Information about the manufacturer of vertical drilling machine 2118

The manufacturer of the vertical drilling machine 2118 is the Novocherkassk Machine Tool Plant

, founded in 1938.

Since January 1957, the plant specialized in the production of only turret machines. The plant produced turret lathes: 1N318, 1N325, 1G325, 1D325, 1E325, 1325F3.

Machine tools produced by Novocherkassk Machine Tool Plant

- 1G325

- turret lathe with a horizontal axis of the turret head, Ø 25 - 1D325P

- turret lathe with a horizontal axis of the turret head of increased accuracy, Ø 25 - 1N318, 1N318r

- turret lathe with a vertical axis of the turret head, Ø 18 - 1N325

- turret lathe with a vertical axis of the turret head, Ø 25 - 1325F30

- CNC turret lathe with a horizontal axis of the turret head, Ø 320 - 2118

— vertical drilling machine, Ø 18

Reviews and Reviews

Watch the videos (above) and reviews (below), they are often better than text reviews. You can read more reviews or leave your own in the comments to this page. Thank you for your review or rating!

I used this lathe CORVET 402. In the “out of the box” state, it requires serious alteration and strengthening of the moving parts, since everything is crooked, loose and replete with jambs at the level of self-taught pioneers. However, it will do for plastic and aluminum.

Alexey 01/30/2019

Rate this model:

Model rating: 4.2 / 5. Number of ratings: 13

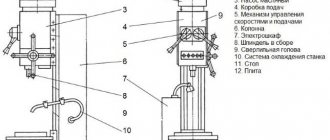

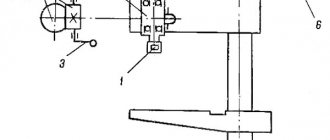

Photo of vertical drilling machine 2118

Photo of vertical drilling machine 2118

Photo of vertical drilling machine 2118

Photo of vertical drilling machine 2118

Photo of vertical drilling machine 2118

Service

All maintenance work on the 2M112 universal tabletop drilling machine consists of monitoring the tension of the pulley belt and lubrication of individual components of the device. Under normal load, the spindle (quill), especially the splined surfaces, most often (every 2 days) requires lubrication and cleaning. Once a week, lubricate the surface of the vertical column and the adjusting nut. The spindle and column bearings require grease replacement every six months. If the number of revolutions is changed frequently, the belt tension regulator and the spindle guard lock need to be lubricated. The bearings are lubricated with CIATIM or Litol type grease.

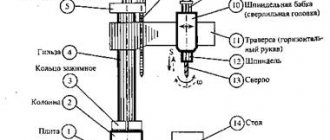

Design of drilling machine 2118

By its design, the drilling machine is very easy to operate. In order to set the selected drilling speed, it is necessary to move the V-belt to the appropriate pulley stage.

In order to transfer the belt from one pulley stage to another, you need to unscrew the special handle on the bracket and, by turning the screw to the left, move the bracket together with the electric motor toward you. After this, you need to rearrange the belt, and then (to tension the belt) by turning the screw to the right, move the bracket with the electric motor away from you.

Automatic feeding is carried out through the feed box, the latter's roller is driven into rotation from the spindle drive through a small gearbox, which is connected to the drive belt.

The automatic feed rate is 0.2 mm per spindle revolution. Feed more than 0.2 mm. can only be done manually, for which a special overrunning mechanism is installed in the feed box.

In order to work with a feed less than 0.2 mm (when drilling on steel up to Ø 6 mm), the automatic feed must be turned off by moving the handle counterclockwise as far as it will go and tighten the stop screw on the side of the disk.

In order to drill to a given depth during automatic feeding, there is a movable stop bar on the switching sleeve disk, and a special scale in millimeters is applied around the circumference of the vernier ring, from which the given depth is measured. The strip is installed in accordance with the required drilling depth.

The machine is started and stopped using an electric motor, and the latter is turned on and off by a drum switch.

Automatic feed 0.2 mm. Can be used for carbon steel, for drilling diameters from Ø 6 mm to 18 mm. For cast iron, for drilling diameters from 3 mm. up to 18 mm.

When operating with automatic feed, the handle must be set to the middle position.

The automatic feed can be easily switched off by selecting the rollers in the feed box: Ø 12.3..12.7.

Drilling machine cooling 2118

To cool the tool when drilling, a special electric pump of type P22-A is mounted on the machine, which can be turned on using a separate package switch.

A special reservoir is provided for coolant in the machine cabinet.

Drilling machine lubrication 2118

The machine is lubricated daily before starting work in the following places:

The feed gear axis is through two oil nipples on the feed box body.

When feeding automatically, it is necessary to generously lubricate the neck of the feed roller of the feed box - through the circular chamfer in the bushing of the feed box.

All other mechanisms are lubricated periodically by filling grease through holes specially provided for this purpose.

The Lenix bearing is lubricated periodically by unscrewing the roller from the bar (left-hand thread). The feed roller bearings are lubricated through a hole in the Z63 gear by turning out the locking screw.

It is necessary to lubricate the gearbox drive gears daily.

The rack and pinion gear of the feed box is lubricated by applying oil to the quill teeth.

The worm gear axis in the table lifting mechanism is lubricated through an oiler at the end of the axis.

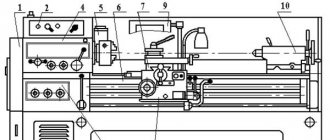

Location of controls for screw-cutting lathe 250-ITV

Location of controls for screw-cutting lathe 250-ITV

Specification of controls for screw-cutting lathe 250-ITV

- Spindle speed selection handwheel

- Spindle speed switch handle

- Handle for setting the feed rate and thread pitch

- Handle for setting the feed rate and thread pitch

- Handle for setting the feed rate and thread pitch

- Switching handle for bit and pitch increase link

- Shift knob

- Input switch

- Cooling pump switch

- Pre-dial remote

- Digital scoreboard

- Button 0 resets the digital display to zero

- Button A calls to the digital display of the initial absolute coordinate

- Switch Network display unit

- Oil pump switch

- General stop and emergency shutdown button

- Manual longitudinal feed handwheel

- Manual cross feed handwheel

- Tool holder fastening handle

- Light switch

- Lead screw nut on/off handle

- Flywheel for moving the upper slide

- Quill clamp handle

- Handle for securing the tailstock to the frame

- Feed reverse handle

- Quill movement flywheel

- Nut for securing the tailstock to the bed

- Safety mechanism adjustment screw

- Start and stop handle

- Vernier flywheel

Technical characteristics of the machine 2118

| Parameter name | 2n118 | 2118 |

| Basic machine parameters | ||

| Largest drilling diameter, mm | 18 | 18 |

| The smallest and largest distance from the end of the spindle to the table | 0…650 | 0…650 |

| Distance from the axis of the vertical spindle to the rack guides (overhang), mm | 200 | 200 |

| Desktop | ||

| Maximum load on the table (center), kg | ||

| Dimensions of the working surface of the table (length x width), mm | 360 x 320 | 350 x 340 |

| Number of T-slots Dimensions of T-slots | 3 | 3 |

| Maximum vertical movement of the table (Z axis), mm | 350 | 445 |

| Table movement per one revolution of the handle, mm | 2,4 | |

| Spindle | ||

| Maximum movement of the spindle head, mm | 300 | 150 |

| Movement of the spindle head per revolution of the handwheel, mm | 4,4 | |

| Spindle sleeve stroke, mm | 150 | |

| Spindle movement by one dial division, mm | 1 | |

| Spindle movement per one revolution of the handwheel-handle, mm | 110 | |

| Spindle speed, rpm | 180 — 2800 | 300, 450, 735, 1200, 1980, 3100 |

| Number of spindle speeds | 9 | 6 |

| Maximum permissible torque, kg*cm | 880 | |

| Spindle taper | Morse 2 | Morse 2 |

| Machine mechanics | ||

| Number of table feed stages | 6 | 1 |

| Limits of vertical working feeds per spindle revolution, mm/rev | 0,1 — 0,56 | 0,2 |

| Maximum permissible feed force, kgf | 560 | |

| Spindle braking | There is | |

| Drive unit | ||

| Main drive motor Type | AOL2-22-4S2 | A-41/6 |

| Electric motor of the main movement drive Number of revolutions per minute, rpm | 1420 | 930 |

| Main motion drive electric motor Power, kW | 1,5 | 1,0 |

| Electric coolant pump Type | PA-22 | PA-22-A |

| Dimensions and weight of the machine | ||

| Machine dimensions (length width height), mm | 870 x 590 x 2080 | 875 x 550 x 2005 |

| Machine weight, kg | 450 | 450 |

- Barun V.A. Working on drilling machines, 1963

- Vinnikov I.Z., Frenkel M.I. Driller, 1971

- Vinnikov I.Z. Drilling machines and work on them, 1988

- Loskutov V.V Drilling and boring machines, 1981

- Panov F.S. Working on CNC machines, 1984

- Popov V.M., Gladilina I.I. Driller, 1958

- Sysoev V.I. Handbook for a Young Driller, 1962

Bibliography

Related Links. Additional Information

- Classification and main characteristics of drilling-milling-boring group of machines

- Selecting the right metalworking machine

- Machine repair technology

- Methodology for checking and testing drilling machines for accuracy and rigidity

- Directory of drilling machines

- Manufacturers of drilling machines in Russia

- Manufacturers of metal-cutting machines

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers

Marking

By the equipment code you can determine its technical characteristics. All drilling device codes begin with the number 2. The fact that the equipment is of a vertical type is indicated by the second number 1. The remaining number shows the largest diameter of the hole being produced. If there is a letter after the first number, the equipment has been improved. The letter at the end means that the equipment is made on the basis of the main model.

For example, the 2s132 machine has the following characteristics: maximum deep drilling diameter is 32 mm, upgraded compared to models 2132 and 2a132.

Domestic models

Let's look at popular vertical drilling machines made in the USSR. These are models 2a125, 2g125, 2l125, 2t140, 2118 and 2118a.

The floor-standing vertical drilling machine 2a125 has a maximum deep drilling diameter of 25 mm. Equipment 2a125 includes 9 speeds from 97 to 1360 rpm and a reach of 250 mm. Has a device for reversing the electric motor. Size 98*82.5*230 cm, weight 870 kg. Manufactured in the USSR at the Sterlitamak plant. The price of this model is from 25,000 rubles.

The improved device 2g125 has a larger reach of 260 mm. Lower power engine – 2.2 kW. The weight of the floor type machine is 2g125 780 kg, dimensions are 73*91*210.5 cm. Number of speeds is 2g125 16. Vertical movement of the table is 425 mm. In the 2g125 device, the threading diameter is 24 mm. The spindle has a Morse taper 3. It was manufactured in the USSR at the Krasnorechensky plant. The price of this configuration is from 20,000 rubles.

Model 2L125 is the smallest and has the best characteristics. The weight of the machine is 475 kg, dimensions 86*56*213 cm. It has a Morse spindle taper of 4. The maximum table stroke is 540 mm.

The 2t140 machine is being produced now and is one of the most advanced models.

The 2118 machine has a maximum deep drilling diameter of 18 mm. The spindle includes a Morse taper 2. The reach of the device is 200 mm. Equipment dimensions 2118 87*59*208 cm, device weight 450 kg. Vertical table movement 350 mm. The unit is turned on by a drum switch, which supplies power to the electric motor. With regular use, the main components of the 2118 machine must be lubricated daily with your own hands. The price of machine 2118 is from 20,000 rubles.

For small jobs, a VSN machine is used. It is distinguished by its small dimensions - 30*58*66 cm and weighing no more than 75 kg. The spindle of the device has 2 speeds and a rotation frequency from 7.5 to 20. The largest diameter of the holes of the VSN machine is 16 mm. The spindle moves 100 mm. The machine operates from a mains voltage of 380 V. The work table is square with a side length of 250 mm. The spindle has a Morse taper B16. Despite its small size, the VSN drills into metal materials. The price of equipment is from 20,000 rubles.

All devices are supplied with operating instructions upon purchase. Models produced in the USSR are sold second-hand.

Equipment classification

A system of symbols has been adopted, which makes it easy to understand the marking of units. Difficulty in deciphering the name of the machine arises in specialized production, when the abbreviation is set by the manufacturer. In the standard case, numbering is based on the decimal system.

The equipment designation includes four numbers and several letters, the latter can be located anywhere. The letters can indicate the degree of automation, accuracy class or new modification. Let's look at the meaning of the numbers:

- It defines a group of machines, depending on the technological operation being performed. There are nine groups in total.

- Indicates the type of equipment, there are nine of them.

- The last numbers show the main size of the unit.

In our case, the first number (2) indicates the drilling group. The second number (1) indicates the vertical drilling type of the machine. Using the last numbers, we determine the maximum size of the hole that the mechanism can drill. The letter (n) indicates a new modification of the base model.

Foreign models

Foreign companies producing vertical drilling machines:

- JET (USA).

- Optimum (Germany).

- Hitachi (Japan).

The price of these devices is high. The best company in terms of price and quality ratio is Hitachi.

One of the most popular Hitachi b16rm models. The maximum diameter of deep drilling is 16 mm. Equipped with an asynchronous motor, which can be operated for a long time.

The Hitachi b16rm machine has a laser pointer and an optical drill axis indicator. The desktop rotates 45 degrees. The electric motor operates at 12 speeds from 210 to 3100 rpm. The reach of the device is 380 mm.

Working in poor lighting is possible using the built-in backlight. The Hitachi b16rm is quiet and virtually vibration-free.

In the basic configuration, the b16rm operates on a voltage of 220 V, but you can power it with your own hands from a 380 V network by connecting an additional frequency converter.

The American analogue of the Hitachi b16rm device is the JET JDP-17F machine. The operating instructions come with translations into several languages. The price of this model is from 30,000 rubles.

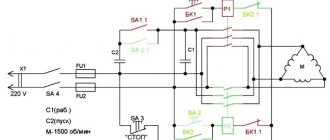

Electrical protection

To prevent unwanted overloads, the manufacturer provides protection - automatic switch AST - 3. Grounding of the machine is provided by a coil of magnetic starters. The drill bit, as well as the contact board, must be connected in accordance with the requirements and regulations that apply to production equipment.

Electrical components: electric power unit, electric pump for supplying liquid to the cooling system, start-up and automatic shutdown mechanisms, rectifiers, local lighting to improve the work process.

It is imperative that every employee, especially those who work at a machine, must strictly comply with the norms and requirements of the labor protection instructions. Otherwise, the worker is not allowed to enter the workplace.

A vertical drilling machine is used for making holes, cutting threads, countersinking ends and boring holes. It can work with almost any material.

Photo of the machine

Vertical drilling machines are available in many modifications. The layout and basic components of all models are almost the same. Main parts of equipment:

- Foundation slab. Provides support for stability.

- Bed. Locates the main components of the equipment. There are guides on the side to which the bracket and spindle are attached.

- Main motion drive. Transmits rotation from the electric motor to the feed box.

- Spindle. Secures the cutting tool.

- Box and feed mechanism. It has gears with which the spindle changes the rotation speed.

- Table. Moves using a handle. In industrial equipment, a cross table is used.

Modern vertical models use quick-change chucks.

The main technical characteristics of drilling devices: maximum spindle stroke, largest diameter of deep drilling and overhang. The operating instructions contain detailed information about the equipment.