Menu:

- How and from what can a shoe be made?

- Using a piece of steel pipe

- Turning method from a steel circle

- Characteristics of pipe benders

- Various DIY pipe benders

- Wood

- Hydraulic

- For profile pipes

- Video

Previously, a blowtorch was used to bend pipes, which was used to heat the bending areas. But this method is already history. Today, many organizations have modern devices with the help of which they easily, simply and efficiently carry out spatial bending of pipes of different diameters, made from various materials and in any quantity.

There is always a demand for such a metal product, for example, from construction companies and firms that lay pipeline systems and need a large number of bent parts.

For your needs, it is best to make a pipe bender yourself, since it will cost much less than traveling to the place where the bending procedure is carried out, paying for the service provided and delivering the finished product back.

What if in a week you need a structure for bending pipes again? Therefore, it is better to make a decent bending tool once that will last for a long time. After all, the economic effect is obvious.

We create a pipe bender with our own hands

Option No. 1 - manual pipe bender

In general, the design of this tool is considered to be quite lightweight, which means that even a person who has not encountered these pipe benders can use such a tool.

To make it you will need:

- Track rollers;

- Stationary roller;

- Chassis elements;

- Adjustment screw;

- Handle (it will set the entire mechanism in motion).

This pipe bender works on the principle of a rolling machine, like most of all tools that you assemble yourself. All structural elements are necessarily made of steel or aluminum alloy, including support and thrust rollers.

This condition is one of the most important, otherwise, when rolling a pipe, the tool may become bent or severely deformed, so it will not be able to work fully.

Option No. 2 - mechanized pipe bender of increased efficiency

This version of the pipe bender was developed by simple craftsmen and lovers of making something with their own hands.

To create you will need:

- Frame welded from channels;

- 2 rolling rollers;

- 3 transmission gears;

- Chain;

- Gearbox and engine with belt drive mechanism.

Rolling rollers are mounted on rolling rollers in bearing structural elements. They acquire torque thanks to gears that are driven by a steel chain.

The chain takes rotation from the gearbox, which rotates using an electric motor. The engine shafts are connected to the pulleys by a belt. In general, the structure of this pipe bender is simple; the bending angle is changed using a clamping screw.

In general, such a tool will not take up much space in the garage or yard, so it makes sense to make this pipe bender.

Option No. 3 - hydraulic version of the pipe bender

The electric drive design is a really cool tool with high efficiency. However, a pipe bender that is equipped with a drive in the form of a machine hydraulic jack is considered even cooler.

To create a powerful pipe bender you will need::

- 3 cutting a wide channel;

- 3 trimming a narrow channel;

- Loop lock;

- 3 rollers mounted on bearing units;

- Pipe direction handle with fixed bias bushing;

- Hydraulic jack.

On channels, all structural elements are bolted together. The top 2 channels are fastened to one another through a loop lock. In this case, one of the channels is well fastened to the base, and the second must remain in a “free” state, this is necessary so that the jack rod can set it in motion.

The axis of the support roller should be connected to the rotation handle; this assembly is secured with a pin.

Note! If in the above-described versions of the pipe bender for adjusting the bend degree, a lead screw was used, a moving support roller along the vertical, then the “floating” channel, which is moved by a hydraulic rod, performs the same work.

This scheme requires less energy to perform useful work, for this reason this pipe bender has a higher efficiency.

Accessories/accessories for pipe benders/profile benders

Any pipe bending or profile bending machine without equipment is just a power unit that allows you to apply a certain force in a certain direction. Therefore, to work with each type of pipe, be it a profile, square or round, you will need specialized equipment; we will list only its main types: bending segment, roller, block, punch, mandrel, die, rolling roller, etc.

Depending on the model of pipe bender or profile bender, a certain type of equipment is used that corresponds to the specific parameter of the pipe being bent and allows bending with different internal radii and at different angles.

For example, in rolling or coiling type machines, equipment (block/punch) is used around which the pipe is bent. In crossbow-type bending machines, the equipment is a special segment with a certain groove for the outer diameter of the pipe, through which the hydraulic rod exerts pressure on the pipe and it takes the shape of the internal groove of the segment. Rolling type roll bending machines are equipped with 3 rollers, also with a shape that follows the cross-section of the pipe, and pressing the roller with a vertical stroke, the two lower ones roll the pipe left and right, changing its geometry, giving the desired bending radius. When working with thin-walled pipes, a special type of equipment is also used - the so-called mandrel, which makes it possible to prevent deformation of the pipe geometry at the point of bending. At the same time, the mandrel is located inside the pipe and, as it were, holds its walls, imparting the required rigidity, and maintaining its conditional passage without deformation.

Thus, as we see, it is not possible to work on pipe bending and profile bending machines without such specialized tools as components/accessories for pipe benders/profile benders. Often, these elements are already included with the equipment, meeting the basic parameters of bent pipes. And it is quite obvious that the correctly selected equipment for bending machines will not only save your time, but will also allow you to maintain the existing geometry of the pipe after giving it the required shape, i.e. flexion.

We would also like to note that in specialized production conditions, all elements of bending equipment are designed and manufactured in exact accordance with the size of the pipe for which this equipment is created, and from high-strength steel. Poor-quality equipment, manufactured in violation of the required tolerances, will not be able to create conditions for proper bending; accordingly, the pipes bent on it will not meet the standards, it will be difficult to join them and use them in one structure.

Assembling a pipe bender (step by step)

- The first step, of course, is to prepare a reliable, stable base; this can be a steel sheet 1 cm thick or a concrete base with built-in nuts for fastening other structural elements.

- Next, the installation of the side drive rollers of the installation is carried out.

- After this, you can begin installing the moving parts of the frame.

- Then you should check the moving parts; this work should be taken with special responsibility. You must ensure that the structural elements do not get stuck while performing the work. If the structure is not diagnosed, it may break when tested with a leading hydraulic drive.

- Then the main drive shaft stand is welded.

- Now the stage of work is to secure the central post of the drive shaft; the shaft should be secured with bolts and a lock nut.

- Lastly, the drive handle is attached.

Useful recommendations from the master

- If this is your first time deciding to bend pipes for any type of work, you should take into account some of the nuances of this process. For example, qualified craftsmen will definitely never sacrifice the quality of the bend in order to save a little time.

- When working with a pipe bender, it would be correct to make several weak pressures on the screw, but in 2 approaches to the machine. If you try to do everything in one go, then most likely you will bend the pipe, or put excessive pressure on it, which will lead to its rupture.

- To make it more convenient for you to work with a pipe bender, you need to create templates from plywood. In this case, it will be possible to create specific pipes for a specific type of work.

- It is important to install rolling rollers that are ideally suited for a specific pipe diameter; in this case, during rolling, the pipe will not move, and therefore its angle will not change. Plus, you won’t need to frequently adjust the pipe as it moves from the center of the support roller to the side border.

If you cannot make a template with your own hands for one reason or another, then keep a small notebook. In it you can record the control distances between the rolling and support rollers, in which case you will also receive a pipe with the desired bend.

The only drawback of this method is that the distance between the shafts can be difficult to measure using a regular tape measure.

We hope that this article was useful and informative for you, now you can make a pipe bender with your own hands. We wish you all the best!

How and from what can a shoe be made?

The main component of the device is a shoe for a pipe bender, which any man who knows how to use welding, a grinder and a hammer can make with his own hands.

Having learned well how to work with such a homemade bending shoe (punch) for pipe benders, you can successfully bend not only water and gas risers, but also various profiles and bundles of reinforcement.

Using a piece of steel pipe

This element of the bending device is made from an old, but still quite reliable, pulley made of steel or cast iron (for example, taken from crane fixtures). Often, to make an indispensable part for a bending machine with your own hands, they use a thick-walled steel riser, the diameter of which must be selected independently, based on the task at hand.

So, the pipe needs to be cut lengthwise with a grinder or edge cutter on a milling machine on both sides to a certain length so that you get two approximately identical gutters. After this, the gutter is bent with a certain bending radius (see photo). From below, the end parts of the groove are welded to a ring of appropriate radius or to homemade supports from a metal strip, square, welding points, possible burrs, etc. are polished.

That's it, a shoe made by yourself can be fixed in a pipe bending structure and used with full load. Such a device is in no way inferior, and maybe even superior in some respects, to factory analogs.

Homemade designs differ:

- increased strength;

- reliability;

- long service life;

- ease of production;

- minimal financial costs.

Turning method from a steel circle

Any good turner can make a shoe with his own hands from a large diameter rolled steel circle. To do this, you first need to thoroughly polish both ends using a cutter, and then make the necessary markings for the future shoe. You can watch the entire procedure for making a punch with your own hands in more detail in this video.

But, before you start making a homemade structure with your own hands, you need to look at the photo drawings and choose the most suitable option.

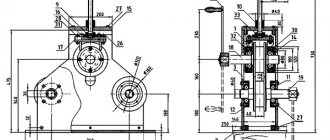

Drawing for the manufacture of a pipe bender with pressure rollers for a profile pipe

Most often, each owner makes his choice taking into account the availability of those materials that are at home, or they can be “obtained” somewhere, purchased “cheaply”. According to the experts, the cost of the device is significantly lower than store-bought analogues.

If you have never made such a tool before, then the best way to start is to make your own front-type machine, the design of which includes:

- three metal rollers;

- drive chain;

- rotation axes;

- a mechanism that will make the parts of the device move;

- massive profiles or angles for making a frame.