General calculation rules

In order to make the correct calculation of fuse links, it is necessary to take into account the rated voltage.

This value should be such that the fuse switches off the electrical circuit. The main indicator is the minimum voltage provided for the base and fuse-link. Another important indicator that should be taken into account in the calculations is the shutdown voltage. This parameter is the instantaneous value of the voltage that appears after the fuse or fuse link itself has tripped. As a rule, the maximum value of this voltage is taken into account.

In addition, the melting current must be taken into account, on which the diameter of the wire installed inside depends. When calculating a fuse link, for each metal this indicator has its own value and is selected using a table or calculator. The material and size of the inserts must provide the required protective characteristics. The length of the insert cannot be too long, as this will affect arc extinction and overall temperature characteristics.

The rated load power is usually indicated on the product label. In accordance with this parameter, the rated fuse current is calculated using the formula: Inom = Pmax/U, in which Inom is the rated protection current, Pmax is the maximum load power, and U is the supply voltage.

Overview of species

Tinned copper wire is quite common. The point is that it is coated with tin using galvanic installations. The coating layer can vary from 1 to 20 microns, depending on the situation. However, on a specific product it is always the same. The tin layering increases wear resistance, allowing the use of thinner wire than usual. The service life of tinned products is much longer than that of uncoated wire. In addition, with such processing, basic technological characteristics are also improved. But it would be very reckless to evaluate the diameter only from the point of view of the durability of the material.

The thickness of the product directly affects its price. So, in many cases it is much more profitable to buy thin wire with a cross-section of 1 mm or 2 mm. But this is not always possible. To make wires, you also have to take into account the level of electrical resistance and resistance to heat. In many household appliances, it is even necessary to use copper conductors with a cross-section of 3 mm, 4 mm, and sometimes more. It all depends on how much current is to be passed through a particular circuit.

For hidden wiring and installation inside electrical appliances, thicker copper is needed than for external installation.

A serious problem for many DIYers and even industrial workshops is that insulated copper wire is extremely expensive. The price for enamel protection is especially high. Therefore, quite often they purchase “bare” metal and cover it with a layer of varnish insulation. But only trained specialists or real electrical engineering enthusiasts can cope with such work. Soft wire is obtained by annealing, and it is valued mainly where tying knots and bending metal are required.

But both hard and soft varieties of products can have:

- square;

- semicircular;

- flat section (it’s unnecessary to talk about a typical round one).

For rivets

Industrial users often purchase spools and drums of copper wire to make rivets. The diameter and length of these rivets vary greatly. In addition to pure copper, they are also used in various alloys, including those containing phosphorus. The peculiarity is that during molding they produce a base in the form of a cylinder and a cap in the shape of a semicircle. The size of the rivets varies greatly and must be selected individually. Rivet products are hollow, complemented by a washer, designed for grip or hammering.

Electrotechnical

This type of wire is used to make network wires and cables for electrical appliances. It is also used in the production of enamel-coated wires and network cables for the LAN protocol. The nominal diameter of electrical wire can be 1.15-4.5 mm. When shipping, coils placed in a box are sometimes secured with plastic tape. When sending wire in steel baskets, stretch film is wrapped around them.

For the electrovacuum industry

The wire intended for it is evaluated primarily by such an indicator as vacuum density. It is determined by the ability of specific parts and components to prevent the leakage of gases and the ingress of other substances from the outside. Therefore, special attention is paid to eliminating miniature cracks and hairlines. Problems can also be caused by pores and cavities that communicate with the external atmosphere. The use of metal containing impurities hazardous to the quality of the vacuum environment is strictly unacceptable.

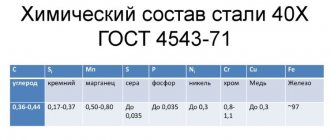

That is why wire for the vacuum industry is produced with strict concentration control:

- zinc;

- cadmium;

- manganese;

- tin;

- phosphorus;

- bismuth;

- antimony and a number of other elements.

If we allow the presence of such impurities, then during the production of various products they will evaporate and create deposits on parts in the vacuum cavity. The maximum concentration of all harmful substances that can evaporate during the production of vacuum equipment is 0.0001%. Not only pure elements are taken into account, but also their oxides and oxides. The concentration of alloying additives is also strictly standardized, and it can vary very slightly in different heats within the same series.

The production of copper alloys with substances having a high melting point usually occurs by mixing the powders and then sintering them. In any case, there are only three key electrovacuum grades of copper - MV, MB, MVK. The presence of oxygen is also normalized - no more than 0.01% by weight. The copper-tantalum alloy is smelted in induction vacuum furnaces with minimal residual pressure.

Of course, only experienced engineers can choose a specific alloy and type of wire.

Welding

No matter how great the demand for copper wire is in the radio engineering industry, a much larger volume is still used for welding work. Since copper and alloys derived from it in the liquid state react violently with oxygen and hydrogen, they are used only in an atmosphere of inert gases. The best results are obtained by welding in helium and argon . But, for reasons of economy, nitrogen is often used - when used skillfully, it turns out to be no worse. Copper wire is used in both manual and semi-automatic welding, and in fully automated production.

Conventional gas welding with such wire is also sometimes used. But this is more typical for jobs that do not require special responsibility. Copper is useful for surfacing operations, when the treated surfaces are given special additional properties (wear resistance, corrosion resistance, and so on).

Welding products of foreign manufacture are marked according to the AWS standard (USA) or in accordance with EU requirements.

Important: it is worth distinguishing between copper filler and copper-plated wire. When a seam is created without special requirements for strength, commercial copper is used (for example, M1 products). It is recommended to brew constantan and cupronickel with copper-nickel additives. Here are some more matches:

- additives based on copper and nickel are suitable for bronze produced from aluminum;

- copper-silicon wire is used to work with silicon-copper, zinc-copper structures, as well as for electric arc welding of galvanized steel surrounded by argon;

- copper-tin wire is needed for electrical connection of tin-based bronzes in an inert environment;

- brass (L60-1, L63 and others) is needed to perform gas welding of brass and to deposit coatings on steel with a high carbon concentration.

Formula for calculating the diameter of copper wire for a fuse

To determine more accurate values for the diameter of a copper wire to repair a fuse, or if a fuse is required for a protection current whose value is not in the table, you can use the formula below.

Formula for calculating the diameter of copper wire for fuse repair

where I pr – fuse protection current, A; d – diameter of copper wire, mm.

Video: Simple calculation and production of fuses

Wire M2

It is primary copper, which has a high content of the base metal and a minimal amount of impurities. M2 wire is made from copper alloy having a technical purity of no less than 99.7%, and impurities of no more than 0.3%, respectively (the same elements as in the M1 grade). The percentage of oxygen is not more than 0.08.

According to the production method, copper wire M2 is: M2b (oxygen-free), M2f (deoxidized with phosphorus), M2k (cathode), M2r (deoxidized with oxygen). According to physical parameters, they are divided into: hard (M2T) and soft (M2M) rolled copper.

Selecting wire diameter and fuse repair

Well, now let's move on to the main issue of our article - the choice of diameter and the repair itself. Let's start with the first one.

Conductor diameter selection

The diameter of the conductor in the fuses is clearly calculated. If you are replacing, you must install a conductor of the same diameter. Otherwise, your fuse will not perform its function of protecting the electrical network.

- There are several ways to do this. The easiest way is to take the wire cross-section for the fuse, and a table of standard values will allow you to make a choice. To do this, just measure the diameter of the wire.

- The diameter of the wire can be measured using a caliper or even a regular ruler. If the diameter of the fuse wire is too small, then measurements can be made as follows. We wrap the wire around any small object - a lighter, a pencil, a pen.

- It is advisable to make 10-20 turns for greater measurement accuracy. We make the coils as dense as possible to eliminate the space between them. Then we measure the diameter of all turns. We divide the resulting value by the number of turns. Here is the diameter of the wire for the fuse.

Note! With this method of measuring diameter, you will probably have a small error due to insufficient density of turns. Therefore, we round the resulting number to the nearest smaller number.

- Calculation of a copper wire fuse can also be made for values not indicated in the table. To do this, we need to know the required fuse-link current and wire material.

- In order to calculate the diameter of the copper wire for a fuse up to 7A, we should use the formula below. In this formula, d is the calculated diameter, Ipl is the required fuse-link current, k is a coefficient taking into account the wire material. For copper it is 0.034.

- If you want to calculate the diameter of the wire for an insert with a rating above 7A with your own hands, then you should use the formula given below. In this formula, m is a coefficient that takes into account the wire material. For copper it is 80.

- If the thickness of the wire for the fuse, as a result of calculation or selection from the table, turns out to be one that is not available. Then you can achieve the required diameter by connecting several wires of different sections. Although this option is somewhat worse.

Fuse repair

Installing a wire instead of a calibrated fuse in a fuse is popularly called installing a “bug”. Any “bug,” according to the PUE standards, is unacceptable, since it is not always capable of properly protecting the electrical installation.

Nevertheless, this method of repairing fuses is resorted to quite often. Especially when there is no spare fuse at hand.

- Installing a bug instead of a fuse depends on its type. If this is a tubular fuse with a high rated current, then such products usually have a collapsible design, as in the video.

- That is, the fuse can be untwisted. Remove the burnt-out fuse-link and replace it with a fuse made of copper wire.

- With products of lower denominations everything is a little more complicated. Usually they are made non-separable, and therefore you have to tinker.

- If you have a glass or ceramic type tubular fuse, they usually have metal ends. To install the “bug” they need to be drilled on both sides and our conductor inserted into the resulting cavity. It is advisable to then solder the hole together with the conductor.

- Do-it-yourself repairs with knife fuses are somewhat more difficult. It will not be possible to drill a hole here, since the wire must be attached to the knives, which are hidden under the body. In this case, the wire cross-section of a 10 A fuse or another rating is attached directly to the knives in front of the housing. And then install the fuse.

Note! This method is much more dangerous. Since when a wire burns out, it may splash onto neighboring equipment. This may not lead to a fire, but it can damage the equipment.

- It is for these reasons that our instructions do not recommend winding wire directly onto the fuse holder contacts. The same applies to winding the wire on top of the tubular fuse housing.

How to choose power wiring

The power cable must be compatible with the system it powers. If the cable is not thick enough, there will be large losses in it, that is, “sagging,” as this phenomenon is now commonly called. It is due to the fact that the cable has, although vanishingly small, resistance.

It is really very small, about 0.3 - 0.8 Ohm per km of cable length. But it still exists, and at high currents on the line, losses can be noticeable.

Selection of cable cross-section

In order to select a cable of the required cross-section, you do not need to calculate anything. You can, of course, set the current consumption, the permissible drawdown, for example, the current in the system is 100A and the drawdown is no more than 0.5 V, and calculate the required cable cross-section, taking into account the length of the line. This is not necessary. There is an old rule of thumb for selecting the cross-section of a power cable, which for simplicity is called “five amperes per square”:

It is based on the fact that the length of the line from the source to consumers (to amplifiers) does not exceed 5 m. This is 99% of all cases. What does this rule mean? This is the standard for current density. With a current density of five amperes per square millimeter, losses on a cable up to 5 meters long will be no more than 0.5V. Precisely no more than 0.5, this is important at maximum, and not operating, current.

How to use this rule? Take the amplifier and see what its fuse rating is. If there are several, consider the total denomination. If you have several amplifiers and you will power them with one cable, add up the ratings of their preamps. We take the result obtained as the maximum current consumption. The real worker will be noticeably smaller. We divide the maximum current by 5 and get the required cable cross-section (“5A per 1 sq mm).

Next, take the next larger standard cable cross-section. Example. We have an Oris TA-150.4 amplifier. It has a 100A fuse installed on it. Typically, the manufacturer provides a margin of 10-20% when selecting a fuse. Accepts maximum current for 100A. Divide 100 by 5 to get 20 squares. To power such an amplifier you will need a cable with a cross-section of at least 20 sq mm. We select the following standard cable cross-section - 25 sq mm. All. To power the Oris TA-150 amplifier.

4, a cable with a cross-section of 25 square millimeters is necessary and sufficient. You can use a cable that is one section larger, and it won’t be any worse. Will it be better? Practice shows that if you take a cable two or more sizes larger, it will definitely not be better. Losses on the cable are already approaching zero.

Use the “five amperes per square” rule, select the required cable cross-section or one size larger. Buying a thicker cable will not be advisable.

The drawdown lives not only on the cable. And, for example, also on the fuse.

Fuse selection

A fuse on the power line must be required and must be installed not far from the power source. In an emergency, it must protect the power source from short circuit. It doesn’t matter what happened, the cable frayed and shorted to ground, or the amplifier burned out and somehow shorted it. The fuse must blow to prevent the wiring from catching fire.

The operating principle of a fuse is simple and is based on Ohm's law for a complete circuit.

Where Un is the voltage drop across the system elements: at the wiring, at the limiter, at the amplifier itself, etc.

These are all dips of their kind, but we don’t call the voltage drop across the amplifier that way. The magnitude of the voltage drop depends directly on the resistance of the system element and is always many times less than the voltage drop on the main link - the amplifier. So far so good, the losses on the cable and fuse are not significant, everything works. Now let’s imagine that some emergency has occurred. The wiring has shorted.

Of all the elements of the system connected to the power source (battery), only the power cable and fuse remain (the amplifier has fallen out of the system). And all its energy will be dissipated precisely on the cable and at the limit. Which one will burn out first, the wire or the front? For a fuse to blow, the drawdown on it must be much greater. Then it will work stably. Therefore, the fuse must be selected strictly according to the cable.

Not by current consumption, but specifically by cable cross-section.

The fuse rating is also selected according to the “five amperes per square” rule. Only in the opposite direction. Let's say you need to select a fuse for a cable with a cross-section of 25 squares, which powers the same Oris TA-150.4 amplifier. Multiply 25 by 5, we get the required rating of 125A. The next larger one is rated 150A.

If the power wiring is selected according to the described rule, the system operates stably, with a good margin, and in the event of a short circuit, the fuse operates clearly. Cable and fuse losses are very small. There is no need to remove the fuse. This is sometimes done in competitions to reduce drawdown. But we don’t need this at all for everyday use.

ACCEPTANCE

2.1. Wire and rods are accepted in batches. The batch must consist of wire or alloy rods of the same grade, the same material condition, the same diameter and is documented in one quality document containing:

- trademark or name and trademark of the manufacturer;

- symbol of wire or rods;

- batch number;

- net weight of wire or rods;

- test results (at the consumer's request).

The batch weight should be no more than 2000 kg.

2.2. To control the surface quality and dimensions of wire and rods, coils (coils, drums, cores) or rods are selected from the batch “blindly” using the most objective method in accordance with GOST 18321. Control plans comply with GOST 18242. The number of controlled coils (coils, drums, cores) of wire and rods are determined according to the table. 7.

Table 7

| Number of skeins (coils, drums, cores), rods in a batch | Number of controlled skeins (coils, drums, cores), rods | Rejection number |

| 2-8 | 2 | 1 |

| 9-15 | 3 | 1 |

| 16-25 | 5 | 1 |

| 26-50 | 8 | 2 |

| 51-90 | 13 | 2 |

| 91-150 | 20 | 3 |

| 151-280 | 32 | 3 |

| 281-500 | 50 | 4 |

| 501-1200 | 80 | 6 |

| 1201-3200 | 125 | 8 |

A batch is considered acceptable if the number of skeins (coils, drums, cores), rods with measurement results that do not meet the requirements of the table. 1 and 2, paragraphs. 1.3.1.4, 1.3.2.2, less than the rejection number given in table. 7.

If unsatisfactory results are obtained, the manufacturer is allowed to control each skein (coil, drum, core) or rod.

The manufacturer is allowed to control the surface quality and dimensions of the wire and rods during the production process.

2.3. To check the curvature of the rods, three bundles are selected from the batch.

2.4. To check the chemical composition of the wire, two coils (coils, drums, cores) are selected, and rods - two rods per batch.

It is allowed at the manufacturing plant to determine the chemical composition on samples taken from molten metal.

2.5. To check the tensile strength and number of wire bends, three coils (coils, drums, cores) are selected from the batch.

2.6. To test rods for bending and fracture, two rods from the batch are selected.

2.7. To check the presence of residual tensile surface stresses, two coils (coils, drums, cores) or two rods from the batch are selected. The check is carried out periodically, at the request of the consumer.

2.8. If unsatisfactory test results are obtained for at least one of the indicators, except for size and surface quality, it is re-tested on a double sample taken from the same batch.

The results of repeated tests apply to the entire batch.

Fuse Types

According to their purpose and design, fuses are of the following types:

- Plugs (mainly used to protect electrical wiring and devices in cars);

- With low-current inserts to protect electrical appliances with current consumption up to 6 amperes;

- Cork (installed in panels of residential buildings, designed for protection current up to 63 amperes);

- Knife type (used in industry to protect networks with current consumption up to 1250 amperes);

- Gas generating;

- Quartz.

The repair technology discussed in the article is intended for restoring fork fuses, with low-current inserts, plug and blade type fuses.

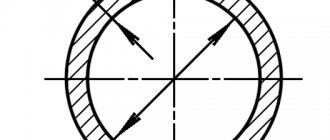

Tubular fuses

A fuse of a tubular design is a glass or ceramic tube, closed at the ends with metal caps, which are connected to each other by a wire of calibrated diameter running inside the tube. You can see the appearance of tubular fuses in the photograph.

The wire is spot welded to the caps or soldered with solder. In fuses designed for very high currents, the cavity inside the tube is often filled with quartz sand.

Automotive fuses

Fuses in cars rarely fail. Usually only in cases where the equipment fails. Most often when the headlight bulbs burn out. The fact is that when the filament of a light bulb breaks, a Voltaic arc is formed, the filament burns out and becomes shorter, the resistance sharply decreases and the current increases many times over.

It happens that a fuse in a car burns out when the windshield wipers jam. Less often during short circuits in electrical wiring. In the photo you see widely used automotive blade (fork) type fuses. Below each fuse is the current of its protection in amperes.

A blown fuse in a car should be replaced with a fuse of the same rating, but it can also be repaired by replacing the blown wire in the fuse with a copper wire of the appropriate diameter. The voltage of the car's on-board network does not matter. The main thing is the correspondence of the protection current. If it is difficult to determine the rating of a blown car fuse, then you can use color coding.

Homemade fusible link from a conductor, selection by cross-section

Under no circumstances should you accept making your own fuse links FOR THE NORM. Installation of such products can be considered as a TEMPORARY MEASURE.

Diameters of COPPER wire for fuse link

| Diameter, mm | Current, A | Diameter, mm | Current, A |

| Ø 0.05 mm | 0.6 A | Ø 0.71 mm | 47.8 A |

| Ø 0.063 mm | 1.25 A | Ø 0.75 mm | 52 A |

| Ø 0.071mm | 1.5 A | Ø 0.8 mm | 57.2 A |

| Ø 0.08 mm | 1.8 A | Ø 0.85 mm | 62.7 A |

| Ø 0.09 mm | 2.1 A | Ø 0.9 mm | 68.3 A |

| Ø 0.1 mm | 2.5 A | Ø 0.95 mm | 68.6 A |

| Ø 0.112 mm | 3 A | Ø 1.0 mm | 80 A |

| Ø 0.124 mm | 3.5 A | Ø 1.06 mm | 87.3 A |

| Ø 0.14 mm | 4.2 A | Ø 1.12 mm | 94.8 A |

| Ø 0.16 mm | 5.1 A | Ø 1.18 mm | 102.5 A |

| Ø 0.17 mm | 5.6 A | Ø 1.25 mm | 111.8 A |

| Ø 0.18 mm | 6.1 A | Ø 1.32 mm | 121.3 A |

| Ø 0.2 mm | 7.1 A | Ø 1.4 mm | 132.5 A |

| Ø 0.224 mm | 8.4 A | Ø 1.45 mm | 139.7 A |

| Ø 0.25 mm | 10 A | Ø 1.50 mm | 147 A |

| Ø 0.28 mm | 11.8 A | Ø 1.6 mm | 161.9 A |

| Ø 0.315 mm | 14.1 A | Ø 1.7 mm | 177.3 A |

| Ø 0.335 mm | 15.5 A | Ø 1.8 mm | 193.2 A |

| Ø 0.355 mm | 16.9 A | Ø 1.9 mm | 209.5 A |

| Ø 0.4 mm | 20.2 A | Ø 2.0 mm | 226.2 A |

| Ø 0.45 mm | 24.1 A | Ø 2.12 mm | 247 A |

| Ø 0.5 mm | 28.2 A | Ø 2.24 mm | 268.2 A |

| Ø 0.56 mm | 33.5 A | Ø 2.36 mm | 290 A |

| Ø 0.63 mm | 40 A | Ø 2.5 mm | 316.2 A |

| Ø 0.67 mm | 43.7 A |

For repairing fuses with protection current from 0.25 to 50A

| Fuse protection current, Ampere | 0,25 | 0.5 | 1.0 | 2.0 | 3.0 | 5.0 | 7.0 | 10.0 | 15.0 | 20.0 | 25.0 | 30.0 | 35.0 | 40.0 | 45.0 | 50.0 | |

| Wire diameter, mm | Copper | 0.01 | 0.02 | 0.04 | 0.07 | 0.10 | 0.18 | 0.20 | 0.25 | 0.32 | 0.39 | 0.46 | 0.52 | 0.58 | 0.63 | 0.68 | 0.73 |

| Aluminum | — | — | 0.07 | 0.10 | 0.14 | 0.19 | 0.25 | 0.30 | 0.40 | 0.48 | 0.56 | 0.64 | 0.70 | 0.77 | 0.83 | 0.89 | |

| Steel | — | — | 0.32 | 0.20 | 0.25 | 0.35 | 0.45 | 0.55 | 0.72 | 0.87 | 1.00 | 1.15 | 1.26 | 1.38 | 1.50 | 1.60 | |

| Tin | — | — | 0.18 | 0.28 | 0.38 | 0.53 | 0.66 | 0.85 | 1.02 | 1.33 | 1.56 | 1.77 | 1.95 | 2.14 | 2.30 | 2.45 | |

For repairing fuses with protection current from 60 to 300A

| Fuse protection current, Ampere | 60 | 70 | 80 | 90 | 100 | 120 | 160 | 180 | 200 | 225 | 250 | 275 | 300 | |

| Wire diameter, mm | Copper | 0.82 | 0.91 | 1.00 | 1.08 | 1.15 | 1.31 | 1.57 | 1.72 | 1.84 | 1.99 | 1.14 | 2.20 | 2.40 |

| Aluminum | 1.00 | 1.10 | 1.22 | 1.32 | 1.42 | 1.60 | 1.94 | 2.10 | 2.25 | 2.45 | 2.60 | 2.80 | 2.95 | |

| Steel | 1.80 | 2.00 | 2.20 | 2.38 | 2.55 | 2.85 | 3.20 | 3.70 | 4.05 | 4.40 | 4.70 | 5.0 | 5.30 | |

| Tin | 2.80 | 3.10 | 3.40 | 3.65 | 3.90 | 4.45 | 4.90 | 5.80 | 6.20 | 6.75 | 7.25 | 7.70 | 8.20 | |

Electrical copper wire

Manufacturing is carried out in accordance with GOST 434-78, from grade M1 or higher. It is characterized by a rectangular cross-section, with a thickness from 0.5 to 12.5 mm, a width from 2 to 35 mm. This copper wire can be purchased in the following grades: PMM (soft), PMT (hard). Produced in coils. Electrical round copper wire is used to make: cords, cables, wires, motor windings, etc.

At 20 ºС, the product has an electrical resistance: not exceeding 0.01724 Ohm•mm2 for MM brand products; 0.01780 Ohm•mm2 – for MT (Ø up to 2.44 mm inclusive); 0.01770 Ohm•mm2 – for MT (Ø above 2.44 mm).

For a product of the MM brand, the relative elongation is:

— Ø from 1.80 to 5.00 mm (inclusive) – 30%;

— Ø more than 5.00 mm – not less than 35%.

Replacing the fuse

When replacing a fuse, to avoid electric shock, be sure to unplug the electrical appliance!

There is an unspoken rule: if after the second replacement the fuse blows again, look for a fault in the electrical appliance itself. This means that the electrical appliance needs to be repaired.

Do not install a fuse at a higher current under any circumstances; such attempts will definitely lead to even greater damage to the device, up to the point of its being beyond repair!

Be careful when purchasing a new fuse. Correctly determine the type and current rating of the replacement candidate. It is better to purchase electronic components from trusted suppliers who guarantee product quality, such as Conrad Electronic.

Fuse repair

Typical people believe that fuses cannot be repaired; in fact, this is not the case. Most types of fuses can be repaired and given a second, third, etc. life. The fuse housing, as a rule, is destroyed extremely rarely, the wire inside burns out, and the repair consists of replacing it. The main task is to use a wire similar to the one in the fuse.

If you need to replace a fuse very quickly, but you don’t have a spare at hand, you can use the following method:

Remove the paint coating from a wire of a suitable diameter (clean it until it shines) and wind several turns around each fuse contact, then insert the fuse into the holder. This method is popularly called “bug”. With its help you can very quickly check the serviceability of the device, but it is not reliable and can be used as a temporary solution to the problem.

The next method is the so-called “factory” one. Repairs will require a soldering iron, and perhaps a Dremel or screwdriver, but the fuse after repair will look like it came straight from the factory.

Heat the ends of the cup contacts with a soldering iron and remove the solder from the holes in the ends using a toothpick or something similar. It happens that the holes are too small or completely absent, then you will have to drill them. Use a drill of small diameter 1 - 2 mm.

Pass a wire of a suitable diameter through the holes and solder it to the cup contacts.

The fuse is ready!

CONTROL METHODS

3.1. Inspection of the surface of wire and rods is carried out without the use of magnifying devices. Surface quality control is carried out with a specified probability of 97.5% (the acceptance level of defects is 2.5%).

3.2. Determination of the sizes of wire and rods is carried out in accordance with GOST 26877 with a micrometer in accordance with GOST 6507 or other devices that provide the necessary accuracy. If disagreements arise, sizing is determined in accordance with GOST 6507. Size control is carried out with a given probability of 97.5% (acceptance level of defects is 2.5%).

3.3. The curvature of the rods is determined according to GOST 26877.

3.4. To analyze the chemical composition of each selected skein (coil, drum, core), rod, one sample is cut out. Selection and preparation of samples to determine the chemical composition is carried out in accordance with GOST 24231.

The chemical composition of wire and rods is determined according to GOST 13938.1 - GOST 13938.12, GOST 13938.13, GOST 1652.1 - GOST 1652.13, GOST 1953.1 - GOST 1953.15, GOST 6689.1 - GOST 6689.22, GOST 9716.1 - GOST 9716.3, GOST 23859.0 - GOST 23859.11, GOST 25086 or others methods that provide the necessary accuracy of determination.

If disagreements arise in assessing the chemical composition of wire and rods, the analysis is carried out according to GOST 13938.1 - GOST 13938.12, GOST 13938.13, GOST 1652.1 - GOST 1652.13, GOST 1953.1 - GOST 1953.15, GOST 6689.1 - GOST 6689.23, GOST 9716.1 - GOST 9716.3, GOST 23859.0 - GOST 23859.11, GOST 25086.

3.5. For tensile testing, two samples are cut from each selected skein (coil, drum, core). Sampling for tensile testing is carried out in accordance with GOST 10446.

3.6. Sampling for the bend test is carried out from both ends of each controlled skein (coil, drum, core) or from two sections at a distance of at least 5 m from each other.

The bend test of the wire is carried out according to GOST 1579.

3.7. Bend testing of rods is performed around a mandrel with a radius of curvature equal to the diameter of the rod.

3.8. To check a bar for fracture, both ends of the bar are cut on one or both sides, after which it is broken. The cut must be made in such a way that the fracture passes through the central part of the rod. The width of the fracture must be at least 60% of the diameter.

3.9. Determination of the presence of residual stresses in wire and rods made of brass is carried out according to GOST 2060.

3.10. The quality of the winding is checked by external inspection.

Calculation of fuse wire diameter

To repair the fuse, it is necessary to replace the burnt wire. In the production of fuses in factories, depending on the current value and speed, calibrated silver, copper, aluminum, nickel, tin, lead and wires made of other metals are used.

For making a fuse at home, only red copper of calibrated diameter is available. All electrical wires are made of copper, and the more elastic the wire, the thinner the conductors and the greater the number of them. Therefore, all the technology proposed below is focused on the use of copper wire.

When choosing a fuse for equipment, developers use a simple law. The fuse current must be greater than the maximum consumed by the product. For example, if the maximum current consumption of the amplifier is 5 amperes, then the fuse is selected at 10 amperes. The first thing you need to do is find its marking on the fuse body, from which you can find out what current it is designed for. Often the current value is written on the product body, next to the location where the fuse is installed. Then, from the table below, determine what diameter wire is needed.

Wire M1

M1 brand wire is considered the highest quality and most expensive. The purity of the copper alloy used for its production is 99.9%. Composition: Cu – 99.9%, impurities (such as Pb, Fe, Ni, S, As, Sb, Bi, Sn) – not higher than 0.1%. According to physical characteristics, there are: hard (M1T), soft (M1M). Other types of M1 wire: oxygen deoxidized (M1P), oxygen-free (M1B), phosphorus deoxidized (M1F), cathode (M1K).

Wire M1 differs from other rolled products (M2, M3) by increased performance characteristics, due to the minimum content of impurities in the material. It has good thermal and electrical conductivity. Bends well while maintaining strength properties. Nice appearance.

This wire is most often used in such areas as aircraft and shipbuilding, and electric power. They produce cords, cables, thermocouples, wires, and high-tech cryogenic equipment.

Operating principle of fuses

The principle of operation of disposable protective devices is very simple. Inside each of them there is a calibrated wire connecting the contacts. If the current value does not exceed the maximum permissible norms, it heats up to approximately 70 degrees. When the electric current exceeds the set rating, the heating of the wire increases significantly. At a certain temperature it begins to melt, resulting in a break in the electrical circuit. Wiring burnout occurs almost instantly. Because of this, fuses got their name - fuse link.

In different designs, the fuse link is selected in such a way that operation occurs at the set current value. During operation, fuses periodically fail and must be replaced. As a rule, they are not repaired, but many home craftsmen quite successfully restore them.

Since only the wire itself burns out, but the body remains intact, it is necessary to replace it and the device will continue to perform its functions. New technical characteristics are often not only not inferior to the old device, but also in many ways superior to it, since the quality of hand assembly is always higher than the factory one. The main condition is the correct choice of conductor material and calculation of its cross-section.

Causes of blown fuses

Let's start with the most important thing - the reasons for blown fuses. After all, nothing just happens, and before installing a bug, you need to determine the reasons for the fuse failure.

There may be several of them:

Fuse links. How to choose and calculate current. Operation and Application

Fuse links are electrical elements for protecting equipment from short circuits and overvoltage by turning off power when current load limits are exceeded. Opening the circuit occurs due to the melting of a safety wire of a certain thickness. Several types of these devices are known to the industry. They all differ in internal and external design features, but function according to the same principle.

Nowadays, in order to protect household electrical equipment, more practical reusable circuit breakers are used, but disposable fusible links are still found in plugs. They are especially relevant for premises of temporary and old buildings, where the installation of effective modern shields is not economically justified. In household appliances, there is still no alternative to the classic fuse.

Fuse links are also actively used in industry. The performance of an entire plant or utility network may depend on them. It is better not to buy industrial fuses secondhand, on the market or from unverified organizations. A wise decision is to turn to electronics professionals, for example, the online store Conrad.ru. In such matters, the miser pays not twice, but three times

We choose the diameter of the fuse wire - we analyze all the subtleties of the issue

A homemade copper wire fuse can be a great temporary way to replace a blown fuse. But if you decide to do this, then it is extremely important to choose the right cross-section of the very conductor that you will use. Why is this important, what are the reasons for blown fuses and ways to temporarily eliminate this inconvenience we will consider in our article.

Transportation and storage

Rules for storing copper wire are regulated by GOST standards. Basic Rules:

- The optimal method of storage and transportation is the use of frame bays. For transportation, the coils must be packed in a special film. It will protect the material from adverse environmental conditions. In most cases, coils can be stored in a fold without packaging.

- The wire must be stored in special warehouses. The basic requirements for storage are low humidity, dry ventilation, minimal risk of prolonged wetting of the material (short-term wetting due to carelessness is allowed), and so on.

- Different grades of copper should be stored separately in the warehouse. If the wire becomes tangled during transportation, untangling is necessary. When unraveling, under no circumstances should the material be allowed to twist in a figure eight pattern.

How to determine the fuse rating from the case and on the board

Before you change something that has gone bad, you need to understand what has gone bad. In our case it burned out. Here you can rely only on the inscription on the board itself or on the fuse, because other methods of finding out what the fuse rating was are very unsteady and groundless. After all, a serviceable fuse will not show anything as zero resistance, but a faulty break. At the same time, do not send it to the laboratory for analysis in order to find out what kind of material it was. Let's look at examples of designation of fuses on the board and SMD elements. By the way, sometimes even a resistor can be used instead of a fuse.

Calculation of conductors for fuses

where: d – conductor diameter, mm; k – coefficient depending on the conductor material according to the table.

where: m is a coefficient depending on the conductor material according to the table.

Formula (1) is applied for low currents (thin conductors d=(0.02 - 0.2) mm), and formula (2) for high currents (thick conductors). Odds table.

The conductor diameter for use in a fuse is calculated using the formulas: For low currents (thin conductors with a diameter of 0.02 to 0.2 mm):

For high currents (thick conductors):

The amount of heat generated at the fuse link is calculated by the formula:

where: I – current flowing through the conductor; R – conductor resistance; t – time the fuse-link is under current I.

The resistance of the fuse link is calculated by the formula:

where: p – resistivity of the conductor material; l – conductor length; s is the cross-sectional area of the conductor.

To simplify calculations, the resistance is assumed to be constant. The increase in resistance of the fuse link due to increased temperature is not taken into account.

Knowing the amount of heat required to melt the fuse link, you can calculate the melting time using the formula:

where: W is the amount of heat required to melt the fuse link; I—melting current; R is the resistance of the fuse link.

APPENDIX 1 Recommended

PURPOSE OF WIRE AND RODS

| Material grade | Purpose |

| M1, M1p | For automatic inert gas, submerged gas and gas welding of non-critical copper structures, as well as the production of electrodes for welding copper and cast iron |

| M2r | For gas welding of general purpose copper structures |

| MCp1 | For gas welding of critical and electrical structures made of copper |

| MNZHKT5-1-0.2-0.2 | For manual, semi-automatic gas-shielded welding of copper-nickel alloys, copper-nickel alloys and copper with bronze, brass and steel (carbon, alloy and corrosion-resistant), as well as surfacing on steel |

| MNZH5-1 | For the manufacture of electrodes for welding copper-nickel alloys with each other and brass and aluminum-manganese bronze |

| BrKMts3-1 | For manual gas-shielded welding of flexible copper structures and automatic submerged arc welding of copper |

| BrAMts9-2 | For manual gas-shielded welding of aluminium-manganese bronze, arsenic brass, copper and copper-nickel alloy with aluminium-manganese bronze; manual and mechanized surfacing on steel |

| BrKh0.7, BrHNT, BrNTsr | For manual argon arc welding of bronzes |

| BrKh0.7 | For automatic submerged arc welding of chrome bronze |

| BrAZhMts10-3-1.5 | For the manufacture of electrodes for aluminum-iron bronze welding and automatic submerged arc surfacing of bronze |

| BrOTs4-3 | For manual welding in shielding gases of copper; mechanized submerged arc welding of copper and brass |

| BrOF6.5-0.15 | For manual gas-shielded welding of tin phosphorus bronze and tin bronzes |

| L63, LS60-1 | For gas welding of brass and surfacing on carbon steel |

| LK62-0.5 | |

| LKBO62-0.2-0.04-0.5 | |

| LOK59-1-0.3 | |

| LMts58-2 | |

| LZhMts59-1-1 |

What do copper wire fuses look like and do?

In appearance, a fuse is a glass or ceramic flask with a calibrated copper wire stretched inside it. It is attached to the element contacts located in the metal caps using soldering or spot welding. The diameter of the wire depends on the current for which the fuse is designed. The flask (tube) of a product with a high rated current is sometimes filled with quartz sand. Because of their appearance, such fuses are called tubular.

Another common type of this device is knife-type automotive fuse links. Depending on the current rating, they are painted in different colors:

- 5 A - orange;

- 7.5 A - brown;

- 10 A - red;

- 15 A - blue;

- 20 A - yellow;

- 25 A - colorless (transparent);

- 30 A - green;

- 40 A - purple;

- 60 A - blue;

- 70 A - black.

The operating principle of the insert is extremely simple. The fuse is turned on and electric current begins to flow through the wire. The wire heats up. As long as the current does not exceed the fuse rating, the wire temperature remains at approximately 70 degrees Celsius. As soon as the current values exceed the permissible limits, the heating of the wire increases to the melting temperature of copper, it loses its integrity, thus breaking the electrical circuit. All this happens very quickly, almost in a split second. It is because of this principle of operation that fuses with copper wire are called fuse links.

There are different types and types of such inserts. But regardless of this, they all act the same way: the copper wire they contain melts and the current flow is interrupted.

It is very important to understand that the fuse “trips” precisely when the permissible current value is exceeded, but the voltage in the network has no meaning for it. In other words, the same element can be installed in both a 12-volt charger and a single-phase or three-phase network.

Naturally, the question may arise: we say that the device protects against power surges in the network, and then we claim that voltage is not important for it, how is this possible? In fact, here it is enough to recall the school physics course, namely Ohm’s law, which states that the current strength in a section of a circuit is directly proportional to the voltage and inversely proportional to the resistance. In other words, the higher the voltage, the higher the current, given that the resistance of the conductor (copper wire of a certain diameter) in any case remains unchanged.

An insert can burn out not only due to voltage surges in the network, that is, due to exceeding the rated current, but also due to a malfunction inside the device itself in which it is installed. You can determine the reason for the failure of the insert yourself - if after replacing it twice, the element burns out again, it means that the device itself is faulty. Sometimes a situation occurs when the reason for the failure of an insert is its poor quality, but this is rare.

How the fuse works in the video

When an electric current passes less than the maximum permissible, the calibrated wire connecting the fuse contacts heats up to a temperature of about 70˚C. If the current exceeds the fuse rating, the wire begins to heat up more strongly and when the melting temperature of the metal from which it is made is reached, it melts, the electrical circuit breaks, and the flow of current stops.

That's why the fuse is called a fuse or fusible link. The video is presented in slow motion so that you can clearly see how the wire in the fuse burns out. In real conditions, the wire in the fuse burns out almost instantly.

Total views: 217944

The fuse protects against excess current in the circuit and the voltage of the supply network in which it is installed does not matter, it can be a 1.5 V battery, a 12 V or 24 V car battery, a 220 V AC network, a three-phase network 380 V.

That is, you can install the same fuse, for example, with a rating of 1 A, both in the fuse block of a car, and in a flashlight and in a 380 V switchboard. All types of fuses differ only in appearance and design, and work on the same principle - when exceeded of a given current in the circuit, the wire in the fuse melts due to heating.

There are two main reasons for fuse failure, due to surges in the supply voltage or a breakdown inside the radio equipment itself. Rarely, fuse failures also occur due to poor quality.

Many people think that the fuse cannot be repaired. But it is not so. In an emergency situation, when there is no spare at hand and, for example, because a car on the road or an amplifier refuses to work, and the musical accompaniment of a school ball or wedding is disrupted, and all the shops are already closed, there is no choice.

With the right approach, you can successfully restore a blown fuse for temporary use until it is replaced with a new one, preserving its protective functions. Often such problems are solved by simply closing the contacts of the fuse holder with any available wire, or even worse, simply inserting a nail or a piece of thick wire instead of the fuse. Such a decision can completely ruin everything and contribute to a fire.