Steel 60 structural carbon steel

Substitutes

Foreign analogues

Decoding

The number 60 means that the average carbon content in steel is 0.60%.

Chemical composition, % (GOST 1050-88)

Chemical composition, % (GOST 1050-2013)

| steel grade | Mass fraction of elements, % | |||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | |

| no more | ||||||||

| 60 | 0,57-0,65 | 0,17-0,37 | 0,50-0,80 | 0,030 | 0,035 | 0,25 | 0,30 | 0,30 |

Characteristics and description

Steel 60 refers to structural unalloyed special quality steels with a high carbon content (0.60%) and normal manganese content, has high strength and high elastic properties.[1]

Steel is prone to cracks when quenched in water.

Purpose

Steel 60 is used for the manufacture of parts that require high strength and wear resistance, for example:

- Eccentrics,

- solid-rolled carriage wheels,

- tires for rolling stock of broad gauge railways,

- working rolls of sheet mills for hot rolling of metals,

- spindles,

- bandages,

- clutch discs,

- shock absorber spring rings,

- lock washers,

- adjusting washers,

- shims,

- work rolls of sheet mills for hot rolling of metal.

Temperature of critical points, °C [81]

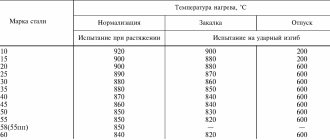

Heat treatment

Small parts made of grade 60 steel (up to 10-12 mm in diameter) are hardened in oil at a temperature of 820-860 ° C, larger parts in water at a temperature of 800-820 ° C, tempering is carried out at different temperatures depending on the required mechanical properties.

Dependence of mechanical properties of steel 60 on tempering temperature

Hardness HB (GOST 1050-2013)

| steel grade | Hardness HB, no more | |||

| hot rolled and forged | calibrated and with special surface finishing | |||

| without heat treatment | after annealing or high tempering | hard-worked | after annealing or high tempering | |

| 60 | 255 | 229 | 269 | 229 |

Mechanical properties of metal products for steel 60 (GOST 1050-2013)

| steel grade | Mechanical properties, no less | |||

| Yield strength σ0.2, MPa | Tensile strength σв, MPa | Relative elongation δ5, % | Relative narrowing ψ, % | |

| 60 | 400 | 680 | 12 | 35 |

NOTE. Mechanical properties for steel 60 were determined on normalized samples.

Mechanical properties of metal products made from steel 60 depending on size (GOST 105-2013)

| Mechanical properties of metal products size | |||

| Yield strength σ0.2, MPa not less | Tensile strength σв, MPa | Relative elongation δ5, % | Impact work KU, J |

| no less | |||

| up to 16 mm incl. | |||

| 580 | 850—1000 | 11 | + |

| St. 16 to 40 mm incl. | |||

| 520 | 800—950 | 13 | + |

| St. 40 to 100 mm incl. | |||

| 450 | 750-900 | 14 | + |

- Mechanical properties are determined on samples cut from heat-treated (hardening and tempering) workpieces.

- The “+” sign means that the tests are carried out to collect statistical data, and the test results are recorded in the quality document.

- The values of mechanical properties are given for metal products with a round cross-section.

Mechanical properties depending on the section [140]

| Section, mm | Sample cutting location | σ0.2, MPa | σв, MPa | δ5, % | ψ, % | KSU, J/cm 2 |

| no less | ||||||

| Quenching from 780-830 °C in oil; tempering at 560 °C | ||||||

| 30 | TO | 590 | 920 | 19 | 50 | 24 |

| 30 | C | 540 | 880 | — | — | 49 |

| Quenching from 780-830 °C in oil; tempering at 610 °C | ||||||

| 10 | C | 600 | 860 | 20 | 58 | 73 |

| 30 | TO | 540 | 880 | 20 | 50 | 49 |

| 60 | TO | 480 | 730 | 25 | 60 | 49 |

| 60 | C | 390 | 680 | 27 | 56 | 49 |

Mechanical properties depending on tempering temperature [140]

| tref., °С | σ0.2, MPa | σв, MPa | δ5, % | ψ, % | KCU, J/cm 2 | Hardness HB |

| 400 | 1430 | 1690 | 2 | 3 | 4,9 | 450 |

| 450 | 1280 | 1430 | 5 | 10 | 19 | 410 |

| 500 | 1120 | 1210 | 7 | 16 | 23 | 375 |

| 550 | 1040 | 1150 | 7 | 20 | 24 | 370 |

NOTE. Hardening at 950 °C in oil.

Mechanical properties depending on test temperature [82]

| tsp., °С | σв, MPa | δ5, % | ψ, % |

| 20 | 700 | 17 | 60 |

| 200 | 680 | 14 | — |

| 300 | 560 | 27 | — |

| 500 | 460 | 30 | — |

| -25 | 760 | (21) | 61 |

| -40 | 790 | (23) | 61 |

NOTE. Hardening at 950 °C in oil.

Types of axes

Based on the shape of the head and ax head, axes are divided into universal and special. The universal ones include:

- Economic. A small ax with an almost symmetrical head.

- Army and tourist. Lightweight tools, the head and ax handle are often made from one piece of metal.

- Plotnitsky. Differs in sharpening angle for easy removal from dense wood.

- Russian. Can be used for woodworking and as a throwing weapon

Special axes are used to perform a certain type of work. Examples:

- A splitting splitter for splitting sawn logs along the grain. The head is massive and hardly sharpens.

- Myasnitsky with a short ax and a wide head.

- Lumberjack's axe. It has the longest ax handle, which increases the impact force.

- Firefighter. All-metal with a spike on the butt and heat-protective linings on the axe.

- Roofing. The butt has the shape of a hammer.

- Adze. Designed to remove layers of wood.

Main types of axes.

Characteristics of steel grade 60

Steel 60 is a structural high-quality carbon steel, not used for welded structures. CTS followed by heat treatment.

Not prone to flake sensitivity, no tendency to temper brittleness. Cutting machinability in a normalized state at HB 241 K υ solid. spl=0.70 and Kυ b.st=0.65. Forging is carried out at temperatures from 1220 to 800 0C, with air cooling of workpieces with a cross-section of up to 300 mm. Steel 60 is used to make solid-rolled wagon wheels, working rolls of sheet mills for hot rolling of metals, eccentrics, spindles, bandages, clutch discs, spring rings of shock absorbers, lock washers, shims, shims and other parts that require high strength and wear resistance. . Work rolls of sheet mills for hot rolling of metal. Solid forged wheels for wagons and tires for rolling stock of broad gauge railways.

Steel 60 g: physical and mechanical properties

Any spring steel must demonstrate high hardness, which in the case of the 60g alloy is HB 10-1 = 241 MPa. This indicator can be achieved due to the increased carbon content. At the same time, this element reduces the ductility of the metal, and therefore it is important to find a compromise between these indicators.

Alloy 60g is not intended for welded structures, however, technologically its welding is possible using the contact welding method. Regarding the ability to form flakes, 60g steel is classified as insensitive. At the same time, the metal of this grade is prone to temper brittleness, but only if the manganese content in its composition exceeds 1%.

Steel C60 / 1.0601 chemical composition

High-quality unalloyed carbon steel C60 with carbon content C (0.57-0.65%), deoxidized with manganese Mn (0.60 - 0.90%) and silicon Si (0.40%) with a homogeneous structure. Residual impurities of sulfur S (0.045%) and phosphorus P (0.045%). Ligating elements Cr (0.40%), Mo (0.10%), Ni (0.40%).

| Chemical composition ,≤% | |

| C | 0,57 — 0,65 |

| Mn | 0,60 — 0,90 |

| Si | 0,40 |

| P | 0,045 |

| S | 0,045 |

| Cr | 0,40 |

| Mo | 0,10 |

| Ni | 0,40 |

| Cr+Mo+Ni | 0,63 |

Hardening

Steel hardening is a heat treatment process, the essence of which is to heat steel to a temperature above the critical temperature, followed by rapid cooling. As a result of this operation, the hardness and strength of steel increase, and ductility decreases.

When steels are heated and cooled, the atomic lattice is rearranged. The critical temperature values for different grades of steel are not the same: they depend on the content of carbon and alloying impurities, as well as on the rate of heating and cooling.

After hardening, the steel becomes brittle and hard. When heated in thermal furnaces, the surface layer of products becomes covered with scale and is decarbonized the more, the higher the heating temperature and the holding time in the furnace. If the parts have a small allowance for further processing, then this defect is irreparable. Hardening modes for hardening steel depend on its composition and technical requirements for the product.

During hardening, parts should be cooled quickly so that austenite does not have time to transform into intermediate structures (sorbitol or troostite). The required cooling rate is ensured by selecting the cooling medium. In this case, excessively rapid cooling leads to cracks or warping of the product. To avoid this, in the temperature range from 300 to 200 degrees, the cooling rate must be slowed down, using combined hardening methods. The method of immersing the part in a cooling medium is of great importance to reduce warping of the product.

Supply steel 60

Supplied in the form of long products, including shaped steel according to the regulations of GOST 2590-88 Hot-rolled round steel , GOST 2591-88 Hot-rolled square steel , GOST 8239-89 Hot-rolled steel I-beams , GOST 19771-93 Equal-flange bent steel angles, GOST 19772 -93 Bent steel angles, unequal flanges , GOST 8278-83 Bent steel channels, equal flanges , GOST 8281-80 , unequal , GOST 8283-93 steel trough equal flange profiles , GOST 380-94 Carbon steel of ordinary quality , GOST 85 09-93 Steel corners hot-rolled equal flange , GOST 8510-86 rolled steel angles unequal-flanged , GOST 8240-97 Hot-rolled steel channels , GOST 535-88 Rolled bars and shaped carbon steel of ordinary quality , GOST 2879-88 Rolled hot-rolled hexagonal steel, GOST 19903-2015 Hot rolled sheet products , GOST 19904-90 Cold-rolled sheets , GOST 16523-97 Rolled thin sheets of high-quality and ordinary quality carbon steel for general purpose, GOST 503-81 Cold-rolled low-carbon steel strip, GOST 103-76 Hot-rolled steel strip , GOST 82-70 Hot-rolled steel Wide-band universal, GOST 3282-74 Wire Steel low-carbon general purposes , GOST 17305-71 Carbon structural steel wires, GOST 10705-80 steel power steel pipes , GOST 10706-76 Pipes steel eight-dimensional , GOST 3262-75 Pipes steel water and gap-pipes .

| Long and shaped rolled products | GOST 8510-86; GOST 2590-2006; GOST 2879-2006; GOST 8509-93; GOST 9234-74; GOST 11474-76; GOST 1133-71; GOST 2591-2006; |

| Sheets and strips | GOST 14918-80; GOST 103-2006; GOST 82-70; GOST 6765-75; GOST 19903-74; |

| Ribbons | GOST 3560-73; |

| Long and shaped rolled products | GOST 8559-75; GOST 1051-73; GOST 14955-77; GOST 7417-75; GOST 7419-90; GOST 1050-88; GOST 8560-78; |

| Sheets and strips | GOST 1577-93; GOST 4405-75; |

| Ribbons | GOST 21996-76; GOST 21997-76; GOST 2284-79; |

| Steel pipes and connecting parts for them | GOST 20295-85; GOST 24950-81; GOST 3262-75; |

| Low carbon steel wire | GOST 792-67; |

| Medium and high carbon steel wire | GOST 7372-79; GOST 9161-85; GOST 9850-72; GOST 9389-75; GOST 3920-70; GOST 26366-84; GOST 9124-85; |

Mechanical properties of steel 60 depending on the section

| Section, mm | Sample cutting location | σ0.2 (MPa) | σв(MPa) | δ5 (%) | ψ % | KCU (J/cm2) |

| Quenching 780-830 °C, oil. Vacation 560 °C | ||||||

| 30 30 | K C | 590 540 | 920 880 | 19 — | 50 — | 24 49 |

| Quenching 780-830 °C, oil. Vacation 610 °C | ||||||

| 10 30 60 60 | Ts K K Ts | 600 540 480 390 | 860 880 730 680 | 20 20 25 27 | 58 50 60 56 | 73 49 49 49 |

Steel grade K60 interpretation:

K60 means steel with strength class K60; it includes the following steel grades: 10G2FBU 10G2FB 10G2SB 10G2SFB 08G1NFB 08G1NFB 09GNFB

Delivery of sheets 16D, 15HSND, 10HSND GOST 6713-91 by special transport:

Sheet K60 10mm, 12mm, 16mm, 20mm, 25mm, 32mm, 40mm, 45mm, 50mm delivery to Surgut:

Sheet K60 12mm, 14mm, 18mm in Omsk:

Sheet K60 12mm, 14mm, 18mm in Omsk:

Mechanical properties of steel 60 at normal temperature

| Type of delivery | Size | Eg. | sв | sT | d5 | y | KCU | Heat treatment |

| mm | — | MPa | MPa | % | % | kJ/m2 | — | |

| Rolled products, GOST 1050-88 | up to 80 | 680 | 400 | 12 | 35 | Normalization | ||

| Annealed tape, GOST 2284-79 | 440-740 | 10 | ||||||

| Cold-worked tape, GOST 2284-79 | 740-1130 | |||||||

| Steel | 700 | 510 | 17 | 60 | Hardening and high tempering | |||

| Steel | 30 | TO | 920 | 590 | 19 | 50 | 240 | Quenching 780 - 830oC, oil, Tempering 560oC |

Rules of care

There are several rules:

- The metal surface after heat treatment is black. A layer of oxides is formed, which protects the tool from corrosion. You cannot remove blackening with grinding wheels “for beauty”. Only the working edge of the blade should shine after sharpening.

- Before long-term storage, the head is lubricated with oil. Experienced carpenters do not recommend using machine lubricants for this purpose. They use castor, linseed or vaseline oil. After lubrication, wipe the head - a thin film is enough to protect against rust.

- The tool should not lie on the ground, on a concrete floor or stand near a wall for a long time. The geometry of the ax is disrupted. That's why they hang him up. The wooden part is impregnated with oil so that the wood does not dry out.

How to sharpen an ax correctly

In production, cutting edge geometry is developed using a grinder. This is a belt sander. On an abrasive of this shape, a convex cutting edge is more easily formed.

- While working with an axe, it is enough to regularly adjust the cutting edge with a fine abrasive stone. The angle specified during sharpening in production is not violated.

- For universal axes, the sharpening angle is 20-30 degrees, for carpentry tools - 35 degrees. The steel is hard enough to hold an edge for a long time.

- If you need to restore the cutting edge and eliminate chips, use an electric sharpener. A grinder is not suitable for this purpose.

- It is very important to maintain the sharpening angle. They operate at low speeds to avoid beating of the blade and strong heating of the metal. As the temperature rises, the structure of the hardened steel changes and the blade loses its hardness.

- To cool, add water or take breaks from work.

Ax sharpening technology.

Analog (substitute) of steel grade K60:

steel grade 10G2FBU, K56, S440. Additional conditions for rolled metal products at the request of the Buyer in accordance with GOST, TU and other normative and technical documentation:

1. 100% ultrasonic quality class 0, 1, 2, 3 according to GOST 22727-88. 2. Trim edge. 3. Flatness: high, especially high. 4. Heat treated: controlled rolling, normalizing, high tempering, high tempering. 5. Z-properties according to GOST 28870-90, relative narrowing in the direction of the thickness of the rolled product, not less than 15%, 25%, 35%.

Products group:

| NAME | PRICE | |||

Interpretation of steel grade 60PP

Interpretation of steel: Structural high-quality carbon steels are produced in converters or in open-hearth furnaces. The designation of these steel grades begins with the word “Steel”. The next two numbers indicate the average carbon content in hundredths of a percent; the numbers 60PP indicate its content of about 0.6 percent. The letters PP indicate hot rolling technology: longitudinal rolling consists of the fact that the strip is brought to rolls rotating in different directions and pulled into the gap between them due to friction forces on the contact surface. The strip is compressed in height and takes the form of a gap (caliber) between the rolls. With this rolling method, the strip moves only forward, that is, it only makes translational motion. Depending on the calibration of the rolls, the shape of the cross-section and longitudinal section of the rolled product may be different. the body being processed (cylindrical in shape) is placed in the gap between two rollers rotating in one direction and receives rotational motion due to friction forces on the contact surface. Body deformation occurs when the rolls approach each other. The body being processed does not move in the longitudinal direction (unless there are special pulling devices). Cross rolling is used for the manufacture of shafts, axles, and bushings.

Physical properties of steel 60

| Temperature | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| 0C | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 2.04 | 7800 | ||||

| 100 | 11 | 68 | 483 | |||

| 200 | 2.08 | 11.9 | 53 | 487 | ||

| 300 | 1.89 | |||||

| 400 | 1.74 | 13.9 | 36 | 529 | ||

| 500 | 14.6 | |||||

| 600 | 567 |

Brand: steel, metal 60G

Brand: 60G

| Brand: | 60G |

| Substitute: | 65G |

| Classification: | Structural spring steel |

| Application: | flat and round springs, springs, spring rings and other spring-type parts that require high elastic properties and wear resistance; tires, brake drums and bands, brackets, bushings and other parts of general and heavy engineering. |

| Foreign analogues: |

| C | Si | Mn | Ni | S | P | Cr | Cu |

| 0.57 — 0.65 | 0.17 — 0.37 | 0.7 — 1 | up to 0.25 | up to 0.035 | up to 0.035 | up to 0.25 | up to 0.2 |

| Ac1 = 726, Ac3(Acm) = 765, Ar3(Arcm) = 741, Ar1 = 689, Mn = 270 |

| Weldability: | not applicable to welded structures. |

| Flock Sensitivity: | insensitive. |

| Tendency to temper brittleness: | inclined. |

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Rolled products, GOST 14959-79 | 980 | 785 | 8 | 30 | Quenching 830oC, oil, Tempering 470oC, | |||

| Cold-worked tape, GOST 2283-79 | 740-1180 | |||||||

| Annealed tape, GOST 2283-79 | 640-740 | 10-15 |

| Hardness 60G without heat treatment, GOST 14959 | HB 10 -1 = 285 MPa |

| Hardness 60G heat-treated, Rolled GOST 14959-79 | HB 10 -1 = 241 MPa |

| Hardness 60G normalized, thick sheet GOST 1577-93 | HB 10 -1 = 269 MPa |

| Hardness 60G after annealing, thick sheet GOST 1577-93 | HB 10 -1 = 229 MPa |

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 2.04 | 7810 | ||||

| 100 | 11.6 | 483 | ||||

| 200 | 11.9 | 487 | ||||

| 300 | 12.9 | |||||

| 400 | 13.8 | 529 | ||||

| 500 | ||||||

| 600 | 14.6 | 575 | ||||

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

Foreign analogues of the material

Both exact and closest analogues are indicated!

| USA | Germany | Japan | France | England | European Union | Italy | Belgium | Spain | China | Sweden | Bulgaria | Hungary | Poland | Romania | Czech | Austria | Australia | Switzerland | South Korea |

| — | DIN,WNr | JIS | AFNOR | B.S. | EN | UNI | NBN | UNE | G.B. | SS | BDS | MSZ | PN | STAS | CSN | ONORM | AS | SNV | KS |

| 1561 | |||||||||||||||||||

| G10600 | |||||||||||||||||||

| G10640 | |||||||||||||||||||

| G15610 |

| C60E |

| C61 |

| Ck60 |

| C60 |

| S65C-CSP |

| AF70 |

| C60 |

| C60E |

| C60RR |

| XC60 |

| XC65 |

| 080A62 |

| 1449-CS |

| 1449-HS |

| 60HS |

| C60 |

| C60E |

| CS60 |

| 1CS60 |

| 2CS60 |

| C60 |

| C60E |

| C60E |

| C60R |

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||