At any metallurgical plant that produces steel and alloys of various grades, you will certainly be offered inexpensive carbon structural steel of ordinary quality, which is used literally everywhere. The VST3 brand is used for the production of standard load-bearing and non-load-bearing elements of welded and non-welded structures, which are operated at temperatures from -40 to +425°C. This material has no restrictions on weldability, is not prone to temper brittleness, and is characterized by relatively high corrosion resistance. In addition, it is a fairly durable metal, which for convenience is available in three versions: normal strength, increased strength and high strength.

VST3 steel, produced in accordance with GOST 380-71, has the following chemical composition (in percent):

- carbon – 0.14-0.22

- manganese – 0.4-0.65

- chrome – 0.3

- nickel – 0.3

- copper – 0.3

- silicon – 0.05-0.17

- arsenic up to 0.08

- sulfur – 0.05

- phosphorus – 0.04

Brand VSt3sp – purpose

Structural carbon steel of ordinary quality VSt3sp is used for the manufacture of parts, non-load-bearing/load-bearing components of welded/prefabricated structures operating at positive temperatures.

Additional information:

1. Sheet/shaped rolled products of category 5 with a cross-section up to 10mm – load-bearing components of welded structures operating under variable loads at temperatures of -40 +4250C.

2. Rolled products with a cross-section of 10–25 mm – load-bearing components of welded structures with guaranteed weldability, operating in the temperature range -40 +4250С.

Supply of VSt3sp

Supplied in the form of long products, including shaped steel according to the regulations of GOST 2590-88 Hot-rolled round steel , GOST 2591-88 Hot-rolled square steel , GOST 8239-89 Hot-rolled steel I-beams , GOST 19771-93 Equal-flange bent steel angles, GOST 19772 -93 Bent steel angles, unequal flanges , GOST 8278-83 Bent steel channels, equal flanges , GOST 8281-80 , unequal , GOST 8283-93 steel trough equal flange profiles , GOST 380-94 Carbon steel of ordinary quality , GOST 85 09-93 Steel corners hot-rolled equal flange , GOST 8510-86 rolled steel angles unequal-flanged , GOST 8240-97 Hot-rolled steel channels , GOST 535-88 Rolled bars and shaped carbon steel of ordinary quality , GOST 2879-88 Rolled hot-rolled hexagonal steel, GOST 19903-2015 Hot rolled sheet products , GOST 19904-90 Cold-rolled sheets , GOST 16523-97 Rolled thin sheets of high-quality and ordinary quality carbon steel for general purpose, GOST 503-81 Cold-rolled low-carbon steel strip, GOST 103-76 Hot-rolled steel strip , GOST 82-70 Hot-rolled steel Wide-band universal, GOST 3282-74 Wire Steel low-carbon general purposes , GOST 17305-71 Carbon structural steel wires, GOST 10705-80 steel power steel pipes , GOST 10706-76 Pipes steel eight-dimensional , GOST 3262-75 Pipes steel water and gap-pipes .

| B03 - Metal forming. Forgings | GOST 8479-70; |

| B20 - Classification, nomenclature and general standards | GOST 380-2005; |

| B22 – Long and shaped rolled products | GOST 8239-89; GOST 8278-83; GOST 8282-83; GOST 8283-93; GOST 2879-2006; GOST 2591-2006; GOST 2590-2006; GOST 8510-86; GOST 19772-93; GOST 19771-93; GOST 11474-76; GOST 8509-93; GOST 9234-74; GOST 8281-80; |

| B23 - Sheets and strips | GOST 103-2006; GOST 82-70; GOST 19903-74; |

| B33 - Sheets and strips | GOST 10885-85; |

| B34 - Tapes | GOST 503-81; |

| B62 — Steel pipes and connecting parts for them | GOST 20295-85; GOST 10705-80; GOST 10706-76; GOST 8734-75; GOST 24950-81; |

cutting

| Initial data | Machinability Ku |

| State | HB, MPa | sB, MPa | hard alloy | high speed steel |

| hot rolled | 124 | 400 | 1,8 | 1,6 |

physical characteristics

| Temperature | E, GPa | l, W/(m °С) |

| 20 | 194 | — |

| 100 | 192 | 55 |

| 200 | 187 | 54 |

| 300 | 183 | 50 |

| 400 | 178 | 45 |

| 500 | 167 | 39 |

| 600 | 159 | 34 |

| 700 | 146 | 30 |

| 800 | 120 | — |

| 900 | 99 | — |

Steel VSt3sp – chemical composition

Mass fraction of elements no more than, %:

| Silicon | Manganese | Copper | Arsenic | Nickel | Sulfur | Carbon | Phosphorus | Chromium |

| 0,12–0,3 | 0,4–0,65 | 0,3 | 0,08 | 0,3 | 0,05 | 0,14–0,22 | 0,04 | 0,3 |

Designations

| Name | Meaning |

| Designation GOST Cyrillic | St3sp |

| Designation GOST Latin | Ct3cp |

| Translit | St3sp |

| By chemical elements | 3 |

| Name | Meaning |

| Designation GOST Cyrillic | VSt3sp |

| Designation GOST Latin | BCt3cp |

| Translit | VSt3sp |

| By chemical elements | 3 |

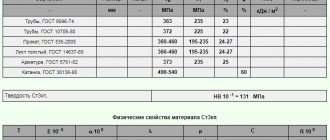

Material VSt3sp – mechanical properties

| Assortment | GOST | Dimensions – thickness, diameter | Heat treatment mode | t | KCU | y | d5 | st | sв |

| mm | 0C | kJ/m2 | % | % | MPa | MPa |

| Forgings | up to 100 | Normalization | 640 | 55 | 28 | 175 | 353 |

| 100–300 | 590 | 50 | 24 | 175 | 353 |

| Rolled hot rolled products. | up to 20 | Delivery status | 26 | 245 | 370–480 |

Impact strength of steel VSt3sp

| Delivery condition, heat treatment | +20 | after mechanical aging | -20 |

| Sheet cross section 5-9 mm | 78 | 39 | 39 |

| Sheet cross section 10-25 mm | 68 | 29 | 29 |

| Sheet cross section 26-40 mm | 49 |

| Wide strip with a longitudinal section of 5-9 mm | 98 | 49 | 49 |

| Wide strip with a longitudinal section of 10-25 mm | 78 | 29 | 29 |

| Wide strip with a longitudinal section of 26-40 mm | 68 |

| Long and shaped rolled steel with a longitudinal section of 5-9 mm | 108 | 49 | 49 |

| Long and shaped rolled steel with a longitudinal section of 10-25 mm | 98 | 29 | 29 |

| Long and shaped rolled steel with a longitudinal section of 26-40 mm | 88 |

Endurance limit, MPa

| Assortment | Dimensions – thickness, diameter, mm | sв | N | s-1 |

| The sheet is hot rolled. – smooth sample | 40 | 107 | 191 |

| notched specimen | 10 | 107 | 93 |

| 440 | 2x103 | 213 |

Impact strength VSt3sp

| Delivery condition, heat treatment | +20 | after mechanical aging | -20 |

| Sheet cross section 5-9 mm | 78 | 39 | 39 |

| Sheet cross section 10-25 mm | 68 | 29 | 29 |

| Sheet cross section 26-40 mm | 49 |

| Wide strip with a longitudinal section of 5-9 mm | 98 | 49 | 49 |

| Wide strip with a longitudinal section of 10-25 mm | 78 | 29 | 29 |

| Wide strip with a longitudinal section of 26-40 mm | 68 |

| Long and shaped rolled steel with a longitudinal section of 5-9 mm | 108 | 49 | 49 |

| Long and shaped rolled steel with a longitudinal section of 10-25 mm | 98 | 29 | 29 |

| Long and shaped rolled steel with a longitudinal section of 26-40 mm | 88 |

Brand VSt3sp – physical properties

| t | r | R 109 | E 10-5 | l | a 106 | C |

| 0C | kg/m3 | Ohm m | MPa | W/(m deg) | 1/Grad | J/ (kg deg) |

| 20 | 7850 | 1.94 |

| 100 | 1.92 |

| 200 | 1.87 |

| 300 | 1.83 |

| 400 | 1.78 |

| 500 | 1.67 |

| 600 | 1.59 |

| 700 | 1.46 |

| 800 | 1.2 |

| 900 | 0.99 |

Standards

| Name | Code | Standards |

| Sheets and strips | B33 | GOST 10885-85, TU 108.1273-84, TU 14-1-3579-83, TU 14-1-4912-90, TU 14-1-5032-91, TU 302.02.988-92, TU 14-1-5241 -93, TU 14-1-4431-88 |

| Classification, nomenclature and general norms | IN 20 | GOST 19281-89, GOST 380-2005 |

| Ribbons | B34 | GOST 19851-74 |

| Steel pipes and connecting parts for them | B62 | GOST 3262-75, GOST 8696-74, GOST 10704-91, GOST 10705-80, GOST 10706-76, GOST 10707-80, GOST 12132-66, GOST 20295-85, GOST 24950-81, STO 79814898 105-20 08 , TU 14-3-1160-83, TU 14-3-1428-86, TU 14-3-1473-87, TU 14-3-377-87, TU 1380-001-08620133-93, TU 1380-001 -08620133-05, TU 14-3Р-56-2001, TU 1303-002-08620133-01, TU 1373-013-02949352-2003 |

| Ribbons | B24 | GOST 3560-73, GOST 6009-74, STP M309-74 |

| Long and shaped rolled products | B22 | GOST 4781-85, GOST 5267.0-90, GOST 5422-73, GOST 5781-82, GOST 8239-89, GOST 8240-97, GOST 8278-83, GOST 8281-80, GOST 8282-83, GOST 8283-93, GOST 8509-93, GOST 8510-86, GOST 9234-74, GOST 10884-94, GOST 11474-76, GOST 12492.1-90, GOST 12492.2-90, GOST 12492.4-90, GOST 12492.5-90, GOST 12492.13 -90, GOST 12492.14-90, GOST 19240-73, GOST 19425-74, GOST 19771-93, GOST 19772-93, GOST 25577-83, GOST 26020-83, GOST 30565-98, GOST 535-2005, GOST 30136-95, GOST 2590-2006, GOST 2591-2006, GOST 2879-2006, OST 5.9086-85, OST 5.9087-84, TU 14-2-341-78, TU 14-2-949-91, TU 14-1-5282- 94, STO ASChM 20-93, TU 14-1-5283-94, TU 14-105-568-93, TU 14-1-5254-94 |

| Rails. Overlays. Linings. Crutches | B42 | GOST 5812-82, GOST 8142-89, GOST 16277-93 |

| Sheets and strips | B23 | GOST 82-70, GOST 8568-77, GOST 14637-89, GOST 14918-80, GOST 16523-97, GOST 19903-74, GOST 16523-89, GOST 16523-70, GOST 103-2006, GOST 19903-90, TU 36.26.11-5-89, TU 108-1126-82, TU 14-1-3023-80, TU 14-1-4632-93 |

| Metal forming. Forgings | B03 | GOST 8479-70, TU 108-11-908-87, ST TsKBA 010-2004 |

| Long and shaped rolled products | B32 | OST 1 92049-76, TU 14-105-454-86, TU 14-2-849-89, TU 14-11-245-88, TU 14-1-1271-75, TU 14-136-367-2008 |

| Blanks. Blanks. Slabs | B31 | OST 3-1686-90, TU 14-1-4944-90 |

| Welding and cutting of metals. Soldering, riveting | B05 | OST 36-58-81, OST 26-260.453-92 |

| Thermal and thermochemical processing of metals | B04 | ST TsKBA 026-2005 |

| Test methods. Package. Marking | B29 | TU 14-106-485-99 |

Legend

Mechanical properties

| HRСе | HB | KCU | y | d5 | sT | sв |

| MPa | kJ/m2 | % | % | MPa | MPa |

| Rockwell hardness | Brinell hardness | Impact strength | Relative narrowing | Elongation at break | Yield strength | Short-term strength limit |

| Ku | s0.2 | t-1 | s-1 |

| Relative machinability factor | Proof of yield strength with 0.2% tolerance when loaded to plastic strain value | Torsional endurance limit (symmetrical cycle) | Endurance limit under compression-tension (symmetrical cycle) |

| N | number of deformation/stress cycles sustained by an object under load before fatigue failure/crack appears |

Mechanical characteristics

| Section, mm | sТ|s0.2, MPa | σB, MPa | d5, % | d4 | y, % | kJ/m2, kJ/m2 | Brinell hardness, MPa |

| Electric welded straight-seam pipes (Dy=10-530 mm) as delivered. The mechanical properties of the base metal are indicated |

| ≥225 | ≥372 | ≥22 | — | — | — | — |

| Solid rolled rings according to OST 1 92049-76. Normalization |

| 100 | ≥215 | ≥355 | ≥16 | — | — | — | — |

| Straight-seam electric welded pipes according to TU 1303-002-08620133-01 as delivered (the wall thickness is indicated in the cross-section) |

| 20-25 | ≥235 | 370-480 | ≥25 | — | — | ≥290 | — |

| 6-20 | ≥245 | 370-480 | ≥26 | — | — | ≥290 | — |

| Forgings. Normalization |

| 100-300 | ≥175 | ≥355 | ≥24 | — | ≥50 | ≥590 | 101-143 |

| 100 | ≥175 | ≥355 | ≥28 | — | ≥55 | ≥640 | 101-143 |

| 100-300 | ≥195 | ≥390 | ≥23 | — | ≥50 | ≥540 | 111-156 |

| 100 | ≥195 | ≥390 | ≥26 | — | ≥55 | ≥590 | 111-156 |

| Hot-rolled thick sheets, sections and shapes in delivery condition |

| 10-20 | ≥245 | 370-480 | ≥26 | — | — | — | — |

| 20-40 | ≥235 | 370-480 | ≥25 | — | — | — | — |

| 40-100 | ≥225 | 370-480 | ≥23 | — | — | — | — |

| 10 | ≥245 | 380-490 | ≥26 | — | — | ≥1080 | — |

| 100 | ≥205 | 370-480 | ≥23 | — | — | — | — |

| Blanks for pipeline fittings. Exposure at 900-950 °C (2.5-4.0 hours depending on the thickness and weight of the workpiece) hardening in air |

| 300 | ≥195 | ≥390 | ≥23 | — | ≥50 | ≥540 | 111-156 |

| Hot-rolled thin sheets in delivery condition (strength group indicated) |

| ≤2 | ≥235 | 360-530 | — | ≥20 | — | — | — |

| 2-3.9 | ≥235 | 360-530 | — | ≥22 | — | — | — |

| ≤2 | ≥255 | 370-530 | — | ≥20 | — | — | — |

| 2-3.9 | ≥255 | 370-530 | — | ≥22 | — | — | — |

| Cold-rolled thin sheets in delivery condition (strength group indicated) |

| ≤2 | ≥235 | 360-530 | — | ≥22 | — | — | — |

| 2-3.9 | ≥235 | 360-530 | — | ≥24 | — | — | — |

| ≤2 | ≥255 | 370-530 | — | ≥22 | — | — | — |

| 2-3.9 | ≥255 | 370-530 | — | ≥24 | — | — | — |

| Thick plates are in delivery condition according to TU 14-1-5241-93. Quenching + Tempering (transverse samples) |

| 20-40 | ≥235 | 370-480 | ≥25 | — | — | — | — |

| 40-50 | ≥225 | 370-480 | ≥23 | — | — | — | — |

| 8-20 | ≥245 | 370-480 | ≥26 | — | — | — | — |

| Sections and shaped rolled products made of high-strength steel as delivered in accordance with GOST 19281-89 (strength class indicated) |

| ≤20 | ≥265 | ≥430 | ≥21 | — | — | — | — |

| Hot rolled billet dimensions 140x120 mm |

| — | ≥220 | ≥445 | ≥33 | — | ≥59 | — | — |

| — | ≥205 | — | — | — | — | — | — |

| — | ≥180 | ≥285 | ≥34 | — | ≥80 | — | — |

| Hot-rolled sheets and shapes up to 30 mm thick |

| — | 205-340 | 420-520 | 28-37 | — | 56-68 | — | — |

| — | 215-285 | — | — | — | — | — | — |

| — | 205-265 | — | — | — | — | — | — |

| — | 155-255 | 275-490 | 34-43 | — | 60-73 | — | — |

| — | 125-175 | 215-390 | 36-43 | — | 60-73 | — | — |

| A sample with a diameter of 6 mm and a length of 30 mm is forged and normalized. Strain rate 16 mm/min, strain rate 0.009 1/s |

| — | ≥73 | ≥100 | ≥57 | — | ≥96 | — | — |

| — | ≥51 | ≥63 | ≥95 | — | ≥95 | — | — |

| — | ≥38 | ≥65 | ≥84 | — | ≥100 | — | — |

| — | ≥25 | ≥43 | ≥79 | — | ≥100 | — | — |

| — | ≥19 | ≥31 | ≥80 | — | ≥100 | — | — |

| — | ≥14 | ≥25 | ≥84 | — | ≥100 | — | — |

Tendency to temper brittleness

Not inclined.

Mass fraction of elements no more than, %:

| Silicon | Manganese | Copper | Arsenic | Nickel | Sulfur | Carbon | Phosphorus | Chromium |

| 0,12–0,3 | 0,4–0,65 | 0,3 | 0,08 | 0,3 | 0,05 | 0,14–0,22 | 0,04 | 0,3 |

| Assortment | GOST | Dimensions – thickness, diameter | Heat treatment mode | t | KCU | y | d5 | st | sв |

| mm | 0C | kJ/m2 | % | % | MPa | MPa |

| Forgings | up to 100 | Normalization | 640 | 55 | 28 | 175 | 353 |

| 100–300 | 590 | 50 | 24 | 175 | 353 |

| Rolled hot rolled products. | up to 20 | Delivery status | 26 | 245 | 370–480 |

Other brands in this category:

- Brand VSt2kp

- Brand VSt2ps

- Brand VSt2sp

- Brand VSt3Gps

- Brand VSt3kp

- Brand VSt3ps

- Brand VSt4kp

- Brand VSt4ps

- Brand VSt5ps

- Brand VSt5sp

- Brand VSt6ps

- Brand VSt6sp

- Brand St0

- Brand St1

- Brand St1kp

- Brand St1ps

- Brand St1sp

- Brand St2kp

- Brand St2ps

- Brand St2sp

- Brand St3Gps

- Brand St3Gsp

- Brand St3kp

- Brand St3ps

- Brand St3sp

- Brand St4kp

- Brand St4ps

- Brand St4sp

- Brand St5Gps

- Brand St5ps

- Brand St5sp

- Brand St6ps

- Brand St6sp

Technological properties

| Name | Meaning |

| Weldability | Weldable without restrictions; welding methods: RDS, ADS under submerged arc and gas shield, ESW, KTS. For thicknesses greater than 36 mm, preheating and subsequent heat treatment are recommended. For manual arc welding, MP-3 or UONI13/45A electrodes are used; for automatic submerged arc - wire Sv-08A, Sv-08GA or Sv-10G2 with flux AN-348A; for welding in shielding gases Ar and CO2 - welding wire Sv-08G2S. |

| Tendency to temper brittleness | Not inclined. |

| Forging temperature | Start - 1300 °C, end - 750 °C. Air cooling. |

| Flock sensitivity | not sensitive. |

| Machinability | In the hot-rolled state at HB 124 and sB = 400 MPa Kn solid alloy = 1.8 Kn b.st. = 1.6. |

Application of VST3 steel

In relation to welding work carried out using any type of welding equipment, this steel is extremely convenient: it does not require preheating. The ease of processing can also be seen in stamping work, which can be carried out with the material in both hot and cold states. In general, VST3 structural steel is indispensable for both builders and metal processors. 1-10 mm rolled steel is used for the manufacture of frames, frames, shields, casings and covers of industrial machines, i.e. parts that do not experience heavy loads and operate without friction.

A separate modification of st3gsp is used for the production of angles, channels and I-beams; Load-bearing elements of welded structures are made from St3ps material. Structural steel is also reinforcement that is obtained after calibrating hot-rolled rods. Cold rolling makes it possible to obtain drawn steel, from which clamps, frames, mounting fittings, wire, mesh, water and gas pipes, etc. are subsequently produced.

Interpretation of steel grade VSt3ps

Interpretation of steel: The letter B at the beginning denotes a group of steel that determines the tensile strength criteria for the chemical composition. Steel, in the name starting with the letter B, the strength is 20-30 MPa lower than steel of group A. The following letters St. indicate that the steel is of ordinary quality, although most steels are high quality. The numbers from 0 to 6 are the conventional brand number depending on the chemical composition and mechanical properties. Typically, the higher the number, the more carbon and the greater the strength. In our case, 3 indicates the carbon content in the alloy is 0.14–0.22%. The letters after the brand number indicate the degree of deoxidation: ps - semi-calm.

Brand: steel, metal VSt3sp

Brand: VSt3sp

| Brand: | VSt3sp |

| Substitute: | VSt3ps |

| Classification: | Structural carbon steel of ordinary quality |

| Application: | load-bearing elements of welded and non-welded structures and parts operating at positive temperatures. Shaped and sheet products (5th category) - for load-bearing elements of welded structures operating under variable loads: with a thickness of rolled products up to 25 mm in the temperature range from -40 to +425 ° C; for rolled products with thickness over 25 mm - from -20 to +425 °C, subject to delivery with guaranteed weldability. |

| Foreign analogues: |

| C | Si | Mn | Ni | S | P | Cr | Cu | As |

| 0.14 — 0.22 | 0.12 — 0.3 | 0.4 — 0.65 | up to 0.3 | up to 0.05 | up to 0.04 | up to 0.3 | up to 0.3 | up to 0.08 |

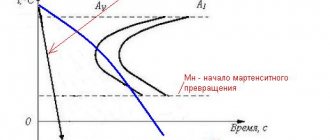

| Ac1 = 735, Ac3(Acm) = 850, Ar3(Arcm) = 835, Ar1 = 680 |

| Weldability: | no limits. |

| Flock Sensitivity: | not sensitive. |

| Tendency to temper brittleness: | not inclined. |

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Forgings | up to 100 | 353 | 175 | 28 | 55 | 640 | Normalization |

| Forgings | 100 — 300 | 353 | 175 | 24 | 50 | 590 | Normalization |

| Rolled hot rolled products. | up to 20 | 370-480 | 245 | 26 | Delivery status |

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 1.94 | 7850 |

| 100 | 1.92 |

| 200 | 1.87 |

| 300 | 1.83 |

| 400 | 1.78 |

| 500 | 1.67 |

| 600 | 1.59 |

| 700 | 1.46 |

| 800 | 1.2 |

| 900 | 0.99 |

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

Foreign analogues of the material

Both exact and closest analogues are indicated!

| USA | Germany |

| — | DIN,WNr |

| | | Mechanical properties : | | sв | — Short-term strength limit, [MPa] | | sT | — Proportional limit (yield strength for permanent deformation), [MPa] | | d5 | — Elongation at break, [%] | | y | — Relative narrowing, [%] | | KCU | — Impact strength, [kJ/m2] | | HB | — Brinell hardness, [MPa] |

| Physical properties: | | T | — Temperature at which these properties were obtained, [Deg] | | E | — Modulus of elasticity of the first kind, [MPa] | | a | — Coefficient of thermal (linear) expansion (range 20o - T), [1/degree] | | l | — Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] | | r | — Material density, [kg/m3] | | C | — Specific heat capacity of the material (range 20o — T), [J/(kg deg)] | | R | — Electrical resistivity, [Ohm m] |

| Weldability: | | no limits | — welding is performed without heating and without subsequent heat treatment | | limited weldability | — welding is possible when heated to 100-120 degrees. and subsequent heat treatment | | difficult to weld | — to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding - annealing |

|