Carpentry work is a real mystery for a professional. Wooden masterpieces created by a talented “left-hander” are valued much more expensive than factory samples. It’s very disappointing when suddenly you don’t have the right tool at hand. At such moments, specialized equipment comes to the rescue of the master.

In this article we will talk about multifunctional household woodworking machines that are capable of solving several tasks at once: sawing, drilling, and milling. Today, together with the editors of the Agronom.guru portal, we will look at popular models of universal woodworking machines for the home, study their functionality and characteristics, and also provide current user reviews.

Universal household woodworking machine - a mini-factory in your garage or workshop

Application area

Universal woodworking machines allow you to replace several individual devices and tools at once, which simplifies working with raw materials and saves effort and time. Such units help to create not only parts, but also completely finished wood products.

FOR YOUR INFORMATION!

There is another type of woodworking equipment - narrowly targeted machines, for example, planers, thicknessers or jointers. These woodworking machines belong to the specialized class, which is very inconvenient for domestic purposes. Such equipment is used in furniture factories or enterprises engaged in the production of finished parts and bars of certain sizes.

Multifunctional woodworking machines for the home workshop are an indispensable thing. They are compact, economical (many plug into a regular outlet), and allow you to do basic work in one go.

Lathe with variator Jet JWL-1443

The next model is again produced by JET. Larger and more powerful, it represents a transitional option between home and industrial equipment.

The design of the frame initially includes removable legs, which allows the machine to be used in both desktop and floor-standing versions. The main feature lies in the headstock. It is equipped with a ten-speed variator, allowing you to change speeds without stopping the spindle. The headstock is not permanently attached to the frame. It can be moved to any location to improve the convenience of operation. The headstock can also rotate 360 degrees around a vertical axis, which allows you to sharpen products not only above the bed, but also in almost any position. Thanks to this solution, JWL-1443 can be used for processing workpieces of increased diameter.

In comparison with previous models, only one drawback stands out - larger dimensions. The rating values of Jet JWL-1443 are higher than previous options, as are its technical characteristics.

Advantages

For an experienced master, mastering such a machine will not be difficult. In addition to relative compactness and accessibility, factory models of multifunctional woodworking machines meet high reliability requirements. Almost all models have protection against jamming, overheating, and a built-in fuse against power surges.

BELMASH SDMP-2200 – household multifunctional woodworking machine

An example of such a woodworking mini-factory at home is the combined woodworking machine BELMASH SDMP-220. It is also called a “changeling”. An interesting engineering solution makes it possible to make maximum use of the available working planes of the machine while saving significant space and space. The new product allows you to perform the following tasks:

- Planing on a plane and at an angle.

- Longitudinal sawing along the plane and at an angle.

- Cross cutting along the plane and at an angle.

- Quarter selection.

- Milling.

Today the cost of such a model barely exceeds 24,000 rubles. The new product has already gained popularity among Russian craftsmen.

Review of the BELMASH SDMP-2200 machine

Read more on Vseinstrumenti:

Diagram of the design of a universal multifunctional wood cutting machine. This installation contains not one, but two power units. The electric motor (2) is connected by cable (1) to a 220 V power supply. If necessary, the gasoline engine (13) is started. The corresponding block is installed under the decorative cover (11). Through a belt drive, it drives (12) a generator, which is connected to an electric motor. Thus, this model also provides autonomous operation from an electric motor. To protect the working area from sawdust, a special partition (4) is provided. The circular saw (3) is installed in a separate table (5), which can be adjusted in height taking into account the physiological characteristics of the user. The built-in ruler (6) is useful for precise cutting of workpieces without additional measuring tools. The specialized unit (7) is designed for drilling and milling operations. This multifunctional household woodworking machine has a sliding blade (8). If necessary, the central part is expanded for the appropriate processing mode. This area (10) is a thickness planer. At the bottom of the machine there was a place to mount a tool box. Tools for machine cleaning and maintenance can be stored here. The example we have given is rather an ideal version of a machine with all possible functions. Typically, craftsmen purchase a 220 V combined woodworking machine for home with one built-in electric motor.

FOR YOUR INFORMATION!

For autonomous power supply, you can use a gasoline or diesel generator. A prudent owner includes such equipment as part of the standard equipment of a personal home. It maintains the operational state of the engineering systems of the property in emergency situations in centralized networks.

Combined woodworking machines for home

The combination of a circular saw, an abrasive wheel, and a cutter makes the combined machine a universal assistant in the home workshop. The devices are often equipped with inclined tables, which expands the functionality. The combined woodworking machine for home is small in size and has a powerful single-phase motor. All working elements are installed on one drive shaft.

Einhell TC-US 400

Designed to perform sanding operations on wooden workpieces. The combination of disk and tape assembly allows you to perform the most complex processing operations. These inexpensive woodworking machines for the home are used for removing paint layers, adjusting models, and sanding furniture parts. It is equipped with an electric motor capable of rotating a 150 mm disc at a speed of 1450 rpm. A V-reverse belt drive is installed, which has a low noise level. The transmission is covered with a casing, which ensures safety and protection from contamination.

The work table can be fixed at any angle; for precision in work, the operator can use a stop with easy-to-read graduations. Control of the device is simple; two different buttons are used to turn it on and off. This increases safety and allows users with any qualifications to operate the equipment.

Advantages:

- Good quality of plastic processing;

- Damping pads reduce vibration levels;

- Low energy consumption;

- Rigid housing design.

Flaws:

- A lot of dust when working without a vacuum cleaner.

Encore Corvette 51

The equipment is intended for grinding parts made of wood, chipboard, plywood, and plastic. The wheel and sanding belt are driven by an asynchronous motor. The launch is carried out by a magnetic switch, which prevents spontaneous start after a temporary power outage. It is easy to replace the sanding belt with an abrasive with a different grain size and adjust the speed of movement.

The drive is equipped with a belt drive, which reduces the load on the electric motor. The angle of the work table is adjustable, making it easier to process surfaces located at 90 degrees to each other. For processing the ends of parts there is a transport stop with informative graduation. The operator can choose any angle to process the workpiece.

Advantages:

- Light weight;

- The desktop can be rearranged to a convenient position;

- Low risk of transmission jamming;

- Economical engine.

Flaws:

- It is difficult to buy abrasive tape.

Belmash BDG 100/152

Inexpensive models in this series are small in size, but retain high technical characteristics. The body is made of cast iron, which has a positive effect on stability and helps reduce vibration levels. The support platform is made of steel, and the work table is made of aluminum alloy, resistant to corrosion. There is a U-shaped groove on the working surface for mounting an angle stop.

The sanding belt unit can be rotated in the desired direction. The table tilt angle is adjustable from 0 to 60 degrees. Damping base feet further reduce vibration levels. The equipment is equipped with a workpiece limiter, a support rod, and a set of keys necessary for operation.

Advantages:

- Good results when sanding chipboard;

- Reliable engine;

- Ergonomic control panel;

- Easy ribbon replacement.

Flaws:

- There is no dust removal system.

How to choose the right one

First of all, you need to think about why you are purchasing equipment: will it be one-time work on the machine, or do you plan to use it for permanent work. It is better to decide in advance on the list of tasks that you plan to perform on the machine. Study the lighting, the presence of sockets, measure the plane on which you plan to install the joinery product.

It’s better to imagine in advance where and how your machine will be located, and what kind of work you will entrust to it.

General recommendations for choosing a universal wood saw: when choosing a combined machine, it is better to pay attention to models with a circular saw. This “helper” is useful for almost all types of work: from preparing timber to cutting blanks for furniture. In addition, many machine models are equipped with a jigsaw. A stationary tool is much more convenient than a manual one, it does not block the master’s view of the material blade, and you don’t have to worry about the progress of the saw, because everything is provided for in advance by the device.

When working on the machine, use only dry wood. This will reduce the load on the machine and improve the quality of the product.

Additionally, woodworking machines are equipped with attachments for drilling, milling, edge processing, cutting quarters and grooves. There are models that combine up to five different functions, while others provide only two.

Types of woodworking units

Lathes perform 5 tasks for processing a wooden workpiece:

The ability to process a raw wooden piece in a plane and along a profile makes a product with a smooth surface. The resulting boards, panels, and bars are of good quality, ideal in shape and smooth in surface cleanliness. Thicknessing devices plane the workpiece to size and thickness.

Planing of a wooden part is done:

Special profiled parts with processing of the front side of panels, frames along the contour, and decoration work can be performed by milling machines. They are 3 types:

Drilling holes and making recesses in a wooden part is performed by drilling and filler machines. They make a tongue and groove connection. Slotting machines are used to produce recesses in the form of nests in a product.

Drilling machines are available in 3 types:

Processing of workpieces by turning to obtain a cylindrical shape is performed by lathes. They are of 1 type. They have various modifications depending on the complexity of obtaining a finished part or workpiece.

Removing waves, irregularities, burrs, smoothing sharp edges, calibration. With their help, perfectly smooth surfaces are obtained.

Tabletop for home and household

Tabletop devices are also available with CNC. These machines are considered high precision machines. They are classified as a group of universal equipment. It performs a variety of wood processing operations.

Manufacturers produce 3 types:

Low-power home type. They are placed on workbenches and small tables. Frequent production of wooden parts is more profitable to do with a unit with a power of 0.8–1.2 kW; the selection indicator is the size of the wooden blank being produced.

On a home machine, the distance from the product to the bed is 250-405 mm. Center-to-center distance 330-1100 mm. Spindle speed 400-3500 rpm. Rapid rotation of the workpiece allows you to process the part more accurately and accurately.

Small-sized series are universal in operation of the device. They allow you to sharpen cylindrical and cone-shaped products.

Small-sized devices are used at home. With their help, small, jewelry-precise parts are made. The weight of such machines is up to 10 kg.

There are 2 types of tabletop type lathe: devices that create a wooden part, a product with a zigzag appearance, or a carved-type design. This is done with a cutter.

Depending on the method of processing the product, devices are divided into: lathe and milling machine. They drill a through hole, make a recess, chamfer, trim the part; turning screw-cutting device and designs.

They are used for cutting threaded ornaments and turning blanks; universal machine, complex type of devices. Allows you to process workpieces of various shapes.

It is easy to select the minimum size turning device. They are characterized by low power and compact size. Their power of 0.15-1.8 kW is enough to produce any type and shape of product. The rotation speed and operating time are sufficient for such a device.

Home-type devices do not require high power. Not economical. There are no large or lengthy jobs. The width of the workpiece is 25-175 cm. Determined by the permissible overall length of the workpiece. The cross section of the wooden part is 10-38 cm, which makes it easy to process it.

The size of the part is determined by the overall dimensions of the installation. The device has a large number of speeds, 10 switchings. This is a good indicator. Speeds make it possible to select the desired rotation of the part for processing and grinding. Carefully make cuts that are accurate in size and zigzag.

There are many modifications of wood processing machines on sale. The home workshop can be replenished with models of small-sized devices. Their purpose is to process wooden products in small spaces.

School

The STD-120M model is used in school labor training classes. They are compact, have an optimal number of operations depending on operating conditions and workpiece sizes. They combine technical capabilities and price.

Difference: spindle rotation speed. The installation operates at spindle speeds: 1100 and 2150 rpm; presence of a push-button start and stop unit; complete with spare and replacement spindles.

Industrial

The turning and copying machine is common in the industrial production of furniture and household products. They are used to make figured racks and structures for decorative flights of stairs. The installation is distinguished by reliability, power, productivity, and production of parts according to the pattern.

They read the exact configuration of the templates and make a copy of them with exact dimensions. What is important for the production of high quality furniture. Products are made serially and in large quantities.

Record Power DML 250 is a small device designed for highly professional professionals. The device allows you to make any product configuration. Blanks fit dimensions 45.7 cm, F up to 25.4 cm.

The bed is extended to 57 cm. Wooden blanks up to 100 cm are processed on the machine. The machine drive allows you to change speeds from 1 to 5. 390W motor for a lathe of this size. The engine is equipped with aluminum cooling fins.

Minimum machine sizes:

The JET series is more compact. They are in high demand among professionals and amateurs. An increase in the machining part up to 90 cm is achieved by lengthening the bed.

Features of JET JWL-1015:

Kinds

Autonomous

Such stationary models have an obvious advantage - the stability of the machine and the good consistency of all elements. The machine usually has a reinforced body; the frame will withstand shock and vibration when processing workpieces. This technique is well suited for performing fairly large volumes of work; for example, such a machine is suitable for a mini-workshop. In addition, autonomous equipment is much more powerful than its mobile counterparts; most often, the power of electric motors reaches 6 kW.

Tabletop household with surface thicknesser

This type of machine is more of a handy tool for quickly repairing wooden products. Such units are installed on a table or other surface.

Tabletop variations of machines are convenient and easy to operate

Multifunctional household woodworking machines with a surface planer are a fairly popular and respected type of machine among woodworkers. A thicknesser or planer is usually equipped with special guides that ensure maximum reliability of operation of the machine. The main purpose of such units is sawing and planing. All other features are considered optional. Modern samples allow you to adjust the cutting accuracy taking into account the clamping depth of the fasteners.

Manufacturers of sawing machines

Construction stores are filled with all sorts of options for such equipment, so quickly choosing the right model can be difficult. Experts recommend taking a closer look at units from well-known manufacturers, the quality of which is confirmed by positive user reviews:

- MakitaCorporation - the main activity of the Japanese corporation is related to the production of professional-type electric and gas tools for construction work. The range includes over 1000 models, ensuring efficient processing of any materials. The advantages of the units include the reliability of the engines and the quality of components. They are often used for work characterized by extreme loads.

- Metabowerke GmbH is a German company that produces equipment for industrial and manual processing of materials. The Metabo brand's core slogan, “when you need reliability,” guarantees users the purchase of a powerful, durable and ergonomic tool that ensures efficient construction work in the toughest conditions.

- TechTronic inductries is a Japanese company that develops, produces and sells power tools and garden equipment under the Ryobi brand. All products are assembled at our own factories in the USA, Germany, and China. The popularity of the models is due to high quality, equipment with innovative technologies, the ability to carry out most of the assigned tasks, and low price.

- Einhell Germany AG is a German company that produces tools for construction, repair work, gardening and recreation. Its innovative products are represented in markets in more than 90 countries. The models are assembled mainly at Asian enterprises. In its work, the company adheres to the principle of combining simple solutions with high quality, which allows it to produce goods at an affordable price.

- Zubr OVK is a Russian company producing construction equipment. The brand’s devices are valued for their high reliability, quality, ease of use, and low price. By constantly updating the range and improving previously released units, the company is able to timely meet the growing needs of users.

- Bosch , a German corporation, is a reliable supplier of construction tools and household appliances. The brand's leading position in the market is due to the quality, reliability and functionality of its products.

Device classification

Universal woodworking machines are suitable for most woodworking tasks.

By degree of versatility

Many devices use the principle of tool multitasking - when the same machine unit can perform several functions, it is enough to change the attachment. This technique is well suited for sequential processing of edges, cutting grooves, and other individual work operations.

Mini woodworking machine for sawing and drilling

All tools must be in stock, at least one at a time. This will reduce the number of downtimes due to the breakdown of one of them.

On average, such machines are capable of performing 5 or 6 functions. The main ones are: cutting wood using a cutter, sawing and planing using a cutting shaft, drilling, milling, grinding, and the last task can be solved using a disk or tape.

By type and power of equipment

Equipment power is one of the most important selection criteria. It determines how thick the workpiece can be processed and what sizes of grooves and holes can be made. With the proper dexterity and knowledge, very soon you will be able to create such a machine - already from wood cut by yourself.

Wood lathe

There is one more characteristic that will allow you to quickly and efficiently create such a masterpiece - the number of revolutions of the electric motor, which is often directly related to the power of the motor.

ATTENTION!

Basically, home machines have a power in the range of 0.9−3 kW. In this case, the shaft rotation speed varies from 2800 to 3600 rpm. That is, lower ones are not produced, and there is no point in purchasing higher ones.

By other criteria

It is very important to pay attention to the replaceability of parts and attachments. Even a multifunctional machine necessarily has its main function, and the rest can be provided by interchangeable attachments. In one, the manufacturer has provided a larger number of replaceable knives; in the other, it has improved the shaft or mounts for drilling.

Multifunctional machine configuration option

Some models may use others instead of these tools. For example, instead of a cutter there is a knife module, instead of a grinding wheel there is a belt. When choosing a machine, you need to pay attention to the size of the circular saw, the maximum dimensions of the drill, the working width of the planing, and the cutting depth. All these parameters must be indicated in the product data sheet.

The machine must be secured to the workbench only with special devices provided by the manufacturer. Self-activity will not lead to anything good here.

By choosing the maximum dimensions, you increase the capabilities of the machine in terms of processing different workpieces on it. But at the same time, the power of the electric motor increases, and hence the energy consumption and the dimensions of the machine itself.

General design and purpose

Woodworking lathes have one functional purpose: processing workpieces. The output products take the form of a detail in the outline of the future furniture design, room interior, or decorative design.

The scale of production and processing of wood products depends on the equipment used. Manufacturers produce 3 types of machines:

The design of the devices is no different. They have different capabilities for processing parts. With high speed, accuracy, availability of devices, closers, sizes of installation fasteners. Their unit electrical power consumption differs.

Work table for the machine

The table or base for the machine is the most important structural element. The quality of the base assembly determines the safety and quality of work at all stages. Most often it is a welded or cast (which is better) structure made of cast iron and steel. Cast structures withstand greater vibrations than prefabricated ones. Cast iron is most often used in professional equipment, while “home” models are usually made of steel.

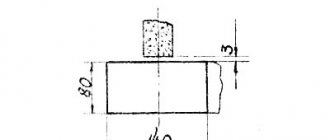

Main parts of the table: 1 – two parts of a split-type frame, 2 – movable table, 3 – fixed table, 4 – saw table, 5 – drum with knives, 6 – electric motor, 7 – sanding drum

To cut small elements, it is better to take a circular saw with sparser teeth. This will make the product look more neat.

The table can be adjusted to suit the height of the carpenter, and in some models this function directly affects the depth of cutting of wood: the lower the table, the higher the thickness of the cut.

Safety rules when working on the machine

Any machine equipment has a class of increased danger to humans. These are the posters that hung in every factory and workshop.

Memo for a carpenter from the times of the USSR Our editors have also compiled their own list of rules, carefully re-read the following points (or better yet, print them out and hang them in your workshop):

- Operating the machine while intoxicated, under the influence of medications or other substances is strictly prohibited.

- Work in the workshop should be carried out in special protective clothing, which will prevent the possibility of being caught by rotating elements.

- The working area must be illuminated; the light should not “blind” the eyes of those working at the machine.

- Eyes must be protected with special glasses.

- During operation of the machine, the necessary fastening elements, as well as protective devices, must be tightly secured.

- Particles of abrasive materials must be removed from work surfaces and the floor after each stage of work.

- Electrical sockets, extension cords, and any electrical equipment must be in good condition and insulated.

- It is necessary to provide the machine with reliable grounding. And the sockets themselves and the channels leading to the panel should be equipped with “automatic devices”.

Tips and tricks for choosing

Online stores allow you to purchase a profitable, convenient lathe. Machines in the catalog of the online salon with a wide level of functionality. They differ in power. Cooperation with store specialists will save money when purchasing goods at a low price.

The same characteristics of equipment in other retail chains will be 1.3-2 times more expensive. Here you can profitably receive your order in the shortest possible time. Buying a tabletop lathe is very simple when you enter the website of the company that sells this equipment. Information center specialists will help you choose the appropriate model.

Source

Comparative review of the most popular models and manufacturers

Today we have already mentioned one of the Belarusian brands. − a fairly strong enterprise that has been manufacturing machine tools for about 6 years. The company's office is located in Mogilev. The company's representative offices are located in almost all countries of the former CIS. Let's look at one more product in more detail.

Belmash SDM-2500 PRO, as its creators assure, is convenience, comfort, safety at the best price

This combined woodworking machine from Mogilev is designed to perform various technological operations.

Main functions:

- planing (jointing) along the plate or edges;

- planing (jointing) at an angle (along the edges);

- sawing along and across the fibers;

- sawing along the grain at an angle using

combined line;

- sawing across the grain at an angle using a rotating bracket;

- milling with disc cutters;

- milling with end mills, drilling.

Review of the combined woodworking machine "Belmash" SDM-2500 PRO

More details on Catalog.Onliner : Woodworking machines “Ant” are the brainchild of JSC “Algorithm” from the city of Rybinsk. The company's official website presents 5 new products of a fairly budget class.

Products of the Ant brand are a budget solution for a small workshop

In addition, here you can find out about the cost of consumables.

But the company offers these prices for related products and replacement parts

And one more manufacturer that needs to be mentioned in this review. Woodworking machines of Uni-Master LLC. One of the most popular models is the Master-Universal 2500E. This machine has been in great demand for many years.

The Master-Universal 2500E machine fully lives up to its name - it is truly universal

Appearance and characteristics of the Master-Universal 2500E machine

It can be used for sawing (longitudinal, transverse and at an angle), thicknessing, planing (horizontally and at an angle), drilling, milling. You can find out how effectively these functions work from the reviews.

Review of the combined woodworking machine “Master-Universal 2500E”

More details on Forum.Woodtools:

| Name | Peculiarities | Functions | Average price (as of April 2022), rub. |

| Designed for processing wood (plywood, particle boards, etc.) by sawing and jointing with manual feeding of the workpiece. | Planing on a plane and at an angle. Longitudinal sawing in different variations, including at an angle. Cross sawing. | 22 000 |

| The machine is equipped with an updated combined ruler, which includes parallel and angular stops. All scales are applied to it by inkjet followed by laser curing. | Planing (jointing) along the plate or edges, as well as at an angle. Sawing in different planes and at an angle. Sawing along the grain at an angle using a combination ruler. Sawing across the grain at an angle using a swivel bracket. Milling with disc cutters. Milling with end mills, drilling. | 35 000 |

| The machine has a combined line, similar to SDM series machines. Using carriages moving along the guides, you can adjust the required position of the parallel guide (for planing and sawing) and the rotary bracket (for sawing at an angle). | Planing (jointing) along a plate or edges. Planing (jointing) at an angle (along the edges). Thickening. Sawing along and across the fibers. Sawing along the grain at an angle using a combination ruler. Sawing across the grain at an angle using a swivel bracket. Milling with disc cutters. | 42 000 |

| A model with the ability to plan lumber to a given thickness (thicknessing). Available in two versions with different types of supply voltage. | Sawing. Jointing. Milling with a disk cutter. Milling with a shaped cutter. Thickening. Drilling. | 46 000 |

| A multifunctional woodworking machine is designed for processing wood blanks and its derivatives. | Thickening. Planing on a plane. Planing at an angle. Planing with a clamping device. Longitudinal sawing. Longitudinal sawing along the edge at an angle. Quarter selection. Cross sawing. Cross cutting at an angle. Milling. Drilling. | 35 000 |

| Connecting the motor using a belt drive reduces noise levels and prevents unnecessary loads. The table is made of cast iron. | Planing, sawing, drilling and milling operations. | 33 000 |

Universal woodworking machines for the home

The universal machine can perform different operations - thicknessing, sawing, planing. Some models are designed for drilling and milling work. Equipment of this class is compact in size, easy to reconfigure, and has a stable frame. Our experts studied 6 models and chose two that attracted attention with their functionality, reliability, and good quality tables.

Encore Corvette 320

The model of the Russian brand is designed for planing, sawing, drilling and milling. It is equipped with a 1.5 kW asynchronous electric motor, which provides high shaft rotation speed - up to 3500 rpm. This guarantees good quality of the operations performed. The user can use blanks 200 mm wide when planing, and up to 3 mm of wood is removed in one pass. When sawing, the possibilities expand: the equipment can easily handle 300 mm boards.

The table is made of cast iron and has an ideal geometry, which reduces the number of defects and errors. The presence of a stop, a degree scale, and mobility expand the possibilities for planing and sawing work. The transmission from the engine to the shaft is belt driven and has a low noise level, which is important when using the equipment in a small workshop. The design provides a high level of protection of the electric motor from overloads.

Advantages:

- Planer shaft protection strip;

- Connection pipe for connecting an industrial vacuum cleaner;

- Saw blade protective cover;

- The reach of the cutting tool is adjustable;

- The clamp securely fixes the workpiece.

Flaws:

- Not detected.

The drilling table is installed in two planes, allowing complex operations to be performed. Milling work can be performed with end mills, moving the workpiece fixed on the work table along three axes.

Mogilev IE 6009

Tabletop model from Belarus with a stable frame. For additional fixation, anchor holes are provided in the base. Performs longitudinal and transverse sawing and copes well with cutting at a given angle. Used for planing workpieces. It is equipped with a 1.7 kW electric motor and has increased performance. Can be used in small businesses.

Safety is ensured by a casing that protects the saw blade. This design has holes for connecting an industrial vacuum cleaner. A sawdust bag can be connected through the pipe. A thermal switch is installed in the electric motor winding, which protects the motor from overheating. An effective ventilation system is hidden behind a metal casing.

Advantages:

- High shaft rotation speed;

- Clamping device as standard;

- No grounding required;

- Light weight;

- Carrying handles.

Flaws:

- Difficult adjustment of cutting depth.