Due to the beauty of the pattern, the variety of colors and its durability, this natural material is very much in demand in high-end and high-class buildings, as well as in renovation projects of old buildings. Therefore, the issue of processing natural stone, including drilling granite, is relevant when carrying out construction and repair work.

Drilling natural stone requires knowledge, skills and special tools. An incorrectly selected drill or a violation of operating technology most often leads to, at a minimum, damaged drills, and in the worst case, to cracked material.

Before you start drilling into granite, think carefully and answer the following questions:

- how much do you need this hole and whether you can do without it;

- what should be the exact dimensions of the hole;

- how many holes are needed in total;

- What is the best tool to do this?

Work related to drilling granite must be carried out very carefully, without haste and only after accurate, verified markings. In this case, it is necessary to follow certain rules for performing such work. Correcting and redoing the mistake will then be very difficult or even impossible.

Diamond coated drill bit.

Four important rules

The rotation speed of the drill or bit should be minimal and selected depending on the diameter of the tool. The larger the diameter, the lower the number of revolutions of the drill should be. So, for example, with a drill diameter of 12 mm, the maximum permissible rotation speed is 950 rpm, and with 20 mm - 700 rpm.

It is necessary to supply water to the drilling site, which will cool the cutting tool and wash away the slag formed during operation. Using water prevents the drill from jamming and increases its service life. In addition, the water will cool the granite, resulting in smooth and neat edges of the hole.

Best answers

Nadezhda Golysheva:

Swedish Mora fittings have a diameter of 32-36 mm.

Vladimir Petrov:

First, buy a faucet and then look at what diameter to cut the hole so that you have a margin

Santa Claus:

35mm

Oleg Zlanepomnyashchiy:

Any self-respecting plumbing manufacturer has instructions that come with the corresponding product.

Oleg Losev:

A 35mm drill usually goes to the sink...

Sergey Anisimov:

In sinks a la stone with a wing, which can be installed with the trough located on the left or right, the kit includes a cutter for independently drilling a hole for the mixer on one side or the other, and this cutter has a diameter of 35 mm.

Instructions for drilling granite

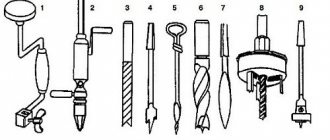

To drill natural stone, you must use a drill with the ability to change the speed of rotation. It is best to use a diamond bit of the diameter you need as a cutting tool. In addition, you need to prepare 2-3 clamps, masking paper tape, a marker and water in a plastic bottle with a hole.

Place the granite workpiece on a flat surface and secure it securely with clamps, and to prevent the clamps from scratching the polished stone, place wooden planks under them. Apply paper tape to the drilling site and mark the center and outline of the hole.

Scratch the center mark with a drill or tap so you can start drilling from that point.

Attach the diamond bit to the electric drill and install the center guide into the scratched center of the hole. If the design of the crown does not provide a guide, then make a template of the required diameter from a wooden plank, secure it to the surface, and use it as a guide during work.

Making a hole in an artificial stone sink: instructions

When purchasing a sink made of artificial stone, the client is often faced with a problem such as the lack of a hole for the faucet. Naturally, you should turn to experts, but this issue can be resolved without the help of others.

In order to understand how to drill a sink made of artificial stone, you must first understand what it is made of. There is no exact definition of “artificial stone”, which is why different manufacturers use this term to refer to different materials that differ in density and properties.

The most common are:

- porcelain stoneware;

- agglomerate (fragranite, silgranite and their analogues);

- acrylic stone.

Working with any of these materials has its own characteristics. In order to decide which drill to use to drill a stone sink, you must first understand what exactly was purchased.

The photo shows a porcelain stoneware countertop

Porcelain stoneware is the strongest and most durable of the materials listed above. It is not afraid of temperature and chemical influences, and is resistant to mechanical damage. It stands out due to its booming “glass” sound.

Other types of artificial stone produce a duller sound due to the addition of plastic and polymer materials. Despite the fact that making a hole in other materials is easier than drilling a porcelain stoneware sink, very often the choice of clients falls specifically on it. Taking into account the extraordinary density of the material, ordinary drills will be powerless here.

Only a crown or a carbide-tipped drill, ideally diamond, can handle porcelain stoneware. Sintered ring drills will also be able to work with it, but their price is even higher, so they are chosen occasionally, only if there is a need for a larger volume of work. Due to its high strength, when working with this material, you need to cool the drill and working surface with water. It is necessary to work with porcelain stoneware at low speeds (300-400 less).

Where to cut the hole?

Another important question that will arise regardless of what material the sink was purchased from: should I cut a hole in it from the front after installation? Or should I do this before installation and from the back?

Each method has a number of pros and cons:

- In the first case, the edges on the front side will be even smoother, but there is a possibility of damaging the front side of the sink with a drill, and if it has a narrow side, then splitting the edge.

- In the 2nd option, the risk of destroying the bowl is even lower, but with all this there is the possibility of getting a sloppy edge of the hole on the front side. Almost always this is not critical, because the edges of the hole are blocked by the mixer. When turning over, there is a possibility of unintentionally making a hole on the wrong side, so it is better to mark the side on which you want to install the faucet.

In any of the methods, it is better to place the hole away from the edge of the product, but at the same time without touching the bowl. To do this, before work, you need to attach the lower nut of the mixer to the sink and mark its center.

If there is no diamond tool

In addition to diamond cutting tools, pobedit drills, diamond dust or corundum can be used to make holes. These methods are less effective and take longer, but still allow you to achieve the desired result.

Drilling holes in granite using a Pobedit drill is performed at high rotation speed and a constant supply of water. If the process begins to slow down, the drill must be removed and sharpened.

To make a hole in granite using corundum, diamond dust or ground pobedite, you will need a copper or brass tube, which will need to be fixed in a drill. On the granite surface, around the diameter of the marked hole, make a rim of plasticine or quick-drying putty 4-5 mm high.

Pour abrasive material inside the fence and drill with a tube at the lowest possible speed of the drill. During operation, do not forget to periodically add water for cooling.

What are the basic rules for laboratory furniture?

The most basic rule for laboratory furniture is that it should be ergonomic and practical. Conducting experiments and research of various types should be carried out in a convenient and well-planned environment. Different decor in such rooms is categorically unacceptable.

The second rule says that a table or some kind of cabinet, whether it is retractable or not, should be simple and multifunctional. For any business there must be certain furniture that will be responsible for a particular task. For example, a drying cabinet must be used only for drying.

The third rule is: laboratory furniture in Moscow

must be very durable, since it will have to withstand difficult loads. The strength of such furniture must be at the highest level; as a rule, laboratory furniture must be resistant to cracks. Often such furniture is made of durable material, such as plastic, metal or glass.

What and how to cut decorative stone correctly

Decorative stone is understood as materials of artificial origin that replicate the appearance and, in part, properties of natural stones: granite, marble, tuff, sandstone, etc. Modern development of technology makes it possible not only to imitate any natural finishing material, but also to ensure its good workability .

For an on-site finisher, it is important to know how to cut decorative stone, how to drill it, and how to assemble a whole object from separate parts. Solving these problems requires familiarity with the properties of such materials.

Sources:

https://stroika-1.ru/oremonte/delaem-otverstie-v-mojke-iz-iskusstvennogo-kamnya.html#i-2 https://stroika-1.ru/oremonte/delaem-otverstie-v-mojke -iz-iskusstvennogo-kamnya.html#i-3 https://litstone.ru/delaem-otverstie-v-mojke-iz-iskusstvennogo-kamnja/ https://xn7sbzghf7ail.xnp1ai/articles/vse-o-kamennyh- mojkah/57-kak-prosverlit-otverstie-v-kamennoj-mojke.html https://kvarremontnik.ru/sverlit-mojjku-iz-iskusstvennogo-kamnya/ https://c-triada.ru/masteru/chem-prosverlit -iskusstvennyj-kamen.html

Making a hole in an artificial stone sink

Decorating sinks today can be very diverse. For example, there are models implemented as a single unit with a tabletop. In this case, a special acrylic stone is used. It has a low density, which makes working with it easier and simpler. If the sink is made of artificial stone, then many people wonder how to drill a hole for it. For this, traditional drills are used, specially designed for working with metal or wood.

To install a water tap, a hole of no more than 35 millimeters is often cut as standard. If the product is made of artificial stone, then you can use a feather blade or a Forstner cutter of the same diameter. The speed should be low and average. During operation, a large amount of chips will be released. Artificial stone contains plastic that has an unpleasant odor. Therefore, it is better to use protective masks.

This type of material is soft, making it great for creating sinks. You need to be as careful as possible when working with such material. The ratio of resin to stone chips may vary. Drilling such material is easier than ordinary stone. But even in this case, you need to be as attentive and careful as possible. No work should be carried out with such material until its temperature is equal to room temperature.

How to punch a hole in a sink for a faucet

There are types of sinks that have special artificial stone. It has molded plugs, they can be knocked out during installation work. If you look from the front side, they are most often marked. Initially, the sink should be installed on the countertop, but should not be fixed.

After this, the necessary tool is selected and the traffic jams begin to break out. In this case, hammer blows are used. You can also use punches having a diameter of eight millimeters. It is better not to use a screwdriver for this activity. The cork is knocked out from above, from the front side. Next, a rasp is used to smooth the edges. This method is not suitable for all types of sinks, but it is simpler. Even a beginner who has never held a tool in his hands can handle it.

Porcelain tiles

Porcelain tiles are the most durable and durable material of these. It is highly resistant to any external influences. As you might guess, a conventional drill cannot cope with such a particularly strong material. For drilling porcelain stoneware, drills with carbide tips (the best one is diamond) are ideal.

Where is the best place to drill a hole? This question arises because there are two drilling options:

- Drill a hole on the front side after the sink is installed.

- Drill a hole from the back before installing the stone sink.

The choice will be up to you, but keep in mind the advantages and disadvantages of each method. In the first option, the edges will be much smoother, but there is a risk that the drill will damage the front part of the sink. The second option reduces this risk to almost a minimum, but the problem may arise in another way: the result may not be a very neat edge. But in fact, this is especially scary because the edges are processed by the mixer.