Home » Types of supports » Clamp supports

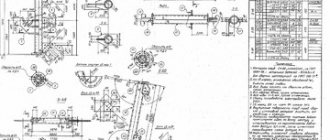

TS-659-00-00 TS-659.00.00 Fixed clamp supports for pipelines with DN 32-219 mm series 5.903-13 release 7-95.

131-2009 Clamp sliding, guide and fixed supports of pipelines according to the organization standard STO 79814898 131-2009 To systematize…

OST 24-125-113-01 OST 24.125.113-01 — Clamp block. Standard OST 24.125.113-01 implies clamp blocks for spring suspensions of pipelines...

TS-625-000 Sliding supports of the TS-625.000 pipeline with a flat clamp in the series 5.903-13 release 8-95.

OST 24-125-114-01 OST 24.125.114-01 - Half clamps. Standard OST 24.125.114-01 describes half-clamps for blocks of clamp hangers for horizontal pipelines…

TS-626-00-000 TS - 626.00.000 Sliding clamp supports for pipelines in the 5.903-13 series, issue 8-95.

OST 24-125-116-01 OST 24.125.116-01 — Clamp blocks with traverse. According to the OST 24.125.116-01 standard, clamp blocks with a traverse are made...

TS-627-00-000 TS-627.00.000 Sliding yoke supports for pipelines in the 5.903-13 series, issue 8-95.

OST 24-125-117-01 OST 24.125.117-01 — Welded clamps. According to the OST 24.125.117-01 standard, welded clamps for clamp blocks are made...

TS-628-00-000 TS-628.00.000 Roller two-tier pipeline supports in the 5.903-13 series, release 8-95.

OST 24-125-118-01 OST 24.125.118-01 Clamp hangers with eyes on the support beam. According to the OST 24.125.118-01 standard, clamps are made...

OST 24-125-119-01 OST 24.125.119-01 — Housings on a support beam with lugs. According to the OST 24.125.119-01 standard, enclosures are made...

OST 24-125-120-01 OST 24.125.120-01 — Half clamps for clamp supports. According to the OST 24.125.120-01 standard, half-clamps for blocks...

Pipeline clamp supports

The clamp support is one of the simplest supports in design, but reliable in its functionality. Depending on the layout, pipeline clamp supports can be movable, sliding or stationary. Easy to assemble, install and maintain, clamp supports are the most popular and occupy their rightful place in this market segment. Pipeline clamp supports are used for fastening process pipelines for a wide range of purposes and various diameters. The material of the supports also varies depending on the conditions when using prefabricated supports. The northern version 09G2S or the usual st. 3 for clamp supports is provided.

Design and types of clamp supports

The single- or double-clamp version of the supports is determined by the technological features of a particular pipeline and depends on the loads and operating conditions.

The clamps are welded to the load-bearing part of the support with a continuous seam and secure the pipe. In some cases, to prevent the pipe from “slipping,” special metal plates are welded to it - “crackers”, which, resting against the surface of the clamp, prevent unwanted movement of the pipe in the axial direction. The clamp support can support both axial and lateral loads.

The second part of the clamp support, the stops, are located on different sides of the supporting structure and are welded to the pipeline using continuous seam welding. As the weight of the pipes increases, the stops are structurally strengthened accordingly.

Operating principle

With the exception of units TU 1468-001-00151756, most designs of pipeline supports can be either movable or fixed. The main problem with long steel structures remains the linear expansion of the structural material.

Therefore, for the most part, movable supports are installed under the pipes to compensate for vertical and lateral loads:

- soil swelling;

- soil shedding in certain areas;

- subsidence of soils with low design resistance;

- snow and wind loads;

- seismic activity of the region;

- water pressure when a floodplain is flooded or an overpass passes along the bottom of a reservoir.

Fixed supports are installed at nodal points, providing a safety margin for the entire pipeline as a whole. The greater the vertical loads the sliding supports experience, the higher the friction force during longitudinal displacement of the pipes and the wear, respectively. The following values of friction forces are taken in the calculations:

- steel/fluoroplastic – 0.1;

- steel/steel – 0.3;

- steel/concrete – 0.5.

In some cases, the coefficient of friction between steel and steel can reach 0.7 units. Misalignment of the shoes relative to the supporting surfaces leads to a sharp increase in contact stresses.

In most sliding supports, friction occurs between the surface of the pipes and individual elements of the assembly unit. The exception is supports for welding (welding) and with gaskets made of polymeric materials. In the first case, welding allows you to shift the emphasis, the parts of the support itself rub against each other, the pipe does not experience such loads. In the second option, the gaskets, which are consumable items, wear out.

Clamp supports are divided into:

Housing clamp supports

They can be movable or immobile. The body of the clamp housing supports is made of a stamped bracket. The clamps for such supports can be made of a rod or strip (round clamp and flat clamp). Clamp supports with a round clamp are used exclusively in steel pipelines, while clamp supports with a flat clamp can also be used in pipelines with various insulations. Housing clamp supports for pipelines are manufactured in strict accordance with OST 36-146-88.

Frameless clamp supports

They can be either movable or immobile. The fixed version of clamp supports is called: clamp guide supports.

Yoke clamp supports

In such pipeline supports, the clamps are reinforced by welding stiffeners.

Sliding clamp supports

This type of pipeline clamp supports can only be movable and only absorb vertical loads from the mass of the heating mains. The clamp support is equipped with an additional insulating gasket that protects the support from unwanted aggressive environments and compensates for various technical shortcomings in the design and construction of heating mains. Sliding clamp supports are one of the most common supports of this type, due to their reliability and efficiency at low cost.

Types of sliding supports

For different operating conditions, in order to save the budget for the implementation of objects, the sliding support for pipelines can be made from different structural materials and rolled products.

Support in polyurethane foam insulation

By default, a pipe sliding support does not prevent the pipe from moving linearly along its axis. Therefore, the main task of the support is to maintain the integrity of the insulation, which is located outside the pipe and has significantly lower strength and wear resistance.

A conventional support is usually made of a channel and a detachable clamp, the lower part of which is welded to the table and serves as a pipe cushion. The reinforced slide support uses a full billet pad and clamp top.

The support is used for diameters of 32 – 1020 mm in systems of steam pipelines, heat pipelines, cold water supply and hot water supply.

Frameless sliding support

The sliding frameless support for pipelines is marked OPB1 or OPB2, it belongs to the L8-515 series. In the first case, the support is a concave plate or a piece of pipe of the appropriate diameter. In the second version, it is additionally equipped with a clamp made of a bent pin.

Used to compensate for vertical loads in pipelines with a diameter of 18 - 530 mm, and to prevent wear from friction forces during linear movement. The clamp is attached not to the pillow, but directly to the rack or foundation elements.

Yoke sliding support

The sliding yoke support for pipelines is marked depending on the design T44, TS-627 or BKHL, BKHNL. The assembly unit belongs to the series 5.903-13 (version 8-95) or 4.903-10 (version 4). The design necessarily includes a band clamp, fastened to the steel body with nuts, or less often by welding.

Conventional yoke supports are designed for medium pressure; when reinforced with stiffening ribs, they are used in loaded critical pipelines. Modifications T44 are designed for diameters of 377 - 1420 mm, temperature +425°C inclusive and operating pressure within 4 MPa. The height of the supports ranges from 100 to 200 mm.

Dielectric sliding support

The yoke modification of a sliding support for pipelines with paronite gaskets is called a dielectric structure. There are several modifications of the dielectric sliding support:

- T16 – one band clamp, diameter 194 – 630 mm;

- T17 – two clamps, diameter 194 – 1420 mm;

- T18 – elongated, with stiffening ribs, diameter 194 – 1420 mm.

Dielectric sliding supports belong to the 4.903-10 series. Paronite is the cheapest insulating material with high wear resistance. The gasket performs two functions at once - it isolates the pipeline from induced and stray currents, and reduces friction during linear movements. Due to the slight elasticity, vibration loads are additionally damped.

Sliding support for pipelines of nuclear power plants and thermal power plants

According to OST 24.125.150 regulations, sliding supports are produced for pipelines of nuclear and thermal power plants. The upper temperature of the working medium reaches +560°C, so pipes made of alloy steels (stainless, heat-resistant, cold-resistant, austenitic) with a diameter of 57 – 920 mm are used.

Therefore, housings, yokes and support ribs are made from similar structural materials.

Sliding support with guide clamp

In the L8 197.000 series, the sliding support for pipelines with a guide clamp is manufactured in accordance with OST 34-10-620-93. The products are intended for pipelines DN 50 – 500 mm with an outer diameter of 57 – 520 mm, respectively, with a working medium pressure of up to 1.6 MPa and a temperature within +80°C.

Structurally, a support with a guide clamp is a curved pin that presses the pipe to one or more pads (frameless support).

Guide sliding support

In the series according to the STO 79814898 130-200 standard, the sliding guide support for pipelines has the most original design:

- the upper part of two side wedges on its own platform is welded to the pipeline;

- the lower part made of steel sheet with guides is rigidly fixed to the foundation.

The support is marked L8-180 and is used in the pipelines of thermal power plants with a high temperature of the working environment. The design is intended for diameters of 50 – 1620 mm, medium pressure within 4 MPa.

Sliding fixed support

The sliding fixed support for pipelines justifies its contradiction in the name due to a special technical solution:

- the lower support plate is rigidly attached to the foundation/rack (welding, bolts);

- The upper part, made of a cushion in a body made of a bent angle and clamps for fixing the pipeline, can slide along the guides in the axial direction.

This allows you to compensate for any operating loads - vibrations, pulsations, linear expansion, vertical and lateral forces. All parts are made of steel 20, which reduces production costs.

Support bracket

For diameters 16 - 89 mm, a sliding support-bracket is used for general purpose pipelines made of carbon and structural steel. It is part of the L8 5113 series, and is designated in the same way in the documentation. The design consists solely of a strip clamp and fasteners for it.

Sliding support with guide bracket

Unlike the previous version, the sliding support for pipelines with a guide bracket is fastened only on one side of the pipe. The clamp is incomplete, installed on one side of the foundation, goes around the body of the pipe, but is not fastened with the free edge. For the guide bracket support, the designation L8 514 is accepted, since the product belongs to this series.

Sliding support with flat clamp

The 5.903 series has a sliding support for pipelines with a flat clamp for diameters 14 – 89 mm. The assembly unit is made from carbon and alloy steels. It is a deep pillow on a stand. A flat clamp fixes the pipeline element in its designed state; external loads are not transferred to it. A support with a flat clamp is designated either TS 625 or L8 512.

Sliding support for pipes in a case

A special sliding support for pipelines made from pipes in a case is designated FSO1. Suitable for diameters 325 – 1420 mm, height 10 – 145 mm. The clamps are solid, they are pulled together over the pipe in the upper position, the lower one-piece part goes under the pillow, and is attached to the housing stand.

Sliding support for polyurethane foam pipes

The sliding support for pipelines in PPU insulation belonging to the 1-487-1997 series is designated by the abbreviation FSO2. Yoke strip clamps have minimal contact with the rather fragile surface of the insulation, so they do not damage it during linear movements of the pipes. The support shoe is made of angle iron; the clamps can be rod or tape. FSO2 is used for diameters 57 – 1420 mm.

Steel sliding support

In the 4.903-10 series, a sliding steel support for pipelines is designated T15 (for diameters 115 - 1420 mm) or T14 (diameter 32 - 1420 mm). It has a height of 100 - 200 mm, all elements are made of 3SP5 or 09G2S steel. A sliding support is used in high-pressure pipelines up to 100 kgf/cm2 inclusive. The pipes are provided with a single degree of mobility - in the axial direction.

Welded sliding support

Initially, the production of sliding welded pipeline supports is regulated by the industry standard OST 34-10-616-93. The products are intended for the following operating conditions:

- pipelines of energy industry facilities;

- ambient temperature maximum +300°C;

- medium pressure 2.5 MPa maximum;

- nominal diameter DN 57 – 1620 mm;

- Construction material: carbon and stainless steel.

The OST 34-10-616 standard contains tables with design options for sliding supports for specific axial and vertical loads. Design features are reflected in the name of the support:

- its upper part consists of saddle-shaped pillows on a stand made of a bent corner;

- the lower part is a plate with two guide angles;

- the top is welded to the pipeline, the bottom is anchored to the foundation;

- the support plate can slide along the guides, providing one degree of freedom of the structure.

Odd markings 001 – 221 are accepted for supports made of carbon steel st. 20, even 002 – 222 for supports made of AISI 304 stainless steel.

Some manufacturers label these supports OPP1 (18 - 48 mm), OPP2 (57 - 1620 mm), OPP3 (57 - 1620 mm).

Adjustable support

The design consists of a support heel with guides along which wedge stops can be moved on both sides. This allows you to change the diameter of the tubular cushion and use a sliding support in pipelines of different diameters.

The support is designated OR, provides height adjustment of 15 – 30 mm, is intended for diameters 175 – 1020 (DN 150 – 1000).

Sliding bearings series T13

For small pipeline diameters 32 – 150 mm, the following design is used:

- a stand made of an I-beam placed at the end;

- sheet material from below to increase the support surface;

- semicircular cutouts in the I-beam flanges to suit the diameter of the pipe.

For diameters 194 – 630 mm, a reinforced box-shaped structure with two pillows made of steel strip is assembled.

T15 Series Pipe Sliding Supports

The design differs from the previous version:

- the channel is laid on its side;

- stiffening ribs are welded on the inside;

- the pillow seat is attached to them.

For T15 sliding supports, standard sizes are 194 - 1420 mm; they are used on straight main sections.