Table salt is a substance widely used in the food industry, medicine, animal husbandry, cosmetology, etc. since ancient times. This white crystalline powder is obtained by different methods. This could be, for example, evaporation of sea water, mining in quarries, collecting from the bottom of lakes. But in any case, the final product always has the same physical characteristics. For example, what is the hardness of salt on the Mohs scale? We’ll talk about that later in the article. We will also look at what other characteristics this very popular product has.

What is the Mohs scale

You might be interested in: What are phenomena? The most beautiful and terrible natural phenomena

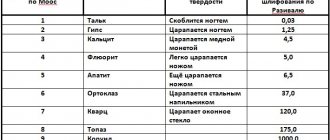

One of the distinguishing features of many substances on the planet is the degree of hardness. This parameter is determined according to a special scheme called the Mohs scale. To facilitate the task of comparing the hardness of different substances, 10 standard elements are included in this system. The hardness of these substances is checked simply by scratching.

The hardest mineral on the planet, diamond, ranks first on the Mohs scale. This gemstone is known to not be scratched even by a strong steel knife. The hardness of a diamond on the Mohs scale is therefore 10. In second place in this scheme are corundums - rubies and sapphires. Their hardness is 9. The softest reference substances on the Mohs scale are talc and chalk. Their hardness in this scheme is defined as 1.

Mohs hardness scale

The Mohs scale (mineralogical hardness scale) is a qualitative ordinal scale that characterizes the scratch resistance of various minerals. Used to determine the relative hardness of mineral samples.

Based on the ability of a harder material to scratch a softer material.

The scale contains 10 minerals as reference minerals, ranking them in order of increasing hardness from very soft (talc) to very hard (diamond).

All of the minerals in the table, except diamond, are relatively common and easy or inexpensive to obtain.

- — Talc

- — Plaster

- — Calcite

- — Fluorite

- — Apatite

- — Orthoclase

- — Quartz

- — Topaz

- — Corundum

- — Diamond

If a mineral scratches a standard, then its hardness is higher; if it is scratched by a standard, it means lower.

The Mohs scale was created in 1812 and named after its inventor, German geologist and mineralogist Friedrich Mohs. Since then, many different methods for determining hardness have been invented: the Brinell, Knoop, Rockwell, Shore, Vickers method.

Mohs hardness is a relative integer comparison of scratch resistance.

Other hardness measurement methods rely on indentation resistance. For testing, an “Indenter” is used, which is pressed into the test sample with a carefully measured force. The size or depth of the notch in the specimen and the magnitude of the force are then used to calculate the hardness value. Because each of these tests uses different apparatus and different calculations, they cannot be directly compared to each other.

The Mohs scale has become widespread because... The hardness test method is easy to perform, inexpensive and quickly understood by people.

Despite its lack of accuracy, the scale is useful for field geologists who use it for rough identification of minerals when examining easily identifiable samples or when more complex tests are not available.

Some use readily available items for a quick test. For example, a geologist may have a pocket knife that can be used to determine whether a sample is harder or softer than a Mohs value of 5-6.5.

- 1 - Pencil

- 2 - Table salt

- 2-2.5 - Can be scratched with a fingernail

- 2.5-3 - Gold, silver

- 3 – Copper coin

- 4-4.5 - Nail

- 4-5 - Iron

- 5 - Glass

- 5-6.5 - Knife blade

- 6.5 - Steel file

- 7 - Easily scratches glass

- 7+ — Hardened steel file

- 8 - Sandpaper, mineral scratches glass very easily

- 9 – Mineral cuts glass

- 10 - Used as a glass cutter

Below is an extended table of substances, minerals, and precious stones:

| Substance or mineral | Mohs hardness |

| Pyrophyllite, molybdenite | 1-2 |

| Bauxite, coal | 1-3 |

| Limonite | 1-5 |

| Ice, sugar, gallium, strontium, indium, tin, barium, thallium, lead, graphite | 1,5 |

| Gypsum, calcium | 1,5-2 |

| Sulfur | 1,5-2,5 |

| Sylvite, glauconite, cadmium, selenium | 2 |

| Rock salt, cinnabar, chlorite, bismuth, amber | 2-2,5 |

| Muscovite | 2-3 |

| Silver, gold, galena, copper, biotite, mica | 2,5-3 |

| Aluminum, limestone, calcite, boric acid, nitrophoska | 3 |

| Aragonite, witherite, anhydrite | 3-3,5 |

| Pearl, brass, arsenic | 3-4 |

| Serpentine | 3-5 |

| Sphalerite, rhodochrosite, malachite, dolomite, cuprite, chalcopyrite, azurite, barite | 3,5-4 |

| Siderite, pyrrhotite, dolomite | 3,5-4,5 |

| Fluorite, phosphor bronze | 4 |

| Marble | 4-5 |

| Tooth enamel, asbestos, apatite, manganese, zirconium, palladium, obsidian | 5 |

| Titanite, monazite | 5-5,5 |

| Jade, uraninite, ilmenite, enstatite, porcelain stoneware (polished) | 5-6 |

| Magnetite | 5-6,5 |

| Nepheline, augite, arsenopyrite, actinolite, bustamite, cobaltite | 5,5-6 |

| Rhodonite, diopside, opal, red iron ore | 5,5-6,5 |

| Titanium, germanium, niobium, rhodium, uranium | 6 |

| Rutile, pyrite, prehnite, plagioclase, orthoclase, amazonite, andesine, anorthoclase, benitoite, helvite, iridium | 6-6,5 |

| Silicon | 6,5 |

| Jasper | 6,5-7 |

| Agate, zoisite, epidote, cassiterite, pyrolusite | 6-7 |

| Marcasite | 6-7,5 |

| Granite, tanzanite, spodumene, olivine, jadeite, axinite, chrysoprase, jadeite | 6,5-7 |

| Sillimanite, garnet | 6,5-7,5 |

| Quartz, stone pebbles, amethyst, aventurine, forsterite, osmium, silicone, rhenium, vanadium | 7 |

| Tourmaline, cordierite, almandine, boracite, cordierite, danburite | 7-7,5 |

| Zircon, andalusite, euclase, hambergite, sapphirine | 7,5 |

| Emerald, hardened steel, tungsten, spinel, beryl, beryllium, aquamarine, red beryl, ganite, painite | 7,5-8 |

| Topaz, cubic zirconia | 8 |

| Chrysoberyl, alexandrite, choltite | 8,5 |

| Porcelain tiles (unpolished) | 8,5 |

| Corundum, ruby, sapphire, alundum, chrome | 9 |

| Moissanite, boron | 9,5 |

| Carborundum | 9-10 |

| Diamond, carbonado | 10 |

What is salt

You may be interested in: What is reaping? Interpretation and example sentences

The chemical formula of this substance is as follows: NaCl. Table salt is also called sodium chloride or rock salt. When crushed, this food product appears as colorless crystals. The latter may have different sizes. In any case, salt in bulk is white.

The main feature of sodium chloride, as is known, is its characteristic taste. In everyday life and in the food industry, table salt can be added to a variety of products. As scientists have found out, sodium chloride is a substance without which human life is completely impossible.

What is the hardness of salt on the Mohs scale?

You may be interested: A caravanserai is... Meanings, history, interesting facts

In nature, sodium chloride is a very common substance. Therefore, rock salt was, among other things, included as a standard in the Mohs scale. Sodium chloride is located in this scheme in the penultimate ninth place. That is, the hardness of table salt is two. Sodium chloride crystals are known to be fragile and easily dissolve in water. The salt grains look quite hard. However, this impression is largely misleading. In fact, salt crystals are easily scratched even with just a fingernail.

Linear hardness

Thus, as we found out, NaCl occupies the penultimate place on the Mohs hardness scale. The linear hardness of minerals is also very easy to determine using this scheme. Of course, this characteristic is also known for standard sodium chloride.

The relative indicator for salt, as we found out, is 2. What is the absolute hardness of salt on the Mohs hardness scale? For NaCl this figure is 3.

Hardness Units

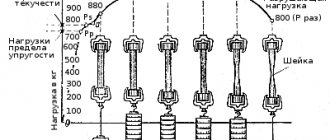

Each method of measuring the resistance of a metal to plastic deformation has its own methodology, as well as units of measurement.

The hardness of soft metals is measured using the Brinell method. Non-ferrous metals (copper, aluminum, magnesium, lead, tin) and alloys based on them, cast iron (except for white) and annealed steel are subjected to this method.

Brinell hardness is determined by indentation of a hardened, polished ball made of ShKh15 ball bearing steel. The circumference of the ball depends on the material being tested. For hard materials - all types of steel and cast iron - 10 mm, for softer materials - 1 - 2 - 2.5 - 5 mm. Required load applied to the ball:

- iron alloys – 30 kgf/mm2;

- copper and nickel – 10 kgf/mm2;

- aluminum and magnesium – 5 kgf/mm2.

The unit of hardness measurement is a numerical value followed by a numerical index HB. For example, 200 NV.

Rockwell hardness is determined by the difference in applied loads to the part. First, a preliminary load is applied, and then a general load, at which the indenter is introduced into the sample and held.

A pyramid (cone) of diamond or a ball of tungsten carbide (hardened steel) is introduced into the test sample. After removing the load, the depth of the indentation is measured.

The unit of measurement for hardness is conventional units. It is generally accepted that one is the amount of axial displacement of the cone, equal to 2 μm. The hardness designation is marked with three letters HR (A, B, C) and a numerical value. The third letter in the marking indicates the scale.

The technique reflects the type of indenter and the load applied to it.

| Scale type | Tool | Applied load, kgf |

| A | Diamond cone with 120° apex angle | 50-60 |

| IN | 1/16" ball | 90-100 |

| WITH | Diamond cone with 120° apex angle | 140-150 |

Basically, measurement scales A and C are used. For example, the hardness of steel is HRC 26...32, HRB 25...29, HRA 70...75.

Products of small thickness or parts with a thin, hard surface layer are measured by Vickers hardness. The blade used is a regular tetrahedral pyramid with an apex angle of 136°. The display of hardness values is as follows: 220 HV.

Hardness measurement using the Shore method is carried out by measuring the rebound height of a fallen striker. Indicated by numbers and letters, for example, 90 HSD.

Microhardness is determined when it is necessary to obtain the values of small parts, thin coatings, or individual alloy structures. The measurement is made by measuring the imprint of a tip of a certain shape. The value notation looks like this:

0.196 — tip load, N;

2800 – numerical value of hardness, N/mm 2.

Minerals with similar hardness

Salt, therefore, is a fairly soft substance. There are many such minerals in nature. For example, gypsum, mica, and chlorite have the same absolute and relative hardness indicators as NaCl. All these substances are easily scratched with a fingernail.

Of course, sugar also has its place on the relative Mohs hardness scale. Salt is used on the scale as one of the reference substances. Sugar, although also a very common food, is not initially listed on the Mohs chart. However, the hardness of this substance, like any other, is, of course, also known. Sugar is slightly softer than salt, but on the Mohs scale its hardness rating is also 2.

What is the hardness of steel? (Part 1)

The concept of metal hardness was previously known only to graduates of technical universities, workers of machine-building plants and blacksmiths. This term came into use with the modern knifeman with the adoption of the law on weapons and GOST standards, which provide signs on the basis of which a knife can be classified as a bladed weapon.

One of the mandatory characteristics by which a particular product is classified as a bladed weapon is the hardness of the steel from which the knife blade is made (or, as it is called in GOST, the warhead of a bladed weapon). And starting from this moment, the nyfomaniacs in Russia began to slowly read reference books that provide the characteristics of different steels, explanations of the differences between powder and laminated steels, and of course the steel hardness indicators, those very noticeable HRC.

If one car enthusiast can ask another about how many “cubes are in the engine,” then an advanced knifomaniac, looking at the characteristics of a field knife that says “57-59 HRC,” can seriously determine that this is a flimsy model for bushcraft and it belongs on kitchen.

This article will tell you in a simple and understandable form what kind of beast this HRC is, where it came from and why it is needed at all.

Interesting fact: On American and European websites, among the parameters indicated by sellers or manufacturers, it is extremely rare to find such a parameter as steel hardness.

This issue is not regulated in any way by law, so the average inexperienced buyer does not need this parameter.

So, what do we need to know about the hardness of metals?

Since ancient times, man has encountered the concept of hardness of materials. I also quickly realized that different materials differ from each other in hardness and strength. If you hit a stone with a stick, the stick will either break or bounce off. If you hit a stick with a stone, the stick will break. If a coconut falls from a tree onto a pebble beach, it will break. And if you hit a softer stone with flint for a long time and diligently, then you can quite easily make a head for a stone axe.

Gradually, in the process of evolution, our ancestors realized that different materials have different hardness, and depending on this hardness, they do or do not have the desired properties. Thus was born a method for determining the hardness of a material by comparing it with a certain standard.

Thus, a good carpenter can determine the degree of shrinkage of a log by tapping it with a mallet made of a harder type of wood. Using a special hammer, a potter can determine the degree of readiness of pottery. Willingly or unwittingly, each of us at least once in our lives has resorted to a similar method of determining the hardness of an object.

However, until recently, the most common method for determining the hardness of a material was the sclerometric method. Sclerometry is a physical process where the material being tested scratches (or scratches) a reference sample. If the material being tested scratches the standard, it means the material being tested is harder.

If the material being tested cannot leave a mark on the standard and is easily scratched by the standard, then the material being tested has a hardness less than that of the standard. Now this procedure seems ridiculous to us, but until recently, this was the only way to determine the hardness of a material. How else could the ancient Sumerians determine that it was possible to write inscriptions with a sharp stick on almost dried clay?

The issue of determining the hardness of materials (especially stones and metals) became acute at the end of the 18th and beginning of the 19th centuries, with the development of geology and the beginning of the flowering of mechanical engineering.

It was at this time that the “Mohs scale”, known to all physicists and archaeologists, appeared. However, the first to propose measuring the hardness of metals by comparing them with a standard was the French naturalist of the mid-18th century, Rene Antoine Reaumur.

Reaumur actively conducted experiments related to the melting and processing of metals and therefore he was faced with the acute question of determining the various characteristics of the alloys that he obtained in the process of his research.

His ideas were picked up and developed by the German naturalist and geologist Karl Friedrich Christian Mohs. In 1811, he came up with a system for standard comparison of minerals, which now bears his name. Until about the middle of the 20th century, this scale was actively used by geological exploration parties around the world.

The Mohs scale is a comparative table in which known minerals of different hardness are indicated and their hardness is measured in the following criteria:

- Scratched with a fingernail;

- Scratched by copper;

- Scratched by glass;

- Scratches glass;

- Processed only with diamond.

Tal is the softest reference mineral, while diamond is the hardest mineral. The hardness of talc on the Mohs scale is “1”, the hardness of diamond is “10”. Between talc and diamond, as hardness increases, there are: gypsum (hardness 2), calcite (hardness 3), fluorite (hardness 4), apatite (hardness 5), orthoclase (hardness 6), quartz (hardness 7), topaz (hardness 8 ), corundum (hardness 9). This simple method of determining the hardness of minerals turned out to be indispensable in field conditions.

In addition to the Mohs scale, there are other methods for determining the hardness of materials, which were actively developed at the end of the 19th and beginning of the 20th centuries. There are usually four most well-known methods for determining the hardness of metals:

- Brinell method;

- Vickers method;

- Shore method;

- Rockwell method.

Looking ahead, we note: all these methods are similar to each other, since they are based on pressing a reference sample into the metal surface. Only the shape of the standard, the pressure force, and the formula for calculating the value differ.

The element that is pressed into the surface of the metal is called an “indenter”. A steel ball (Brinell method), a diamond cone (Rockwell method), or a diamond pyramid (Vickers and Shore methods) can be used as an indenter.

Other physical characteristics

So, we found out what the hardness of salt is on the Mohs hardness scale. But what other properties does this substance have?

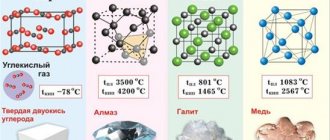

In mineralogy, ordinary table salt or rock table salt is called halite. The history of this transparent stone goes back millions of years. Halite forms in the form of cubic crystals, the color of which can vary from colorless to pinkish or yellow. The color of this mineral is associated with the type of impurities present in its thickness.

Halite can be found in the wild most often in layers of chemogenic sedimentary rocks, as well as in the bottom sediments of drying lakes and estuaries.

The main physical properties of salt are:

- ability to dissolve in water;

- the ability to crystallize on objects;

- salty taste;

- density - 2.165 g/cm3 at a temperature of 20 ° C;

- melting point - 801 °C;

- boiling point - 1413 ° C;

- solubility in water - 359 g/l at 20 °C.

NaCl has a pronounced taste. But no one will ever be able to smell the salt. This substance has a low hardness on the Mohs scale, and it is also brittle. Small particles of salt, for example, in places where it is found, can fly in the air and even get into a person’s nose. However, humans do not have receptors responsible for the perception of this substance. Some people claim that they can smell salt. However, in this case we are still not talking about NaCl, but about various kinds of impurities contained in this substance.

Mechanical methods for determining hardness.

The hardness of a material is the ability to resist mechanical penetration of another hard material into its surface layer. It is determined by the magnitude of the load required to begin the destruction of the material. Hardness is divided into relative and absolute. Relative hardness is the hardness of one material relative to another. Absolute hardness is determined using indentation methods.

Hardness depends on many factors. Among them: interatomic distances of a substance, valence, the nature of chemical bonds, fragility and malleability of the material, flexibility, elasticity, viscosity and other qualities.

The hardest materials existing today are two allotropic modifications of carbon - lonsdaleite, which is one and a half times harder than diamond, and fullerite, which is twice as hard as diamond. However, among the common substances, diamond is still the hardest.

There are several scales (measurement methods) for measuring hardness. They will be different for different materials. The following methods are used to measure the hardness of metals:

Brinell method

— hardness is determined by the diameter of the imprint left by a metal ball pressed into the surface. Hardness is calculated as the ratio of the force applied to the ball to the area of the indentation.

There are two types of hardness calculation methods:

Using the reconstructed indentation method, hardness is calculated as the ratio of the applied load to the surface area of the indentation:

,

- — applied load, H;

- — ball diameter, mm;

- — imprint diameter, mm.

According to the unrestored indentation method, hardness is determined as the ratio of the applied load to the area of the part embedded in the material and the indenter:

,

where is the penetration depth of the indenter, mm.

Units of measurement are kgf/mm². The hardness determined by this method is denoted by HB, where H = hardness, B - Brinell. These are some of the oldest methods, used back in the 19th century.

Rockwell method

— hardness is determined by the relative depth of indentation of a metal or diamond cone into the surface of the material being tested. Hardness is denoted by HR, where H is hardness and R is Rockwell. Hardness is calculated by the formula HR = 100 − kd, where d is the depth of indentation of the tip after removing the main load, and k is the coefficient. Thus, the maximum Rockwell hardness corresponds to HR 100. The 3rd letter in the designation is the name of the scale type, for example. HRA, HRB, HRC, etc. For knives, hardness is determined according to the HRC scale, which actually ends at 70 units, since the high hardness of a knife does not allow them to be fully used due to a decrease in toughness, increased fragility, etc. This system was the most common in the 20th century.

Rockwell hardness can be measured:

1) Diamond cone with a total load of 150 kgf. Hardness is measured on the C scale and is designated HRC (for example, 62 HRC). The method allows you to determine the hardness of quenched and tempered steels, materials of medium hardness, surface layers with a thickness of more than 0.5 mm;

2) Diamond cone with a total load of 60 kgf. Hardness is measured on the A scale, which is the same as the C scale, and is designated HRA. Used to evaluate the hardness of very hard materials, thin surface layers (0.3 ... 0.5 mm) and thin sheet material;

3) A steel ball with a total load of 100 kgf. Hardness is designated HRB and is measured on the B scale. This is how the hardness of mild (annealed) steel and non-ferrous alloys is determined.

When measuring hardness using a Rockwell instrument, it is necessary that the surface of the sample is free of scale, cracks, gouges, etc. It is necessary to control the perpendicularity of the load applied to the surface of the sample and the stability of its position on the instrument table. The indentation distance must be at least 1.5 mm when pressing the cone and at least 4 mm when pressing the ball. Hardness is measured at least 3 times on one sample, then the average value is displayed. The advantage of the Rockwell method over the Brinell and Vickers methods is that the hardness value according to the Rockwell method is recorded directly by the indicator needle, eliminating the need for optical measurement of the indentation dimensions.

Vickers method

- the widest scale in scope, hardness is determined by the area of the imprint left by a tetrahedral diamond pyramid pressed into the surface. It is designated HV, where H is Hardness, V is Vickers. When testing hardness using the Vickers method, a diamond tetrahedral pyramid with an angle is pressed into the surface of the material. After removing the indentation load, the diagonal of the indentation is measured. The Vickers hardness number is designated by the symbol HV indicating the load P and the holding time under load, and the dimension of the hardness number (kgf/mm2) is not specified. The duration of exposure of the indenter under load is 10–15 s for steels, and 30 s for non-ferrous metals. The advantages of the Vickers method over the Brinell method are that the Vickers method can test materials of higher hardness due to the use of a diamond pyramid.

Shore hardness

(Indentation method)

- hardness is determined by the depth of penetration into the material of a special hardened steel needle (indenter) under the action of a calibrated spring. This measurement method uses a device called a durometer. Typically, the Shore method is used to determine the hardness of low-modulus materials (polymers). Shore's method involves 12 measurement scales. The most commonly used options are A (for soft materials) or D (for harder materials). The hardness determined by this method is indicated by the letter of the scale used, written after the number indicating the method. As an example, the rubber in a passenger car tire has a hardness of approximately 70A, and a school eraser has a hardness of approximately 50A.

Shore Hardness (Rebound Method)

- a method for determining the hardness of very hard materials, mainly metals, by the height to which, after an impact, a special striker falling from a certain height rebounds. Hardness according to this Shore method is assessed in conventional units proportional to the height of the striker’s rebound. It is designated HSx, where H is Hardness, S is Shore and x is a Latin letter indicating the type of scale used in the measurement.

Libu method (hardness testers)

This is the most widely used method in the world today, hardness is defined as the ratio of the velocities before and after the striker rebounds from the surface. It is designated HL, where H is Hardness, L is Leeb, and the 3rd letter indicates the type of sensor, for example. HLD, HLC, etc. When using this method, a striker falling normally to the surface of the material under study collides with the surface and rebounds. The speed of the striker is measured before and after rebound. It is assumed that the firing pin is not subject to permanent deformation.

Asker method

— hardness is determined by the depth of insertion of the steel hemisphere under the action of a spring. Used for soft rubbers. According to the measurement principle, it corresponds to the Shore method, but differs in the shape of the probe surface. Asker uses a hemisphere with a diameter of 2.54 mm.

Kuznetsov-Herbert-Rehbinder method

— hardness is determined by the damping time of the oscillations of the pendulum, the support of which is the metal under study.

Poldi method (double ball imprint)

— hardness is assessed in comparison with the hardness of the standard, the test is carried out by impact pressing a steel ball simultaneously into both the sample and the standard.

Hardness of minerals.

Mohs mineral hardness scale

(scratching sclerometers) - a method for determining the hardness of minerals by scratching one mineral with another, for comparative diagnosis of the hardness of minerals among themselves according to the softer-harder system. The mineral being tested is either not scratched by another mineral (Mohs standard or sclerometer) and then its Mohs hardness is higher, or it is scratched - and then its Mohs hardness is lower. Mohs scale - determines which of ten standard minerals scratches the test material, and which of ten standard minerals scratches the test material.

Solubility degree

The peculiarities of salt, among other things, include the fact that its solubility in water depends little on the temperature of the latter. This indicator for NaCl increases by 7 g from 0 to 100 °C. However, the solubility of the salt is significantly reduced if the water contains MgCl2 or CaCl2. This indicator increases sharply for NaCl with increasing pressure. The process of salt dissolution occurs with significant heat absorption. This substance is practically insoluble in alcohol.

Chemical properties

In terms of its composition, NaCl belongs to the group of medium salts. The chemical composition of table salt is as follows:

- Na - 39.34;

- Cl – 60.66.

In its pure form, the composition of this substance fully corresponds to the theoretical one. Table salt contains Br (up to 0.098%) as an isomorphic impurity. Halite may also contain: NH3, He, As, J, Pb and some other substances. The atoms in the Na and Cl structure alternate evenly at the sites of the cubic crystal lattice.

Salt crystals can reach significant sizes. Halite is also characterized by skeletal formations - fragile, cloudy-white pyramidal boats.

Methods of artificial production

Rock salt for the food industry or, for example, medicine can be obtained using different technologies. In laboratories, brines of underground dissolution of rock salt are usually used to isolate NaCl. This allows you to get the purest possible product without industrial impurities. In this case, underground brines are subjected to conventional evaporation. In this case, pure salt is obtained with a hardness on the Mohs hardness scale of 2. Evaporation of brines using this technique is carried out in special multi-vessel installations.

Methods for measuring hardness

The degree of strength of a material is assessed by pressing a stronger object into it, as well as grinding and scratching its surface. The choice of which scale to measure the hardness of minerals is large. Besides leaving a groove with Mohs reference crystals, there are 6 main measurement methods:

- Rockwell scale - the depth of penetration of an identifier with a diamond tip into the material is recorded. Applicable to metals and alloys.

- Shore hardness is determined in the same way. Additionally, the method allows you to study the strength of plastic and elastic objects.

- The Knoop scale works on the principle of indentation. The result is assessed in Knoop units: diamond – 8500, corundum – 2000.

- Rock hardness using the Schreiner method is quantitatively determined by the ratio of the load on the punch to the die area. The measurement is accompanied by drawing a deformation diagram.

- The Rozival scale is based on the example of the Mohs table: indicators for a number of minerals were obtained using a hardness tester based on the results of grinding samples. The complexity of the method did not allow it to displace the classics.

- A Vickers pyramid reinforced with diamonds is statically pressed into the test object, and the result is viewed from the area of the indentation through a microscope. The devices are called hardness testers (for example, PMT-3).

All accurate methods for finding strength are inferior to the quick tabular method of determining by comparing the strength properties of minerals. It is not always necessary to see the breaking load; in most cases, it is enough to know which stone is harder.

Interesting Facts

The hardness of salt on the Mohs hardness scale is accurately determined. This indicator for NaCl is 2. People started thinking about the physical and chemical properties of salt not so long ago. But man has used this substance for various purposes since ancient times. First of all, salt has always been used, of course, primarily as a food product. However, sometimes she could perform other functions in society. For example, in Ethiopia this substance was used as currency until the 20th century.

In the Middle Ages, salt was so expensive that it was sometimes called white gold. In Germany, for example, there is still a special “salt pavement” along which this valuable food product was once transported between cities located on the shores of the Baltic Sea.

Salt is indeed a very important product for the human body. If you drink very large amounts of water, this substance will be washed out of the tissues. In this case, a person may even experience lethal hyponatremia.

Lack of salt in the human body is therefore very dangerous. But an excess of this substance, of course, cannot be useful. You should never eat too much salt at one time. Taking this substance in an amount of 1 g per 1 kg of weight can lead to death.

Source