The use of fasteners is standard practice when assembling most modern products used in the household or industrial sphere. An important factor is a competent choice taking into account the technical characteristics. Fastenings must withstand not only the mechanical load that occurs after final installation, but also cope with the influence of external factors, ensuring strength, safety and reliability of operation. To make it easier to navigate the variety of existing types, there are markings of bolts - deciphering the designations allows you to clarify the properties of the hardware.

General overview

Metal fasteners manufactured in accordance with GOST standards differ in many parameters - from diameter and thread size to material class. The information necessary to understand the specifics of a particular product is applied to the head or cap. Before choosing, you need to calculate strength indicators, clarify the chemical composition and resistance to certain categories of substances, and also take into account special requirements related to operating conditions.

By purpose

Based on their purpose, the following types of bolts can be distinguished:

- Ploughshare – designed for fastening heavy suspended structures. Based on the name, you can understand that it is widely used in agriculture, usually for attaching shares to tillage equipment.

- Furniture - differs from other types in that the thread is not cut along the entire length of the rod. The third part remains the usual integral part. The head of such fasteners is usually smooth, which is necessary so that the bolt does not protrude above the surface of the furniture. Despite the names, such elements are also used in other areas, especially often in construction.

- Road – widely used when installing fences. It is distinguished by a semicircular head, under which there is a square headrest. This design allows the fencing elements to be firmly fixed to the posts. It is used in all areas where there is a need to fix thin sheets of metal, wood, plastic and other materials.

- Mechanical bolts are the most common type of bolts used in mechanical engineering. It is characterized by increased strength properties and resistance to aggressive external environments.

- Track - used in the railway sector, most often for connecting individual parts of the rails. They differ in that the thread can be less than half the length of the rod.

You can understand what type of hardware it is based on the symbol of the bolts.

How are bolts marked?

Symbols are regulated by the state standard, first adopted back in 1977. The last update of the regulations dates back to 2006, however, as practice shows, there are still quite a lot of old-style fasteners in circulation - which means that full-fledged operation requires the ability to read not only new, but also previous markings.

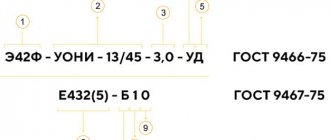

The basic codification of hardware involves the use of digital and letter designations. For products manufactured by domestic manufacturers, the following algorithm is considered a characteristic feature: the letters are located at the top, while the numbers on the bolts are printed directly below them.

The first GOST, No. 22353-77, provides for a special decoding procedure. First, as a rule, comes the manufacturer's mark - each plant has its own identification symbol, which uses elements of the Latin or Cyrillic alphabet. The number series, in turn, begins with the resistance indicator. After the digital combination, the HL marking may also be indicated, indicating that the hardware belongs to the category of products that can withstand low-temperature conditions without loss of strength characteristics. On models with non-standard threads, a small arrow is applied, directed counterclockwise.

The changes contained within the framework of GOST R 52644, approved in 2006, provide for the indication in numbers of bolt strength parameters - in accordance with the updated table of standards - as well as the climatic area of operation, batch number, strength and dimensions. To designate the latter, the standard metric system is used - for example, a marker 16x32 means that the cross-section of the hardware is 16 and the length is 32 mm.

GOST and DIN standards for high-strength fasteners

Today, “high-strength” comes to the market from domestic, European and Asian manufacturers.

And if the quality of Chinese fasteners causes distrust among consumers, then Russian and European products are in great demand. Many foreign DIN and EN standards stipulate the use of bolt sets (bolt, nut, washer assembly) from one manufacturer. There are no such rules in our documents. They also do not have requirements for the type of protective coating, whereas European hardware is usually hot-dip galvanized. Table 2. Standards for high-strength fasteners in Russia and Europe.

| National standards of the Russian Federation | European standards |

| GOST R 52643-2006 General technical conditions | DIN EN 14399-1:2006 General requirements |

| GOST R 52644-2006 (ISO 7411:1987) Bolts | DIN EN 14399-2:2006 Testing suitability for pretensioning |

| GOST R 52645-2006 (ISO 4775:1984) Nuts | DIN EN 14399-4:2006 Assemblies of bolts and nuts. HV system |

| GOST R 52646-2006 (ISO 7415:1984) Washers | DIN EN 14399-5:2006 Washers |

| DIN EN 14399-6:2006 Beveled washers |

The main types of high-strength bolts, screws and studs used in Russia by construction companies and engineering enterprises:

GOST 52644, GOST 22353, DIN 6914, ISO 7412

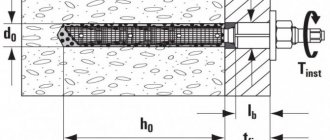

The listed standards apply to high-strength hex bolts (HSB), designed for use in the installation of structural steel structures, as well as in bridge construction and heavy engineering to create highly loaded connections. The size range is limited to diameters M16 – M48. Available in climatic versions “U” and “HL”

GOST 7798, GOST 7805, DIN 933, DIN 931, ISO 4014, ISO 4017

Standards for BVP with normal hex head, full and partial thread, used for fastening parts and structural elements in the automotive industry and other manufacturing and construction fields. They have a wide range of diameters from M3 to M64. They are produced uncoated or galvanized using different methods (galvanic, thermal diffusion, hot). Analogues with fine threads - DIN 960, DIN 961.

DIN 912, DIN 6912, GOST 11738, ISO 4762

These standards produce hex socket and cylinder head screws that are used in a wide range of industries. DIN and ISO screws have a longer list of sizes and are produced only in high strength classes 8.8, 10.9, 12.9, while GOST allows their production in low classes, but with a limited diameter from M3 to M36.

DIN 444, GOST 3033-79

These standards describe the requirements for eye screws (bolts) with metric threads with a diameter of M5 to M36, which are used in machine tools, as a connection part in mechanical engineering or in conjunction with construction anchors with internal threads.

DIN 975, DIN 976

These standards regulate the dimensions, length, pitch and type of thread of threaded rods (rods). High-strength studs include studs with a strength limit of 800...1200 Nm. They have a fixed length of 1000 or 2000 mm, diameter from M4 to M48. They are used in mechanical engineering, the construction industry, and for the installation of cable and pipe racks.

All of the above hardware are manufactured in black (for painting) and galvanized in various ways.

Ready-made solutions for all areas

Stores

Mobility, accuracy and speed of counting goods on the sales floor and in the warehouse will allow you not to lose days of sales during inventory and when receiving goods.

To learn more

Warehouses

Speed up your warehouse employees' work with mobile automation. Eliminate errors in receiving, shipping, inventory and movement of goods forever.

To learn more

Marking

Mandatory labeling of goods is an opportunity for each organization to 100% exclude the acceptance of counterfeit goods into its warehouse and track the supply chain from the manufacturer.

To learn more

E-commerce

Speed, accuracy of acceptance and shipment of goods in the warehouse is the cornerstone in the E-commerce business. Start using modern, more efficient mobile tools.

To learn more

Institutions

Increase the accuracy of accounting for the organization’s property, the level of control over the safety and movement of each item. Mobile accounting will reduce the likelihood of theft and natural losses.

To learn more

Production

Increase the efficiency of your manufacturing enterprise by introducing mobile automation for inventory accounting.

To learn more

RFID

The first ready-made solution in Russia for tracking goods using RFID tags at each stage of the supply chain.

To learn more

EGAIS

Eliminate errors in comparing and reading excise duty stamps for alcoholic beverages using mobile accounting tools.

To learn more

Certification for partners

Obtaining certified Cleverence partner status will allow your company to reach a new level of problem solving at your clients’ enterprises.

To learn more

Inventory

Use modern mobile tools to carry out product inventory. Increase the speed and accuracy of your business process.

To learn more

Mobile automation

Use modern mobile tools to account for goods and fixed assets in your enterprise. Completely abandon accounting “on paper”.

Learn more Show all automation solutions

Reading the markings

The order of arrangement of numeric and letter values is determined by the norms of the standard. Thanks to this, deciphering the technical specifications used in the implementation of construction, installation and production projects becomes much easier. A specialist who understands what the numbers on the head of the bolt mean can easily understand what specific fasteners we are talking about and what criteria should be used to select the material.

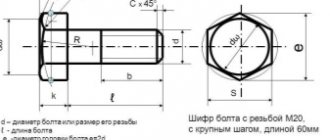

For clarity, it is worth examining the designations of fasteners, the technical characteristics of which are expressed using the following markings: A2M12x1.50 LH-4gx60.66. C.097. It is important to emphasize that, in accordance with the given sequence, the actual name must be indicated first. This applies to all marked products of the category in question, so in our case the word “bolt” will be placed before the alphanumeric combination.

The rest of the reading principle will look like this:

- The first in order is the letter A, which determines the accuracy class of the hardware. The existing gradation involves division into three groups (A, B, C), so in this example we are talking about the best possible option.

- Number 2 characterizes the performance format. The standards include 4 possible varieties, the first of which is not used for labeling.

- The letter M indicates the type of thread applied to the rod part of the fastener. There are three varieties - conical, trapezoidal and metric, which is discussed in this example.

- The number 12 is the millimeter diameter of the rod. It is curious that the combination of M12 markers is typical only for A-class products.

- 1.50 is a value characterizing the thread pitch. Moreover, in cases where the combination of dimensions is typical, inclusion in the description is not considered a mandatory condition.

- Similar to the previous point, the LH mark, indicating that a left-hand cut has been applied, belongs to the special category. If processing is carried out in a standard manner, the designation is excluded from the general list.

- The 4g marking on the bolt head indicates that the thread accuracy is at a basic level. The maximum possible indicator on the scale used is 8.

- The number 60 is the length of the hardware in millimeter terms.

- The number 66 is a strength characteristic, a dot is used to separate it from the previous value.

- C - grade of steel alloy selected during manufacturing. This particular marker is used in the production of fasteners made of “quiet” steel, while the letter A denotes “automatic” products.

- 097 - element coating. There are thirteen possible options, of which nine is galvanized. 7 in this case is the thickness of the outer layer in microns, equal to seven microns.

A designation on the bolt head that complies with a unified standard is a practical and convenient way to quickly and accurately select the required products. It is worth noting that the products of European and American manufacturers have a different description, including one that uses inches as the base measurement, so to read it you will need to use a conversion table.

Food grade stainless steel

This type of rolled metal is ground and differs from other types in a special way of treating its surface. The final layer of food-grade material is sanded until shiny. This type of stainless steel is environmentally friendly and does not react with acids, alkalis, or detergents.

Popular brands and their applications:

- 08Х18Н10 – widely used for the production of food equipment.

- 08Х13 – metal suitable for making kitchenware and cutlery.

- 20Х13, 40Х13 are ideal materials for the production of sinks and containers in which thermal and hygienic processing of products is carried out. It is used to produce equipment intended for the production of wine, alcohol, and food.

- 08X17 is a popular material for cookware exposed to high temperatures.

The optimal amount of alloying elements included in the composition of stainless steel forms a protective film on the surface of the metal. The use of this type of steel is necessary for the production of products that are exposed to long-term exposure to water vapor, heating and boiling of liquid food products. Due to the properties of food grade steel, when cooking food, there is no chemical interaction between the products and the container in which they are located.

Features of marking high-strength hardware

Fasteners belonging to class 8.8 (or higher) represent a group of durable elements for which special requirements are imposed. This also applies to alphanumeric designations - for example, in accordance with GOST of 2006, the marking on the head of carbon steel bolts will look like W11.14 8.8S HL, where:

- W - manufacturer's mark.

- 11.14 - heat batch number.

- 8.8 is a parameter in which the product of the first number and 100 gives the maximum load for the thread, while the second number indicates a tenfold increase in the ratio of yield strength and strength.

- S - Compliance with the category of high-strength fasteners with a large hex head.

- HL - permissibility of operation at low temperatures.

Thus, deciphering the meanings used in labeling is also not particularly difficult - even taking into account the differences between the old and new standards.

Material of manufacture

The technology for producing bolts characterized by strength class 6.8 is the so-called.

volumetric stamping using upsetting presses. quality carbon structural steel, mainly grades St.35 and St.45, is used as raw material The following properties of this material contribute to this choice:

- the value of the HB index (Brinell hardness) ranges from 181 to 238 units;

- the yield strength is 480 MPa;

- ultimate strength – 600 MPa.

The use of steels of other grades is allowed. Instead of

- Article 35 – Article 30, Article 40 and Article 35g;

- Art.45 – Art.50G2, Art.40X.

What markings are applied to stainless bolts?

But in the case of hardware, for the manufacture of which austenitic steels are used, the alphanumeric code will differ from the previous version. Such products are usually marked as A2-50 or A4-60, with the possible addition of the manufacturer's mark at the beginning. The letter A and the number after it characterize the specific grade of the alloy, while the second group of numbers represents a value equal to one tenth of the tensile strength established for carbon-type models. Thus, the A4-80 marker applied to the fasteners will indicate that they are made of stainless material with the addition of molybdenum, and are capable of withstanding mechanical loads of up to 800 MPa, corresponding in their characteristics to elements made of carbon steel of category 8.8.

Classification

In the metallurgical industry, more than two hundred types of alloy alloys are distinguished. They differ in the presence of different amounts of additional chemical elements in their composition.

There are four main types of stainless steel.

Modern requirements

The updated standards, which determine what the numbers and letters mean in the markings on the bolt heads, are not much different from the previous edition, both in terms of meaning and in terms of the location of the elements. The addition of strength characteristics, as well as other nuances related to operational properties, is not considered by experts as a radical change - however, for those whose professional activities are closely related to design and assembly, it is important to be able to read not only the old, but also the new format.

The most popular grades and areas of their application of stainless steel

All grades of stainless steel can be divided into several types: 200, 300, 400. Each of these classes includes several varieties. The 200th grade includes the AISI 201 brand. It is practically no different from the classes above, but is slightly inferior to them in its anti-corrosion properties. However, there is a very significant difference in price. The 300 series includes the following brands:

AISI 304. Good weldability. It has found wide application in the food industry.

AISI 316. It differs from the previous brand in that it contains molybdenum (2%), this makes the steel more resistant to corrosion. Able to retain its properties under the influence of high temperatures and acidic environments. Used in the shipbuilding, chemical and oil and gas industries.

AISI 316T. This steel contains titanium, which makes it possible to use products at high temperatures and under the influence of chloride ions. Used in the chemical, gas and food industries.

AISI 321. Contains a large amount of titanium. For this reason, it can withstand high temperatures up to 800 degrees. Well weldable. Seamless pipes are made from it.

The 400 series is distinguished by the fact that it contains virtually no extraneous elements. All of them are replaced by containing large amounts of chromium. Carbon in this steel is present in minimal quantities. The alloy is very ductile and welds well. Steel of this class is represented by AISI 430 grade.

Markings

The class indicator - two numbers written through a dot, or sequentially - is one of the most significant characteristics. The first number is used to describe 1/100 of the nominal strength limit of the fastener, measured in MPa, the second shows the ratio of the yield and strength limits, which must be multiplied by 10 to obtain the final value. This, in fact, is the maximum working load of the hardware used - when calculating connections, a coefficient of 0.5-0.6 is used, which excludes exceeding the permissible norm.

What do the numbers on stainless steel bolts mean?

Austenitic products are marked indicating the specific type of alloy (A2, A4), as well as one tenth of the limit value (50, 60, 70) characteristic of carbon compositions.

Nut markings

In the case of elements of this category, a similar designation principle applies, however, due to limited space, the information is located on the side and is presented in an abbreviated format. To read completely, you will need the original packaging and accompanying specifications.

The marking order remains unchanged - name, accuracy level, thread type, diameter, pitch and direction (for non-standard cutting), strength characteristics and coating thickness in microns. At the same time, at the end of the description, GOST is indicated, which corresponds to the manufacturing technology of a specific model, which is why not all of the specified points are necessarily included in the designation.

Bolt and nut sizes

Recently, car manufacturers are increasingly using metric fasteners and moving further away from inch fasteners. But, it is important to know the difference between the sometimes used inch (also called American, or SAE standard) and the more universal metric fasteners in the system of measures, since, despite their external similarity, they are not interchangeable.

All bolts, nuts, studs and other fasteners, both inch and metric, are classified by diameter, thread pitch and length. For example, a standard 1/2 x 13 x 1 bolt is one-half inch in diameter, 13 threads per inch, and 1 inch long. A metric bolt M12 x 1.75 x 25 has a diameter thickness of 12 mm, a thread pitch of 1.75 mm (distance between threads) and a length of 25 mm. Both bolts are very similar in appearance, but are not interchangeable.

Ready-made solutions for all areas

Stores

Mobility, accuracy and speed of counting goods on the sales floor and in the warehouse will allow you not to lose days of sales during inventory and when receiving goods.

To learn more

Warehouses

Speed up your warehouse employees' work with mobile automation. Eliminate errors in receiving, shipping, inventory and movement of goods forever.

To learn more

Marking

Mandatory labeling of goods is an opportunity for each organization to 100% exclude the acceptance of counterfeit goods into its warehouse and track the supply chain from the manufacturer.

To learn more

E-commerce

Speed, accuracy of acceptance and shipment of goods in the warehouse is the cornerstone in the E-commerce business. Start using modern, more efficient mobile tools.

To learn more

Institutions

Increase the accuracy of accounting for the organization’s property, the level of control over the safety and movement of each item. Mobile accounting will reduce the likelihood of theft and natural losses.

To learn more

Production

Increase the efficiency of your manufacturing enterprise by introducing mobile automation for inventory accounting.

To learn more

RFID

The first ready-made solution in Russia for tracking goods using RFID tags at each stage of the supply chain.

To learn more

EGAIS

Eliminate errors in comparing and reading excise duty stamps for alcoholic beverages using mobile accounting tools.

To learn more

Certification for partners

Obtaining certified Cleverence partner status will allow your company to reach a new level of problem solving at your clients’ enterprises.

To learn more

Inventory

Use modern mobile tools to carry out product inventory. Increase the speed and accuracy of your business process.

To learn more

Mobile automation

Use modern mobile tools to account for goods and fixed assets in your enterprise. Completely abandon accounting “on paper”.

Learn more Show all automation solutions

Strength classes of threaded fasteners

According to the standard classification, there are seven categories for nuts (4, 5, 6, 8, 9, 10, 12), which, as in the case of hardware, indicate 1/100 of the total limit value determined when calculating the pressure on the structure. However, there are also differences - in particular, these categories apply only to parts with a standard and high profile, while the designations 04 and 05 are applied to the sides of low models, indicating that this option is not suitable for operation under high load conditions.

APPENDIX 1 (for reference). Weight of steel bolts (version 1) with coarse thread pitch

APPENDIX 1 Reference

| Bolt length, mm | Theoretical weight 1000 pcs. bolts, kg, with nominal thread diameter , mm | ||||||||||||||

| 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 36 | 42 | 48 | |

| 8 | 4,306 | 8,668 | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 10 | 4,712 | 9,394 | 16,68 | — | — | — | — | — | — | — | — | — | — | — | — |

| 12 | 5,118 | 10,120 | 17,82 | — | — | — | — | — | — | — | — | — | — | — | — |

| 14 | 5,524 | 10,850 | 18,96 | 27,89 | — | — | — | — | — | — | — | — | — | — | — |

| 16 | 5,930 | 11,570 | 20,10 | 29,48 | 43,98 | — | — | — | — | — | — | — | — | — | — |

| 18 | 6,336 | 12,300 | 21,23 | 31,12 | 46,21 | 65,54 | — | — | — | — | — | — | — | — | — |

| 20 | 6,742 | 13,020 | 22,37 | 32,76 | 48,45 | 68,49 | 95,81 | — | — | — | — | — | — | — | — |

| 22 | 7,204 | 13,520 | 23,51 | 34,40 | 50,69 | 71,44 | 99,52 | — | — | — | — | — | — | — | — |

| 25 | 7,871 | 14,840 | 25,22 | 36,86 | 54,05 | 75,87 | 105,10 | 133,3 | — | — | — | — | — | — | — |

| 28 | 8,537 | 16,330 | 26,92 | 39,32 | 57,40 | 80,29 | 110,60 | 140,2 | — | — | — | — | — | — | — |

| 30 | 8,981 | 17,120 | 28,52 | 40,96 | 59,64 | 83,24 | 114,30 | 144,8 | 193,0 | — | — | — | — | — | — |

| 32 | 9,426 | 17,910 | 29,43 | 42,59 | 61,87 | 86,19 | 118,00 | 149,4 | 198,6 | 237,0 | — | — | — | — | — |

| 35 | 10,090 | 19,090 | 31,28 | 45,34 | 65,24 | 90,62 | 123,60 | 156,3 | 207,0 | 246,9 | 340,6 | — | — | — | — |

| 38 | 10,760 | 20,280 | 33,18 | 48,00 | 68,59 | 95,04 | 129,20 | 163,2 | 215,4 | 256,9 | 353,3 | — | — | — | — |

| 40 | 11,200 | 21,070 | 34,36 | 49,78 | 71,25 | 97,99 | 132,90 | 167,8 | 221,0 | 263,5 | 361,8 | 474,8 | — | — | — |

| 45 | 12,310 | 23,040 | 37,45 | 54,22 | 77,30 | 105,70 | 142,10 | 179,4 | 235,0 | 280,1 | 373,0 | 500,9 | — | — | — |

| 50 | 13,420 | 25,020 | 40,53 | 58,67 | 83,35 | 113,60 | 152,40 | 190,9 | 249,0 | 296,7 | 404,1 | 526,9 | 834,5 | — | — |

| 55 | 14,530 | 26,990 | 43,62 | 63,11 | 89,39 | 121,50 | 162,40 | 203,7 | 263,1 | 313,3 | 425,3 | 553,0 | 872,1 | 1304 | — |

| 60 | 15,640 | 28,970 | 46,70 | 67,55 | 95,44 | 129,40 | 172,40 | 216,0 | 278,9 | 329,9 | 446,5 | 579,0 | 909,8 | 1356 | — |

| 65 | 16,760 | 30,940 | 49,79 | 71,99 | 101,50 | 137,30 | 182,40 | 228,4 | 293,8 | 348,8 | 467,7 | 605,1 | 947,4 | 1407 | 2009 |

| 70 | 17,870 | 32,910 | 52,87 | 76,44 | 107,50 | 145,20 | 192,40 | 240,7 | 308,8 | 366,5 | 491,1 | 631,1 | 985,0 | 1458 | 2076 |

| 75 | 18,980 | 34,890 | 55,96 | 80,88 | 113,60 | 153,10 | 202,40 | 253,0 | 323,7 | 384,3 | 513,6 | 659,7 | 1023,0 | 1509 | 2143 |

| 80 | 20,090 | 36,860 | 59,04 | 85,33 | 119,60 | 161,00 | 212,40 | 265,0 | 338,6 | 402,1 | 536,1 | 687,5 | 1061,0 | 1561 | 2211 |

| 85 | 21,200 | 38,840 | 62,13 | 89,77 | 125,70 | 168,90 | 222,40 | 277,7 | 353,6 | 419,8 | 558,6 | 715,2 | 1098,0 | 1612 | 2278 |

| 90 | 22,310 | 40,810 | 65,21 | 94,20 | 131,70 | 176,80 | 232,40 | 290,1 | 368,5 | 437,6 | 581,0 | 743,0 | 1141,0 | 1663 | 2345 |

| 95 | — | 42,790 | 68,30 | 98,64 | 137,80 | 184,70 | 242,40 | 302,4 | 383,4 | 455,4 | 603,5 | 770,8 | 1181,0 | 1715 | 2412 |

| 100 | — | 44,760 | 71,38 | 103,10 | 143,80 | 192,60 | 252,40 | 314,7 | 398,3 | 473,2 | 626,0 | 798,5 | 1221,0 | 1766 | 2479 |

| 105 | — | — | 74,47 | 107,50 | 149,90 | 200,50 | 262,40 | 327,1 | 413,3 | 490,9 | 648,5 | 826,3 | 1261,0 | 1826 | 2546 |

| 110 | — | — | 77,55 | 112,00 | 155,90 | 208,40 | 272,30 | 339,4 | 428,2 | 508,7 | 671,0 | 854,1 | 1301,0 | 1880 | 2614 |

| 115 | — | — | 80,63 | 116,40 | 162,00 | 216,30 | 282,30 | 351,8 | 443,1 | 526,5 | 693,5 | 881,8 | 1341,0 | 1934 | 2690 |

| 120 | — | — | 83,72 | 120,90 | 168,00 | 224,20 | 292,30 | 364,1 | 458,1 | 544,2 | 716,0 | 909,6 | 1381,0 | 1989 | 2760 |

| 125 | — | — | 86,80 | 125,30 | 174,00 | 232,10 | 302,30 | 376,4 | 473,0 | 562,0 | 738,5 | 937,4 | 1421,0 | 2043 | 2831 |

| 130 | — | — | 89,89 | 129,70 | 180,10 | 240,00 | 312,30 | 388,8 | 487,9 | 579,8 | 761,0 | 965,2 | 1461,0 | 2098 | 2903 |

| 140 | — | — | 96,06 | 138,60 | 192,20 | 255,80 | 332,30 | 413,5 | 517,8 | 615,3 | 806,0 | 1021,0 | 1541,0 | 2207 | 3045 |

| 150 | — | — | 102,18 | 147,50 | 204,30 | 271,60 | 352,30 | 438,1 | 547,6 | 650,8 | 850,1 | 1076,0 | 1621,0 | 2315 | 3187 |

| 160 | — | — | 108,38 | 156,40 | 216,40 | 287,40 | 372,30 | 462,8 | 577,5 | 686,4 | 895,9 | 1132,0 | 1701,0 | 2424 | 3329 |

| 170 | — | — | 114,58 | 165,30 | 228,50 | 303,20 | 392,30 | 487,5 | 607,4 | 721,9 | 940,9 | 1188,0 | 1780,0 | 2533 | 3471 |

| 180 | — | — | 120,68 | 174,20 | 240,60 | 319,00 | 412,30 | 512,2 | 637,2 | 757,5 | 985,9 | 1243,0 | 1860,0 | 2642 | 3614 |

| 190 | — | — | 126,88 | 183,10 | 252,70 | 333,80 | 432,30 | 536,9 | 667,1 | 793,0 | 1031,0 | 1299,0 | 1940,0 | 2751 | 3756 |

| 200 | — | — | 133,08 | 191,90 | 264,70 | 350,60 | 452,20 | 561,5 | 697,0 | 828,6 | 1076,0 | 1354,0 | 2020,0 | 2860 | 3898 |

| 220 | — | — | — | 209,70 | 228,90 | 382,20 | 492,20 | 610,9 | 756,7 | 899,6 | 1166,0 | 1465,0 | 2180,0 | 3077 | 4182 |

| 240 | — | — | — | 227,50 | 313,10 | 413,80 | 532,20 | 660,3 | 816,4 | 970,8 | 1256,0 | 1576,0 | 2340,0 | 3295 | 4466 |

| 260 | — | — | — | 245,20 | 337,60 | 445,40 | 572,20 | 709,6 | 876,1 | 1042,0 | 1346,0 | 1687,0 | 2500,0 | 3513 | 4751 |

| 280 | — | — | — | — | 361,50 | 476,90 | 612,20 | 759,0 | 935,9 | 1113,0 | 1436,0 | 1798,0 | 2660,0 | 3730 | 5035 |

| 300 | — | — | — | — | 385,70 | 508,50 | 652,20 | 808,3 | 995,6 | 1184,0 | 1526,0 | 1910,0 | 2820,0 | 3948 | 5319 |

(Changed edition, Amendment No. 5).

Full symbol

The full designation of bolts, screws, studs and nuts is standardized by GOST 1759.0-87 “Bolts, screws, studs and nuts. Technical specifications"

In the post-Soviet space, in accordance with GOST 1759.0-87 and GOST 18126-94, the following symbol scheme has been adopted for bolts, screws and studs and nuts made of carbon steels and non-ferrous alloys:

For washers, a slightly different symbol scheme is used according to GOST 18123-82 “Washers. General technical conditions":

The above diagrams have a general appearance, with all possible elements. Depending on the type of fastener, the designation may contain more or fewer elements. It should also be noted that some types of bolts, studs, nuts and washers have their own specific symbols, standardized by a specific standard (for example: foundation bolts GOST 24379.1-80, studs for flange connections GOST 9066-75, etc.)

The importance of choosing the right fasteners

The products offered by modern manufacturers differ from each other in terms of technical and functional characteristics. Bolts, studs, screws, nuts - to solve each specific problem, the appropriate equipment is required. The main indicators depend on the grade of steel used for manufacturing - when selecting a suitable option, it is worth paying special attention to the parameters that a particular alloy provides, as well as the conditions and the maximum load that can arise during the use of fasteners.

Nuances associated with labeling

The generally accepted norms on which state standards are based correspond to the system developed by the International Organization for Standardization. In addition to the features and requirements already discussed, there are several more rules that must be taken into account by manufacturers of fasteners:

- Bolts and screws with a diameter of more than 6 mm are required to be marked, while for products with a smaller cross-section the procedure is voluntary.

- The alphanumeric designation is not applied to hardware with a cross-shaped or straight slot, as well as to fasteners made without stamping, while hexagons with any head shape must be designated in all cases.

- For marking, the end or side of the cap is used, while in the second option the method of applying in-depth marks is used. Convex elements are subject to restrictions directly related to the thread diameter - the maximum permissible value is 0.3 mm.

The geometry of various types of threaded fasteners is regulated by separate standards that require strict compliance.

Pros and cons of threaded connections

The advantages that determine the demand in everyday life and industry for products with applied threads include:

- Versatility and reliability.

- Strength characteristics.

- Resistant to axial and lateral loads.

- Ease of installation and disassembly.

- Affordable cost of organizing work.

Among the shortcomings, one can note only the increased stress in the section of the depression profile, which necessitates the need for a competent choice of marking technique. Matching loads reduces the risk of accidental loosening or tearing.

Advantages of stainless steels

With the development of economic, scientific and technological progress, the requirements for the quality of materials used in areas of the national economy are growing.

Advantages of alloy metals:

- High level of anti-corrosion properties.

- Compliance with the standards stipulated by fire safety regulations.

- Reliability, long service life without changing technical characteristics.

- Ideal combination with any building materials.

- Variety of surfaces: polished, polished, matte, decorative.

- Wide selection of rolled metal products.

- Ease of processing, molding, and assembly of parts made from this type of steel.

- A wide range of brands with unique properties.

- Environmental safety, hygiene.

Types of threaded fastening

The considered principle of connecting elements is based on the use of at least two parts, the first of which has an external thread, and the second - an internal thread. The following types of configurations are distinguished:

- Bolted - the formation of through holes with the subsequent insertion of a rod tightened from the reverse side.

- Screw - in this case, the base itself acts as a retainer, the channels in which are prepared in advance, or - when using self-tapping screws - are formed during the integration process.

- Using studs, one of the ends is screwed into the component part, and the corresponding nut is screwed onto the second in a special way.