How much does a nickel cost?

Prices for related items:

| Position | Cash payment (individuals) | Cashless payment (legal entities) |

| Nickel-containing Ni from 21 to 98% | 1020 rub. for 100% Ni | 1085 rub. for 100% Ni |

| Copper-Nickel alloy MN20 - MN70 | 1020 rub. for 100% Ni | 1085 rub. for 100% Ni |

| Nickel scrap | 1150 rub/kg | 1223 RUR/kg |

| X20Н80 (nichrome 80) | 900 rub/kg | 960 rub/kg |

Final: the process of electrolysis at home

Electrolysis occurs when passing an electrical current through a circuit creates a chemical reaction. In fact, an electrolytic cell is created, which consists of two metal electrodes immersed in an electrolyte (table salt dissolved in water).

For a home procedure, a salt solution is quite suitable as an electrolyte. Indicator paper is moistened with this solution. Electrodes - a metal sample to be tested and metal tweezers.

Both electrodes must be in contact with the electrolyte to complete the circuit; Therefore, it is important that the indicator paper placed between the metal sample and the tweezers is completely wet.

With information: Canada

Where is nickel taken?

Most expensive

nichrome in coils.

Nichrome scrap is accepted in the form of strips, rods, wire, as well as thermoelements, rheostats, electrodes, etc. There are two types of copper-nickel alloys: electrical and structural. The higher the percentage of nickel

in the alloy, the more expensive its cost.

Interesting materials:

Pot diameter: What are the two needles on the barometer for? What are OZS 12 electrodes for? What is HDMI used for? What is adhesive interlining used for? What is coaxial cable used for? What is river sand used for? What is STB used for? What is carbon dioxide used for? What is ammonium used for?

Homemade electrolysis cables

Below is an example of a DIY electrolysis device powered by a 9-volt battery.

A device design that helps determine nickel or iron directly at home. All that remains is to buy indicator paper to determine a specific metal

Components and accessories of the device:

- 9 volt battery

- interface for connecting the battery,

- polyvinyl chloride tube,

- hair dryer (for heating the solution),

- stainless steel tweezers.

Attaching the wire (negative) to the tweezers is easy to do. It is enough to drill a hole in the handle of the tweezers for a screw with a diameter of 3 mm and install a ring terminal with a hole. The wire, thin, stranded, insulated, is attached to the terminal as standard - using a soldering iron and solder.

The positive battery cable, the same standard as the negative one, is attached to an alligator clip. A constant resistor is connected to the wire break: 300-360 Ohm, 0.25 W. For normal operation, the electrolysis installation circuit current must be within 25-30 mA (regulated by a resistor).

Identifying real metal

To understand how to distinguish silver from other metals, you need to clearly understand the main characteristics of the imitations that are so often passed off as silver. It becomes clear that modern jewelry factories and industrial factories conduct careful control and do not allow silver of dubious quality to enter the market. They all work in accordance with certain standards and GOSTs, so you don’t have to worry about quality when purchasing silver products from reliable places and trusted jewelry stores.

Counterfeiting of silver began in ancient times, when the price of silver was much higher than in our time. Sometimes its value exceeded even pure gold. To replace or counterfeit this white metal, various analogues were used or alloys were made from them. The ornamental metals were lead, zinc and aluminum. Often, pseudo-jewelry was made from them, and the top was covered with a thin layer of silver to distract the eyes of inexperienced buyers. But after some time, such products begin to lose their aesthetic appearance, turn black, become covered with plaque, and the test marks and marks are erased. If after thorough cleaning these signs only worsened, then the product really turned out to be a fake.

Types of nickel scrap (recyclables)

Conventionally, scrap nickel waste can be divided according to its physical state into several basic categories: lump scrap, shavings and other recyclable materials, for example, cathode hooks with an overgrown layer of this metal. Depending on the Ni content, each of them is divided into several subgroups:

- Pure metal scrap;

- Slag waste. Characterized by Ni content up to 85%;

- Alloys sold for scrap, where nickel is one of the main components. This is the well-known nichrome, in which the concentration of Ni is 55 - 78%, as well as permalloy (up to 76%), constantan, nickel silver and others, which are unfamiliar to most;

- Secondary alloys alloyed with nickel. Stainless steel scrap and waste of this type are usually various grades of steel with a small content. The fractional concentration of the element Ni in heat-resistant and stainless materials reaches 20%, while in low-alloy steels this value does not exceed 5%;

- Nickel-containing sludge, representing galvanic and metallurgical types of waste.

All of the above recyclables are actively purchased by collection points. As a standard, the price per kg of nickel scrap is determined by the percentage of the latter in metal waste.

Nickel scrap will also include:

- nickel catalysts;

- nickel oxide (NiOH);

- nickel oxide hydrate (Ni(OH)2);

- nickel agglomerates and concentrates, etc.;

- TNZh batteries;

- Waste containing Ni as pure metal.

A significant segment of such secondary metals consists of spent nickel anodes and cathodes, which are easily detected by the naked eye, with some experience. They have a light gray color; the spent elements are usually covered with a greenish coating. When heated, nickel electrodes acquire a yellow tint; they are also characterized by a short red spark and are magnetic. The surface of nickel cathodes is pimply, while the anodes are smooth.

The next common source of metal received at reception points is granulated nickel; it is difficult to call it scrap or waste, but you can sell it at a high price. The exception is ferronickel granules. They, like granular grades of metal H0 - H4, are used for alloying steels, however, they have a lower acceptance cost, since this is not pure Ni, but its alloy with iron. Granular ferronickel can be distinguished by color: the metal is characterized by a matte gray tint. On the contrary, nickel granules have a metallic luster.

Another two groups are shavings and wire. The second component, like Ni scrap, is much easier to detect. Nickel wire is used to make thermocouples, electrodes for electroforming, and mesh used in catalysis.

Nickel winding strings

RESULT: HOW TO IDENTIFY STAINLESS STEEL

Thus, the task of how to identify and distinguish stainless steel from any other types of metals and steels seems quite possible even without the use of serious industrial expert measures. It is enough to remember and apply at least some of the above methods, which provide completely objective information on the distinctive features. If doubts remain, it is better to turn to expert data. Especially when it comes to medical or food products. By the way, many people are also tormented by the question: is it possible to weld stainless steel to ferrous metal? In this article we will break everything down.

What does the price depend on?

Low-carbon, corrosion-resistant alloys are used to produce a wide variety of products: blades, profiled sheets, roofing materials, medical supplies. Scrap stainless steel can be collected when dismantling an old fence, dismantling an old refrigerator, throwing away unnecessary kitchen utensils, etc. In this case, potential income will depend on the following factors:

- type of steel (austenitic, ferritic, martensitic, etc.);

- steel grade (AISI 304, AISI 630, 12Х21НБТ);

- type of rolled metal (sheet, section, pipe);

- sheet thickness;

- compound;

- quality.

You can determine the stainless steel brand and composition in a laboratory setting by contacting a reliable collection point. We have the necessary equipment to analyze the composition, assess the quality and test the radiation activity of non-ferrous scrap. But you can pre-evaluate scrap metal at home.

The most expensive types of stainless steel

The cost is affected by the amount of nickel in the alloy: in the cheapest types its content does not exceed 5%. The most expensive are high-alloy alloys containing nickel from 12%. The expensive scrap includes plumbing fittings and rings, wire and various electrical connectors (connectors, adapters, etc.). Matte (a by-product of non-ferrous metallurgy) with a nickel content of over 35% is also highly valued, although it is classified as slag.

But the most common steel grade is A2, containing approximately 10% nickel and 18% chromium. It is usually used to make household items. To find out the exact price, visit our collection point: to evaluate scrap, specialists must inspect the metal, assess the degree of contamination, composition and properties.

Babbitt is a tin or lead based anti-friction alloy intended for use as a layer poured or sprayed onto the bearing shell housing.

Copper additions further increase the hardness of tin babbits.

Lead-calcium babbit is used in bearings for railway rolling stock.

Babbitt B83 comes only in GOST ingots with the B-83 terminal knocked out.

If the lead content is more than 0.35%, then it is closed as B-80.

Babbitt B-50 (Sn 49-78% rest lead)

Babbitt B-16 (Sn 15-48%, Sb 15-17%, Cu 1.5-2% rest lead)

Babbitt BN (Sn 10-15%, Sb -10%, rest Pb)

Tungsten ( W ) is a shiny light gray metal that has the highest proven melting and boiling points, is one of the heaviest, hardest and most refractory metals, is easily forged and can be drawn into a thin thread. It is found in the form of wire, tape, furnace screens and other parts. In its purified form, tungsten is silvery-white and resembles steel or platinum in appearance. (not magnetic, has a yellow spark, may be radioactive)

Tungsten – chemical composition W-99%

Tungsten VN (W from 85%, Ni no more than 10%)

Tungsten VND (W from 85%, Ni no more than 10%, Cu no more than 5%)

Tungsten residence permit (W from 85%, Ni no more than 10%, Fe no more than 3%)

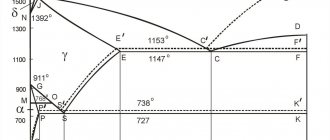

VK TK (hard alloys) are hard and wear-resistant metal materials that can maintain these properties at 900–1150 °C. They are mainly made from highly hard and refractory materials based on tungsten, titanium, tantalum, chromium carbides, bound with a cobalt metal binder, with varying cobalt or nickel content. VK TK (checked with a grinder) short yellow spark, VK TK magnetite with copper-brass surfacing, yellow.

UNDK magnets are an alloy of iron (53%), aluminum (10%), nickel (19%) and cobalt (from 18%). Foreign analogues are called alnico (English Alnico) - an acronym for the elements included in the composition. The alloy has high residual magnetization and is used for the manufacture of permanent magnets. Alnico is produced by casting, from powders and by hot deformation of an ingot. Alnico has high corrosion resistance, a high Br value (magnetic field strength) and stability at high temperatures (up to 550 °C). The material has a coarse-grained structure, pressed into various shapes (disc, semicircle, etc.)

Molybdenum ( Mo ) is extracted from ores containing up to 50% of the substance itself, about 30% sulfur, 9% silicon and a minor presence of other elements. In fact, the ore is used as a concentrate that is roasted. The temperature of this stage is 570 - 600 0C, it takes place in special ovens. The result is a cinder containing molybdenum oxide contaminated with impurities. Molybdenum is added to steel along with a number of other elements. The percentage determines the type of product obtained: alloy (0.1 - 0.3%) or tool (3 - 10%) steel. It is this that is subsequently used when steel is alloyed. This direction remains the main one in the use of metal. Only 30% of mined molybdenum finds its way into industry as a pure metal or alloy, where it retains its primary importance. It is used in the production of nuclear reactors and spaceship skins.

High-speed steels (P9, P18, P6M5, P6M3, P3M3) are alloy steels intended primarily for the manufacture of metal-cutting tools operating at high cutting speeds. Alloying high-speed steels with tungsten, molybdenum, vanadium and cobalt ensures hot hardness and red-hardness of the steel. The number after the letter “P” indicates the average tungsten content in it (as a percentage of the total mass). Then the content of molybdenum, vanadium and cobalt is indicated after the letters M, F and K. Foreign-made high-speed steel tools are usually marked with the abbreviation HSS. The material has a short red spark, which can be easily distinguished from ferrous metal by passing it with a grinder. When using drills, pay attention to the ends of the drills; most often they are made of iron (additional blockage).

Nickel ( Ni ) is a silver-colored metal, often coated with a greenish oxide film that prevents further oxidation. Pure nickel is a magnetite like ferrous metal, a hard metal, but, nevertheless, it is very plastic, easy to forge, and all types of drawing. Cathode nickel has an uneven rough surface; it is used in electroplating; a short red spark is visible on the grinder.

Alloys based on the element Ni

This type of secondary non-ferrous metal, although inferior in price per kg to nickel scrap, remains a fairly profitable product on the scrap metal market. Nickel alloys with metals are accepted quite effectively:

Heat-resistant nichrome is a compound based on Ni (60 - 80%) and Cr. The alloy grade X15N60 additionally includes iron. This material is supplied to the secondary market in the form of heating elements, after being used inside thermal impact devices: kilns, dryers, etc. Nichrome can also be found among parts operated at high temperatures: rheostats, substrates for spraying systems.

Wire grade X15N60

Alloys of copper and nickel are represented by a fairly wide range of compounds (Ni content is indicated in parentheses):

- Monel (29 - 70%) . The nickel-containing alloy is used as a structural material in aircraft and marine engineering. Many equipment components for the oil and chemical industries: drilling tools, pump shafts, scrapers, blades, etc.; also made of monel. The price of scrap depends on the nickel content, which is determined by the brand name or analyzer. It should not be confused with the MNC alloy; in contrast, Monel does not contain zinc;

- Permalloy (45 - 82%) . The compound also contains iron and chromium. Sources of scrap of this alloy: transformers, coil shielding, relays. The high iron content in the compound means that permalloy waste is often disposed of as recycled ferrous metal. The alloy is accepted as nickel-containing scrap by specialized scrap collecting enterprises equipped with spectral analyzers. Payment is made based on the presence of the Ni element;

Transformer housings made of permalloy

- Constantan (39 – 41%) . Thermocouples, rheostats, as well as electric heating elements operating at operating temperatures up to 500 °C are made from this compound. Constantan is found in measuring instruments of low accuracy class;

- Cupronickel (5 – 30%) . This nickel-containing alloy is well known thanks to the dishes and coins of the USSR in denominations of 10, 15 and 20 kopecks (they were in circulation before the monetary reform of 1961). The compound is less known as a material for the manufacture of thermogenerators, high-precision resistors, and submarine parts. Cupronickel is used to create artistic objects: candlesticks, boxes and others. Therefore, it is not always profitable to hand over certain cupronickel products simply as nickel-containing scrap;

Cupronickel spoon

- Nickel silver (5 – 35%) . The alloy differs from cupronickel in the presence of zinc in the compound. The use of nickel silver also differs in a variety of directions. With his participation, silver-plated dishes and many artistic objects are created. On the other hand, nickel silver is in demand as a hard and elastic alloy in the manufacture of pins, fasteners, and springs for relay electrical equipment. Various types of medical instruments, steam and water fittings are made from this compound.

Nickel silver wire - soft

Another type of alloy that is of interest as a secondary metal is nickel-iron compounds, such as invar. The compound is widely used in precision instrument making; measuring standards and parts of watch mechanisms, in particular chronometer balances, are made from it. Additionally, this nickel-containing alloy is a material for massive slats of geodetic equipment, such as levels.

HOW TO IDENTIFY STAINLESS STEEL: 13 WAYS

Identifying stainless steel using a magnet

Stainless steel does not allow magnetization due to the action of Futko currents. But this technique does not always give the correct result, since iron and martensitic alloys have magnetic properties, and therefore, using a magnet, it is possible to reliably determine only austenitic-iron alloys, which contain a high percentage of nickel and chromium. In other words, it is impossible to 100% identify stainless steel with a magnet, but you can recognize its subtype.

Saline solution

The essence of the method of determining stainless steel with a saline solution is to identify susceptibility to corrosion. A strong saline solution serves as a good provocateur of corrosive destruction. For this purpose, the product to be checked is immersed in a saline solution for a day. Stainless steel, having a high degree of resistance to such aggressive environments, will remain undamaged by corrosion.

Slice method

An incision is made using improvised means. The color of the cut will help distinguish stainless steel from brass, which is similar in color. In the case of the latter, the cut will have a yellow tint. While stainless steel will remain light gray.

Determination of stainless steel with copper sulfate

The top layer is sanded using sandpaper. After which the surface of the stainless steel is treated with a solution of copper sulfate. In this case, the definition of stainless steel, as in the case of the above methods, the stainless steel will not change its external characteristics.

Physical method for determining stainless steel

How to check stainless steel physically?

The method is based on knowledge of the law on the volume of displaced fluid. Stainless steel placed in a container of water will displace a different amount of water than the metal can displace. To do this, you need to know the mass of the product, the mass of the displaced liquid, and have a table of weight differences on hand.

Marking

The marking indicates the properties characteristic of a given material. Based on these properties, you can understand how to identify and distinguish stainless steel from ordinary metal.

Blank Slate Method

Stainless steel does not leave marks from tight contact, while aluminum will give noticeable gray stripes.

Thermal conductivity

For aluminum, unlike stainless steel, it is much higher. In this regard, water in an aluminum container will boil much faster.

Aggressive environments.

When in contact with alkaline and acidic environments, the surface of stainless steel will remain unchanged. Spots will appear on the surface of the aluminum.

Reaction with nitric acid

A few drops of acid reacting with any carbon steel will cause the formation of corrosive fumes. Stainless steel will not react even if the surface is damaged.

Light ebb

The surface of stainless steel gives a yellowish-blue tint.

A mixture of hydrogen peroxide and 20% sulfide

Such a mixture applied to a cut will cause significant darkening visible to the eye if a non-ferrous metal has interacted with the reagent.

Hole

Drilling a hole will help distinguish stainless steel from duralumin by the appearance of the chips.

Identifying stainless steel using a spark

How to identify stainless steel using a spark? That's how:

- V (volume) of carbon in steel has a direct relationship with the number of flashes and sparks;

- The hue of the sparks gives information about the structure of the metal (if they are lightish white, then most likely it is steel with a low carbon content);

- If the sparks have a very bright light shine, this means that the material contains a large amount of titanium.

To conduct such a test to determine stainless steel, you need to start the process of grinding the material with a grinder, and sparks and flashes, as mentioned above, will provide the necessary information.

To carry out the test, an angle grinder (grinder) is required. Start grinding the surface of the steel and observe the reaction. The color, length and shape of the sparks will help you accurately determine metal or stainless steel.

A separate point is worth highlighting the differences between food-grade stainless steel and technical stainless steel. Due to the fact that cookware made from this type of steel is in high demand, such differences are quite relevant. The surface of food-grade stainless steel is distinguished by high quality processing, giving it smoothness. Even matte surfaces visually and to the touch do not have even the slightest defects or protrusions. As a rule, much more metal impurities are added to steel for this purpose. This is due to regular exposure to aggressive environments. The listed properties and requirements also apply to medical products.

In addition to all of the above, markings can provide a large portion of information about the steel from which the product is made.

PROPERTIES AND CHARACTERISTICS OF STAINLESS STEEL

How to define stainless steel ? Stainless steel gained its relevance due to a number of positive properties:

- Resistance to aggressive environmental influences;

- High wear resistance, due to which the service life of the products is more than ten years;

- Thermal resistance to sudden temperature changes;

- High level of resistance to corrosion and other types of destruction;

- Environmental Safety;

- Aesthetically attractive appearance;

- Easy to use and maintain.

Speaking about what stainless steel is and how to define stainless steel , we can say that it is the result of a successful mixture of steel and impurities that enhance its properties. Such impurities are the main component that prevents the formation of rust and premature aging of products. The more impurities, the longer the service life of the steel in general.

The main additional components are:

- Copper;

- Nickel;

- Molybdenum;

- Chromium;

- Manganese;

- Titanium.