In the history of iron metallurgy, there were three revolutionary upheavals that had a profound impact on the entire course of human history: the first took place in ancient times, when cheese furnaces appeared; the second occurred in the Middle Ages, after the discovery of the remaking process; the third occurred in the second half of the 19th century and was associated with the beginning of cast steel production. Steel at all times remained the most necessary and desirable product of iron metallurgy, because only it possessed the hardness and strength required for the manufacture of tools, weapons and machine parts. But before being transformed into a steel product, the metal had to undergo a number of labor-intensive operations. First, cast iron was smelted from ore. The cast iron was then reduced to soft iron. Finally, by lengthy forging of the iron core, the necessary steel part was obtained from it (or only a blank for it, which was then subjected to final finishing on metal-cutting machines).

The production of soft iron and especially forging have long been the bottlenecks in the iron processing process. They took the most effort and time, and the results were not always satisfactory. This problem became especially acute in the 19th century, when the demand for cheap steel increased sharply.

Naturally, many scientists and inventors had an idea, which was later expressed by Bessemer: how to obtain metal with the properties of iron and steel, but in liquid form, so that it could be used for casting? Resolving this problem required several decades of hard work by many metallurgists. Along this path, several important discoveries and inventions were made, each of which constituted an era in the history of iron processing. But in this essay we will talk specifically about the open-hearth process.

Let us consider the production of cast steel in open-hearth furnaces of metallurgical or machine-building plants. Steel is produced by oxidative smelting of iron-containing materials loaded into a furnace - cast iron, scrap steel, iron ore and fluxes as a result of complex physical and chemical processes of interaction between the metal, slag and the gaseous environment of the furnace.

Open hearth furnaces, along with other types of steel production, are the second link in the overall production cycle of ferrous metallurgy; The other two main steps are the smelting of iron in blast furnaces and the rolling of steel ingots or billets.

Steel production in open hearth furnaces - Metalworker's Handbook

By design, open hearth furnaces are divided into:

- stationary;

- swinging.

Stationary ovens are most widespread.

Oscillating furnaces are mainly common in foundries of machine-building plants, when it is necessary to produce metal in separate portions or download large amounts of slag.

Depending on the composition of the charge used in smelting, there are different types of open-hearth process:

- scrap-ore process, in which the charge consists of liquid cast iron (55 - 75%), scrap and iron ore. The process is used in metallurgical plants that have blast furnaces;

- scrap process in which the charge consists of steel scrap and pig iron (25 - 45%). The process is used in factories that do not have blast furnaces, but are located in industrial centers where there is a lot of scrap metal.

What is an open hearth furnace?

An open hearth furnace is a special metallurgical installation in which steel is produced from scrap iron and cast iron.

With the help of convective flows of a hot gas-air mixture, the heating process itself occurs, as well as further melting of the material.

Below is a photo of an open hearth furnace and a steelmaker servicing it, as well as controlling the metal smelting process:

Photo 1

Photo 2

Photo 3

History of appearance

The open hearth furnace was invented by French metallurgical engineer Pierre Emile Martin in 1864. Since that time, this is the official date of the invention of the open-hearth furnace.

In the second half of the 19th century, open hearth units became a real breakthrough in steel production.

In Russia, the first open-hearth furnaces appeared in 1870 at the Sormovsky plant near Nizhny Novgorod. Engineer A. Iznoskov took an active part in their creation.

Thanks to the intensive development of industry in the USSR, in the 30s of the 20th century, by the beginning of the Great Patriotic War, this plant consistently provided the Soviet army with spare parts, parts of steel and cast iron hulls for military equipment.

Device

The main elements representing the structure of an open hearth furnace are:

- A body consisting of front and rear walls, as well as its arch.

- Heads equipped with channels located vertically. Through them, gas exchange occurs between the working chamber and the external environment, and fuel is also supplied.

- Slag tanks are air and gas type, in which coarse-grained smelting dust is collected and accumulated.

- Regenerators, which provide a stable temperature of the supplied gas and air, due to the thermal energy coming out of the working chamber.

- Pipe for removing smoke and gases.

- Waste heat boiler.

- Reversing control valves, their function is to remove combustion products, as well as to properly supply gas fuel and air into the chamber.

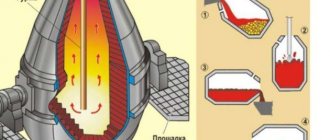

Below are typical diagrams of open hearth furnaces:

Principle of operation

An open hearth furnace is a flaming reflective mechanism that operates on the principle of metal regeneration. Natural gas or fuel oil is burned in the working space.

The temperature in an open hearth furnace can reach 18,000 degrees Celsius. This high temperature level is maintained through the recovery of thermal energy from furnace gases.

Description of operating principle:

- Gas heated to 1200 - 1250 degrees enters the working chamber, where the process of mixing it with fuel occurs. The resulting torch is directed to the charge and the metal is smelted from it.

- In turn, the exhaust gases, mixed with charge dust, are removed through the chimney into the atmosphere, undergoing filtration in the regenerator. At the end of the cycle, the regenerators and vertical heads are switched using valves. The process is repeated in a mirror image, thanks to the symmetrical design of the open hearth.

- The process of producing steel in such an installation lasts several hours. During work, the steelmaker carries out a control extraction of the melt with a special device, after which he sends it to the workshop laboratory to determine the percentage of metal and impurities, such as manganese, phosphorus, sulfur and others.

- Based on the results of this analysis, special additives are added to the working chamber to improve the quality of steel. At the end of the process, a procedure is carried out to remove oxygen from the melt using deoxidizers, these are ferromanganese, aluminum and ferrosilicon.

Design

The elements of an open hearth furnace are (standard assembly option):

- Under the stove.

- Front and back walls.

- Arch.

- Loading windows through which material is fed into the furnace for processing.

- Powerful concrete supports.

- Slopes towards the walls.

- Air channel, which is also called heads.

- Gas channel for supplying heating material - gas.

- Vertical channels.

- An important part of the design are the so-called slag tanks of air and gas regenerators.

The front wall of the furnace is equipped with loading windows; the charge is supplied here. The back wall has a hole for unloading finished steel.

Heat and material balance of melting

For two typical compositions:

Material balance 1

- Consumption: scrap - 66, cast iron - 34, limestone - 4, filling material - 3, ore - 2, ferromanganese - 1

- Incoming: liquid steel - 96, final slag - 8, slag after tapping - 5, CO from carbon oxidation - 3, CO from decomposition of lime and limestone - 2, moisture - 1, beads - 1

Heat balance 1

- Consumption: fuel combustion heat - 61, air heat in regenerators - 29, exothermic reactions of impurity burnout - 8

- Income: carried away with products - 61, losses to the environment - 16, for heating steel - 15, for heating slag - 3

Material balance 2

- Consumption: scrap - 34, cast iron - 66, ore for filling - 15, limestone - 5, filling material (dolomite and magnesite) - 3, ore during the boiling period - 2, ferromanganese - 1

- Incoming: liquid steel - 103, final slag - 8, slag after tapping - 7, CO from carbon oxidation - 6, CO from decomposition of lime and limestone - 2, moisture - 1, beads - 1

Heat balance 2

- Consumption: fuel combustion heat - 48, air heat in regenerators - 20, gas heat in regenerators - 11, exothermic reactions of impurity burnout - 8

- Income: carried away with products - 58, losses to the environment - 15, for heating steel - 20, for heating slag - 5, decomposition of limestone - 1

Technology

Exterior view of the open hearth furnace

The periods of the steel production process in an open-hearth furnace last from five to eight hours (with high-speed steelmaking - up to 4.5-5.5 hours) and consist of the following stages:

- Melting

. Melting begins even before the furnace is loaded. They try to carry out melting at the maximum temperature in order to prevent gases from dissolving in the metal and to prevent excessive oxidation. During this period, silicon, manganese, iron, phosphorus are intensively oxidized, and a large amount of iron oxide FeO{\displaystyle \mathrm {FeO} } is formed. - Oxidation

. Carbon oxidation occurs due to previously formed FeO{\displaystyle \mathrm {FeO} }. Reaction formula: C+FeO=CO+Fe−Q{\displaystyle \mathrm {C+FeO=CO+Fe-Q} }. The resulting carbon monoxide CO {\displaystyle \mathrm {CO} } causes the melt to boil. Within 2-3 hours, the proportion of carbon in the melt decreases and becomes below 2%. - Deoxidation

. If a large amount of FeO{\displaystyle \mathrm {FeO} } is dissolved in the steel by the end of melting, this gives the steel brittleness when hot - red brittleness. To remove oxygen, steel is deoxidized with ferrosilicon, ferromanganese or aluminum. Sometimes, to check, a red-hot piece of steel is forged; if it is poorly deoxidized, cracks form.

If necessary, after deoxidation, alloying elements are introduced: ferrotitanium, ferrochrome, high-silicon ferrosilicon, pure nickel and others.

After melting is completed, the steel is released into the ladle.

To speed up the process and increase productivity by 15-25%, oxygen is used. It is introduced during melting in two ways:

- enriching the flame during the filling and melting of charge materials;

- blowing through a liquid bath during the carbon burnout period.

XXI Century

Since the 1970s, new open-hearth furnaces have no longer been built in the world. The open-hearth process has practically been replaced by the much more efficient (about 63% of world production), as well as electric smelting (more than 30%). According to the results of 2008, the open-hearth method of production accounts for no more than 2.2% of global steel production. Based on the results of 2008, the largest share of steel smelting using the open-hearth method in the world was observed in Ukraine.

In 2022, the last large open-hearth furnace in Russia was closed. After this, this method of steel production was preserved only in Ukraine and India.

Since 1999, the use of oxygen-free low-intensity blast has begun in open-hearth production. The proposed technology of “hidden” bottom blowing was based on the supply of neutral gas through blowing elements installed in the hearth masonry, and the use of special refractory powders for filling it.

Over the course of 6 years, 32 open-hearth furnaces of various capacities - from 110 to 400 tons - were converted to this technology, 26 of which operated using the scrap process. Depending on the capacity of the furnace, 3-5 blowing elements were installed in the hearth with a flow rate of 30-100 l/min per element.

This technology allowed:

- significantly reduce hot and cold downtime, including for hearth repairs;

- reduce the duration of melting by 10-20%;

- increase the productivity of furnaces in actual hours and steel production in the workshop by 12-18%;

- reduce the costs of standard fuel, refueling materials and furnace refractories;

- The durability of the arch and the duration of the campaign during the period between repairs increased by 1.3-2 times.

Double bath steel melting unit

Another type of open hearth furnace, which has two baths connected to each other by a channel for transferring material from one container to another. The steel smelting process occurs as follows:

- Cast iron is poured into one bath and purged with oxygen.

- At the same time, the charge in solid form is filled and heated in the second bath, for which the hot gases escaping from the first tank are used.

- Gradually the process changes and the baths also perform the functions of the previous ones.

With a certain amount of cast iron in the charge (more than 65%), the two-bath furnace begins to operate without fuel consumption, somewhat copying the oxygen converter.

As a conclusion, it is worth saying that the open-hearth method of steel production at one time became a real breakthrough and helped the global industry make a significant breakthrough.

Now the share of its use in world metallurgy does not exceed 2–3%, since modern smelting methods (the same converter process) are much more efficient. True, in some countries, it still accounts for up to 50% of all production volumes.

What is the "hearth" made of?

The working space of a melting plant is subject to the greatest thermal loads. The design of the open hearth furnace is such that the refractory materials of the smelter are under constant thermal and mechanical loads of varying intensity. Chemical processes also contribute to the destruction of refractories. Therefore, the heat resistance and structural strength of the melting compartment, the conditions and stability of its operation determine the main characteristics when choosing materials.

The lining for the hearth depends on the characteristics of the slag that is planned to be obtained during production. For the acid smelting method, the hearth is made from acidic refractories, which are covered with a layer of quartzite sand on top. The back and front walls of the acid smelter are built from siliceous refractory (dinas). For basic slags, a basement is built from basic refractory materials, the top of the structure is covered with magnesite sand, less often with fine-grained dolomite material. The front and rear slopes of the hearth are laid out of magnesite bricks. In places where the bath comes into contact with hot slag, after the end of melting, small sintering occurs, which is removed, and destruction is eliminated by filling with sand (magnesite powder) supplied by the filling machines.

The vault is made from any heat-resistant and fire-resistant materials, but more often silica or magnesite-chromite bricks with increased heat resistance properties are used for lining. The vault is built as a spacer-suspended vault with fastenings and gaskets between the bricks. A horizontal vault layout is used to minimize the volume of the combustion space in order to reduce heat loss for heating the entire volume. Basic magnesite-chromite vaults are used everywhere, since their service life reaches 1000 melts, and the service life of a dinas vault is 200-350 melts.

To ensure conditions for maintaining high temperatures, heads with a system of channels and niches (regenerators, soots, hogs) are built from heat-resistant magnesite-chromite or forsterite bricks (for upper, hotter structures) and fireclay bricks (for lower, “cooler” conditions).

The pipe for removing burnt gas is made of simple ceramic bricks with an internal lining of simple refractory material - fireclay bricks. A number of elements (fences and window covers, vault beams, elements of the changeover valve system) are made of metal. These elements require continuous water or evaporative cooling.

For the construction and repair of open hearths, special large-sized blocks are used, which saves downtime (one melt takes 3-8 hours, repairs and maintenance should take 1 hour). In modern open-hearth furnaces, water cooling is being actively introduced, which replaces the lining. These elements are coated with a special substance - a garnissage, which increases their heat resistance.

Steel production

Steel is one of the most common materials today. It is a combination of iron and carbon in a certain percentage. There are a huge number of varieties of this material, since even a slight change in the chemical composition leads to a change in physical and mechanical properties.

The raw materials for steel production today are represented by waste steel products. The production of structural steel from cast iron was also established. Leading countries in the metallurgical industry produce billets in accordance with the standards established in GOST.

Let's consider the features of steel production, as well as the methods used and how the resulting products are marked.

Features of the steel production process

In the production of cast iron and steel, different technologies are used, despite the fairly similar chemical composition and some physical and mechanical properties.

The differences are that steel contains less harmful impurities and carbon, due to which high performance is achieved. During the smelting process, all impurities and excess carbon, which causes an increase in the fragility of the material, go into slag.

Steel production technology involves forced oxidation of basic elements due to the interaction of iron with oxygen.

Melting steel in an electric furnace

When considering the production process of carbon and other types of steel, several main stages of the process should be highlighted:

- Rock melting. The raw materials that are used to produce metal are called charge. At this stage, during the oxidation of iron, impurities are also deoxidized. Much attention is paid to reducing the concentration of harmful impurities, which include phosphorus. To ensure the most suitable conditions for the oxidation of harmful impurities, a relatively low temperature is initially maintained. The formation of iron slag occurs by adding iron ore. After the release of harmful impurities on the surface of the alloy, they are removed, and a new portion of calcium oxide is added.

- Boiling of the resulting mass. After the preliminary stage of cleaning the composition, baths of molten metal are heated to a high temperature, and the alloy begins to boil. Due to boiling, the carbon contained in the composition begins to actively oxidize. As previously noted, cast iron differs from steel in having too high a carbon concentration, due to which the material becomes brittle and acquires other properties. This problem can be solved by injecting pure oxygen, due to which the oxidation process will occur at high speed. When boiling, bubbles of carbon monoxide are formed, to which other impurities also adhere, due to which the composition is purified. At this stage of production, sulfur, which is a harmful impurity, is removed from the composition.

- Deoxidation of the composition. On the one hand, adding oxygen to the composition ensures the removal of harmful impurities, on the other hand, it leads to a deterioration in basic performance qualities. That is why, to clean the composition from harmful impurities, diffusion deoxidation is often carried out, which is based on the introduction of a special molten metal. This material contains substances that have approximately the same effect on the molten alloy as oxygen.

In addition, depending on the characteristics of the technology used, two types of materials can be obtained:

- Calm ones who have gone through the deoxidation process to the end.

- Semi-quiet, which have a state between calm and boiling steels.

During the production of the material, pure metals and ferroalloys can be added to the composition. Due to this, alloyed compounds are obtained that have their own specific properties.

Steel production methods

There are several methods for producing steel, each with its own specific advantages and disadvantages. The chosen method determines what properties the material can be obtained with. Main methods of steel production:

- Martin's method. This technology involves the use of special furnaces that are capable of heating raw materials to a temperature of about 2000 degrees Celsius. Considering the methods for producing alloy steels, we note that this method also allows the addition of various impurities, due to which steels of unusual composition are obtained. The open hearth method is based on the use of special furnaces.

- Electric steel melting method. In order to obtain high quality material, steel is produced in electric furnaces. By using electrical energy to heat raw materials, it is possible to precisely control the progress of the oxidation process and the release of slags. In this case, it is important to ensure the appearance of toxins. They are a transmitter of oxygen and heat. This technology allows you to reduce the concentration of harmful substances, for example, phosphorus and sulfur. Electric smelting can take place in a wide variety of environments: excess pressure, vacuum, or a certain atmosphere. Conducted research indicates that electric steel is of the highest quality. Technology is used to produce high-quality high-alloy, corrosion-resistant, heat-resistant and other types of steel. To convert electrical energy into heat, a cylindrical arc furnace with a spherical bottom is used. To ensure the most favorable melting conditions, the internal space is finished using heat-resistant metal. The device can only operate when connected to a three-phase network. It is worth considering that the electrical supply network must withstand a significant load. The source of thermal energy is an electric arc that occurs between the electrode and the molten metal. Temperatures can be over 2000 degrees Celsius.

- Oxygen converter. Continuous casting of steel in this case is accompanied by active injection of oxygen, due to which the oxidation process is significantly accelerated. This manufacturing method is also used to produce cast iron. It is believed that this technology has the greatest versatility and allows the production of metals with various properties.

The methods for producing galvanized steel are not very different from those considered. This is due to the fact that the change in the qualities of the surface layer occurs through chemical-thermal treatment.

There are other steel production technologies that are highly efficient. For example, methods based on the use of vacuum induction furnaces, as well as plasma arc welding.

Open hearth method

The essence of this technology is the processing of cast iron and other scrap metal using a reverberatory furnace. The production of various steels in open hearth furnaces can be characterized by the fact that the charge is exposed to high temperatures. To supply high temperature, various fuels are burned.

Scheme of an open hearth furnace

Considering the open-hearth method of steel production, we note the following points:

- Open hearth furnaces are equipped with a system that supplies heat and removes combustion products.

- Fuel is fed into the combustion chamber alternately, from the right and then from the left. This ensures the formation of a torch, which leads to an increase in the temperature of the working environment and its maintenance for a long period.

- At the time of loading the charge, a sufficiently large amount of oxygen enters the combustion chamber, which is necessary for the oxidation of iron.

When producing steel using the open-hearth method, the holding time of the charge is 8-16 hours. Throughout the entire period, the oven operates continuously. Every year the design of the furnace is improved, which makes it possible to simplify the steel production process and produce metals of various qualities.

Today, various steels are produced in oxygen converters. This technology involves purging liquid cast iron in a converter. To do this, pure oxygen is supplied. The features of this technology include the following points:

- A converter is a special equipment, which is represented by a pear-shaped steel vessel. The capacity of such a device is 100-350 tons. The inside of the structure is lined with refractory bricks.

- The design of the upper part includes a neck, which is necessary for loading the charge and liquid cast iron. In addition, gases formed during the melting of raw materials are removed through the neck.

- Pouring cast iron and adding other charge is carried out at a temperature of about 1400 degrees Celsius. In order to ensure active oxidation of iron, pure oxygen is supplied under a pressure of about 1.4 MPa.

- When a large amount of oxygen is supplied, cast iron and other mixtures oxidize, which causes the release of a large amount of heat. Due to strong heating, the entire charge material melts.

- At the moment when excess carbon is removed from the composition, the blowing stops and the lance is removed from the converter. Typically, purging continues for 20 minutes.

- At this stage, the resulting composition contains a large amount of oxygen. That is why, to improve performance, various deoxidizing agents and alloying elements are added to the composition. The resulting slag is removed into a special slag ladle.

- Converter melting time may vary, as a rule, it is 35-60 minutes. The holding time depends on the type of charge used and the volume of steel produced.

Oxygen converter method

It is worth considering that the productivity of such equipment is about 1.5 million tons with a capacity of 250 tons. This technology is used to produce carbon, low-carbon, and alloy steels.

The oxygen-converter method of steel production was developed quite a long time ago, but today it is still very popular.

This is due to the fact that when using this technology, high-quality metals can be obtained, and the productivity of the technology is very high.

In conclusion, we note that it is almost impossible to produce steel at home. This is due to the need to heat the charge to a sufficiently high temperature. At the same time, the process of iron oxidation is very complex, as is the removal of harmful impurities

, please select a piece of text and press Ctrl+Enter.

Modernity or anachronism?

In some sources on the Russian Internet you come across the expression: “Modern open-hearth furnace.” This is already an anachronism, because... Since 1970, open hearth furnaces have not been built all over the world. True, in China, India and the countries of the “third world” there are not fully accounted for the number of steel-smelting mini-furnaces, mainly made in China, operating on the open-hearth cycle, see Fig. below. Mostly, these are rotary furnaces: mold baths are located radially on a rotating hearth. Melting lasts one revolution of the hearth: take out the pellet with the melt, insert the trough with the charge, etc., etc. Such stoves are notorious: they smelt that same “Chinese” raw metal, the products from which can still be “shopped up” in tool stores and iron bazaars. If the jaws of the pliers become wrinkled when you try to cut through aluminum wire, then this is anything but metallurgy.

Mini steelmaking furnace

Wikipedia claims that as of 2009, steel was smelted using the open-hearth method only in India, Ukraine and Russia. Here, it must be said, VP, in its characteristic manner, is disingenuous: data for statistical processing are taken only from metallurgical enterprises, and machine-building enterprises with the accompanying open-hearth enterprise are not taken into account. If you want to make sure, type Siemens martin in the search. However, the share of open hearth steel in global production today (summer 2022) is approx. 2% and slowly but steadily falling. Although prices for scrap metal are falling, this is a consequence of the reduction in open-hearth production due to the depletion of reserves of rich pure iron ore, and it is more profitable to use oxygen and fuel energy for converting and electric arc smelting.

In the Russian Federation, in 2012, a resolution was adopted to completely stop open-hearth production in 2015. At the beginning of 2016, in the Urals, another 3 or 4 small open-hearth furnaces were completing their TBO life, after which they were subject to shutdown and liquidation. In the first half of 2016, these furnaces produced approx. 650 thousand tons of steel, after which information about open-hearth furnaces operating in Russia cannot be found.

Against this background, Ukraine stands out as a bright but heterogeneous spot. Donetsk residents on both sides of the front line, despite the civil war, did away with their open-hearth furnaces: during 2015, all open-hearth furnaces in Donbass were stopped and dismantled. But at Zaporizhstal, a full-scale open-hearth shop is still smoking and fuming, and at the former Krivorozhstal (now the Indian Arcelor Mittal Krivoy Rog) a large two-bath open-hearth furnace is in operation. Both are smelted per year approx. 7 million tons of open hearth steel, or approx. 25% of its global production. During the entire existence of Ukraine as a separate state, no official documents regarding the liquidation of open-hearth production have been made public, and the current Ukrainian government has extended the permit for the operation of existing national open-hearth furnaces until 2022 without any clarification about their future fate.

Below you can share your thoughts and results with our readers and regular visitors.

You can also ask questions to the author*, he will try to answer them.

Operating principle

The operating principle of an open hearth furnace is based on a curious property of alloys called eutectic or simply eutectics. Sometimes eutectics are called solid solutions, but this is incorrect. In solution, substances mix at the molecular or submolecular (cluster) level, and the microstructure of eutectics is clearly visible under a conventional optical microscope. Eutectics are widely used in industry and in everyday life: brass, bronze, lead-tin solders are eutectic alloys of 2 or more metals. Cast iron and simple structural steel are eutectics of iron and carbon, and alloy steel is a complex eutectic of them with alloying additives, see Fig.

Microstructures of cast iron and steels

Note: some grades of special steel contain less iron than chromium, nickel, titanium, tantalum, etc.

Pierre Martin used the fact that the melting point of the eutectic is always lower than that of its components for his furnace. A typical dependence of the melting temperature of a simple eutectic of two metals depending on the content of both in the alloy is qualitatively shown in the figure:

Dependence of the melting temperature of a eutectic alloy of two metals on the ratio of component contents

Compare, for example: the melting point of tin is 230 degrees Celsius, lead is 330 degrees, and POS-61 solder for soldering electronic components, consisting of (60...62)% tin (the rest is lead) is 190 degrees. This is explained by the fact that when heated, mutual diffusion of the components in microgranules begins and microscopic droplets are formed from a real solution, which quickly dissolves the entire ingot. When the melt cools below the critical temperature for the eutectic, the melt also quickly solidifies, dividing into microgranules of components.

Pierre Martin, as an experienced metallurgist, knew that the melting point of cast iron is significantly lower than that of steel, and even more so of pure iron (1539 degrees), see table. below. I also knew that the foundry temperature must be higher than the melting point, otherwise a high-quality casting will not work. Martin also set out to remove metallurgical poisons from the melt during the smelting process: sulfur, phosphorus, silicon. Their presence in steel causes its red brittleness - brittleness during hot forging and unsatisfactory toughness of rolled and cold forged products.

| Casting alloys | Temperature, degrees Celsius | |

| melting | pouring into molds | |

| Gray cast iron (ordinary) | 1150-1260 | 1280-1400 |

| White cast iron | 1150-1350 | 1380-1450 |

| Cast carbon steel | 1420-1520 | 1500-1600 |

But the main obstacles that Marten had to overcome were the lower and upper temperature thresholds. In small-scale diversified metallurgical production, a smelter cannot be continuously operating, like a blast furnace. Depending on market circumstances, the furnace may be stopped and mothballed, and then there will be a need to quickly start the furnace and carry out smelting. If, during the subsequent start-up, the temperature of the melt drops below 1200 degrees, the melt will become saturated with gases and all the metal will be rejected.

The upper temperature threshold of 1500 degrees is also determined by tactical and economic considerations. Below it, you can get by with relatively inexpensive and accessible fireclay; higher - more heat-resistant refractories are needed, which were 100% imported in France at that time.

Marten solved this puzzle, firstly, by taking as the basis of the charge cast iron, liquid directly from the blast furnace or imported pig iron, mixed with scrap - steel scrap metal. Secondly, by equipping the reflective puddling furnace with torch heating with excess air supply and heat regenerators operating on the principle of blast furnace cowpers. The solution, frankly speaking, is far from genius; rather, technically far-fetched. But in the end, Marten received a furnace in which it was possible to establish the production of steel of a given quality, even alloyed, both on a large scale in a well-equipped metallurgical plant, and occasionally in semi-handicraft conditions.

Automation of open hearth furnaces

Since open-hearth smelting consists of four periods, characterized by their own thermal and technological tasks, each of them imposes corresponding requirements for process automation. The main tasks that are necessary to ensure appropriate melting parameters and control actions are:

- Ensuring minimum duration of melting.

- Obtaining steel of a given composition and temperature.

- Ensuring the durability of fire-resistant masonry.

- Economical use of fuel.

The following features of open-hearth furnaces are distinguished from the point of view of automation in comparison with other melting furnaces:

- the process is repeated cyclically from charging to tapping the melt (frequency);

- the heat supply to the furnace and the temperature of various parts of the furnace change during the melting process, from melting to melting and during the furnace campaign;

- technological processes occurring in the furnace involve the absorption and release of heat and the release of flammable gas from the bath;

- the furnace operating mode is subject to sudden disturbances associated with periodic reversal of the torch;

- there is no complete mathematical description of technological and thermal processes;

- There are no many sensors necessary for automatic control of open-hearth smelting (sensors for the composition of metal, slag, etc.);

- many elements of the stove, especially the bath, have poor dynamic properties.

Acid open hearth process

Implemented using a high-purity charge, it is capable of producing steel with a very low content of non-metallic impurities, such as hydrogen or oxygen. It is precisely because the requirements for the purity of the charge are too high that the acid process is not used so often.

This melting method uses acidic slag, which eliminates the possibility of removing phosphorus, sulfur and other hazardous substances from the metal. Working in an acid furnace requires the use of cast iron with an amount of impurities of no more than 0.025%.

In this case, scrap metal is processed in advance in the main furnaces, from where it is poured in liquid form into an acidic open-hearth furnace. Due to the use of two furnaces (base and acidic), this process is often called a duplex process.

The resulting steel is distinguished by high mechanical properties, has good ductility, toughness and is used exclusively for the manufacture of the most important and critical parts in technology - turbine rotors, large engine shafts, and in the production of artillery installations.

Turbine rotor made of steel with high mechanical properties

Mentions in popular culture

Days and nights at the open-hearth furnaces Our Motherland did not close its eyes

- The work of open-hearth steelworkers is dedicated to V. F. Popov’s novel “Steel and Slag” (1948), dedicated to the labor and patriotic feat of Donetsk metallurgists during the Great Patriotic War, which received the Stalin Prize of the second degree (1949), as well as the sequel novel “Steel Boiled” "(1955).

- In one of the most popular films of the 1950s in the USSR film distribution, “Spring on Zarechnaya Street”, one of the main characters of the film is an open-hearth steelmaker, labor drummer Alexander Savchenko (artist Nikolai Rybnikov). The film footage shows the work of the open-hearth workshop and open-hearth furnaces. And in the popularly beloved popular song from the film there are the following lines:

When on Zarechnaya Street the lights are turned off in the houses, the open-hearth furnaces are burning, and they burn day and night.

Fragment of the song “Workers' Quarter” (music and lyrics by Yuri Shevchuk):

In the working-class quarter, the bright distances are burning in the fierce open-hearth furnaces. Like the sky, the titans held the power and carry it on their shoulders.

Poem by Vladimir Mayakovsky “Khrenov’s story about Kuznetskstroy and the people of Kuznetsk”:

There will be construction walls here. Beetles, steam, sipi. We will ignite Siberia with open hearths of a hundred suns.

Fragment of the song “Utkina Zavod (song)” (music and lyrics by Boris Grebenshchikov)

You walked past the workshop, there was an open-hearth explosion. Not even Bin Laden himself can do such things.

general information

Huge industrial complexes were built everywhere, complex agricultural and production equipment was developed, the main efforts of many states were aimed at increasing industrial capacity and obtaining large quantities of materials needed for development.

One of these materials was steel, since it is an indispensable component in so many applications.

Its production was carried out thoroughly and amounted to huge numbers annually.

Although many inexperienced people think that this technology was the work of Soviet scientists, its author is the French engineer P. Martin. He developed this technology in 1865.

Cast iron, charge, scrap metal, and various other steel components are placed in a special furnace, heated by fuel combustion products. All this is melted under the influence of high temperature to a homogeneous state, to which other necessary impurities are added. The next step after forming the desired mixture is to release it into ladles and pour it into molds.

The advantages of this method of creating steel are the possibility of processing any feedstock and the variety of options for fuel used to heat furnaces.

The technology allows us to obtain high-quality clean steel. A typical Marten furnace has a capacity of 10 to 900 tons of liquid material, so using this method it is not difficult to create parts of quite an impressive size.

Technology

Bessemerizing is an iron smelting process that produces steel of relatively high quality. It should be noted that such technology is used extremely rarely today. This is due to the emergence of quite a large number of modern technologies that make it possible to obtain higher quality steel in less time.

The entire Bessemer steel production process can be divided into several main stages:

- Cast iron is poured into the converter through the neck. An important point is that in this position the device must be in a horizontal position, since there is a possibility that the nozzle will be filled with metal. Nozzles are necessary to blow through the charge. It is the oxidation of impurities and their removal as slag that makes it possible to obtain steel of improved quality.

- The next stage is to start the blast and turn the converter into a vertical position.

- In order to ensure the oxidation of harmful impurities and excess carbon, the metal is blown with air. At this stage, slag is formed, with which unnecessary chemicals are removed.

- After a sufficiently long period of purging, the converter is turned over again into a horizontal position, and the purging of molten metal stops.

- The molten metal is drained into a ladle and deoxidized by adding special substances.

At the time of the start of purging the composition, active oxidation of manganese and silicon occurs. At the initial stage, carbon is practically not oxidized. This is due to the fact that this component reacts exclusively to exposure to high temperatures. In addition, the process of oxidation of impurities is influenced by thermodynamic factors that determine the activity of oxygen transfer to the sites of the Bessemer process.

Considering this technology, we note the following points:

- At the first stage, a large number of different slags are formed, which contains a high concentration of silica. The time interval for the first stage is 2-5 minutes.

- The second stage of the Bessemer production process provides the most favorable conditions for carbon oxidation. An example is an increase in operating temperature to approximately 2000 degrees Celsius. The duration of this stage is approximately 13 minutes. At the end of this stage, the temperature drops to approximately 1600 degrees Celsius.

- High quality steel can be achieved using various bessemerization methods. It all depends on the characteristics of the composition of the scrap used and the concentration of the cream in the composition.

- In order to eliminate the possibility of metal overblowing, the active air supply is stopped already at the second stage.

- Only at the third stage can active oxidation of iron be noted, which causes the release of brown smoke. This stage begins at the moment when the carbon concentration is less than 0.1%.

As previously noted, the Bessemer method of steel production has become widespread due to its high productivity. Foundries quite often install equipment that has a charge of about 35 tons.

Bessemer method of steel smelting

Today, the Bessemer method of steel production is practically not used, which is due to the low quality of the resulting metal and its fairly high cost.

Scap-ore process

It is used in facilities equipped with blast furnaces. The composition of the steel in this case looks like this: 55–75% cast iron, iron ore, scrap. This open-hearth production method helps produce steel with low levels of health-hazardous impurities, such as sulfur, phosphorus and a number of other substances.

Production by this method begins with loading the solid components of the charge (limestone, scrap, iron ore) into the furnace and heating it. The next step is pouring liquid cast iron. A rapid melting process of the charge occurs and all impurities are very actively oxidized.

And at low operating temperatures, phosphorus, silicon, manganese, carbon and other impurities are very actively oxidized and turn into slag.

A single download of slag is enough to obtain high-quality steel. But sometimes, for example, if phosphorous cast iron is processed, then the slag is downloaded several times.

Russian factories that used open hearth furnaces

On March 16, 1870, the first open-hearth furnace in the Russian Empire was launched at the Sormovo plant. It was intended for processing pig iron and scrap into steel of the required chemical composition and quality. The founder of the plant, a Greek merchant who accepted Russian citizenship, Dmitry Egorovich Benardaki, brought in a young engineer Alexander Iznoskov in 1870, who built the first open-hearth furnace in Russia weighing 2.5 tons.

In 1998, open-hearth furnaces at the Sormovo plant ceased to operate. In June 2005, a security obligation was concluded for the workshop building where the first Russian open-hearth furnace was installed between OJSC Krasnoe Sormovo Plant and the Ministry of Culture of the Nizhny Novgorod Region, in which the owner undertook to ensure the safety of the object, as well as the immutability of its appearance and interior . In May 2012, the rolling shop building was dismantled in violation of the requirements of the federal law “On objects of cultural heritage (historical and cultural monuments) of the peoples of the Russian Federation.” Police Department No. 8 of the Russian Ministry of Internal Affairs for the city of Nizhny Novgorod is identifying those responsible for the destruction of a cultural heritage site.

Information as of August 2009[

source not specified 3213 days]

- Bezhitsa steel plant

- Volgograd Metallurgical Plant "Red October"

- Vyksa Metallurgical Plant - the last open-hearth furnace was closed in the first half of 2022.

- Guryev Metallurgical Plant - two furnaces are still in operation today

- Zlatoust Metallurgical Plant - open-hearth shop decommissioned

- Izhevsk Metallurgical) - open-hearth production was stopped in 2009

- Kulebaki Metallurgical Plant - stopped on December 20, 2011

- Metallurgical plant Petrostal (a subsidiary of OJSC Kirov Plant)

- OJSC "Ural Steel" (formerly Orsko-Khalilovsky Metallurgical Plant) - all furnaces were stopped in April 2013

- Nizhny Tagil Metallurgical Plant named after V.V. Kuibyshev

- Nizhny Tagil Iron and Steel Works

- Omutninsky metallurgical)

- Seversky Pipe Plant - open-hearth production stopped in 2008

- Taganrog Metallurgical Plant - open-hearth production ceased in October 2013

- Chelyabinsk Metallurgical Plant

- Chelyabinsk Pipe Rolling Plant

- Cherepovets Metallurgical Plant - stopped in 2011

- Chusovsky Metallurgical Plant - stopped in 2013

- Beloretsk Metallurgical Plant - 4 open hearth furnaces, taken out of operation under the leadership of the Mechel group.

Why can't you stop an open-hearth furnace?

They always knew that the open-hearth furnace could not be stopped. The fact is that such structures worked for thirty years without interruption. They were forced to stop only a few times due to repairs.

It is impossible to stop the open-hearth furnace, because as a result of further reheating, the lining will be destroyed.

A similar process occurs, for example, in the silica refractory of coke oven batteries. When a brick is heated to a thousand degrees, it sinteres and becomes a magnificent material. However, when cooled, its lining is destroyed. There are about a thousand tons of such materials in the furnace. Not only do they cost more than eight hundred dollars per ton, but you also have to wait several months for a new unit to be manufactured. That is why open hearth furnaces operated continuously for several decades.

How the open-hearth got up

By the time Monsieur Martin filed a patent application for his stove, the social formation now called the Industrial Age had reached its apogee. In developed countries, large-scale machine production dominated. The railway network expanded. Steel steamships made transoceanic communication regular. The electric telegraph became common: by 1860, all continents were connected by underwater telegraph cables; The British established direct telegraph communication with India. All this required a large number of steels of various grades and quality much better than puddling iron.

The military were especially demanding. The Crimean War put an end to the history of smoothbore weapons using black powder. The pressure in rifled barrels has increased several times, and the dynamic loads on them have increased by more than an order of magnitude. A rifled barrel, in principle, cannot be made of cast iron, raw iron, copper or bronze. In return, the penetrating ability of rifled projectiles also increased significantly - two-foot oak sides and wicker fascines with earthen backfill, in which cast iron cores got stuck, the ogive-shaped steel projectile pierced butter like a knife. Military fleets finally said goodbye to sails and dressed in armor. During the competition between projectile and armor, the torpedo was invented. Its ideal carrier seemed to be a submarine already known at that time, but fast and deep-sea, made of special steel. During the American Civil War, the world's first armored train was built and tested in battle.

Demand creates supply - in 1856, Henry Bessemer patented the converter method for producing steel. However, it was only feasible in large-scale production, located near sources of good iron ore and fuel for blast furnaces: cast iron must be converted into steel using the converter method immediately after its smelting. This gave a decisive advantage to countries capable of organizing complex metallurgical production: there was no trace of a unified system of world economic relations, the world community and international laws at that time. It took two more world massacres after the Franco-Prussian War (which Marxists consider the first of the imperialist wars) to really think about them. In the meantime, the economic map of the world was like a patchwork quilt that owners of high-quality coal and steel could reshape as they saw fit.

In France it was the time of the Second Empire. The country was ruled by a very stupid, narcissistic, warlike, arrogant and boorish drunkard's nephew of Napoleon Bonaparte, Napoleon the Third, to whom Victor Hugo gave the delicately mocking nickname Napoleon the Small - the last French emperor was tall and powerfully built. The Bonapartists considered Napoleon II to be Bonaparte's son, who never ruled and died in exile. The country was dominated by corruption, nepotism, police brutality and persecution of those unwanted by the special services; censorship was rampant.

Napoleon the Small did not hide his plans of conquest, not bothering to provide them with either a coherent constructive ideology or a clear state doctrine. He also did not hide the fact that the first target of the future attack was Germany, which had successfully risen into a single strong state from the heap of political rubbish left over from the “Holy Roman Empire of the German nation.” Insular England, which owned a powerful steam fleet, openly incited the Small: Churchill's principle of “Let's pit them against each other and let them kill as many as possible” dominated British foreign policy long before the birth of Sir Winston.

Germany, then still called Prussia, was led by the cold, cruel, but intelligent, experienced, far-sighted and calculating Bismarck. He pretended to turn a blind eye to Maly’s Napoleonic plans, but gradually intensively prepared the country for war, paying special attention to infrastructure, metallurgy and heavy engineering. It was thanks to Bismarck that the Ruhr industrial complex emerged. And at the same time, Bismarck played a complex diplomatic game, skillfully maneuvering between England and Russia, with the goal of excluding direct military assistance to France from anyone.

Meanwhile, in France, large deposits of high-quality iron ore were not explored at that time, and very mediocre coal was mined. With heat-resistant materials and alloying additives, the situation was completely bad. Even such, excuse me, an idiot of the king of heaven, like Napoleon the Third, could not help but understand that without developed metallurgy, France was doomed to a humiliating defeat, which was confirmed by the course of subsequent events. Pierre Martin's invention seemed like a godsend in this context: an open-hearth furnace with a capacity of approx. 1 ton ensured stable metal quality. The grades of steel being smelted could be quickly changed, influencing the course of smelting (see below) and weapons metal could be obtained even in a village forge from readily available raw materials. Therefore, the open-hearth furnace could and should have been invented in France at that time. Why the Second Empire, which attacked Prussia, was completely defeated in less than six months, and Prussia did not have to use its mobilization reserves, how England was deprived of the opportunity to directly intervene in the war, and why all the efforts of the British Empire to bleed its closest competitors were paralyzed, these are other questions. Let us only note that in Russia Bismarck came across his equal - the then Minister of Foreign Affairs, Prince Gorchakov. This is what he expressed in his political testament: “Gentlemen, you can do what you want, but I conjure you - do not fight with Russia!” What happened when a certain Austrian corporal did not heed the advice of his wise predecessor is known. And we will return to the technical features of open-hearth furnaces and open-hearth smelting.