Mining is one of the most important areas of activity, designed to provide raw materials for many industries, construction, transport and energy. Since ancient times, it has made it possible to extract gaseous, liquid and solid natural resources from the surface of the Earth, as well as from its depths, and since the middle of the last century - from the bottom of seas and oceans.

- Ferrous metal ores

- Mining chemical raw materials

Mineral deposits in Russia

The largest country in the world has more than 20 thousand mineral deposits, estimated at 30 trillion in resource reserves. dollars. This gigantic natural wealth, almost evenly distributed across the territory of Russia, should be enough for several centuries of continuous use. Therefore, in terms of reserves of natural resources, our state occupies one of the leading places on the planet.

The economic geography of mineral resources of the Russian Federation is such that:

- The largest natural reserves of gold are concentrated in the Far East and Yakutia.

- The Yamalo-Nenets Autonomous Okrug is richest in hydrocarbons. They are partially found in Tatarstan, Bashkortostan, Udmurtia, the Orenburg region, in the Volga River basin and on Sakhalin Island.

- Silver is present in significant quantities in Eastern Siberia and the Ural Mountains.

- Non-metallic building materials have been discovered in Eastern Siberia.

- Most of the coal lies behind the Ural Range.

- Oil shale is found in areas adjacent to the Baltic Sea.

- Iron ore has been discovered on the Baltic Shield, in the Kursk region and on the Kola Peninsula.

- Uranium reserves are present in Transbaikalia.

- The Urals and Western Siberia are rich in aluminum.

- Non-ferrous metals are concentrated in Taimyr and eastern Siberia.

- Precious and semi-precious stones are common in the Ural, Altai and Sayan mountain ranges.

However, it should be noted that most natural resources are located in hard-to-reach areas and have a low content of useful components.

Mining

Leading heavy industry

The basis for the functioning of manufacturing production for the manufacture of various machines is ferrous metallurgy. This industry includes the receipt of raw materials, the preparation of fuel and additional elements for the production of rolled products with the products of subsequent metal processing. The main activities include:

- mining, beneficiation and agglomeration of iron, chromium and manganese ores;

- production of steel, cast iron and rolled products;

- creation of electroferroalloys;

- alloy processing process;

- coal coking;

- production of fire-resistant components;

- obtaining minor elements (magnesite, limestone, etc.);

- production of industrial products.

The main activity of enterprises consists of piggyback work, and the rest are secondary, but no less important. Today Russia occupies a leading position in the world in terms of the degree of saturation of ferrous metals production. Russian metallurgical plants produce most of the world's rolled steel and cast iron.

The bulk of large enterprises on the geographical map are located in the Siberian and Ural regions. In this territory there are 7 plants that produce 4/5 of all steel, 9/10 of cast iron and more than 4/5 of rolled products. Every year, these enterprises process 2/5 of scrap metal and 9/10 of iron ore.

The plants that produce heavy metals are much larger, but in terms of production modernization they lag behind non-ferrous metallurgy enterprises. The peculiarity of modernization is to solve the problem of production waste and reduce costs.

Many enterprises use a combined production method, for example, coking of coal is carried out together with processing.

In Russia, almost all coke (95%) is produced at metallurgical enterprises. Today, in terms of their characteristics, almost all large plants are metallurgical and energy chemical plants.

In some cities of Russia there are small factories that are engaged in conversion activities without producing pig iron. There are also small workshops that produce steel and rolled products directly at machine-building plants. If we consider all types of industry, then ferrous metallurgy with a full production cycle is the main factor for regional formation.

Main mining methods

Depending on the depth of occurrence of mineral resources, one or another method of their extraction is chosen:

- Career or open path. It is used to extract metal ore, nonmetallic building materials, and coal. This is the most economical, but at the same time quite strong impact on the soil method. Which further reduces its fertility and has a harmful effect on the environment.

- Mine or underground method. It is also called closed. This method is used for deep occurrence of mineral raw materials, ores and polymetals. Its disadvantages are significant costs and a high level of production risk for miners and miners.

- Open-underground or combined method. In fact, it combines the first two and is used in cases where minerals occur both on the surface and deep in the earth's crust.

- Borehole or geotechnological method. It is used to extract raw materials in a liquid or gaseous state. Typically, it is used to extract oil and gas, sulfur and lithium, uranium and phosphorus from drilled wells, resorting to leaching, precipitation and smelting. In order to then extract through pipes the mineral resources that are so needed in the national economy.

- Dredging method. It combines mining and mineral processing. Most often it is used in the development of placer deposits of diamonds, gold, cassiterite and platinum group metals.

Ferrous metallurgy

Ferrous metallurgy is based on the processing of iron, namely the ores in which it is contained. Most iron ores are natural oxides. That is why the first stage of production is the separation of iron from the oxide. Large blast furnaces are used for this. This method of producing cast iron is carried out at temperatures above 1000 degrees.

Ferrous metallurgy

In this case, the properties of the resulting raw materials directly depend on the temperature of the blast furnace and the melting time. With further processing of cast iron, steel or foundry cast iron is obtained, with the help of which blanks and products are cast.

To produce steel, iron and carbon are used, the addition of which gives the resulting alloy the desired properties. Various alloying components can also be used to achieve certain characteristics of the steel.

There are several methods for producing steel, which are based on smelting the metal in a liquid state. The following should be highlighted: open hearth, oxygen-converter and electric melting.

Each type of steel is called a grade, which indicates its composition and properties. To change the properties of steel, an alloying method is used, that is, adding additional components to the alloy. The elements most often used for such purposes are chromium, manganese, boron, nickel, tungsten, titanium cobalt, copper and aluminum. Typically, such components are added to molten steel.

But there is another method, which consists in pressing fine-grained powder of the components and then baking at high temperatures.

Fuel and energy minerals

Oil

Our country ranks seventh in the world in terms of the number of proven oil reserves. Deposits estimated at 14.1 billion tons are located in 9 oil and gas provinces:

- Volga-Ural,

- Yenisei-Anabar,

- West Siberian,

- Leno-Vilyuiskaya,

- Leno-Tunguska,

- Okhotsk,

- Pricaspian,

- North Caucasus-Mangyshlak,

- Timan-Pechorskaya,

and in 3 oil and gas regions:

- Anadyrskaya,

- East Kamchatka,

- Baltic.

The leader among domestic oil fields is Samotlor - 7.1 billion tons. The productive period for using the reserves of this liquid hydrocarbon fuel on the territory of our state is estimated at 22 years.

oil

Natural gas

Russia is the undisputed global leader in blue fuel reserves, the total volume of which is estimated at 40 billion tons with a production prospect of more than 80 years.

The largest part of it (over 75%) falls on the deposits of Siberia. The largest among them are: Urengoyskoe – 10 trillion. m3 and Yamburgskoye – 8.9 trillion. m3.

Coal

According to the reserves of this natural resource, estimated at 2.23 trillion. t, Russia is in third place. Moreover, a significant part of the deposits – 69% – is brown coal. Most of the reserves, accounting for 63% of this valuable energy resource, are located in the eastern part of the country:

- The Kuznetsk coal basin is one of the largest in the world, with gigantic reserves of hard and coking coal.

- Kansko-Achinsky (brown coal).

- Pechersky.

- South Yakutsk.

The majority of domestic coal mining - 75% - is carried out using the closed mine method, which significantly increases its cost.

coal

Oil shale

Most of the oil shale deposits are located in the European part of Russia, in the Leningrad and Samara regions. There are also large deposits in the north of the country and in Siberia.

However, they are not actively developed due to competition from more common fuels such as oil and gas. Perhaps it will be started after the main hydrocarbon reserves have been exhausted.

Uranus

In terms of reserves of this natural resource, Russia is confidently in the top ten. According to studies five years ago, its reserves amount to 507.8 thousand tons, which is a tenth of the world's uranium resources. The main deposits are concentrated in Yakutia and Buryatia and in the Trans-Baikal Territory.

Main metallurgical bases

All of the above factors led to the uneven distribution of metallurgical enterprises. Entire metallurgical bases were formed in certain territories. In Russia there are three:

- The central base is a fairly young center, the foundation of which is the iron ores of the Kursk magnetic anomaly region, the Kola Peninsula and Karelia. The main production centers are the cities of Lipetsk, Stary Oskol and Cherepovets;

- The Ural base is one of the largest centers of metallurgy in Russia, the main centers of which are Magnitogorsk, Novotroitsk, Chelyabinsk, Nizhny Tagil and Krasnouralsk;

- The Siberian base is a center that is still in the development stage. The main source is Kuznetsk coal and iron ore from the Angara region and Mountain Shoria. The main center is the city of Novokuznetsk.

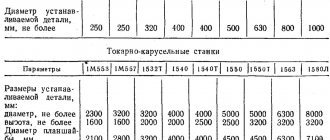

A comparative description and operating diagram of metallurgical bases in Russia can be presented in the following table:

| Central | Siberian | Ural | |

| Iron ores | Kursk magnetic anomaly, Kola Peninsula, Karelia | Angara region, Mountain Shoria | Ural Mountains |

| Coking coal | Privoznoy (Donetsk and Kuznetsk coal basin) | Local (Kuznetsk coal basin) | Privoznoy (Kazakhstan) |

| Enterprises | Full cycle enterprises (produce cast iron, steel, rolled products) | Full-cycle and marginal metallurgy enterprises (produce only steel and rolled products) | Full cycle enterprises (produce cast iron, steel, rolled products) |

Metal fossils

Metals play a vital role in society. Without them, it is impossible to imagine either industrial production or the life of modern people.

Ferrous metal ores

Ferrous metals include iron and its alloys: steel, cast iron and ferroalloys. Their ores are divided into groups named after the main mineral:

- Red iron ores or hematites are iron oxides (Fe2O3), most used in ferrous metallurgy; and also used as a dye, known as red lead.

- Magnetic iron ore or magnetites, which are iron oxides and iron oxides (FeO and Fe2O), are distinguished by their magnetic properties.

- Brown ironstones or goethites, also called limonite or bog ore, are hydrous iron oxides. Their value lies in the fact that they can be directly used in the process of smelting iron in blast furnaces. The most valued by metallurgists is limonite from the Kerch deposit, which contains vanadium, manganese and phosphates.

- Spar iron ores or siderites are gray minerals containing iron carbonate (FeCO3). Russia is the world leader in iron ore deposits: proven reserves are estimated at 264 billion tons.

black ore

Non-ferrous metal ores

A significant part of minerals is called non-ferrous metals - these are all metals except iron, which received their name for their specific color.

The raw ores of these metals are characterized by extremely low metal content and very diverse composition. It is not surprising that they are called polymetallic ores. In this regard, in non-ferrous metallurgy there is often a complex use of natural raw materials.

Depending on density, they are divided into ores of light metals: aluminum, titanium, potassium, calcium, lithium, magnesium. And ores of heavy metals: copper, tin, lead, zinc.

Rare metal ores

A vast group of 36 chemical elements received their name purely for historical reasons. In fact, they are found in nature no less often, and sometimes much more often than ferrous, non-ferrous and noble metals.

Rare metal ores either occur independently or are present incidentally during the development of other minerals. A significant part of rare metals is extracted from non-ferrous metal ores, as well as from other minerals: germanium from brown coals, vanadium from iron and titanium ores, hafnium and rubidium from ores of other rare metals.

On the territory of Russia, significant accumulations of rare metal ores have been discovered in the Caucasus, the Urals, Siberia, the Far East, and also in Yakutia (Tomtor deposit).

Rare metal ores

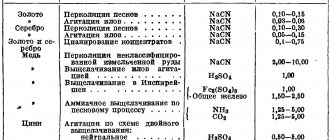

Precious metal ores

This group includes precious metals: gold and silver, as well as platinum and platinum group metals: iridium, osmium, palladium, rhodium and ruthenium, which are resistant to oxidation and corrosion.

Our state has significant reserves of precious metal deposits:

- Gold – 25 thousand tons. Of these, 4/5 are ore deposits, 1/5 are placer deposits. The most significant are the Bodaibo gold deposit in Eastern Siberia and the Bam gold deposit in the Far East.

- Silver. In terms of its reserves, Russia holds first place in the world, having 16 direct deposits of silver (27% of all-Russian reserves) and a number of complex deposits. The first of them are located in Chukotka and Yakutia.

- Platinum group metals – 6-10 thousand tons, which is the third figure in the global list. The leading positions in the industry are occupied by the Nizhny Tagil field in the Urals and the Fedorov-Panskoye field in the Murmansk region.

Meaning and structure of metallurgy

From ancient times to the present day, metal has remained the main structural material.

Recently, thanks to scientific and technological progress, the specific gravity of metal in many industries has been reduced. But it continues to play an important role in the development of the economy of any country. Definition 1

Metallurgy is a set of industries and enterprises responsible for the extraction of metallurgical raw materials, their enrichment and metal production.

Metallurgy consists of two main parts: ferrous metallurgy and non-ferrous metallurgy. Each of them is divided, in turn, into a number of industries. The basis for this division was the final product of production (the metal itself). It is the metal that determines the principles of location of each production.

Are you an expert in this subject area? We invite you to become the author of the Directory Working Conditions

The basis of metallurgical production is the mining industry. They develop in places where raw materials are located. Mining and processing plants are also located there. They make it possible to increase the content of useful substances in raw materials, “weed out” waste rock, and increase the efficiency of transportation of raw materials.

On the basis of mining industries, the production of the metal itself (metallurgy itself) is developing. The finished metal is supplied to the production of rolled products.

All branches of metallurgy are closely related to the chemical industry, mechanical engineering and energy. Russia occupies a leading position in the amount of metal produced. But production needs technical and technological re-equipment and reduction of energy costs.

Finished works on a similar topic

Course work Ferrous and non-ferrous metallurgy of Russia 490 ₽ Abstract Ferrous and non-ferrous metallurgy of Russia 220 ₽ Test work Ferrous and non-ferrous metallurgy of Russia 220 ₽

Receive completed work or specialist advice on your educational project Find out the cost

Non-metallic fossils

Non-metallic or non-metallic natural resources, used in their direct form for construction and industry or as raw materials, occur in nature in the form of minerals or rocks.

Mining chemical raw materials

Mining raw materials for chemical production are:

- Apatity. On the territory of our state there is the largest apatite deposit on the Kola Peninsula (Khibiny).

- Barytes. Used to produce barium salt, glaze and enamel.

- Borats. Act as water softeners in the production of washing powders.

- Phosphate ores. Russia has more than two hundred large deposits of phosphorites.

- Sulfur, largely used in the production of sulfuric acid. Large reserves of this natural raw material are located in the Samara region, the Urals (sulfur pyrites), Kamchatka, and the Kuril Islands.

Mining chemical raw materials

Mining raw materials

This type of minerals includes materials used in metallurgy, as well as in the production of abrasives, dielectrics, ceramics, glass and thermal insulation materials. The main minerals used as mining raw materials are:

- various clays, dolomites, limestones, quartz sands, porcelain stones;

- anhydride, gypsum, perlite, dolomites, limestones, talc, graphite and much more.

Optical materials

Materials of natural or artificial origin that are transparent and intended for the manufacture of optical devices. These are mainly glasses, photositalls (synthesized materials) and single crystals.

Lead and zinc

of lead and zinc , these inextricably linked metals, have their own characteristics The main mineral of lead is lead luster, or galena, a silvery-white mineral in cubic crystals.

Lead ores

Silver, bismuth, and antimony are extracted from lead concentrates. The latter form only an insignificant impurity in the lead luster, but given the enormous scale of smelting lead ores, they constitute a very important addition to the extraction of these valuable elements from their own minerals.

The main mineral of zinc is sphalerite (zinc blende). It is called decoy because it has a diamond-like luster rather than a metallic luster, like ore. Its color varies: from brown to black and cream. These two minerals, galena and sphalerite, have been said to constantly occur together.

Zinc concentrates

Germanium, indium, cadmium and gallium are extracted from zinc concentrates They form a very minor impurity in zinc blende, where they replace zinc atoms in the crystal lattice, taking their place. And, despite the insignificant content, it is the extraction of these small impurities from zinc blende that is the main source of their production.

They are of great value! For example, cadmium is used in the production of nuclear reactors, batteries, and low-melting alloys. Gallium, due to its low fusibility (melting point of only 30 degrees Celsius), is used as a substitute for mercury in thermometers.

Cadmium with tin and bismuth produces a Wood's alloy with a melting point of 70 degrees. Indium added to silver gives the latter great shine, and when alloyed with copper it protects ship hulls from corrosion in sea water. Germanium is used in the production of semiconductors.

Sulfide Ore

Silver, bismuth, arsenic, and copper are often found in ores together with lead and zinc, which is why lead-zinc deposits are called polymetallic. These deposits are formed from hot aqueous solutions and are especially common as deposits and veins among limestones that are replaced by sulfide ore .

Salts and brines

A group of minerals that have a salty taste and easily dissolve in water. According to their chemical composition, they are divided into borates, halides, iodites, carbonates, sulfates of potassium, magnesium, sodium and chlorides.

Salts and brines are used in construction, in the production of mineral fertilizers and as a food additive:

- Potassium salts. The largest Verkhnekamskoye deposit of potassium-magnesium salts (VMKMS) is located in the Perm region.

- Rock or table salt. The largest suppliers to the Russian market are:

- JSC "Bassosl", Astrakhan - 1.3 million tons per year;

- OJSC "Uralkali", Berezniki - 1.0 million tons per year;

- OJSC “Iletsksol”, Orenburg – 0.5 million tons per year.

- Gypsum or hydrous calcium sulfate is widely used in construction, medicine, and arts and crafts.

Salts and brines

Tin and tungsten

Tin and tungsten are rarer metals and represent a special group (in practice they are now classified as “non-ferrous”). The use of non-ferrous metals is very wide: in mechanical engineering, other fields of technology, and in military affairs.

Let’s imagine for a moment that the resources of such a metal as tin were depleted, all life would immediately stop: after all, tin alloys are used for bearings necessary in any mechanism, without tin alloys it would be impossible to produce cars, electric locomotives, machine tools, the production of canned food (tin) would fall – metal of tin cans).

It would seem that such an inconspicuous metal as tin is an extremely necessary link in all technology.

Rare metal minerals

These metals are found in the form of oxygen compounds: tin - in the oxide, cassiterite, or tin stone, tungsten - in salts of tungstic acid: tungsten and scheelite.

Minerals of these elements are often found in quartz veins in or near granites. Shiny black or brown wolframite crystals stand out against white quartz. Sometimes they are found in other types of deposits: scheelite at the contacts of granites with limestones in skarns, cassiterite in sulfide veins.

Oxygen compounds form many so-called rare metals : lithium, rubidium, cesium, beryllium, neobium, tantalum - they are often found in pegmatite veins. Ancient Precambrian pegmatites (Africa, Brazil, Canada) are especially rich in them.

Precious and semi-precious stones

Minerals used in jewelry making and stone cutting. Distinctive features of precious stones are their beautiful color, bright shine, transparency, and various optical effects. In addition, they have high strength and durability.

Ornamental stones are not transparent, although they have a beautiful texture and can be easily machined. They are usually used in the decoration of buildings and some products.

Deposits of these minerals are present in the Urals (gems), Yakutia (diamonds) and Eastern Siberia.

Aluminum

aluminum and its even lighter brothers – magnesium and beryllium are currently becoming important These metals are competitors of the all-powerful iron, designed to replace it in many areas. These metals and their alloys are widely used in technology, especially in aircraft construction, rocket production, in the production of drill pipes - wherever light metal is needed.

Raw material for aluminum - bauxite

Aluminum, as is known, is very widespread in the earth's crust, and in the future it will be possible to obtain it from any aluminosilicate rocks rich in this element. In the meantime, the traditional raw material for aluminum is bauxite .

They consist of aqueous alumina compounds formed both by sedimentation during deposition in marine basins and by weathering of aluminosilicate rocks. Recently, a method has been developed for obtaining aluminum from ancient crystalline schists formed during the metamorphism of clay deposits, as well as from alkaline igneous rocks.

Thus, the problem of sources for obtaining aluminum will never face a person: this metal will be abundantly enough for all subsequent generations. It's just a matter of the technology for its extraction and electricity to create powerful energy-intensive industries.

Construction Materials

Natural minerals used in construction include:

- Gravel is a small, rounded stone.

- Crushed stone – sharp-angled stones, no more than 70 mm in diameter, used as filler.

- Sand is a fine-grained stone fraction up to 5 mm in size.

As well as minerals used in the production of concrete, cement and other binders.

On the territory of Russia there are 8,500 deposits of more than 100 types of non-metallic building materials. The largest of them are located in the Vyazemsk, Kirov, Moscow and Smolensk regions.