A car wheel is an integral element of the vehicle's design. Tires and wheels give the car various performance characteristics. For example, they affect cross-country ability and speed performance. At the same time, such a simple parameter as the total weight of the wheel plays an important function. Let's figure out what the weight of wheels and tires affects when operating a car.

Moments of inertia

To characterize the distribution of masses in bodies when considering rotational movements, it is necessary to introduce the concepts of moments of inertia.

Moments of inertia about a point and an axis

The moment of inertia of a mechanical system consisting of material points relative to a point is the sum of the products of the masses of these points by the squares of their distances to the point (Fig. 22), i.e.

The moment of inertia about a point is often called the polar moment of inertia. In the case of a solid body, the sum goes into an integral and for the polar moment of inertia we have

where is the mass of an elementary particle of the body, taken in the limit as a point; —its distance to the point .

The moment of inertia of a system of material points relative to an axis is the sum of the products of the masses of these points by the squares of their distances to the axis (Fig. 22), i.e.

Rice. 22

In the special case of a solid body, the sum should be replaced by an integral:

The moments of inertia of homogeneous bodies of the same shape, made of different materials, differ from each other. A characteristic that does not depend on the mass of the material is the radius of gyration. The radius of gyration relative to the axis is determined by the formula

where is body mass.

The moment of inertia relative to the axis through the radius of inertia relative to this axis is determined by the expression

In reference books on moments of inertia, tables are given for the values of the radii of inertia of various bodies.

Formula (5′) allows us to consider the radius of inertia of a body relative to an axis as the distance from this axis to the point at which the mass of the body should be placed so that its moment of inertia is equal to the moment of inertia of the body relative to the axis in question.

The moments of inertia about the axis and the point have the same dimension - the product of mass and the square of length.

In addition to moments of inertia about a point and an axis, moments of inertia about planes and centrifugal moments of inertia are also used. It is convenient to consider these moments of inertia relative to the coordinate planes and axes of the Cartesian coordinate system.

Moments of inertia about coordinate axes

The moments of inertia relative to the Cartesian coordinate axes , and and their origins - points (Fig. 23) - are determined by the expressions

where are the coordinates of the material points of the system. For solid bodies these formulas take the form

From the above formulas follows the dependence

If we draw another system of Cartesian coordinate axes through a point, then for them using formula (8) we obtain

From comparison (8) and (8′) it follows that

Rice. 23

The sum of the moments of inertia relative to the Cartesian coordinate axes does not depend on the orientation of these axes at the point under consideration, i.e., it is a quantity invariant with respect to the direction of the coordinate axes.

For the coordinate axes, the following three centrifugal moments of inertia :

Centrifugal moments of inertia are often called products of inertia.

Moments of inertia about axes and points are positive quantities, since they include the squares of the coordinates. Centrifugal moments of inertia contain products of coordinates and can be either positive or negative.

Centrifugal moments of inertia are important when considering pressures on bearings during rotation of a rigid body around a fixed axis and in other cases.

In addition to the considered moments of inertia, moments of inertia relative to coordinate planes are sometimes used, which are determined by the expressions

Theorem on moments of inertia about parallel axes (Steiner's theorem)

Let us establish the relationship between the moments of inertia of the system relative to parallel axes, one of which passes through the center of mass. Let us have two systems of rectangular, mutually parallel coordinate axes and . The origin of the coordinate system is located at the center of mass of the system (Fig. 24).

Rice. 24

By definition of the moment of inertia about the axis we have

where is the mass of the point, and and are the coordinates of this point relative to the coordinate systems and, respectively. If we denote the coordinates of the center of mass relative to the coordinate system, then for mutually parallel axes the coordinates of the same point are related by the parallel translation relations

Let's substitute these coordinate values into the expression for the moment of inertia. After transformations we get

In this relation, is the mass of the system, , since and due to k = 1

the fact that, by condition, the center of mass is located at the origin of this coordinate system.

Value , where is the distance between the axes and . Finally

The connection between the moments of inertia about two parallel axes, one of which passes through the center of mass, is the content of the so-called Steiner or Huygens-Steiner theorem: the moment of inertia of the system about any axis is equal to the moment of inertia about the parallel axis passing through the center of mass, plus the product of the mass system per square of the distance between these axes.

From Steiner's theorem it follows that for a set of parallel axes the moment of inertia is the smallest relative to the axis passing through the center of mass.

If we take the axis parallel, then for it we get

where is the distance between the parallel axes and .

Excluding the moment of inertia from the last two formulas, we obtain the dependence of the moments of inertia relative to two parallel axes that do not pass through the center of mass:

Let us establish the change in centrifugal moments of inertia during parallel translation of coordinate axes. We have

Considering that we get

where are the coordinates of the center of mass relative to the coordinate system. Similar formulas are obtained for the other two centrifugal moments of inertia:

Since the origin of the coordinate system is at the center of mass, then , , and then

i.e., the centrifugal moments of inertia during parallel translation of the coordinate axes from any point in the center of mass change in accordance with (10).

If a parallel transfer of axes is performed from a point to the center of mass, then, according to (10), we have:

Excluding from (10) and (10′) the centrifugal moments of inertia L'z» Lu, we obtain formulas for changing the centrifugal moments of inertia during parallel transfer of coordinate axes from point to point:

where and are the coordinates of the center of mass in two systems of mutually parallel coordinate axes.

Moments of inertia of the simplest homogeneous bodies

The moments of inertia of bodies of complex shape can often be calculated if they are first divided into bodies of simple shape. The moments of inertia of complex bodies are obtained by summing the moments of inertia of the parts of these bodies. Let us obtain formulas for calculating the moments of inertia of some homogeneous simple bodies.

Homogeneous rod

We have a uniform rod of length and mass (Fig. 25). Let's direct the axis along the rod. Let us calculate the moment of inertia of the rod relative to the axis passing perpendicular to the rod through its end. According to the definition of the moment of inertia of a solid body relative to the axis, we have

since , where is the density of the rod.

Calculating the integral, we get

Rice. 25

Thus,

The moment of inertia of the rod relative to the axis passing through the center of mass and parallel to the axis is determined by Steiner’s theorem:

Hence,

i.e.

Rectangular plate

A rectangular thin plate has dimensions and mass (Fig. 26). We will place the axes and in the plane of the plate, and the axis is perpendicular to it. To determine the moment of inertia of the plate relative to the axis, we divide the plate into elementary strips of width and mass and integrate over from 0 to . We get

because .

Similar calculations for the axis will give

since this axis passes through the middle of the plate. To determine the moment of inertia of the plate relative to the axis, one must first calculate the moment of inertia of a separate shaded strip relative to the parallel axis using formula (12) for the rod and then apply Steiner’s theorem. For an elementary strip we have

Rice. 26

Integrating this expression over the range from 0 to , we get

So, for the moments of inertia of the plate relative to the coordinate axes, the following formulas are obtained:

Round disk

We have a thin homogeneous disk with radius and mass (Fig. 27). Let's calculate its moment of inertia relative to the point. This moment of inertia for a thin disk coincides with the moment of inertia about the coordinate axis perpendicular to the plane of the disk. Let us divide the disk into concentric strips of width , taken in the limit to be material circles. The mass of the strip is equal to its area multiplied by its density, i.e. . The moment of one strip relative to a point is equal to . For the entire disk

Thus,

Rice. 27

For the coordinate axes and located in the plane of the disk, due to symmetry. Using (8), we have , but , therefore

In the case of a thin wire ring or a round wheel, in which the mass is distributed not over the area, but along its rim, we have

Round cylinder

Rice. 28

For a round homogeneous cylinder, whose mass, radius and length (Fig. 28), let us first calculate its moment of inertia relative to the longitudinal axis of symmetry. To do this, we divide the cylinder with planes perpendicular to the axis into thin disks of mass and thickness. For such a disk, the moment of inertia relative to the axis is equal to . For the whole cylinder

those.

Let's calculate the moment of inertia of the cylinder relative to its transverse axis of symmetry. To do this, we divide the cylinder with cross sections perpendicular to its longitudinal axis into elementary disks of thickness . The moment of inertia of an elementary disk with mass relative to the axis, according to Steiner’s theorem, .

To obtain the moment of inertia of the entire cylinder relative to the axis, one should integrate the resulting expression over the range from 0 to and double the result. We get

But - the mass of the cylinder. Hence,

Thus, the moment of inertia of the cylinder relative to its transverse axis of symmetry is obtained as the sum of the moments of inertia relative to this axis of the disk and the rod, the masses of which are individually equal to the mass of the cylinder. The disk is obtained from the cylinder by symmetrically compressing it from the ends to the middle plane while maintaining the radius, and the rod is obtained by compressing the cylinder into a homogeneous rod located along the axis of the cylinder, while maintaining the length.

Metal calculator

With relative accuracy, you can calculate the weight of rolled metal and the amount of steel reinforcement. By entering dimensions and lengths, you can calculate the weight of the products. The calculator works in online mode for quick weight calculation, for this you need:

- select the required steel grade;

- select rental category;

- Enter the dimensions and dimensions of the sides.

Our resource specialists periodically update the steel grade for accurate and up-to-date calculations of products. In the calculation process, the specific gravity of rolled metal (calculator table) steel and size (metal thickness, sheet width, pipe wall diameter, etc.) are used.

Sometimes when the grade of steel from which it is made is unknown, in this case you can use universal grades such as St10 and St20. If you still have suspicions about the raw materials, you can perform a chemical test. metal analysis.

Sheet Metal Weight Table

Rolled sheet metal according to GOST

Calculation of how much 1m2 of steel sheet weighs using the formula

Calculation of sheet metal weight

performed on a regular calculator using the formula:

P- theoretical weight, kg

L – length of the metal sheet in linear meters, m;

H – sheet thickness, mm;

B – width of rolled sheets, m;

7.85 kg/dm3 – density of black steel, specific gravity – corresponds to the weight of a square meter of steel 1 mm thick.

The weight of sheet metal is calculated in kilograms (kg), if the dimensions of the sheet thickness are substituted into the formula for calculating the weight of the metal sheet

in millimeters (mm), and the length and width of the sheet in meters (m). Knowing the weight of a steel sheet, you can easily calculate how many sheets are in a ton or pack of a certain mass.

The weight of galvanized sheet will differ slightly from black, because... The thickness of the zinc coating is several micrometers.

To quickly calculate the weight of rolled sheets, use the “Metal Calculator” in the “Metal Assortment” section of the website. The sheet weight calculator calculates the weight for different grades of steel, which is important if you need to calculate the weight of a stainless steel sheet or made of non-ferrous metal. The sheet metal calculator calculates the weight based on the dimensions of the workpiece and thickness in mm, and the dimensions of the steel sheet (based on the total weight of the package and the thickness of the rolled sheet).

The assortment of sheet steel is needed primarily by suppliers for metal purchases to calculate the weight of rolled metal. If in the process of work the question often arises about how to find out the weight of sheet metal, but there is no assortment of rolled metal at hand, the best way to solve this problem is to calculate the weight of the sheet using the above formula on a calculator.

In the rolled metal weight calculator, you can calculate the theoretical weight of reinforcement, beams, wire, square, round and profile pipes, angles, hexagons, channels, as well as the area and theoretical weight of sheets, PVL sheets, tapes. Types of metal from which the above metal products are produced: stainless steel, ferrous metal, aluminum, zinc, cast iron, brass, bronze, copper, lead, titanium, nichrome.

Wheel weight

Today, a car owner can choose several types of wheels for his car: steel, light alloy and forged. They differ significantly from each other in technical characteristics.

- Steel wheels are produced by stamping. Such wheels have a heavy construction, but at the same time they are the most affordable for the consumer. In most cases, cars at factories are equipped with steel wheels in order to reduce the cost of production. The advantages of such wheels are low price and maintainability.

- Alloy wheels weigh 20-40% lighter than their steel counterparts. Aluminum and various alloys based on it are easy to process. The simplified manufacturing process allows manufacturers to provide a wide range of attractive rims. The rapid heat transfer of aluminum has a beneficial effect on the cooling of brake discs and pads.

- Forged wheels are even lighter than their aluminum counterparts. And thanks to hot die forging, manufacturers are able to reduce the weight of the product by up to 50% in relation to the steel rim. In addition, a forged disk is not inferior in strength to a steel one. It does not burst upon impact, but only deforms. This type of wheels is more expensive than its steel and light alloy counterparts. But, the costs are paid off by durability and increased dynamic characteristics.

Example. What will be the weight of a wheel for a VAZ 2110 with different rims? The 185/65R14 summer tire weighs 7.6 kg. The R14 steel wheel weighs 8.01 kg, the light alloy wheel weighs 6.29 kg, and the forged wheel weighs 3.94 kilograms. This means that the assembled wheel will weigh:

- Option 1 15.61 kg;

- Option 2 13.89 kg;

- Option 3 11.54 kg.

If we add to this a camera that weighs 1 kg, then a set of four wheels will increase the weight by another 4 kilos. Although at this time, car owners prefer tubeless tires.

As can be seen from the article, the choice of disks will affect the performance characteristics of the machine. With lighter wheels, the owner saves on fuel and suspension repairs. But first, you will have to overpay a little. However, after 1.5 - 2 years, lightweight wheels are guaranteed to pay for themselves.

Online metal calculator

When you need to buy rolled metal, you need to know which transport will be more convenient to transport it. The tonnage of cars or other vehicles for delivery depends on the total mass of metal products. Therefore, the question arises of how to calculate the mass of the required amount of rolled metal.

Once upon a time, solving this issue took a lot of time even for highly qualified specialists. After all, to perform the necessary calculations, it was necessary to know the theoretical mass of the weight of various metals, formulas for calculating the volume of various rolling forms, etc. Such computational complexity required the search for new solutions. This solution was the online metal calculator.

Now, when drawing up any construction specifications, a rolled metal calculator is used instead of many tables, formulas and painstaking calculations. Using our online rolled metal calculator service, you can calculate the mass of the following metals: – steel; – cast iron; – aluminum; – bronze; – brass; – magnesium; – nickel; - copper; – tin; - lead; – titanium; – zinc.

Read also: What is a diode measured in?

In order to make the calculation, you need to select the type of metal and type of rental in the drop-down menu of the Free Online Metal Calculator program. The calculation is made for the following types of rental: – corner; – leaf; - pipe; – circle/wire/wire rod; – square pipe; – rental; – channel; – tape/strip; – beam; - hexagon.

For each type of metal, it is possible to select a specific brand. For example, when steel is selected in the “Metal Type” drop-down menu, then in the “Grade” drop-down menu, to the right of the metal type field, you can select any of the standard steel grades. The program also includes all existing grades of metals from which rolled metal is produced.

Next, having selected the type of rolled product, the type of metal and its grade, all that remains is to indicate the main parameters of the product itself. The program clearly displays which parameter needs to be entered for the calculation. Each type of rolled metal is accompanied by a graphic image of its cut with the name of each face, shelf, etc. displayed in the form of letters. The type of rolled metal itself is also shown. You probably won’t confuse the “sheet” type with the “strip” type, or the “square pipe” with the “square” type. For convenience and ease of measurement, the graphical representation of a rolled metal cut shows the names of each shelf, for example, a, b, c. For example, if you are calculating the mass of an aluminum corner, you need to indicate the height and width of its shelves, as well as the wall thickness (thickness of the metal sheet). To calculate the mass of a copper pipe, you need to indicate its total diameter and wall thickness. The fields in which you need to enter specific dimensions have the same name as the names in the graphic image.

This data is entered into the metal calculator in millimeters. In addition, indicate the length of a specific metal product in the appropriate field; the length is indicated in meters. Now all that remains is to click on the “Calculate” button and in the “Mass” field the program will display the value of the mass of the specified rolled metal in kilograms, accurate to the nearest gram.

To calculate the total mass of various metal products with different dimensions, perform the calculation for each type of product separately. Then simply add up the results - and you will find out the exact mass of the entire amount of rolled metal you need.

It is also possible to specify the required weight of rolled metal (for example, when you know that you can transport metal using a truck with a certain carrying capacity) and, knowing its basic measurements, determine the total length of the product.

A site about pipes. Calculations, master classes, sewerage

A metal calculator for stainless steel products will help you calculate the weight and cost of products based on given overall dimensions and specified steel grades.

The widget allows you to get the weight of products of almost any steel grade used today: black, non-ferrous, stainless steel. In particular, the non-ferrous rolled metal calculator will help in calculating products made from alloys of copper, bronze, aluminum and others. In the product catalog you can buy the following types of rolled metal: pipes, long products (angle, circle, channel, beam), strip, wire rod, hexagons and sheets.

Center of mass

the center of mass is important . If a mechanical system consists of a finite number of material points

where is the mass of the system. Denoting the Cartesian coordinates of material points, from (1) by projecting onto the Cartesian coordinate axes we obtain the following formulas for the coordinates of the center of mass:

Rice. 21

The center of mass is not a material point, but a geometric one . It may not coincide with any material point of the system, as, for example, in the case of a ring. The center of mass of a system characterizes the distribution of masses in the system.

The vector quantity is called the static moment of mass relative to the point. The scalar quantity is called the static moment

mass relative to the coordinate plane. The quantities and are respectively the static moments of mass relative to the coordinate planes and .

The radius vector and coordinates of the center of mass through static moments of mass are expressed by the formulas

If the mechanical system is a solid body, then it is divided into elementary particles with infinitely small masses and with a radius vector varying from particle to particle.

The sums in the limit turn into integrals. Formulas (1) and (D) take the form

where is body mass.

For homogeneous solid bodies, where is the density of the body, common to all elementary particles; —volume of an elementary particle; - body volume.

For bodies such as a thin sheet, which can be taken as homogeneous material surfaces, , where is the surface density; —surface area of an elementary particle; —surface area.

For a thin wire that can be taken as a line segment, , where is the linear density; —length of the line element; — the length of the line segment.

In these cases, determining the center of mass of bodies is reduced to calculating the center of mass of volumes, areas and line lengths, respectively.

Theoretical and actual weight of rolled metal

Angle weight.

As noted at the beginning, in order to reduce the cost of products, some factories make the thickness of the corner flange smaller than in places where measurements are taken with a caliper or micrometer. This far exceeds the inaccuracies allowed by GOST. Although tolerances can reach up to 12%, some manage to exceed even this limit. As a result, the theoretical weight of a metal angle can vary greatly from the actual weight of rolled products from individual manufacturers. The most popular are equal-flange metal angles 25, 30, 40, 50, 100. The range of all types of angles can be viewed in the table of rolled metal weights.

Channel weight

and

the weight of an I-beam

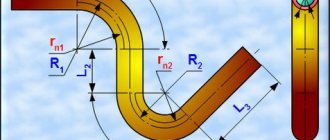

is not easy to calculate using the standard approach, because the complex cross-sectional shape of both types of rolled steel requires entering many parameters, which is inconvenient. The figure shows that the thickness changes smoothly from the middle to the edges, there are roundings of the shape. To avoid confusion, the entire range of I-beams and channels is strictly standardized and is produced under its own number. By selecting a number from the drop-down list in the calculator, you will see all the overall dimensions of one linear meter of a channel or beam. All you have to do is enter the required footage and the calculation will display a tabular weight multiplied by the length. Therefore, unlike other software tools, our metal mass calculator is more accurate in this regard.

Profile pipe weight

. For the construction of some structures, it is very convenient to use rolled metal of non-standard cross-section, such as profile metal pipes. When calculating engineering structures, it becomes necessary to find out the weight of the profile pipe, how much a linear meter weighs. To do this, it is important to know the wall thickness and side dimensions. There is a certain range of pipes that are in great demand, developed by manufacturers. The most popular profile pipes are 20x20, 40x20, 60x60, 80x80, 100x100, 50x50, 25x25, 40x30. If we calculate the weight using geometric formulas, we get a mass that differs from the real one to a lesser extent, due to the fact that the internal corners are rounded during rolling. This increases the actual weight and makes the entire pipe structure stronger. For comparison, you can download a table of the weight of a profile pipe from one of the domestic metallurgical plants. There you can see the standard dimensions of the profile pipe and its range.

Round pipe weight

, like

the weight of a metal circle

(rod), is the easiest to calculate, because their cross-sectional area is the only correct shape from the point of view of geometry among all rolled metal products. The error in calculating the mass in this case is minimal and approaches the actual weight. Ultimately, it all depends on how much the pipe wall thickness declared by the manufacturer corresponds to the actual thickness.

Therefore, when choosing metallurgical products for the construction of structures, the production of machine tools and other purposes, it will not be superfluous to check the correspondence of the calculated tabulated weight of the rolled metal product with its actual weight. This is especially true if the quality of the metal determines the safety of people or the durability of technological equipment.

Download rolled metal calculator. (Offline version of the program in zip archive)

The file size is 2.8 MB, does not require installation.

Updated version of the calculator.

Navigation has been improved - you can now navigate through input fields using the keyboard arrows.

Added the ability to calculate the mass of a bent channel.

Calculation of the mass of a hollow cylinder

It is interesting to calculate how much mass a copper cylinder will have if it is empty inside. For example, let it be made of a thin copper sheet with a thickness of only d = 2 mm.

To solve this problem, you need to find the volume of the copper itself from which the object is made. Not the volume of the cylinder. Since the thickness of the sheet is small compared to the dimensions of the cylinder (d = 2 mm and r = 10 cm), then the volume of copper from which the object is made can be found by multiplying the entire surface area of the cylinder by the thickness of the copper sheet, we obtain: V = d *S3 = d*2*pi*r*(r+h). Substituting the data from the previous problem, we get: V = 0.2*2*3.14*10*(10+10) = 251.2 cm 3. The mass of a hollow cylinder can be obtained by multiplying the resulting volume of copper required for its manufacture by the density of copper: m = 251.2 * 8.96 = 2251 g or 2.3 kg. That is, the considered hollow cylinder weighs 12 (28.1/2.3) times less than a homogeneous one.

Code for embedding a metal calculator on the site

How does wheel weight affect vehicle performance?

Let's start with the fact that all motorists know the fact of increased fuel consumption when transporting goods. In this case, the car becomes heavier, which means the engine needs to generate more energy to transmit torque to the drive axles. About the same thing happens if the car is equipped with heavy wheels. The weight of the car will increase, which will affect increased fuel consumption.

Many drivers have noticed that after switching to alloy wheels, the car becomes more maneuverable and economical. That's right, the weight of the unsprung mass has decreased, and this has led to a decrease in engine energy consumption.

Lighter wheels increase the service life of the suspension and steering. And this also affects the savings of your personal budget. The car accelerates faster and has a reduced braking distance. In addition, riding on light wheels improves the quality of comfort, since the sprung mass easily absorbs transmitted vibrations from the lightweight unsprung mass.

The weight of the assembled wheel may vary depending on the tire pressure. Although a flat tire contains air, at atmospheric pressure its mass is 20 grams (m=V*p=3.14*0.14^2*0.9*1.25/4=0.02kg). And the air density of an inflated tire is approximately 3 times greater. Therefore, the difference in mass is 20*3-20=40 grams.

Description

We constantly monitor innovations in the service sector and offer them to our clients. The rolled metal calculator allows suppliers to simplify their work as much as possible and save valuable time. It makes it possible to calculate the theoretical weight of almost all types of rolled metal; this calculator can be used to calculate products made from ferrous steel, stainless steel and non-ferrous metal.

Each visitor to our website can download a calculator and quickly calculate any rolled metal. For example, the calculation of a profile pipe is carried out by entering data on the height, width, wall thickness and required length of the product. When calculating the corner, you also need to indicate its height, width, thickness and length. Other types of rolled metal are calculated in a similar way.

A simplified calculation is also possible when calculating the channel and beam weight. To do this, you need to indicate the product number and its length in the calculator; the program will indicate the rest of the data itself.

All rolled products, depending on their shape, can be divided into four main groups:

a) grade steel;

b) sheet steel;

d) special types of rental.

Rolled sheets of steel and non-ferrous metals are used in various industries and construction. In this regard, sheet steel, for example, is divided into automotive, transformer, roofing tin, etc. The production of sheet steel with tin, zinc, aluminum and plastic coatings, polymer coating, as well as flat, smooth and profiled: corrugated sheets, expanded metal, perforated.

Sheet steel

divided into groups depending on the thickness of the section. Sheets more than 4 mm are classified as thick sheet steel, and sheets less than 4 mm are classified as thin sheet metal. In this case, there are the following types of sheet steel: shipbuilding, boiler, electrical, tin, acid- and heat-resistant, armor, etc. The qualitative characteristics of flat products are determined by mechanical properties, chemical composition, molecular structure, use for further processing and, finally, smelting method. When producing rolled sheets, the thickness may have plus or minus tolerances, which entails changes in the actual weight of a square meter of sheet. The larger the dimensional tolerance for a given flat product (the difference between the maximum and minimum dimensions of the flat product), the greater will be the difference between the theoretical weight of the sheet steel and the actual weight.

Hot rolled sheet of ordinary quality is made from thin sheet steel (thickness 0.5 mm - 3.9 mm) GOST 16523-89 and thick sheet steel (thickness 4 mm - 160 mm) GOST 14637-89. Flat rolled sheets are widely used in the production of steel containers.

The range of steel sheets corresponds to GOST 19903-74, the chemical composition of steel corresponds to GOST 380-88. The assortment for cold-rolled sheet steel provides for the supply of sheets with a width of 600-1400 mm and a thickness of 0.2-3.9 mm. Sheet length 1200-3500 mm. Assortment standards for cold-rolled steel coils provide for the supply of strips with a width of 200-2300 mm and a thickness of 0.2-4 mm. The current standards stipulate specific gravity, tolerances for sheet thickness and thickness variations, depending on the dimensions of the sheet or tape and delivery conditions. The standard includes standards for tensile strength and elongation. The permissible warpage per 1 linear line is also specified. m along the length and width of the sheet and control for decarbonization. In some cases, the technical conditions stipulate tighter tolerances than in the standards.

Read also: How to measure wire diameter

Rolled sheets are divided into cold-rolled and hot-rolled.

Cold-rolled sheet with a thickness of 1 mm, 1.2 mm, 1.5 mm, 2 mm, 3 mm, available from steel grades 08KP, 3SP/PS.

Hot rolled sheet thickness 2mm, 2.5mm, 3mm, sheet 4, 5, 6mm, 8-10mm, 12mm, 14-16mm, 18mm, 20-32mm, 35mm, 36mm, 40 mm, 45 mm, 50 mm, 60 mm, 65 mm, 70 mm, 80 mm, 90 mm, 103 mm, available in grade st 3SP/PS, steel 09G2S-12; thickness from 4 mm to 50 mm steel grade 45.

Galvanized sheet thickness 0.5 mm, 0.55 mm, 0.6 mm, 0.7 mm, 0.8 mm, 0.9 mm, 1 mm – galvanized iron + polymer coating.

Cold rolling has two great advantages over hot rolling: firstly, it allows the production of sheets and strips with a thickness of less than 0.8-1 mm, down to several microns, which is unattainable by hot rolling; secondly, it ensures products of higher quality in all respects - dimensional accuracy, surface finish, physical and mechanical properties. These advantages of cold rolling have led to its widespread use in both ferrous and non-ferrous metallurgy.

In the production of hot-rolled steel sheet, the metal is first heated and then deformed using special rolling mills by rolling. Cold rolling ensures uniform sheet thickness and also improves its properties by hardening the surface.

Hardening is formed as a result of changes in the structure of the steel sheet

.

sheet, metal

grains are stretched and oriented along the direction of plastic flow of the metal with axes of greatest strength.

A metal sheet

acquires different properties along and across, i.e.

along the length and width of the steel strip

.

At large degrees of plastic deformation, all metal grains are almost identically oriented in the structure of rolled steel sheets

.

Plastic deformation during rolling of a steel sheet

causes hardening of the metal - cold hardening or, in other words, cold hardening. In this regard, to restore plastic properties it is necessary to carry out annealing.

Hot-rolled and cold-rolled sheets are used in mechanical engineering, construction, mining and other industries. The actual scope of application determines the requirements for sheet metal. For the manufacture of products by stamping, sheet metal is used: cold-rolled, hot-rolled, cold-rolled coil, galvanized steel in coils, strip metal.

This table is used when calculating the mass of rolled sheets based on the specific gravity of a square meter of sheet metal.

Tire weight

The second influencing factor on wheel weight is the size and seasonality of the tire. For example, low profile tires and regular tires will weigh differently for the same vehicle. Because a low profile tire has less material. The second example is winter and summer tires. For winter, tires use a softer composition of rubber materials and a complex design. This makes the product heavier. Wheels with multi-layer cord and deep tread for off-road use will also be heavier than their highway counterparts.

Some brands of SUVs go on sale with reinforced tires made using run-flat technology. These are special tires that you can drive on after a puncture. But, the weight of such rubber is 1.5 times more than conventional pneumatic tires.

Volume and surface area

As can be seen from the above, a cylinder is determined by two parameters: the height h and the radius of its base r. Knowing these parameters, it is possible to calculate all other characteristics of the body in question. Below are the main ones:

- Base area. This value is calculated by the formula: S1 = 2*pi*r 2, where pi is the number pi equal to 3.14. The number 2 in the formula appears because the cylinder has two identical bases.

- The area of a cylindrical surface. It can be calculated as follows: S2 = 2*pi*r*h. It is simple to understand this formula: if a cylindrical surface is cut vertically from one base to another and unfolded, you will get a rectangle, the height of which will be equal to the height of the cylinder, and the width will correspond to the circumference of the base of the volumetric figure. Since the area of the resulting rectangle is the product of its sides, which are equal to h and 2*pi*r, the formula presented above is obtained.

- Surface area of a cylinder. It is equal to the sum of the areas S1 and S2, we get: S3 = S1 + S2 = 2*pi*r 2 + 2*pi*r*h = 2*pi*r*(r+h).

- Volume. This value is easy to find; you just need to multiply the area of one base by the height of the figure: V = (S1/2)*h = pi*r 2 *h.