- home

- Equipment for furniture makers

Dina

Reading time: 9 minutes

1605

An edge banding machine (or edge maker) is one of the most complex devices actively used in furniture production. Its task is to veneer the edge of a furniture piece with a straight or curved shape.

After processing with an edger, the elements of future furniture acquire an aesthetic, neat appearance and receive additional protection from mechanical damage and delamination.

Not a single modern furniture production can do without this device. Even private production and repair of furniture requires an edger. Unfinished ends are already considered low production.

- Principle of operation of the mechanism Basic classification of edgers

- Main characteristics

Version LGS-26

We will continue the description of edge bending machines with a manual compact version, which is part of a series of equipment produced by the Lipetsk profile bending plant.

This unit is optimally suited for small workshops and field operation directly on site. It is designed to work with metals whose thickness does not exceed 0.7 millimeters. The main purpose is high-quality and fast production of shaped parts, including slopes, ebbs, stands, ridges, narrow strips and profiles. When processing parts, the edge is bent by 15 millimeters at an angle of up to 180°. The evenness of cutting sheets is guaranteed by the presence of rollers made of durable alloys in the design. The standard equipment of the unit includes:

- main mechanism with clamp;

- beam;

- bending device;

- goniometer;

- cutting machine;

- frontal stops that speed up the cutting process;

- set of spare knives.

The edge bending machine in question is a fairly practical and well-thought-out design. It is quite possible to use it as a prototype for creating a sheet bending machine with your own hands. It is worth noting that all parts are made using standard metalworking tools and welding. In a small workshop, such a machine can be made at minimal cost. Assembled from ready-made parts, the unit will cost 2-3 times less than purchased ready-made.

Self-production of an edge bending machine

Design, types and principle of operation of the steering mechanism

How to make a device for performing edge bending operations? This problem can be solved quite simply.

Option one. Long straight edge bending machine

In order to make such a device, you will need its drawings, which are easy to find on the Internet, as well as the following equipment and consumables:

- metal channels from which the base and clamps of the edge bender are made;

- thick-walled corner for making a crimping punch;

- metal sheet from which the edge bender brushes will be made;

- a metal bracket used as a handle for a device.

Scheme of operation of a homemade edge bender

The assembly diagram for making a machine for performing edge bending operations is as follows:

The edges of the punch and base are chamfered, the size of which should be 7x45°, and the length should be 30 cm. Metal rods with a diameter of 10 mm are welded to the punch, which will act as axes. When welding such rods, it is necessary to ensure that their axis coincides with the edge of the angle. Samples are made at the ends of the working part of the clamp. A homemade edge bender is pre-assembled in a vice, with the help of which the punch is compressed with the base

In this case, it is important to ensure that the wall of the punch and the working shelf of the base, between which the cardboard spacer is placed, are located in the same plane. Steel brushes are placed on the punch axis and pressed to the base using clamps. After checking the correct position of the brushes, they are welded to the base of the device. Holes are drilled at the base of the edge bender into which clamping bolts are screwed. Studs are welded to the base of the machine - a metal channel - onto which nuts are screwed. Having unscrewed the bolts, they are inserted into the drilled holes of the clamping mechanism and the restriction nuts are screwed onto them. A handle is welded to the metal corner of a homemade edge bender.

Drawing of a bending beam (click to enlarge)

Drawing of the lower beam (click to enlarge)

Drawing of the pressure beam (click to enlarge)

Once your edge bending device is assembled, all that remains is to secure it in a bench vise.

Edge bender mounted on a workbench

https://youtube.com/watch?v=EBreqnlypps

Option two. Manual edge bender for flanging

With this homemade device you can bend edges of any length, and the design is taken from manual factory-made edge benders.

Using these examples, we examined the procedure for manufacturing standard edge benders, which can be used to perform a whole list of technological operations. If you need an edge-bending device, which is used to carry out auto repairs, then it has an even simpler design and, accordingly, low cost, so it is not practical to make it yourself: it is better to purchase such a device.

Industrial press brakes and machines

Solenoid solenoid valve: where it is used + types and principle of operation

This category includes multifunctional metalworking devices. They are often equipped with CNC and can be used for piece or large-scale production. Let's look at the features of the operation of press brakes using the IB-1424 machine as an example. It is produced by the Nelidovsky plant for the production of hydraulic presses.

This equipment does not belong to the most powerful category, but it performs all the provided processes quickly and efficiently. This type of edge bending machines is capable of processing sheets and strips of various materials and develops a force of about 25 t/s. Main features:

- straight bending with a minimum bead height of 5 mm;

- cutting of blanks;

- making holes;

- processing profiles of complex configurations;

- The maximum length of parts is up to 2500 mm.

Advantages of KAMI

DHW pumps: design, principle of operation, types, areas of application

The company offers to choose and buy equipment for the production of furniture from a large assortment: edge banding machines with manual and automatic feeds, manual machines for removing overhangs and rolling corners; universal CNC machining centers for large-scale industry; devices for post- and softforming, as well as near-station mechanization and used installations. In our catalog you can find products at affordable prices from China, as well as machines at higher prices from Europe.

The company manager will help you select, compare technical specifications, organize delivery in Moscow and any region of Russia, and order additional equipment. Leave applications on the website.

Positional Edge Banding Machine

An “edge maker” of this type is a kind of compromise between a manual and semi-automatic machine. Mainly used in small and medium-sized cabinet furniture production. With its help, you can cover the ends with various synthetic roll materials - melamine, PVC, ABS, veneer, laminate, etc.

When edging, manual feeding of the workpiece is used. The positional edge banding machine has two rollers - one of them applies glue to the workpiece, the other to the tape. A pedal is provided to adjust the tape feeding speed; there is a control panel for controlling the heating of the glue, switching modes, adjusting the thickness and width of the material, automatic cutting, etc.

Industrial presses and machines

In terms of functionality, this is not the most powerful of machines, but it performs all the basic operations characteristic of this type of equipment efficiently and quickly. The edge bending press develops a force of up to 25 t.p. and can work with sheet and strip of various materials. In addition to straight bending itself, which it can perform with a minimum side height of 5 mm, the press can perform:

- cutting out parts;

- punching holes;

- bending of complex profiles.

The length of the workpieces that the press brake can work with is in the range of 1-2.5 m.

The press force is adjustable over a very wide range. To ensure that it does not exceed the critical value and the metal is not damaged, special force tables have been developed, which provide data based on the length of the bending line, metal thickness and radius.

The HBS hydraulic press brake is the second most popular machine of this type. It works with metals up to 3.5 mm thick and belongs to the average performance equipment. It can work with workpieces up to 3050 mm long (depending on the model) and bends edges and sheets up to 135, developing a force of up to 16 MPa. It is not equipped with numerical control and is controlled manually. Has a wide range of settings.

A manually driven machine can handle sheets up to 0.7 mm thick (steel) and help in the high-quality and quick production of various types of shaped parts - ebbs, slopes, valleys, ridges, corners, strips, narrow profiles. It provides an edge bend of at least 15 mm at an angle of 180 and smooth cutting of sheet metal using carbide rollers.

The machine package includes, in addition to the pressure beam and bending mechanism, a cutting machine and a protractor. The machine is equipped with front stops for quick sheet cutting. The kit also includes spare knives.

This machine is a very thoughtful and practical design that can be used as a prototype to create a machine with your own hands. All parts are manufactured using conventional metalworking tools and connected by welding. In a small workshop or workshop, even at home, such a machine can be made at a minimum of financial costs. Even if you have to buy all the parts, it will cost at least half as much as buying it ready-made.

Rating of the best edge makers

Having studied the statistics, reviews and technical parameters of the most popular models of edge banding machines, a rating of the best was compiled:

| Manufacturer (model) | Specifications | Description and additions |

| Brandt models Ambition-1200, 1400, 1600 and 1800 | made in Germany, Ambition models - single-sided machines, designed to work with an edge of 0.4-2 mm for gluing it to workpieces of 8-50 mm, operating speed 6m/minute | created for processing (gluing edges) to straight end parts, the adhesive layer is applied evenly with special rollers and pressed tightly using rotating cylinders, the higher the serial model number, the higher the technical parameters of the machines become |

| Company KROM Russian manufacturer offering the best manual edge edging machines | model KROM-750 is a new product in the series of manual machines, ideal for private use and small businesses, works with PVC edges with a thickness of 0.3-3 mm at a working speed of 5 m/minute | The model is distinguished by high build quality and an affordable price, an order of magnitude lower than its foreign analogues, has a built-in reservoir for adhesive mass with a volume of 270 ml, and comes with a repair kit for quickly eliminating minor breakdowns |

| Felder Company The German company presents its customers with edging machines of various levels and classes. | universal (NEW-G320, G460, G330 and ForKa300-s-eco); professional (G500, NEW-G680, NEW-G670 and NEW-G660); Premium (perfect-710x-motion, perfect-608x-motion-plus, perfect-710e-motion, perfect-710x-motion-plus, NEW-perfect812e-motion and NEW-perfect812x-motion-plus); mobile (Felder-ForKa-200) | universal edgers are small in size and work with edges of 0.4-3 mm and workpieces of 10-45 mm; they are used for gluing edges to curved or straight workpieces; professional models are multifunctional edgers designed for rounding corners, jointing, polishing and scraping workpieces at a high level; they work with edge material of 0.4-3 mm and workpieces with a thickness of 8-60 mm; Premium-level machines - devices characterized by high productivity, the most accurate result of work and an almost invisible seam; Mobile edgers are flexible, small-sized, hand-held and very convenient tools, they are designed for additional, auxiliary work for furniture processing |

| Griggio Company Italian manufacturers offering machines of various levels: automatic and manual, designed for gluing straight edges made of laminate and natural wood | small-sized models are designed for facing an edge layer up to 3 mm thick and work with 45 mm workpieces, operating speed 1-4 m/minute | the GB-M model machine, weighing about 8.5 kg, is the smallest and easiest to operate; it has a variable temperature mode and speed adjustment; the rest of the presented models from this manufacturer differ in weight and dimensions, as well as stated power; these are highly professional devices for gluing edges of 0.4-8 mm on furniture pieces measuring 10-60 mm and operating speeds of 1-17 m/minute |

| company CEHISA Spanish manufacturers leading in the wood processing industry | Cehisa edge maker is one of the most popular, it is a one-sided, automatic machine for high-quality gluing of edges made of wood, veneer, laminate and melamine | machines from this manufacturer are in great demand and are actively used in large furniture production, as well as in low-power enterprises |

Features of the device

The workpiece is fed to the work table manually by the operator. While the workpiece is moving along the work table, the limit switch is triggered, giving a command that activates the process of feeding edge material from the magazine.

Modern edging machines can be equipped with 1 or 2 rollers for applying glue not only to the film, but also to the product itself. Thanks to this, it is possible to veneer straight and radius profiles.

The design of edge trimming units is small in size and compact, and consists of several units:

- applying a separating liquid, which prevents the PUR glue from drying out in visible places;

- preliminary cutting, jointing and gluing;

- finishing trimming and removal of overhangs - to remove excess material along the length and width of the workpiece;

- rolling corners to process film joints on the corners of parts, especially effective and indispensable on thick ends;

- flat and radius cycles for refining the radii along the overhangs, removing waves after removing the overhangs and bringing the adhesive seams between the edge and the material to an aesthetically beautiful, invisible look;

- applying washing liquid - applies detergent to the part and edge, eliminating dust and traces of glue;

- polishing - restores color and creates a shiny finish on the surface;

- edge tape feed store.

Semi-automatic edge banding machine

More functional and “faster” equipment compared to the previous one. Capable of providing high productivity and can be operated in several shifts in continuous mode. The edge is fed automatically using a rubber roller. The thickness of the edges and panels used is the same as that of positioning machines.

A semi-automatic edge banding machine carries out lining with melamine and some synthetic materials, which can be applied not only to straight, but also to inclined and profiled planes with beveled ends.

For convenience, the semi-automatic edge banding machine is equipped with several speeds. The equipment also provides separate automatic magazines for different types of materials (strip and reel).

Areas of application

An edge bending machine or a simple hand tool designed for bending edges is widely used in many areas. The edge bender makes it possible, in particular, to produce air duct elements from thin sheet metal and to prepare the edges of workpieces for joining them by welding. Auto repair (body work) is another area of application for such tools and equipment.

Edge bending is also actively used in construction and when performing home repair work. Using such a tool, seam joints of thin-sheet metal elements are formed and even products of various configurations are manufactured.

Bending the end of a drainpipe on an electromechanical edge bending machine

If we talk about the principle by which the edge bender operates, it is quite simple. To bend the edge of a thin-sheet product, the edge bender scale is set to the required processing width, then the edge of the workpiece is placed between the working rollers of the device and, moving the device, the bend is performed.

Automatic Edge Banding Machine

This equipment is designed for large production lines. An automatic edge banding machine is not cheap and has a number of specific parameters that are selected for specific tasks. All previous types are more universal.

For example, most often there is a limitation on the thickness of the processed parts, width and length. Since the automatic edge banding machine is designed for large volumes of work, its equipment includes a large glue bath with stirrers, two motors, several replaceable knives and edge material holders.

Types of edge bending machines

For bending sheets and edges, various machines have been created that work with metal up to 2 mm thick or more. The highest quality of bending is achieved on stationary machines, which are installed in the workshops of metalworking enterprises. Mobile or manual machines are designed for work in small workshops and directly at sites where ventilation, drainage systems are installed or metal roofs are installed.

According to the type of working equipment, edge bending machines are divided into:

- rotary;

- press;

- rotary.

According to the drive method, edge benders (sheet benders) are:

- mechanical manual;

- mechanical with a rotary flywheel;

- electromechanical;

- hydraulic;

- pneumatic;

- electromagnetic.

Regardless of the drive, the machines can work with galvanized and black steel, copper, and aluminum. When bending painted sheets, the protective layer is preserved. Using bending equipment, various structural parts of complex shapes are produced - boxes, gutters, segments, bottoms, stands, long narrow profiles.

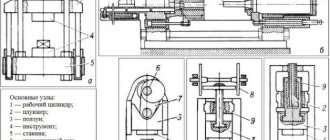

Main structural elements:

- bed;

- rear support table, which serves to place the workpiece, move it in the desired direction and perform basic bending work - the bender and cutter are located on it;

- front adjustable supports, with the help of which the width of the cut part is set;

- roller knife for aligning edges and cutting fragments of a given width.

- pressure beam;

- flexor;

- sharp and angular tires;

- goniometers;

- height clamps that regulate the height of the side;

- drive unit;

- controls.

Each edge bending machine has its own set of required elements, depending on the functionality. For example, segment machines can bend metal along non-parallel lines, producing trapezoidal, triangular, segmented parts of a given configuration. Continuous machines can only perform bending along parallel lines - the clamping and bending beams cannot move from the longitudinal axis.

How the machine works

The sheet of metal is placed on the table and pressed against the table by a beam of the required configuration. The bending beam rises up, grabs an edge or sheet of metal, presses it against the busbar, which acts as a matrix, and bends it to the required angle.

In the manual version of such a machine, the required force is achieved using a lever handle.

As a rule, when bending metal up to 1 mm, the force required is not too great; a person of average physical strength can handle the machine. On such a machine, the edge bend reaches 120-1350. Further bending is done using an eccentric tie, which brings the angle to 1800. Metal processing up to 1 mm is possible on manual industrial or home-made machines with manual or mechanical drive. For thicker sheets, you will need a hydraulic or electromechanical press brake.