OKOF 330.28.41.3 - Other metal-working machines OKOF 330.28.41.3 - Other metal-working machines

- OKOF - All-Russian Classifier of Fixed Assets

- 300.00.00.00.000 - Machinery and equipment, including household equipment, and other objects

- 330.00.00.00.000 - Other machinery and equipment, including household equipment, and other objects

- 330.28 - Machinery and equipment not included in other groups

- 330.28.4 — Metalworking equipment and machines

- 330.28.41.3 — Other metalworking machines

330.28.41.3 — Other metalworking machines

Classifier: OKOF OK 013-2014 Code: 330.28.41.3 Name: Other metalworking machines Subsidiary elements: 4 Depreciation groups: 2 Direct adapter keys: 4

Subgroups

Group 330.28.41.3 in OKOF contains 4 subgroups.

- 330.28.41.31 — Bending, edge bending and straightening machines for metal processing

- 330.28.41.32 — Mechanical shears, punching and cutting machines for metal processing

- 330.28.41.33 - Forging or stamping machines and hammers; hydraulic presses and presses for metal processing, not included in other groups

- 330.28.41.34 - Machine tools for working metals, sintered metal carbides or cermets without removing material, not included in other groups

Shock absorption groups

In the classification of fixed assets included in depreciation groups, code 330.28.41.3 is listed in the following groups:

| Group | Subgroup | Deadlines | Note |

| Third group | cars and equipment | property with a useful life of over 3 years up to 5 years inclusive | equipment for gas-flame processing, metal coating, thermal spraying, flexible production systems (robots) |

| Fifth group | cars and equipment | property with a useful life of over 7 years up to 10 years inclusive | turning groups, drilling and boring groups, gear cutting, milling groups; planing and slotting; bolt- and nut-threading; cutting machines, special and specialized |

Transition keys

To move from the old OKOF to the new OKOF, use a direct transition key:

| OKOF OK 013-94 | OKOF OK 013-2014 | ||

| Code | Name | Code | Name |

| 142922010 | Metalworking, metal-cutting machines (lathe group, drilling-boring group, gear-working, milling; planing and slotting; bolt- and nut-threading; cutting, special and specialized machines) | 330.28.41.3 | Other metalworking machines |

| 142922163 | Machine tools for electrophysical and electrochemical metal processing | ||

| 142922169 | Other metal-cutting machines | ||

| 142922030 | Metalworking machines not included in other groups (equipment for gas-flame processing, metal coating, thermal spraying, flexible production systems (robots)) | ||

© 2022 okof2.ru - All-Russian classifier of fixed assets with decoding and search

OKOF 330.28.41.3 – Other metalworking machines

OKOF 330.28.41.3 – Other metalworking machines

- OKOF - All-Russian Classifier of Fixed Assets

- 300.00.00.00.000 - Machinery and equipment, including household equipment, and other objects

- 330.00.00.00.000 - Other machinery and equipment, including household equipment, and other objects

- 330.28 - Machinery and equipment not included in other groups

- 330.28.4 — Metalworking equipment and machines

- 330.28.41.3 — Other metalworking machines

330.28.41.3 — Other metalworking machines

Classifier: OKOF OK 013-2014 Code: 330.28.41.3 Name: Other metalworking machines Subsidiary elements: 4 Depreciation groups: 2 Direct adapter keys: 4

Subgroups

Group 330.28.41.3 in OKOF contains 4 subgroups.

- 330.28.41.31 — Bending, edge bending and straightening machines for metal processing

- 330.28.41.32 — Mechanical shears, punching and cutting machines for metal processing

- 330.28.41.33 - Forging or stamping machines and hammers; hydraulic presses and presses for metal processing, not included in other groups

- 330.28.41.34 - Machine tools for working metals, sintered metal carbides or cermets without removing material, not included in other groups

Shock absorption groups

In the classification of fixed assets included in depreciation groups, code 330.28.41.3 is listed in the following groups:

| Group | Subgroup | Deadlines | Note |

| Third group | cars and equipment | property with a useful life of over 3 years up to 5 years inclusive | equipment for gas-flame processing, metal coating, thermal spraying, flexible production systems (robots) |

| Fifth group | cars and equipment | property with a useful life of over 7 years up to 10 years inclusive | turning groups, drilling and boring groups, gear cutting, milling groups; planing and slotting; bolt- and nut-threading; cutting machines, special and specialized |

Transition keys

To move from the old OKOF to the new OKOF, use a direct transition key:

| OKOF OK 013-94 | OKOF OK 013-2014 | ||

| Code | Name | Code | Name |

| 142922010 | Metalworking, metal-cutting machines (lathe group, drilling-boring group, gear-working, milling; planing and slotting; bolt- and nut-threading; cutting, special and specialized machines) | 330.28.41.3 | Other metalworking machines |

| 142922163 | Machine tools for electrophysical and electrochemical metal processing | ||

| 142922169 | Other metal-cutting machines | ||

| 142922030 | Metalworking machines not included in other groups (equipment for gas-flame processing, metal coating, thermal spraying, flexible production systems (robots)) | ||

© 2022 okof2.ru - All-Russian classifier of fixed assets with decoding and search

okof2.ru

Page not found | MIT

Skip to content ↓

- education

- Research

- innovation

- Reception + assistance

- student life

- News

- Alumni

- About MIT

- More ↓ Reception + assistance

- student life

- News

- Alumni

- About MIT

Menu ↓ Search Menu Oh, looks like we couldn't find what we were looking for!

Try looking for something else! What are you looking for? View more results Suggestions or feedback?

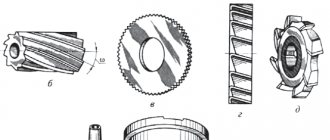

, Milling technologies, Milling cutters, Milling machines, Tools

Edge milling machines

Edge milling machines can be used for a broaching system (stationary milling station, the insert is pulled), as well as for a system with a movable milling station and a fixed insert.

Possible applications

Examples

- Plate production (steel and aluminum)

- Production of longitudinal welded pipes

- Shipyards

- Wagon and container structure

- Construction of reservoirs

Your benefits

- Creation of I-, X-, Y- and tulip profiles

- Parallel and straight edges

- Milling stations operate independently of each other

- Tool system with replaceable chucks

Profile milling machines

Profile milling machines

are the right solution for the production of various high-precision quality profiles.

Possible applications

Milling specimens for tensile testing

Tensile test specimen milling machines do a first-class job for material manufacturers as they create ideal specimens for testing material quality.

Possible applications

- Standardized parts for tensile test specimens

Seam welding milling machines

Milling systems for machine seam welding of large pipes can be adapted to the performance requirements and individual customer conditions. Compared to grinding, this grinding procedure differs in that there is no sparking and grinding dust, and noise absorption is reduced.

Possible applications

Your benefits

- Fully automated processing of internal and external welds

- Accurate measurement thanks to scanning

- Efficient chip removal equipment

- Low tooling costs

Milling Machines

This slab milling machine can mill horizontally and vertically in one process.

Possible applications

- Aluminum plates

- Steel plates

Your benefits

- Minimum chip removal thanks to 3D laser measurement of the board surface

- Simultaneous machining with several spindles (milling heads)

- Removal per cycle up to 15 mm

- Chips can be recycled up to 100%

- Possibility of installing a chip removal system or a chip briquetting system

Pipe chamfering machines

Pipe chamfering machines are used to deburr raw pipe ends and to apply various types of bevels to pipe ends.

Possible applications

- Pipes

- Diameter approx. 0.5 - 1.4 m

- Wall thickness from 7 mm to 48 mm

Your benefits

- Ideal preparation of weld seams

- portable machine

- High precision installation of pipe ends

Peeling machine

These cleaning machines are designed to process OD chips. Thanks to the special arrangement of the cutting edges on the cleaning head, they ensure optimal surface quality.

Possible applications

Your benefits

- Fully automatic diameter adjustment via conical ring – even during processing

- Surface quality (roughness) R z below 1.6

- Diameter accuracy is ±0.005mm, so only minimal overshoot is required for grinding.

- Cutting speed up to 120 m/min.

- Short set-up times thanks to replaceable inserts

OKOF 330.28.49.12.110 – Woodworking machines

OKOF 330.28.49.12.110 – Woodworking machines

- OKOF - All-Russian Classifier of Fixed Assets

- 300.00.00.00.000 - Machinery and equipment, including household equipment, and other objects

- 330.00.00.00.000 - Other machinery and equipment, including household equipment, and other objects

- 330.28 - Machinery and equipment not included in other groups

- 330.28.4 — Metalworking equipment and machines

- 330.28.49.1 - Machine tools for working stone, wood and similar hard materials

- 330.28.49.12 - Machine tools for working wood, cork, bone, hard rubber, hard plastics or similar hard materials; electroplating equipment

- 330.28.49.12.110 — Woodworking machines

330.28.49.12.110 — Woodworking machines

Classifier: OKOF OK 013-2014

Code: 330.28.49.12.110 Name: Woodworking machines Subsidiary elements: 7 Depreciation groups: 0 Direct adapter keys: 1

Subgroups

Group 330.28.49.12.110 in OKOF contains 7 subgroups.

- 330.28.49.12.111 — Woodworking machines for circular saws, band saws and jigsaws

- 330.28.49.12.112 — Woodworking planing machines

- 330.28.49.12.113 — Woodworking machines: milling, tenoning, grinding and polishing

- 330.28.49.12.114 — Woodworking machines: drilling, grooving and slotting

- 330.28.49.12.115 — Woodworking machines, universal and combined, and household

- 330.28.49.12.116 — Specialized woodworking machines

- 330.28.49.12.119 — Other woodworking machines

Shock absorption groups

Code 330.28.49.12.110 does not belong to any depreciation group (based on the appendix to the Decree of the Government of the Russian Federation “On the Classification of fixed assets included in depreciation groups”).

Transition keys

To move from the old OKOF to the new OKOF, use a direct transition key:

| OKOF OK 013-94 | OKOF OK 013-2014 | ||

| Code | Name | Code | Name |

| 142922620 | Woodworking machines | 330.28.49.12.110 | Woodworking machines |

© 2022 okof2.ru - All-Russian classifier of fixed assets with decoding and search

okof2.ru

see also

- Machine 1k62 technical specifications

- Vertical milling machines for metal

- Schemes for weaving with beads on a loom

- Loom information

What can be made from rubber bands for weaving without a machine- Valve Seat Processing Machine

- Lathe 250itvm

Accessories for waterjet machine- Bending machine for fittings sga 1

- Machine for the production of wood concrete blocks

- Universal table sharpening machines

OKOF 330.28.41.21 — Metal-cutting lathes

OKOF 330.28.41.21 — Metal-cutting lathes

- OKOF - All-Russian Classifier of Fixed Assets

- 300.00.00.00.000 - Machinery and equipment, including household equipment, and other objects

- 330.00.00.00.000 - Other machinery and equipment, including household equipment, and other objects

- 330.28 - Machinery and equipment not included in other groups

- 330.28.4 — Metalworking equipment and machines

- 330.28.41.2 — Metal-cutting lathes, boring and milling machines

- 330.28.41.21 — Metal-cutting lathes

330.28.41.21 — Metal-cutting lathes

Classifier: OKOF OK 013-2014 Code: 330.28.41.21 Name: Metal-cutting lathes Subsidiary elements: 2 Damping groups: 0 Direct adapter keys: 6

OKOF 330.28.41.22.130 – Metal-cutting milling machines

OKOF 330.28.41.22.130 – Metal-cutting milling machines

- OKOF - All-Russian Classifier of Fixed Assets

- 300.00.00.00.000 - Machinery and equipment, including household equipment, and other objects

- 330.00.00.00.000 - Other machinery and equipment, including household equipment, and other objects

- 330.28 - Machinery and equipment not included in other groups

- 330.28.4 — Metalworking equipment and machines

- 330.28.41.2 — Metal-cutting lathes, boring and milling machines

- 330.28.41.22 — Drilling, boring or milling machines for metal cutting; Nut-cutting and thread-cutting metal-cutting machines, not included in other groups

- 330.28.41.22.130 — Metal-cutting milling machines

330.28.41.22.130 — Metal-cutting milling machines

Classifier: OKOF OK 013-2014 Code: 330.28.41.22.130 Name: Metal-cutting milling machines Subsidiary elements: 0 Damping groups: 0 Direct adapter keys: 7

Subgroups

Grouping 330.28.41.22.130 in OKOF is final and does not contain subgroups.

Shock absorption groups

Code 330.28.41.22.130 does not belong to any depreciation group (based on the appendix to the Decree of the Government of the Russian Federation “On the Classification of fixed assets included in depreciation groups”).

Transition keys

To move from the old OKOF to the new OKOF, use a direct transition key:

| OKOF OK 013-94 | OKOF OK 013-2014 | ||

| Code | Name | Code | Name |

| 142922150 | Milling machines | 330.28.41.22.130 | Metal-cutting milling machines |

| 142922151 | Vertical milling machines | ||

| 142922152 | Horizontal milling machines | ||

| 142922153 | Universal milling machines | ||

| 142922154 | Copy-milling machines | ||

| 142922159 | Other milling machines | ||

| 142922175 | Special machines, specialized milling machines | ||

© 2022 okof2.ru - All-Russian classifier of fixed assets with decoding and search

okof2.ru

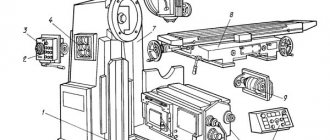

Milling machine parts and their functions

The main details of the milling machine are given:

The machine's gray cast iron base is precisely machined on its top and bottom surfaces and serves as a foundation member for all other parts that rest on it. It is carried by a column at one end. In some machines, the badge is hollowed out and acts as a coolant reservoir.

The column main supporting frame is installed vertically on the base. The column is box-shaped. Heavily ribbed inside and houses all drive mechanisms for spindle and table feed. The front vertical surface of the column is precisely machined and has dovetailed guide ways to support the knee. The top of the column is finished with a hand grip that extends outward to the front of the machine.

The elbow is a rigid gray iron casting that slides up and down the vertical path of the column face. Height adjustment is accomplished via a lifting screw on the base, which also supports the knee. The knee houses the table feed mechanism and various controls to operate it. The upper surface of the knee is formed in a sliding manner for the saddle to provide lateral movement of the table.

The saddle is located on top of the knee, which slides along guides set at an exact 90 angle to the face of the column. The cross feed screw on the top of the elbow engages the nut on the bottom of the saddle to move it horizontally, by hand or force, to apply the cross feed. The top of the saddle is carefully machined to provide a guide path to the table.

The rest table is placed on the saddle and moves forward longitudinally. The top of the table is precisely finished and the T-slots are designed to secure work and other fixtures to it. A lead screw under the table engages a nut on the seat to move the table horizontally by hand or force. Longitudinal movement of the table can be limited by fixing the dog's ride on the side of the table. In universal machines, the table can also be rotated horizontally. To do this, the table is mounted on a round frame, which in turn is mounted on a saddle. the circular plate is graded according to degree.

A hanging arm mounted on the top of the column extends beyond the boundary of the column and serves as a bearing support that can be provided closer to the cutter. There may be more than one bearing support provided for the gazebo.

A front brace is an additional support that is installed between the knee and shoulder to provide additional rigidity to the frame and knee. The front brace has slots to adjust the height of the knee in relation to the above arm.

- spindle

The machine spindle is located at the top of the column and receives power from the motor through belts, gears and clutches and transmits it to the front end arbor. The spindle is simply projected from the face of the column, and it is provided with a conical hole into which various cutting tools and mandrels can be inserted. The accuracy of metal processing with a cutter depends, first of all, on the accuracy, strength and rigidity of the spindle.

- Alcove

The arbor is considered an extension of the machine spindle, on which the cutters are securely mounted and rotate. Arbors are manufactured with tapered shanks to ensure proper alignment with machine spindles that have a tapered hole in the nose. The tapered shank of the arbor corresponds to the Morse taper or Self-healing taper, the value of which is 7:24. The gazebo may be supported at the farthest end from the overhanging arm or may be of a cantilever type called a cap.

,

OKOF 330.28.41.22.110 – Metal-cutting drilling machines

OKOF 330.28.41.22.110 – Metal-cutting drilling machines

- OKOF - All-Russian Classifier of Fixed Assets

- 300.00.00.00.000 - Machinery and equipment, including household equipment, and other objects

- 330.00.00.00.000 - Other machinery and equipment, including household equipment, and other objects

- 330.28 - Machinery and equipment not included in other groups

- 330.28.4 — Metalworking equipment and machines

- 330.28.41.2 — Metal-cutting lathes, boring and milling machines

- 330.28.41.22 — Drilling, boring or milling machines for metal cutting; Nut-cutting and thread-cutting metal-cutting machines, not included in other groups

- 330.28.41.22.110 — Metal-cutting drilling machines

330.28.41.22.110 — Metal-cutting drilling machines

Classifier: OKOF OK 013-2014 Code: 330.28.41.22.110 Name: Metal-cutting drilling machines Subsidiary elements: 0 Damping groups: 0 Direct adapter keys: 2

Subgroups

Grouping 330.28.41.22.110 in OKOF is final and does not contain subgroups.

Shock absorption groups

Code 330.28.41.22.110 does not belong to any depreciation group (based on the appendix to the Decree of the Government of the Russian Federation “On the Classification of fixed assets included in depreciation groups”).

Transition keys

To move from the old OKOF to the new OKOF, use a direct transition key:

| OKOF OK 013-94 | OKOF OK 013-2014 | ||

| Code | Name | Code | Name |

| 142922111 | Drilling machines (vertical drilling, jig drilling, radial drilling) | 330.28.41.22.110 | Metal-cutting drilling machines |

| 142922172 | Special machines, specialized drilling and boring group | ||

© 2022 okof2.ru - All-Russian classifier of fixed assets with decoding and search

okof2.ru