Brand VSt3sp – purpose

Structural carbon steel of ordinary quality VSt3sp is used for the manufacture of parts, non-load-bearing/load-bearing components of welded/prefabricated structures operating at positive temperatures.

Additional information:

1. Sheet/shaped rolled products of category 5 with a cross-section up to 10mm – load-bearing components of welded structures operating under variable loads at temperatures of -40 +4250C.

2. Rolled products with a cross-section of 10–25 mm – load-bearing components of welded structures with guaranteed weldability, operating in the temperature range -40 +4250С.

Supply of VSt3ps

Supplied in the form of long products, including shaped steel according to the regulations of GOST 380-2005 Carbon steel of ordinary quality (grade), GOST 8281-80 Bent steel channels, unequal flanges, GOST 8278-83 Bent steel channels, equal flanges, GOST 8240-97 Hot-rolled steel channels . 2590-88 Hot-rolled round steel, GOST 8510-86 Hot-rolled unequal-flanged steel angles, GOST 19772-93 unequal-flanged bent steel angles, GOST 19771-93 Equal-flanged bent steel angles, GOST 11474-76 Bent steel profiles (technical conditions), GOST 850 9- 93 Hot-rolled equal-flange steel angles, GOST 9234-74 Bent steel sheet profiles with trapezoidal corrugation, GOST 103-2006 Long-rolled hot-rolled steel strip. Assortment, GOST 82-70 Hot-rolled broadband universal steel, GOST 82-70 Hot-rolled broadband universal steel, GOST 503-81 Cold-rolled low-carbon steel strip, GOST 8734-75 Seamless cold-deformed steel pipes, GOST 10706-76 Electric-welded straight-seam steel pipes ( technical requirements), GOST 10705-80 Electric-welded steel pipes, GOST 20295-85 Welded steel pipes for main pipelines (technical requirements)

cutting

| Initial data | Machinability Ku | |||

| State | HB, MPa | sB, MPa | hard alloy | high speed steel |

| hot rolled | 124 | 400 | 1,8 | 1,6 |

Steel 45 and its analogues

Such material can be replaced by the following three grades of steel: 50, 50 G 2 and 40 X.

They are also used to create gears, cylinders, eccentric shaft attachments, rotating shafts, crankshafts and distribution shafts, as well as other products used in industry.

Steel grade 45 may be called differently in other countries and have several analogues. For example, in the USA, its properties are equal to 8 grades of steel, in Germany - 10, in France - 14. In Poland there is only one analogue and it is simply called 45, in Austria - C45SW.

Steel VSt3sp – chemical composition

Mass fraction of elements no more than, %:

| Silicon | Manganese | Copper | Arsenic | Nickel | Sulfur | Carbon | Phosphorus | Chromium |

| 0,12–0,3 | 0,4–0,65 | 0,3 | 0,08 | 0,3 | 0,05 | 0,14–0,22 | 0,04 | 0,3 |

Which is better: galvanized or stainless steel?

In order to successfully solve various technological problems and not get confused: buy a galvanized sheet instead of a stainless steel one, contact a trusted, reputable supplier. Although both metals are corrosion-resistant, and when constructing structures with a service life of no more than 10 years, it is quite possible to get by with cheaper galvanized steel, for critical objects it is still not worth skimping on quality.

A guarantee that you are purchasing a certified product will be choosing as a partner a reliable supplier with attractive market offers. Today we are the best and are ready to supply any volumes of highest quality metal products in the shortest possible time.

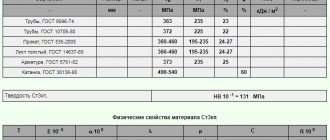

Material VSt3sp – mechanical properties

| Assortment | GOST | Dimensions – thickness, diameter | Heat treatment mode | t | KCU | y | d5 | st | sв |

| mm | 0C | kJ/m2 | % | % | MPa | MPa | |||

| Forgings | up to 100 | Normalization | 640 | 55 | 28 | 175 | 353 | ||

| 100–300 | 590 | 50 | 24 | 175 | 353 | ||||

| Rolled hot rolled products. | up to 20 | Delivery status | 26 | 245 | 370–480 |

Main characteristics and properties

When choosing a metal, much attention is paid to the main characteristics. We include:

- Hardness index. It can vary over a wide range and depend on whether heat treatment has been carried out. The hardness of steel 20 is maintained at 163 MPa. This is quite enough for the manufacture of various products that have high wear resistance.

- Density is also taken into account. Less dense materials are used to make products that will be lightweight. In the case under consideration, the indicator is 7.85 k/cm3.

- When considering the main characteristics, the yield strength and tensile strength are taken into account. They are considered when creating various projects. Metal St 20 can be improved in order to increase the characteristics of the material.

- The structure is characterized by the fact that it is not prone to temper brittleness and the formation of flakes.

- The heat treatment of steel 20 can significantly increase the service life of the product. It is carried out under certain conditions. For example, for forging, the structure is heated to a temperature of 1,280 degrees Celsius.

- If necessary, it is possible to weld parts.

- The impact strength of steel 20 determines that the metal is often used in the manufacture of shafts and other similar products that can be used to create elements used in the creation of various mechanisms. The elastic modulus is also taken into account when considering the basic properties of the metal.

- The average thermal conductivity coefficient determines that the structure can heat up quickly enough, but at the same time heat is removed with high efficiency.

Properties St 20

The mechanical properties of steel 20 determine the fairly wide distribution of this grade in mechanical engineering and other industries. As previously noted, technical characteristics can be improved by heat treatment or alloying. Restructuring the structure of the metal makes it possible to increase the hardness of the surface layer; by adding other chemicals, special qualities can be imparted, for example, corrosion resistance.

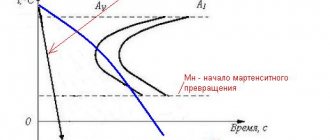

Heat treatment involves changing the structure due to exposure to a certain temperature. Critical points are selected depending on the characteristics of the chemical composition. The features of such a procedure include the following points:

To provide the required impact, special equipment is used. Examples include blast furnaces and induction furnaces. For a long period, blast furnaces were used, but they are inferior to induction furnaces. The second version is suitable for installation in small workshops. Critical points are taken into account when carrying out the procedure under consideration. It is worth considering that they have already been identified for all metals, so there is no need to conduct the research again. The workpiece is heated to the required temperature, after which the initial restructuring of the structure occurs

The holding time is also an important indicator that must be taken into account, as is the heating rate. Attention is also paid to the cooling process. Workpieces that are too large are cooled in air, as problems arise in creating the required environment

For a long period of time, cooling was carried out in water, but this led to the appearance of scale. It is possible to ensure a higher quality of heat treatment by using oil as a cooling medium. However, when cooling in oil, one should take into account the high probability of toxic smoke formation and surface ignition due to high temperature.

Steel hardening colors

In many cases, surface defects are formed after heat treatment. That is why the procedure is used for workpieces or products that are created taking into account the allowance. After hardening, tempering is often carried out, which allows you to relieve internal stresses and reduce the likelihood of damage to the product when dropped or subjected to an impact load.

Endurance limit, MPa

| Assortment | Dimensions – thickness, diameter, mm | sв | N | s-1 |

| The sheet is hot rolled. – smooth sample | 40 | 107 | 191 | |

| notched specimen | 10 | 107 | 93 | |

| 440 | 2x103 | 213 |

Impact strength of steel VSt3ps

| Type of rental | Pattern cutting direction | Section, mm | Temperature +20 °C | Temperature -20 °C | after mechanical aging |

| no less | |||||

| Sheet | Transverse | 5-9 | 78 | 39 | 39 |

| 10-25 | 29 | 29 | |||

| 26-40 | 49 | — | — | ||

| Wide band | Longitudinal | 5-9 | 98 | 49 | 49 |

| 10-25 | 78 | 29 | 29 | ||

| 26-40 | 68 | — | — | ||

| Varietal and shaped | Longitudinal | 5-9 | 108 | 49 | 49 |

| 10-25 | 98 | 29 | 29 | ||

| 26-40 | 88 | — | — | ||

Brand VSt3sp – physical properties

| t | r | R 109 | E 10-5 | l | a 106 | C |

| 0C | kg/m3 | Ohm m | MPa | W/(m deg) | 1/Grad | J/ (kg deg) |

| 20 | 7850 | 1.94 | ||||

| 100 | 1.92 | |||||

| 200 | 1.87 | |||||

| 300 | 1.83 | |||||

| 400 | 1.78 | |||||

| 500 | 1.67 | |||||

| 600 | 1.59 | |||||

| 700 | 1.46 | |||||

| 800 | 1.2 | |||||

| 900 | 0.99 |

CONTROL METHODS

4.1. Sampling to determine the chemical composition is carried out according to GOST 7565.

4.2. Chemical analysis of steel is carried out according to GOST 22536.0—GOST 22536.12, GOST 27809, GOST 12346, GOST 12347, GOST 12348, GOST 12350, GOST 12351, GOST 12352, GOST 12355, GOST 12356, GOST 12357, GOST 1 2358, GOST 12359, GOST 12361, GOST 12364, GOST 18895 or other methods that provide the necessary accuracy of analysis.

In case of disagreement in quality assessment, the assessment is carried out using the methods established in the standard. (Changed edition, Amendment No. 1).

4.3. Carbon equivalent (Ce) is calculated using the formula

where C, Mn, Si, Cr, Ni, Cu, V, P are the mass fractions of carbon, manganese, silicon, chromium, nickel, copper, vanadium and phosphorus.

4.4. Control of surface quality and dimensions of rolled sheets according to GOST 14637, long products - according to GOST 535.

4.5. Delamination of rolled products during cutting is controlled by inspection of the edges and ends without the use of magnifying devices.

If necessary, the quality of the metal on the edges of sheets and universal strips is checked by removing chips: in this case, bifurcation of the chips serves as a sign of discontinuity of the metal.

4.5.1. Ultrasonic testing of the continuity of rolled sheets is carried out in accordance with GOST 22727.

4.6. Sampling and production of samples for mechanical and technological tests are carried out in accordance with GOST 7564. Samples are cut lengthwise from shaped rolled products and universal strips, and across the rolling direction from sheet metal. When testing for impact bending on samples with a sharp notch, samples are taken along the rolling direction.

For rolled products with a diameter or side of a square greater than those indicated in the table. 1 and 7, it is allowed to determine the mechanical properties on samples cut from blanks, forged or rolled to the dimensions regulated by Table. 1 and 7. The standards of mechanical properties in this case must correspond to table. 1 and 7.

(Changed edition, Amendment No. 1).

4.7. From each rod, sheet, universal strip, roll selected for control, one sample is taken for tensile and bending tests, and two samples for each temperature are taken to determine impact strength. The quality of bent profiles is controlled by the workpiece.

4.8. Tensile testing of rolled products is carried out on samples of five times the length in accordance with GOST 1497.

(Changed edition, Amendment No. 1).

4.9. The bending test is carried out according to GOST 14019.

4.10. Determination of the impact strength of rolled products with a nominal thickness of up to 10 mm inclusive is carried out on samples of type 1, 2 or 3, and for categories 8 and 9 - types 11, 12, 13 according to GOST 9454. For rolled products with a thickness of more than 10 mm, the impact strength is determined on samples of type 1, and for categories 8 and 9 - type 11 according to GOST 9454.

The impact strength of shaped and strip products with a thickness of 3-4 mm, and sheet products with a thickness of less than 5 mm can be determined on samples with a width equal to the thickness of the product.

(Changed edition, Amendment No. 1).

4.11. Impact strength after mechanical aging is determined according to GOST 7268 on samples with a U-type concentrator. The thickness of the samples must correspond to those adopted in clause 4.10.

4.12. When testing samples with a type U concentrator, a reduction in impact strength on one sample is allowed by 15%; when testing samples with a type V concentrator, a reduction in impact strength on one sample is allowed by 30%; in this case, the average value of the test results must not be lower than the standards in Table. 6 and 7.

4.13. When the manufacturer uses statistical and other non-destructive methods for monitoring mechanical properties in accordance with regulatory and technical documentation, the manufacturer may not carry out control of mechanical properties according to the methodology provided for by this standard. The manufacturer guarantees compliance of manufactured products with the requirements of this standard. In case of disagreement in quality assessment and during periodic product quality checks, control methods provided for in this standard are used.

Legend

Mechanical properties

| HRСе | HB | KCU | y | d5 | sT | sв |

| MPa | kJ/m2 | % | % | MPa | MPa | |

| Rockwell hardness | Brinell hardness | Impact strength | Relative narrowing | Elongation at break | Yield strength | Short-term strength limit |

| Ku | s0.2 | t-1 | s-1 |

| Relative machinability factor | Proof of yield strength with 0.2% tolerance when loaded to plastic strain value | Torsional endurance limit (symmetrical cycle) | Endurance limit under compression-tension (symmetrical cycle) |

| N | number of deformation/stress cycles sustained by an object under load before fatigue failure/crack appears |

Features and Benefits

from - 70 to +450 degrees

Advantages

Considering the main advantages of this grade of steel, it is necessary to highlight the following:

- the ability to withstand exposure to negative temperatures, as well as maintain its performance characteristics in the Far North;

- high strength characteristics, due to which steel can be used in the manufacture of bridges, machines and other critical structures;

- low costs for installation work. This effect is achieved due to the absence of the need for preheating of the material and its further heat treatment, including hardening, tempering and annealing.