cases they are simply not cost-effective. For example, the cost of aluminum after zone refining can be several times higher than that of primary electrolytic aluminum. An alternative way is to control impurities through additional alloying and heat treatment. Special alloying changes the phase composition, properties and morphology of excess phases, and heat treatment can lead to dissolution, fragmentation and coagulation of particles with unfavorable morphology.

Let us compare the properties of the aluminum atom with neighboring chemical elements by group and period

Let's compare the properties of the aluminum atom with neighboring chemical elements by group and period.

In the group: Boron - Aluminum - Gallium On the outer shell - 3 electrons each (similarity) Number of shells: aluminum has 1 shell more than boron, but 1 shell less than gallium, therefore, the radius of the pluminium atom is greater than boron, but less than gallium, the metallic and reducing properties of aluminum are stronger than boron, but weaker than gallium In the period: Magnesium - Aluminum - Silicon Number of shells - 3 each (similarity) Number of external electrons: silicon 4e , for aluminum - 3, for magnesium - 2e, therefore, the radius of the aluminum atom is greater than that of silicon, but smaller than that of magnesium, the metallic and reducing properties of aluminum are weaker than those of magnesium, but stronger than those of silicon. Slide 5 from the presentation “Chemistry 8th grade acids in the light of ted”

Dimensions: 720 x 540 pixels, format: .jpg. To download a free slide for use in class, right-click on the image and click “Save Image As.” " You can download the entire presentation “In chemistry, grade 8, acids in the light of ted.ppt” in a zip archive of 223 KB in size.

Eutectic of iron and aluminum

Iron is a transition metal that forms a eutectic with aluminum and has very low solubility in solid aluminum. Iron, unlike transition metals such as manganese, chromium, zirconium, titanium and scandium, does not tend to form a solid solution. Moreover, a solid solution does not form not only at industrial cooling rates (up to 1000 K/s), but even during rapid solidification at rates of the order of 1,000,000 K/s. Moreover, the phases that iron forms have lattice parameters and structures that are different from aluminum. Therefore, iron is not used as a grain grinder or a retarder for the recrystallization of aluminum alloys.

Other methods of welding aluminum to steel

The laser method is used not only to create miniature joints, but also to obtain long seams, for example, in the automotive industry. This method allows you to finely control the thermal power of pulsed laser radiation.

To make a lap joint, laser heating must be carried out from the steel side. It will heat up to a temperature where the aluminum will already melt, but will remain solid.

The strength of seams can be increased using an aluminum-based additive.

Diffusion

In this welding process, the parts being joined are not melted. But due to their prolonged contact at high temperatures, intermetallic phases are formed.

Electron beam

Buffer coatings of titanium, nickel and zirconium are applied to the steel: then the welding process will be successful.

Point contact

A good point connection between steel and aluminum is not always obtained, even if welded on capacitor machines with severe discharge conditions.

This can be avoided by using an intermediate bimetallic tape. The strength of the resulting point connections can be compared with riveted ones.

Aluminum-iron phase diagram

For the analysis of aluminum alloys in which iron is an impurity or alloying element, an indispensable tool is the iron-aluminum phase diagram (or phase diagram).

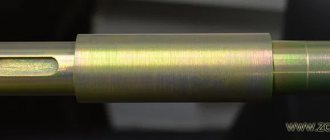

Figure - “Aluminum” edge of the aluminum-iron phase diagram

Alloys rich in aluminum are characterized by the eutectic interaction of the aluminum solid solution and the Al3Fe phase:

L –> Al + Al3Fe.

The eutectic reaction occurs at 652-655 ºС with an iron concentration at the eutectic point of 1.8%.

The Al3Fe phase (40.7% Fe) occupies a vast homogeneous region from 37.3 to 40.7%. The Al5Fe2 phase has an iron concentration of 27.5-29% Fe.

Characteristics and properties

Alloys of iron and aluminum have the following characteristics:

- number of thermal heating cycles up to 240, depending on the chemical composition;

- tensile strength 100 MPa;

- excellent casting properties of the alloy;

- Alloying elements can be used: Cr, Ni, Ti, Mo, Cu, B, Si, Nb, Zr.

Alloy properties:

- good weldability subject to heat treatment above +7000C;

- high chemical resistance;

- the need to form a stable melt phase at temperatures up to 9000C;

- corrosion resistance.

Aluminum as a simple substance: physical properties

If we talk about aluminum as a simple substance, then it is a silvery-white shiny metal. In air it quickly oxidizes and becomes covered with a dense oxide film. The same thing happens when exposed to concentrated acids.

The presence of such a feature makes products made of this metal resistant to corrosion, which, naturally, is very convenient for people. That is why aluminum is so widely used in construction. The properties of the substance are also interesting in that this metal is very light, yet durable and soft. The combination of such characteristics is not available to every substance.

There are several basic physical properties that are characteristic of aluminum.

- High degree of malleability and ductility. Light, strong and very thin foil is made from this metal, and it is also rolled into wire.

- Melting point – 660 0 C.

- Boiling point – 2450 0 C.

- Density – 2.7 g/cm3.

- The crystal lattice is volumetric face-centered, metal.

- Type of connection – metal.

The physical and chemical properties of aluminum determine the areas of its application and use. If we talk about everyday aspects, then the characteristics we have already discussed above play a big role. As a lightweight, durable and anti-corrosion metal, aluminum is used in aircraft and shipbuilding. Therefore, these properties are very important to know.

Chemical properties of aluminum

From a chemical point of view, the metal in question is a strong reducing agent that is capable of exhibiting high chemical activity while being a pure substance. The main thing is to remove the oxide film. In this case, activity increases sharply.

The chemical properties of aluminum as a simple substance are determined by its ability to react with:

It does not interact with water under normal conditions. In this case, of the halogens, without heating, it reacts only with iodine. Other reactions require temperature.

Examples can be given to illustrate the chemical properties of aluminum. Equations of reactions of interaction with:

- acids – AL + HCL = AlCL3 + H2;

- alkalis – 2Al + 6H2O + 2NaOH = Na[Al(OH)4] + 3H2;

- halogens – AL + Hal = ALHal3;

- gray – 2AL + 3S = AL2S3.

Read also: DIY plasterboard profile cutter

In general, the most important property of the substance in question is its high ability to restore other elements from their compounds.

Properties of aluminum hydroxide

Hydroxide is the most common compound that aluminum forms. Its chemical properties are the same as those of the metal itself - it is amphoteric. This means that it is capable of exhibiting a dual nature, reacting with both acids and alkalis.

Aluminum hydroxide itself is a white gelatinous precipitate. It is easily obtained by reacting aluminum salts with alkali or ammonium hydroxide. When reacting with acids, this hydroxide gives the usual corresponding salt and water. If the reaction occurs with an alkali, then hydroxo complexes of aluminum are formed, in which its coordination number is 4. Example: Na[Al(OH)4] – sodium tetrahydroxoaluminate.