It is difficult to name an industry that does not use metal and products made from it, for the production of which a rolling mill is actively used. Metallurgical enterprises today place quite high demands on equipment. That is why modern industrial machines, in particular rolling mills, differ significantly from the models that were produced earlier.

Rolling mill for the production of corrugated sheets

Why is this equipment needed?

The need for such a durable and reliable material as metal is constantly growing, which leads to the need to open new metallurgical enterprises and modernize existing ones. The list of industries in which metal simply cannot be used can be continued indefinitely. These are mechanical engineering, automobile and shipbuilding, construction and many others.

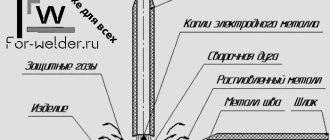

In order for metal ore to be turned into rolled metal of a certain grade, it is necessary to perform a lot of basic and auxiliary operations, for each of which special equipment is used. One of the main types of metallurgical equipment, which produces a sheet of metal as a result of plastic deformation from a hot billet, is a rolling mill. It is here that the bulk of the work carried out by metallurgical enterprises is carried out.

Rolling pins for metal

A manual rolling mill for producing thin sheets of soft metal was invented by Leonardo da Vinci in 1495. In the 16th century. on such mills with smooth iron-clad rollers rotated by a gear or worm gear, tin, lead and copper strips and sheets began to be rolled for brewing vats, drainpipes and gutters, barrel rims and other products. Rollers rotated by a water wheel rolled out these soft metals like rolling dough.

Types of rolling mills

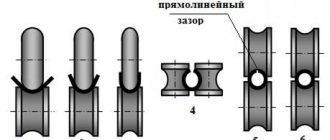

As we have already found out, a rolling mill is equipment on which, through sequential operations, a metal billet is transformed into long products with the required geometric parameters. Depending on the parameters of the final product, these machines can be of several types. Billet and crimping (slabing and blooming) are designed to produce a billet from a large metal ingot, which is supplied for further processing to a special rolling device. The latter type of equipment, which already produces rolled metal of the required configuration, includes section, pipe and wire mills.

The category of section mills includes equipment for the production of various types of rolled products. Thus, these can be mills for the production of sheet steel, angles, channels, rails, etc. Depending on their functionality, such mills can be large- and medium-grade, rail-rolling and MPS category, on which profiles of various sections are produced. Sheet rolling mills, capable of processing workpieces by cold or hot forming, are used to produce metal plates (50–350 mm thick), sheet metal (3–50 mm) and strips (1.2–20 mm). After production, finished products are wound into rolls weighing up to 50 tons.

The classification of rolling mills that produce various types of seamless pipes divides them into the following categories:

- continuous extensions, which produce pipes with a cross-section of up to 110 mm;

- short straightening mills necessary for the production of pipes with a diameter of 60–450 mm;

- three-roll type equipment - for the production of thick-walled pipes with a diameter of 35–200 mm (pipes produced on such equipment are characterized by a reduced degree of wall thickness);

- pilgrim mills used for the production of seamless pipes of significant diameter (400–700 mm).

Rolling stand of a sheet rolling mill

Modern enterprises also use parts-rolling or special-type mills. They are used for the production of profile and pipe blanks, the length of which does not exceed 3 meters. In addition, the capabilities of such equipment make it possible to use it to produce workpieces in the form of balls, bent profiles, gears, screws, pipes with a ribbed section, etc. The workpieces are processed already at enterprises that use them to produce their products.

Formation of rolled metal

The emergence of rolled metal products is associated with the fastest growing industry of the 19th century. - by rail . In 1828, by order of J. Stephenson for the Liverpool-Manchester railway, steel rails began to be rolled at the steam forming rolling mills . to make rails entirely from puddling steel , so the rails were made from a package (set) of different types of iron: wrought iron was used the base of the rail , and the mushroom-shaped protrusion along which the locomotive wheels rolled was made from puddling steel.

It was possible to transform this package into a monolithic product of a strictly standard form only by rental. The package was heated and rolled several times in a mill using profile streams: with each rolling, the shape of the workpiece became closer to the specified one. After the last rolling in the finishing mill , a smooth standard rail was obtained. Rolling mills also produced steel sheets for locomotive hulls and steam boilers.

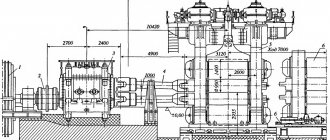

Components of a rolling mill

The design of any rolling mill includes three main elements: the so-called working stands, transmission devices and drive motors. The rollers along which sheet or profile metal moves are part of the working stands. They also include installation mechanisms, frames, plates and wiring. The movement of all working parts of the rolling mill is provided by powerful electric motors, which are connected to them through elements of the transmission device: couplings, spindles and gears.

You should know that the main characteristic of billet and crimping rolling mills is the diameter of the work roll. If, in the process of processing a workpiece, several working stands are used at once, then the diameter of the roll on which the finishing operation is performed is used as such a characteristic.

A section rolling mill, where products of complex shapes and with fairly accurate geometric parameters are produced, includes several stands at once through which the rolled stock passes sequentially during its processing.

Modern enterprises today use universal rolling mills equipped with 3 or 5 working stands. Some of the rolls of such mills (2–3) have a diameter of 1350 mm, the rest - 800 mm. Equipment for producing sheet metal of considerable thickness is, as a rule, equipped with one or two working stands. The working width of such mills, determined by the length of the rolls, is in the range of 3.5–5.5 meters. A sheet metal mill is most often equipped with additional working stands with vertical rolls, which ensure compression of the side edges of the formed sheet of metal. Sheet metal in the form of strips is produced in a device equipped with 10–15 working stands equipped with horizontal rolls with a length of 1.5–2.5 meters and vertical rolls for crimping the ends.

A rolling mill, as can be seen from its design, can be of considerable length. The most notable thing in this regard is pipe rolling equipment, which includes three mills simultaneously. At the first of them, a hole is pierced in a metal workpiece, at the second, the workpiece is drawn into a pipe, and at the third, calibration is performed, which is carried out to give the finished product the required diameter. On part rolling mills, the workpiece is subjected to both helical and transverse processing.

Rolling mill design

Master the iron

In Sweden in 1707, a rolling mill with a powerful hydraulic engine rolled cast iron plates 2 cm thick, softened in a furnace, turning them into thin sheet iron . In the 1710s. In Saxony , flattening mills operated for rolling strip iron from cast rods. The rollers of the mills squeezed out the remaining slag from the iron, increasing the quality of the metal in the product. In 1719, the Saxon experience was adopted by the German engineer in the Russian service G.V. de Gennin and established similar production at Ural factories, replacing brittle cast iron in rollers with wrought iron.

Rolling mill of de Gennin at the Ural factories. Drawing from the 18th century. The workpiece softened in the oven - an iron rod (1) - was inserted by a worker (2) between the iron rollers of the mill. The rollers were compressed by screws (3), squeezing the workpiece. The water wheel (4) rotated the lower roller (5), which transmitted rotation to the upper roller (7) through a gear transmission (6). The rod was rolled, uniformly flattening and thinning, and another worker (8) pulled out an even thin strip of iron from the rollers.

Story

With the development of railway transport, the need for rolled products has increased significantly. The first rails were cast iron, but at the beginning of the 19th century in England they switched to the production of iron rails. In 1828, the first rolling mill for rolling rails from puddling iron appeared, and in 1825 they began to roll rails from Bessemer steel. Rails were the main product of the rolling mill. In addition to rails, it was necessary to produce various parts for steam locomotives; armor was also required for the development of the fleet, in which wooden ships were replaced by armored metal ones. The first armored rolling mill was designed in 1859 by Russian mechanic V.S. Pyatov. Before this, armor plates were obtained by binding thinner sheets together. All these mills were quite primitive: the rollers of the machines were driven into rotation by a water wheel, and later by a steam engine. The movement of hot metal to and from the mill was carried out manually. In one of the museums of an old Ural plant there is a picture: a team of workers passes a red-hot billet along a hot iron flooring using hooks to the mill. The work of a rolling stock operator was the hardest at the plant[1].

First machines

It is believed that the first rolling mill (with wooden rolls) was designed by Leonardo da Vinci. The first rolling mills appeared at the end of the 16th century. Their structure was very simple and consisted of wooden machines with two iron rolls. The upper roll was mounted on a tetrahedral axis. A large cross was placed on one end of this axis. A metal blank heated to a high temperature was inserted at one end between the two rollers, and then the upper roller began to rotate with a cross. The blank passed between the rollers and was flattened. At such mills, they first rolled lead sheets for the manufacture of organ pipes, and then they began to roll silver and gold for minting coins[2].

For a long time there was a widespread belief that iron should not be rolled. The heated iron quickly cooled from contact with the rolls during slow operation. The cooled iron could not be rolled out; it could only be bent and cut.[2] The first rolling mills for the production of strip iron and small grades were built in the 18th century. They were driven by water wheels.

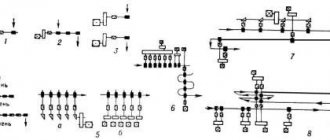

Duo and Trio Stans

Duo-stans

Rolling in such machines occurred as follows. Steel ingots or bars were heated to high temperatures in special furnaces and then fed into rotating rolls. Now both rolls were rotating: both the upper and the lower. The metal was pulled into the gap by friction. This was achieved by rotating the rolls in different directions. It is impossible to roll a thick blank into a thin sheet at once. Therefore, the strip that passed through the roller was passed back “empty” through the upper roller, meanwhile they pressed each other against the roller circle and again passed the strip, but into a narrower slot. By repeating this operation several times, a strip of the required thickness was obtained. To avoid the need to press the upper roll against the lower, in some rolling mills grooves or streams (calibers) were machined into the rolls. The ingot was fed first into a larger caliber, then into a smaller one, and so on. Thanks to this, it was not necessary to adjust the distance between the rollers each time[2].

Trio stans

To increase the productivity of rolling mills, they began to make not two rolls, but three. Such a pack was called a three-roll or “trio” mill. Now the strip did not have to be transferred back “idle”. It was passed in the opposite direction between the middle roll and the third, upper one. The top roll rotates in the same direction as the bottom one, but in the opposite direction compared to the middle roll. To feed metal between the middle and top roll, a special device called a “lifting table” was installed in rolling shops. The lifting table was a platform onto which the blank fell, emerging between the lower and middle rolls. The worker operating the lifting tables released water or steam into the cylinders on which the platform rested. Air or steam moved the piston in the cylinder and raised the table to the level of the gap between the middle and upper rolls[2].

Blooming

The main part of the blooming is two frames, into which two steel shafts are embedded. The upper shaft can be raised and lowered. Blooming rolling shafts are driven by an electric motor. The ingot moves on rollers to the shafts. As soon as it touches the surface of the shafts, they capture it in the throat, compress, stretch, make it thinner and push it out to the other side. Next, the connector between the shafts is made smaller. Then the engine rotating the shafts makes a “reverse”, that is, it begins to rotate in the opposite direction. The ingot on rollers rolls up to the shafts again, but on the other hand, the shafts again grab it, compress it again, make it even thinner and even longer. To avoid obtaining a long sheet instead of a blank, after several passes, the ingot is rotated 90° using a special so-called bending apparatus. The tilting apparatus has levers with hooks at the ends. With these hooks, the ingot coming out of the rolls is picked up from the side, under the lower side. The levers rotate as if on a hinge and turn the ingot 90° with their hooks (turn over) [2]