Let's look at forging operations in detail, with videos and drawings.

You may need the following links:

- Where to buy a hammer https://fas.st/Jzz1Zf

- Where to buy an anvil https://fas.st/ujTE_

- Where to buy pliers.

- How to make pliers is here, and here is a simplified version from construction ones.

- How to make an anvil with your own hands.

Classification, types of broaches and their application.

1. As intended

broaches are divided into two groups.

For treating internal surfaces

(holes):

— round — for processing round holes;

- spline - for processing spline holes;

— keyed – for processing keyways;

— faceted – for multifaceted surfaces;

— broaches for processing helical grooves.

For treating external surfaces

various profiles:

— broaches for processing gears;

— broaches for pulling cylindrical surfaces of shafts;

— broaches for external splines of various profiles on shafts;

— broaches for producing dovetail-shaped grooves, T-slots, herringbone profiles, etc.

2. By design

broaches can be:

3. In the direction of the blades

Regarding the speed of the main movement, they are distinguished:

— broaches with ring and screw teeth. These are broaches for internal pulling.

- broaches with straight and inclined teeth. These are broaches for external broaching, flat and keyed.

4. According to the material of the cutting part

distinguish:

- broaches made of tool steel,

5. According to the applied cutting pattern

broaches are distinguished from:

— profile (or ordinary);

— progressive (or group);

— generator (or step) cutting schemes.

6. According to the number of broaches in the set

broaches are distinguished:

Broaches and broaching machines for metal broaching

A broach is a tool with which metal is processed by broaching (one of the most common technological operations for metal cutting). This technology is used for parts used in many industries.

The working surface of the broaches can have a different profile depending on the purpose and type of tool

What are broaches?

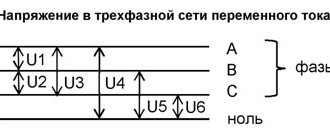

Broaches are a tool that is used during electrical installation work. Its job is to guide the target cable to its destination. At home, a broach can be made from available materials. The main thing is to ensure rigidity when running the cable. But if the length of the wire is more than 10 meters, then improvised means are unlikely to be useful. It will be necessary to use broaches. To achieve the desired result in your work, your choice must be treated with special responsibility.

In the store, broaches are presented in coils and have different characteristics. When choosing them, pay special attention to the length, since if it is not enough, this device will become useless. The length can range from 6 to 71 meters, and the diameter from 3 to 6 mm. The most commonly used broach is 51 m with a diameter of 3.5 mm. This is considered a standard size. This diameter is perfect for home work, but in production you need to use a thickness greater than 5.5 mm.

Why is stretching necessary?

A technological operation such as broaching is considered one of the most effective methods of metal cutting. To carry it out, you need a broaching machine and a special tool, the use of which gives a surface with a roughness of the order of 0.32 microns and an accuracy of geometric parameters corresponding to grade 6.

The tool used to perform broaching metal cutting consists of many teeth. Each is taller than the other when measured in a plane perpendicular to the direction in which the main cutting motion is carried out. Equipping the broach with many cutting blades and placing them in a certain position allows you to use only one such tool in order to remove the entire required volume of chips both during roughing of the surface and during its calibration.

Most broaching machines are set up for processing similar parts

Using broaching machines, as well as specialized tools, it is possible to process both external and internal surfaces of products of various configurations. When broaching, no feed movement is used: all processing is carried out by the main movement of the broach, which can be rotational or translational. The hole punching tool works on a similar principle. Despite the similarity of these technological operations, the fundamental difference between them is that the broaching tool works in compression, while broaching works in tension.

The video below shows the process of processing the inner surface of a pipe using the pulling method.

Broaching, when compared with other methods of metal cutting, has a whole list of advantages, which include:

- the possibility of reducing the cost of operating the equipment used;

- high wear resistance of the broach;

- high rate of minute feed due to the fact that processing is performed by several cutting teeth at once;

- the ability to work on broaching machines even for specialists with a low level of professional training;

- removal of stock from the surface at a high relative speed (this means high processing productivity);

- the ability to eliminate any types of defects in the treated surface;

- high precision processing of metal products.

Schemes of various types of broaching holes and surfaces

The tools that broaching machines are equipped with are made mainly from high-speed steels with a medium alloy level, which are quite expensive. For this reason, its use is recommended for industries that produce their products in large and mass batches.

Meanwhile, broaching machines and broaching can be used for small-scale and single-piece production of metal products, if their geometric parameters are standardized. One cannot do without such a technological operation even in cases where it is the only possible or most profitable method of processing.

Manufacturers

A practical and domestic manufacturer is Elix-Cable products. Its products have low prices and good technical characteristics. This company is perfect for installations in the home. But if we are talking about production, then it is advisable to use Estiare brands. The products of this company are more durable and have a wide selection of additional accessories that will make broaching easier.

Thanks to broaching, you will save a lot of time, and by choosing suitable lugs or rollers, you will not damage the twisted pair! We hope this information was useful and interesting.

Similar articles on the topic

Share your opinion Cancel reply

Popular on the site

Polls

Our All-Electricity website provides you with detailed information about electricians. Publication of our materials may only be permitted if you provide a link to the source indicating our project. Before using our project, we recommend reading the user agreement. All information on the All-Electricity website is provided for informational and educational purposes. The site administration is not responsible for the use of this information.

Types and design of broaches

Broaches are classified according to a number of parameters. The following types of broaches are distinguished:

- with a cutting part made of high-speed, tool steel or hard alloy;

- solid or prefabricated - depending on the design;

- single- or multi-pass - depending on how many broaches are contained in one working set;

- working using a stepwise, profile or progressive method - depending on how the allowance is removed from the surface of the part;

- with straight and inclined or helical and ring arrangement of cutting blades on the working part.

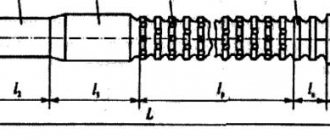

Significant elements of a round broach

Various types of broaches are also distinguished according to their main purpose, and this classification can be called one of the most important. So, depending on this parameter, broaches for external and internal surfaces are distinguished. Using a tool designed for external work, it is possible to process surfaces of various configurations (gears, herringbone profiles, grooves, including T-type, cylindrical shafts, grooves of various shapes, including dovetail, splined shafts, etc.).

Broaching can process surfaces of various profiles

Hole broaching is a more common process operation than external surface broaching. Using a broaching machine and a broach, the following types of internal surfaces can be machined:

- keyways;

- screw type grooves;

- round holes (broaches for round holes);

- holes with different numbers of edges (faceted broaches);

- holes with slots (slotted broaches).

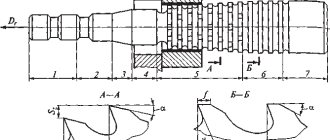

Slotted broach for machining holes

Despite the fact that different types of broaches are used to process internal surfaces, the design of these tools is almost identical and includes several components.

This is the guiding element. Before processing, the part is fixed precisely on the front part of the tool, which then smoothly transfers the processed surface to the cutting edges of the broach. The nominal cross-section of the front part of the tool and the size of the hole being machined must match, and the choice of the degree of fit is carried out taking into account the required gap between the broach and the walls of the hole.

Using this element, the broach is fixed in the chuck of the equipment used. For broaches of both round and flat types, the dimensions of the shanks are strictly specified by the provisions of the relevant regulatory documents (GOSTs 4043-70 and 4044-70).

Standard spline broach shank

This broach element consists of many teeth and is responsible for removing the required allowance from the machined surface. The geometric parameters of the cutting teeth of the broach, starting from its front part and ending with the rear, gradually change. Thus, the front tooth has the shape and dimensions of the hole that is to be processed, and the rear cutting element has geometric parameters corresponding to the characteristics of the finished hole. Due to the fact that the height of the broach teeth gradually increases towards its rear, there is no feed movement during processing, and the allowance is effectively removed from the surface being processed.

Main elements of the cutting part of the keyway broach

Long and heavy broaches are equipped with this element in order to ensure their support with the help of a steady rest.

Rear guide part

This part of the broach is necessary so that the workpiece does not become warped when the last cutting tooth leaves its hole.

This element is characterized by fewer teeth than the cutting part of the broach. The shape and dimensions of the teeth located on the calibrating part are completely identical to those of the finished hole.

In order to identify errors, the parameters of the broaches are periodically monitored. The photo shows checking the front and rear angles of the keyway broach

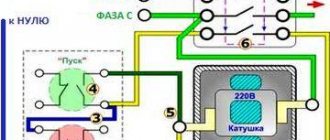

UZK operation procedure

High-quality laying of wires is possible only if the broach is used correctly. The method for using the probe is as follows:

- Initially, you will need to route the probe into the required switching channel without a wire. After installing the tip of the probe into the inlet of the channel, you should push the cable until it comes out on the other side. This process may be accompanied by difficulties that are caused by the presence of turns, and sometimes even contamination, in the internal cavity of the wire channels.

- It is recommended to carry out work with smooth, forward movements so that the probe has time to straighten after passing through difficult areas.

- After the probe appears from the end point of the switching channel, a wire should be attached to it using a specialized tip.

- The next step will be laying the wire into the channel by pulling the pulling cable back.

- After the fixed cable appears to the probe from the side of the first hole, you should disconnect the fixing tip and make the required connection of the supply wires.

Types of spline broaches and areas of their application

Splined broach, as mentioned above, is used for processing internal surfaces on which there are splined elements. Such tools, depending on the number and type of cutters with which they are equipped, can be:

- involute;

- sharp-slotted;

- 6-spline;

- 8-spline;

- 10-spline.

The broach for slotted holes TsL-2408-4333-8Х42Х46 is made of R6M5 steel

Splined broaching, depending on its type, can be produced according to one of the following regulatory documents:

- with an involute type profile: 50038-92 – two-pass combined; 50035-92, 28050-89 – conventional combined type; 25158-82, 25159-82 – for processing holes with a cross-section of 15–90 mm; 25157-82 – for processing holes with a cross-section of 12–14 mm; 25160-82 – for processing holes with a cross-section of 45–90 mm;

- with a straight-sided profile: 25971-83, 25972-83 – for processing eight-spline holes; 25969-83, 25970-83 – for processing six-spline holes; 24822-81, 24823-81 – for ten-spline holes;

- with screw-on shank: P 50035-92, 50036-92, 50037-92, 28048-89, 28049-89, etc.

In some cases, when it is not possible to select a standard tool, the manufacture of broaches can be carried out according to specially developed design documentation.

Using spline-type broaches, you can effectively perform the following technological operations:

- cutting keyways and splines;

- processing of rifled weapon barrels;

- calibration of internal holes of various types;

- production of aircraft engine turbine elements;

- stretching external surfaces with complex configurations.

Broaching Equipment

Broaching machines are divided into different types according to a number of parameters. These parameters, in particular, are:

- purpose - for processing external or internal surfaces;

- degree of versatility – machines for general and highly specialized purposes;

- the direction in which the drawn element moves (working movement) - horizontal broaching machines or vertical broaching machines;

- type of working movement performed - with a circular movement, with a broaching or workpiece movement;

- number of carriages installed on the machine - single or multi-carriage;

- number of positions occupied by the working mechanism of the machine - single- and multi-position (with a rotating work table);

- level of automation – with and without CNC.

What features do steel broaches have?

It is very important what material the broach is made of, as this will affect its working properties. At the moment, steel broaches are quite practical. In it, the rod is packaged in a nylon sheath, which gives the surface slip and ease of installation. At the same time, the base will retain its flexibility and elasticity.

Steel broach for cable

The steel tape base provides this effect, thanks to which you can easily overcome all bends and reach the fixation point. This cannot be achieved by working with nylon broaches or fiberglass.

Cable pull (UZK). Types and work. Device and how to choose

Pulling, or UZK (cable laying device) is a highly specialized installation tool that is used in the installation of electrical, computer and telephone systems. A cable puller allows you to pull the wire through hard-to-reach places where it begins to bend and therefore does not pass through on its own. In this case, the probe is first installed, after which a wire is attached to one of its ends. The broach is removed, while pulling the cable along with it. The peculiarity of ultrasonic testing is its greater rigidity and tendency to level, which allows for controlled installation through voids, boxes and pipes.

What is a cable pull?

A pull can be used to pull electrical or other types of wires into communication channels. The device is a rod twisted into a coil that can be easily straightened. Inside it there is a cord that forms an elastic rod. The reinforcing fibers and radial threads that surround the core make the structure flexible and rigid enough to overcome complex shaped voids. At the same time, the probe is tensile strength, so it is capable of dragging along even a thick cable or wire that has a large mass.

The outer coating of the broach is abrasion resistant. This reduces the likelihood of damage to the straightened rod during operation. Despite this, with intensive use, the ultrasonic device may well wear out. If you use the device professionally and daily, the service life on average does not exceed 2 years. It largely depends on the materials used.

Broaches are usually marked with two numbers, between which there is a fraction. For example, the inscription on the probe “9/80” means that the diameter of the broach is 9 mm and the length is 80 m.

Where is broaching used?

A cable puller is used to install wires through hard-to-reach places that represent a long void, such as:

- Pipe.

- Box

- Channel.

- Corrugation.

- Insulating sleeve.

- Space under the roof.

- Fixed wall panels, etc.

Basically, broaches are used when it is necessary to lay wires through a previously created structure, with already existing voids for installation, which cannot be disassembled to insert the wire manually without additional devices. Similar situations are encountered when laying telephone or computer communication lines in old houses where they did not exist before. Broaches are also professionally used by installers of intercoms, video surveillance and alarm systems. Using ultrasonic testing, you can lay wires above suspended ceilings or under flooring.

How to work with a broach

To carry out cable installation using a pull-through, it is first laid through the cavity where the wire is to be installed. The end of the ultrasonic probe is inserted into the hole into which the cable should go. The probe is then pushed through the entire installation space until its end comes out the other side. In this case, it is quite possible that you will have to tinker, especially if the cavity has slight bends and irregularities. The more there are, the more difficult it is. Due to the fact that the straightened rod retains sufficient flexibility, it can bend around obstacles and straightens further as it moves.

Once the cable pull comes out from the back of the cavity, a wire is attached to its protruding end. For this purpose, a special tip is used, which securely fixes the cable, creating the impression that the extension wire becomes part of the probe.

Once the cable is secured, all that remains is to pull the broach back from the side from which it entered into the empty cavity. As it is pulled out, the cable will tighten. As soon as the probe leaves the cavity and the end of the wire appears, the broach is disconnected. All that remains is to twist, solder or otherwise connect the wire to the common line.

If you immediately try to pull the wire through the cavity, then in most cases this will not give any result, since it does not have the necessary elasticity and will constantly rest against something. The cable also has a big drawback, namely the memory effect. When unwinding from the coil, it tends to twist back into the rings. The same thing will happen in the cavity if it is wide enough. Pulling does not have a similar effect, so even if it has been stored wound on a reel for years, when unwinding it remains smooth and well controlled.

Types of broaches depending on the material of manufacture

Depending on the material used to make the broach, there are 3 types:

- Steel.

- Fiberglass.

- Nylon.

Steel is a metal wire covered with a nylon sheath on top. This system is resistant to stretching and can withstand heavy loads if it is necessary to pull the cable through hard-to-reach places. Such systems cope well with L-shaped turns and standard cable channels.

Fiberglass broaches have high rigidity. They are capable of straightening even after many years of storage in a rolled coil. This probe is great when you need to go through a straight line. Fiberglass is a rather fragile material, so if you have to make a sharp bend, the probe may crack and break under tension.

What other material can broaches be made of?

Broaches can also be made of plastic. They provide a high degree of rigidity and strength. Thanks to them, it is possible to push through all possible dirt accumulations on the way to fixation. At the same time, the shape of the plastic does not deteriorate, but retains its original condition. But there is a very big disadvantage in such broaches - under heavy bending loads they break.

There are auxiliary materials that improve the quality of broaching. These include nylon, Kevlar and its fibers. These substances are also used in combination with protective corrugations for wiring.