The purpose of this article is to introduce you to the most common metals from which spirals are made and discuss their characteristics, advantages and disadvantages. Some wires can only be used in watt mode, some in temperature control mode and there is an exception that can be used in all modes.

The main goal is not to overwhelm you with technical specifications, but simply to give you an idea and help you choose the metal for the coils, the material that will best suit your vaping style. The main attention will be paid to single-core wires, no exotic spirals - clapton, alien, braids, etc.

Diameter, resistance and TCR

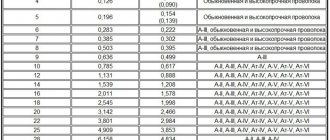

There are basic characteristics that apply to all wires, regardless of the material from which they are made. The first thing you should pay attention to is the diameter of the wire. In the metric system, the diameter is measured in millimeters (for example: 0.4 mm), in the imperial system the diameter is marked as a gauge (gauge) and is indicated by a digital value (for example: 26 gauge). If everything is clear with millimeters, then in the imperial system, the higher the caliber, the smaller the diameter of the wire. For a better understanding or quick conversion to millimeters, you can use the winding calculator, where in the “Wire diameter” field you can see the main dimensions and their values.

The second feature of the wire is that as the diameter increases, the resistance decreases, but it takes more time to heat it up. Thick wires of 0.8mm and 0.6mm will have low resistance and will take longer to heat up than thinner wires of 0.4mm or 0.3mm.

Temperature Control (TC)

For temperature control, metals are used whose resistance depends on the temperature of the coil (Temperature Coefficient of Resistance (TCR)). To regulate power, your mod reads the resistance every 0.25 seconds and supplies the required power to the coil to maintain a certain heating temperature.

I promised that the article would be without technical difficulties, but with temperature control it won’t be easy. Therefore, a simple example: the box mod knows the resistance of the cold coil and the TCR, with the help of which it easily calculates the temperature and decides how much power to supply to the coil, and if the temperature is higher than the set one, then stop supplying electricity altogether. All calculations occur 4 times per second, which is why it will be difficult for you to see and feel any changes in the operation of the mod. I hope it was clear, now let's move directly to the wires and spirals.

Atomizers for winding

Before purchasing an atomizer, it is better to seek advice from specialists, namely experienced vapers.

The most popular models among the vaping community are as follows:

- Kanger SubTank is a popular and highly advertised self-propelled clearomizer that has won many followers for its ability to use both factory and homemade coils. Recently a modification of this model was released - TopTank. The new version allows the top, thus without unscrewing the device from the mod.

- Kayfun is a Russian-made clear, which is created only for self-winding;

- Billow v2 – the main difference of this clearomizer is the ability to install two coils, and not, as usual, one.

- Zefirus is a double-coil clear of excellent quality, which is also loved by vapers for its ability to work with both homemade heads and factory ones.

- Velocity – unlike previous models, it is a drip device, not a clearomizer. That is, its device does not have a liquid tank. The refill must be dripped onto the spiral. Despite not being very convenient to use, Velocity will provide you with excellent taste.

Kanthal, also known as fechral (FeCrAl)

Kanthal is the name of the manufacturer, which has become a household name in the vaping community. It is an alloy of three metals - iron (Fe), chromium (Cr) and aluminum (Al). The alloy is called fechral (FeCrAl), and can sometimes be found on sale under the name eurofechral. There are no differences between Kanthal and Fechral, except that Kanthal A1 wire also contains 0.15-0.4% titanium, and has a slightly increased operating temperature and melting point. Otherwise, there are no differences and usually the canthal is equal to the fechral.

Kanthal works well in wattage mode and is the most popular material for coils. It is easy to work with, it does not spring, especially after burning, and oxidizes very slowly. This makes it possible, along with changing the cotton, to once again burn through the bare coils, clean off carbon deposits from them and use them again. As a result, such coils can last for months if they are properly maintained and cleaned.

The big advantage of Kanthal is its low TCR, so it cannot be used in temperature control mode. This means that regardless of temperature, the resistance remains unchanged, which at 30 °

C, which is at 200

°

C.

You can buy kanthal at any vape shop, where you can get yourself a couple of meters of wire with a diameter of 0.4 mm to start with, the price can reach up to 50-100 rubles per meter. This is enough for most standard windings and simple experiments.

pros

- Ideal in variwatt mode and on mech mods

- Kanthal is easy to work with, twisting, bending, etc.

- Doesn't spring back and keeps its shape

- Sold in every vape shop

- Inexpensive

Minuses

- Does not work in temperature control (TC) mode

Is it worth it?

You should not expect that winding an evaporator at home will give you financial benefits instantly and immediately. But after several months of use, the savings will be obvious.

If, as an example, we take evaporators for Kanger Sub Tank with a resistance of 0.5 Ohm, which cost about one and a half thousand rubles for 5 pieces per package, then the monthly costs will be 550-750 rubles.

Consumables of your own production will cost you about 120 rubles per month, which will be a difference of almost 5 times. The benefit is obvious, but do not forget that this will be preceded by some costs for materials simply damaged during the learning process. But the result is undoubtedly worth it.

Plus, an important factor will be that you will be able to adjust the parameters of the evaporator yourself, since devices whose manufacturers have a narrow range of consumables. Based on this, you can adjust either the throat hit or the amount of steam to the ideal of your own requirements and preferences.

Nichrome

Another type of wire well suited for spirals and vari-watt mode is nichrome (NiCr) . Nichrome is an alloy of nickel and chromium, in some cases a little iron may be added to it.

In vari-watt mode, nichrome behaves the same as kanthal, but for the same size and thickness will have a lower resistance than kanthal. In addition, nichrome heats up faster. But like kanthal, it does not spring and the spirals retain their shape well after burning. You need to be as careful as possible with burning, the combustion temperature of nichrome is lower than that of kanthal and if you are used to burning kanthal heavily, then there may be problems with nichrome, it may simply start to burn and melt. Be careful and do not burn through the nichrome too much.

The main disadvantage of nichrome and why it is less popular is that a large number of people on earth are allergic to nickel. You may not even suspect it and live peacefully all your life, and then try to vape on nichrome and feel a sore and itchy throat, and the appearance of sores in the oral cavity.

Note: The author of this article is allergic to nickel and I can tell you in detail about ulcers on the mucous membrane and how to deal with them. But believe me, it’s better to just stop vaping with nichrome if you are allergic to nickel.

You most likely won’t be able to buy nichrome in a vape shop; it is a very unpopular material for coils. But faster heating and lower resistance can give you a new vaping experience. Another thing is that nichrome will most likely have to be ordered from China.

pros

- Warms up faster than Kanthal

- Nichrome is easy to work with, twist, bend, etc.

- Doesn't spring back and keeps its shape

Minuses

- Low combustion and melting temperature

- Many people are allergic to nickel

- Hard to find in local stores

Right choice

It is worth noting here that wire for electronic cigarettes is often sold in the form of a finished spiral. In this case, you will only have to replace the old winding with a new one. Before you start making a spiral, carefully review our catalog - perhaps the manufacturer has already taken care of this for you.

You can buy wire for rewinding evaporators both in the Vardex online store and in the nearest branch of our retail network.

Steamers are divided into two categories. Yes, yes, just two. The first is lazy asses,

the second is

damn drug addicts with their delays, cotton wool and other incomprehensible stuff.

This series of articles is for those who are offended by the title of lazy ass, and who want to become a damn drug addict. Go!

—

Well, I'm a lazy ass, yes. And what will this advanced training course give me to become a damn drug addict?

Let's start with the pros:

- saving money

Winding it yourself is cheaper than buying replacement evaporators or ready-made winders. So, for example, a head for a tank costs from 150 to 300 rubles, which is equivalent to buying from 3 to 10 meters of kanthal. One spiral requires an average of 6 to 10 centimeters of wire. In my opinion, the benefits are obvious.

- fame of manufacturing materials

If you wind yourself, you always know what kind of wire you are using. Well, to the best of your knowledge and to the best of the seller’s honesty. Different wires have different characteristics - resistivity, melting point, softness and others. We'll talk about the characteristics of different wires in the next part.

- the opportunity to achieve a match that suits you

Maintenance-free atomizers or replaceable heads do not provide the user with a large choice of resistances, evaporation areas, wire thickness and other coil characteristics that are important for the resulting vapor. By winding it yourself, you get unlimited scope for experiments, as a result of which you can achieve a result that suits you on your device.

- the opportunity to wind something that is basically not on sale

It is not always possible (if not completely impossible) to find ready-made flat-fused claptons, for example. But I want to try it. Or come up with something of your own. Exclusivity, so to speak.

- a huge amount of information and examples

Finding how to wind a specific atomizer is absolutely no problem! The amount of materials on winding (from forums to YouTube) is huge. So you will always have an example before your eyes.

- winding is interesting

Winding yourself is a kind of creativity, a hobby. You are not limited by anything! Experiment, create, do strange things.

It's fun!

But, of course, “self-service” atomizers also have disadvantages:

- requires practice

Don't think that you will wind the perfect coil the first time. Although, of course, such cases did occur. However, in most cases it will take some practice, and the first results may be, well, let's just say, not great.

- you will have to spend some free time on the winding itself

On average, rewinding an atomizer takes no more than 10 minutes if the build is not complicated. However, beginners may need more at first. Well, complex builds (coil porn and that’s all) can take much, MUCH longer.

- Tools will be required

For winding you will need a number of tools: screwdrivers, pliers, side cutters. Nothing extraordinary - but still. If you want something more complicated, then you can’t do without a drill with an adjustable speed of rotation or a screwdriver.

- Requires basic knowledge of physics

In order to wind it yourself, you need to know and understand Ohm's law at the 8th grade level. We'll talk about it in this series of articles, so don't be afraid if you don't remember anything from school.

- there is a chance of getting hurt

When working with tools and wire, there is always a chance of getting hurt - getting pricked, getting burned during burning, scratching. The number of “injuries” directly depends on your attentiveness and accuracy.

It is worth noting here that not everyone wants and loves and will waste it. Many are more than happy with what the maintenance-free atom market offers. So now the choice is yours - on one side of the scale we put the pros, and on the other - the cons combined with your laziness.

Well, since you’re still here, that means you’ve decided to hang around. That's right, we approve!

Stainless steel

Stainless steel (SS) is the most versatile option for coils and can be used in wattage mode and temperature control mode. This can make your life easier if you frequently switch between operating modes, experiment with windings, or simply test the tank and drip. Stainless steel is an alloy of chromium, nickel and carbon. There are many varieties of steel, each grade has a number (for example: 316L). Again, I promised not to go too deep into the technical features and differences, just know that 316 stainless steel is one of the best choices, used in the pharmaceutical, food and medical industries.

Stainless steel bends easily, weaves and holds its shape without springing. Like nichrome, it heats up quickly and in this regard is superior to kanthal. Steel is not easy to find in local stores, especially of a certain brand, and often has to be ordered from online stores.

Note: Some older mods (pre-2016) do not support stainless steel in TC mode. If this is your case, then you can look for new firmware on the manufacturer’s website or manually configure the TCR for thermal control.

pros

- Works in variable watt and TC mode

- Heats up faster than Kanthal

- Doesn't spring back and keeps its shape

Minuses

- Contains nickel

- Hard to find in local stores

Mechanical properties at elevated temperature

All values are representative average values in delivery condition. The samples are taken in the longitudinal direction from tube and in length and cross directions on hot rolled plate.

Impact test

The graph shows Charpy-V results tested on heating.

Standard samples were machined from 12 mm hot rolled plate. A transition from low to high absorption energy regime occurs at ~200°C (390°F). Similar behavior exists for other product forms in relatively heavy section, like extruded tube. Hot tensile test (deformation rate 10-3 s-1)

| Temperature °C (°F) | Tensile strength Rm MPa (ksi) |

| 600 (1112) | 420 (61) |

| 800 (1472) | 120 (17) |

| 1000 (1832) | 42 (6) |

| 1200 (2192) | 16 (2.3) |

Hot tensile test — Gleeble test (deformation rate ~1 s-1)

Creep strength - 1% elongation

| Time | Temperature/Stress (MPa) | ||||||

| h | 700°C | 800°C | 900°C | 1000°C | 1100°C | 1200°C | 1300°C |

| 100 | 39,9 | 26,2 | 19,7 | 12,7 | 7,0 | 3,4 | 2,1 |

| 1000 | 36,8 | 23,4 | 16,2 | 9,9 | 5,0 | 2,3 | 1,5 |

| 10000 | 34,0 | 21,0 | 13,2 | 7,8 | 3,6 | 1,6 | 1,2 |

| 100000 | 31,4 | 18,8 | 10,8 | 6,1 | 2,6 | 1,1 | 0,9 |

1% elongation data are calculated from minimum strain rate data.

In general, there is an initial amount of primary creep in the order of 0.3 — 1% depending on product form, temperature and stress level. Total elongation to rupture depends on temperature and stress but is typically in the order of 3 to 12% where the lower range is representative for low stress levels. Creep strength - rupture

| Time | Temperature/Stress (MPa) | ||||||

| h | 700°C | 800°C | 900°C | 1000°C | 1100°C | 1200°C | 1300°C |

| 100 | 45,0 | 29,2 | 21,6 | 14,4 | 8,7 | 4,6 | 2,7 |

| 1000 | 39,7 | 24,8 | 17,0 | 10,8 | 5,5 | 2,5 | 1,5 |

| 10000 | 35,0 | 21,1 | 13,4 | 8,1 | 3,5 | 1,4 | 0,9 |

| 100000 | 30,8 | 18,0 | 10,6 | 6,1 | 2,3 | 0,8 | 0,5 |

Creep rupture data are representative average values for tube, bar and hot rolled plate based on creep tests performed within the time and temperature range indicated by the length of the solid lines in the diagrams (test times less than 50,000 hours). It should be pointed out, that component lifetime on thinner sections may be limited by oxidation/corrosion rather than creep rupture at low stress levels and long exposure times as indicated by the shaded area in the tables. 10,000 hour rupture compared to some other alloys are given in diagram.

Nickel

Nickel wire, also called Ni200 , is usually pure nickel and was first used for thermal control mode, followed by titanium and stainless steel.

The main disadvantage of nickel is its softness; in addition, the coils are very springy, which complicates their installation. The second disadvantage is allergies, this is not an alloy, it is pure nickel and people with allergies to it will have a very difficult time vaping. If there is very little nickel in stainless steel and you can fight allergies, if they manifest themselves at all, then such tricks will not work with Ni200.

Otherwise, it will be your personal choice why you decided to use Ni200, because there are no reasons to use it in 2022. But it can still be easily found in local vape shops, which is definitely a plus.

pros

- Works well in TC mode

- Easy to find locally

Minuses

- Difficult to work with, very soft and springy

- Nickel for allergy sufferers

The ability to make coils will give your device uniqueness

As mentioned above, the ability to wind can give your fur or board a new color. You can wind up some incredible fat spirals that look very brutal and really complex. All respect among the vape community will fall at your feet the next time you open your drip to drip some cotton wool. The main thing here is not to go too far. For example, you can wind up something very interesting, but what good is it if the coils barely heat up? Here you need to think a little and just try.

Titanium

The last material for spirals that we will consider is titanium . Titanium wire consists of pure titanium, without impurities.

Titan works great in TC mode, but is not at all suitable for variwatt. In addition, there is disagreement in the vaping community regarding burning titanium coils. The fact is that titanium at a temperature of 648℃ releases titanium dioxide, which is a toxin. Another big disadvantage is that titanium is easy to ignite when burned, and then difficult to extinguish, you can melt all the o-rings on your tank or drip in this case. Some vape shops don't even sell titanium wire for this very reason.

But another part of the vaping community calmly uses titanium in thermal control mode, they simply do not burn through the coils and do not set the temperature to high. Be careful and always check which mode you are going to vape in.

In my case, I easily used titanium spirals and never burned anything. You can easily make any coils from titanium, it is easy to work with and does not cause any problems in vaping and setting the TC mode. Although it is still inferior to stainless steel. Titanium is very difficult to buy in local vape shops; you will have to order five to ten meters online at once.

pros

- Works well on TC

- Doesn't spring back and keeps its shape

- Titanium is easy to work with, twist, etc.

Minuses

- Toxic at high temperatures

- May burn

- Very difficult to find in stores

Types of weaving

There are several types of coil weave that are used in e-cigarettes today. These include:

- Microcoil or nanocoil.

This spiral is small in size. The winding turns are located very close to each other, due to which the maximum possible heating zone is achieved. Microcoil is used on small clears and ensures the generation of a large volume of steam.

- Spacecoil, or regular coil.

All winding turns of this spiral are separated by empty space. Such design features ensure uniform distribution of liquid throughout the cotton wool, thereby reducing the likelihood of the latter burning. Spacecoil is often used by beginning vapers when creating their own coil winding. The disadvantage of a coil is that it produces little steam.

- Coil braid.

In essence, it consists of two spirals intertwined with each other. With such an organization of winding, the heating area significantly increases, due to which the volume of vapor increases and the taste of the electronic cigarette improves. However, there is a possibility of liquid getting into your mouth when you puff. The coil braid is only used on certain clears.

- Parallel coils.

They are microcoils or spacecoils created by winding two wires. Such spirals have a small heating area, as a result of which the volume of steam is reduced. Parallel coils are rarely used for self-winding.

- Art coils.

Art coils are distinguished by rather complex weaving. They have a large heating area and are the most attractive in terms of vapor volume and taste of an electronic cigarette.

Advantages of winding yourself

The very first and most useful thing is cheapness. If you find someone and where to buy metals, then you will literally spend 15-50 rubles to rewind your vape according to the material. But if you buy and install ready-made windings in a store, it will cost you a little, 200-500 rubles.

The second thing I would note is that it’s just interesting; what other reason is needed if doing this is really just interesting? Simple and without unnecessary words.

The third advantage is that, being able to wind beautiful and interesting coils, you can always surprise your friends and those around you with your interesting solutions. And if you are a teenager and under 20 years old, then the older generation will generally call you a master of turning, and this is still pleasant.

Applications

- Radiant tubes for electrical and gas heated furnaces

- Retorts and muffles for heat treatment and high-temperature sintering of powder metallurgical components

- Shielding tubes

- Burner components, nozzles and flame detectors

- Load carriers, eg load carrying trays or baskets

- Furnace furniture, and furnace construction components

- Uncooled components in coal, gas, and biofuel fired power plants

- Thermocouple protection tubes in power plants and high temperature petrochemical processes

Values and diagrams are representative for all product forms in delivery condition unless otherwise stated. Values presented in imperial units are interpolated from tests made in SI-units.

High Temperature Oxidation and Corrosion Properties

Kanthal APMT exhibits excellent high temperature corrosion properties due to the spontaneous formation of a thin layer of aluminum oxide (Al2O3) that protects the base material from corrosion attack. The most important properties of the scale are summarized below:

- Thermodynamically stable – forms also in protective atmospheres at very low dew points

- Inert – once formed, it is very stable with respect to chemical reactions

- Dense – forms a very effective barrier against carbon diffusion and penetration from contaminants

- Thin – very small amounts of aluminum is consumed to form and maintain the scale which results in very long oxidation life time

- Adherent – resistant to spallation during thermal cycling

Oxidation Properties

The oxidation resistance of Kanthal APMT is superior to that of Ni-base and high alloyed austenitic chromia forming alloys due to its alumina protection. It gives less scale spallation, and alumina is, in contrast to chromia, not sensitive to emit volatiles in humid atmospheres.

Kanthal APMT is recommended for service in air and in most oxidizing and reducing gases up to 1250°C (2280°F) which is approximately 100°C (180°F)higher than that of the best performing chromia forming alloys. For shorter periods, temperature up to 1300°C (2372°F) is acceptable without substantial detrimental effects.

Corrosion resistance in dry N2 or H2/N2 is very good when DP is higher than -25°C (-13°F). Below this level of water content, the alloy might be susceptible to nitriding in certain situations.

The figure below shows mass change during intermittent oxidation in air at 1100°C. After an initial period, cycle times were approximately 100 hours. Kanthal APMT shows a sub-parabolic weight gain, while the oxide scale on the Fe25Cr35Ni alloy starts to flake after less than 24 hours.

Oxidation limited lifetime

Oxidation limited lifetime is determined by the gradual consumption of Al within the alloy. The protective aluminum scale breaks down after extended time at high temperature when the level of Al has reached between 1 and 3wt% depending on temperature and thermal cycling. Comparative oxidation lifetime may be estimated according to ASTM B78-81. The test is performed on Ø 0.7 mm wire and results are shown in the diagram for APMT and some other high temperature alloys.

Carburization Properties

The formation of a protective aluminum scale gives Kanthal APMT superior resistance to carburization compared to chromia forming alloys.

In the figure below the average depth of carburization was calculated based on total loss of material during the test.

Mechanical properties at elevated temperature

All values are representative average values in delivery condition. The samples are taken in the longitudinal direction from tube and in length and cross directions on hot rolled plate.

Impact test

The graph shows Charpy-V results tested on heating.

Standard samples were machined from 12 mm hot rolled plate. A transition from low to high absorption energy regime occurs at ~200°C (390°F). Similar behavior exists for other product forms in relatively heavy section, like extruded tube. Hot tensile test (deformation rate 10-3 s-1)

| Temperature °C (°F) | Tensile strength Rm MPa (ksi) |

| 600 (1112) | 420 (61) |

| 800 (1472) | 120 (17) |

| 1000 (1832) | 42 (6) |

| 1200 (2192) | 16 (2.3) |

Hot tensile test — Gleeble test (deformation rate ~1 s-1)

Creep strength - 1% elongation

| Time | Temperature/Stress (MPa) | ||||||

| h | 700°C | 800°C | 900°C | 1000°C | 1100°C | 1200°C | 1300°C |

| 100 | 39,9 | 26,2 | 19,7 | 12,7 | 7,0 | 3,4 | 2,1 |

| 1000 | 36,8 | 23,4 | 16,2 | 9,9 | 5,0 | 2,3 | 1,5 |

| 10000 | 34,0 | 21,0 | 13,2 | 7,8 | 3,6 | 1,6 | 1,2 |

| 100000 | 31,4 | 18,8 | 10,8 | 6,1 | 2,6 | 1,1 | 0,9 |

1% elongation data are calculated from minimum strain rate data.

In general, there is an initial amount of primary creep in the order of 0.3 — 1% depending on product form, temperature and stress level. Total elongation to rupture depends on temperature and stress but is typically in the order of 3 to 12% where the lower range is representative for low stress levels. Creep strength - rupture

| Time | Temperature/Stress (MPa) | ||||||

| h | 700°C | 800°C | 900°C | 1000°C | 1100°C | 1200°C | 1300°C |

| 100 | 45,0 | 29,2 | 21,6 | 14,4 | 8,7 | 4,6 | 2,7 |

| 1000 | 39,7 | 24,8 | 17,0 | 10,8 | 5,5 | 2,5 | 1,5 |

| 10000 | 35,0 | 21,1 | 13,4 | 8,1 | 3,5 | 1,4 | 0,9 |

| 100000 | 30,8 | 18,0 | 10,6 | 6,1 | 2,3 | 0,8 | 0,5 |

Creep rupture data are representative average values for tube, bar and hot rolled plate based on creep tests performed within the time and temperature range indicated by the length of the solid lines in the diagrams (test times less than 50,000 hours). It should be pointed out, that component lifetime on thinner sections may be limited by oxidation/corrosion rather than creep rupture at low stress levels and long exposure times as indicated by the shaded area in the tables. 10,000 hour rupture compared to some other alloys are given in diagram.

Forms of supply

| Form | Dimensions (mm) | Dimensions (inch) | |

| Plate | Width | ≤ 1200 | ≤ 47,24 |

| Thickness | 3 — 20 | 0.12 — 0.79 | |

| Length | ≤3000 | ≤ 118,44 | |

| Extruded tubes | Outer dia. | 26 — 260 | 1.05 — 10.24 |

| Wall thick. | 2.87 — 11.0 | 0.11 — 0.43 | |

| Length** | 3000 — 13000 | 118.11 — 511.81 | |

| Cold Rolled Strip* | Width | ≤ 205 | ≤ 8.07 |

| Thickness | 0.2 — 3 | 0.01 — 0.12 | |

| Wire | Ø | 0.2 — 9.5 | 0.01 — 0.37 |

| Rod | Ø | 5.5 — 12 | 0.22 — 0.47 |

| Round bar | Ø | ≤ 100 | ≤ 3.94 |

| Length | ≤ 4500 | ≤ 177.17 | |

| Forging blanks | Width | ≤ 500 | ≤ 19.69 |

| Thickness | 35 — 170 | 1.38 — 6.69 | |

| Length** | ≤ 3000 | ≤ 118.11 | |

| Square bar | f | ≤ 150 | ≤ 5.91 |

| Length | ≤ 4500 | ≤ 177.17 |

Other sizes and forms can be discussed on request

*) Cold rolled strip can be delivered as cut to length products