Metal can be different. For example, copper is much more ductile than steel, and cast iron, although strong, is brittle. Therefore, drilling metal in each case requires an individual approach. Let's look at how to properly make holes in steel parts, including large diameter ones. And also how to expand an already made passage with a drill.

Drilling a hole in metal Source kovkingorod.ru

Tools required for work

On an industrial scale, special machines are used for drilling metal parts. In everyday life, a drill is used, both manual and electric. Moreover, the first is irrevocably a thing of the past, since such a tool is already inconvenient and unproductive.

Many home workshops are equipped with compact drilling machines. They differ from industrial designs not only in size, but also in performance. And the most practical option for the home is a special device in which an electric drill is attached.

Previously, such a stand could only be seen among folk craftsmen. Now it is sold in any hardware store. The convenience of the device is that it has a vice. The part is fixed motionless, and the cutting tool, clamped in the drill chuck, is fed to it strictly vertically.

They make holes in the metal using special drills. And most often they are called drills. They have a cutting part, a shank and a working surface that removes chips from the hole. Cutting tools differ from each other primarily in diameter, length and shape.

Metal drills Source skladom.ru

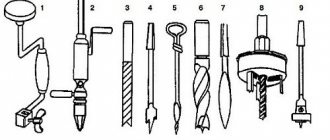

Types of drills for metal:

- Spiral, as a rule, have a cylindrical shape. Their diameter can reach up to 80 mm, and the cutting edge is sharpened at an angle of 118 degrees.

- Conical ones are made in the form of a cone with a stepped surface. In addition to drilling holes, they are good at correcting defective passes that have already been made.

- Crowns are often called annular cutters. A hollow serrated drill can make a neat hole in the thinnest metal. The cavity in the bit also helps with deep drilling by allowing chips to pass through.

- The feather ones have replaceable working plates. With their help you can get the perfect hole by penetrating to great depth. Moreover, in metals of any strength.

Good drills are made either from cobalt or high-strength alloys. Typically, tool steel is selected for the base, and the cutting edge is either alloyed with cobalt, or carbide alloy plates are fixed to it. Cobalt drills are not afraid of high temperatures and can drill metal with the highest viscosity. Carbide tools are capable of self-sharpening during operation.

Drill with cobalt coating Source zakaz64.ru

How to drill a perpendicular and vertical hole

Although it is sometimes necessary to drill at an angle, it is most common to make vertical holes (that is, perpendicular to the surface). In order for drilling to take place strictly at an angle of 90 degrees, it is necessary to use special guides. They will allow you to drill perpendicularly without deviating in any direction.

The simplest guides allow you to make only vertical holes, but there are also more complex designs that allow drilling at certain angles.

Drilling mode

To drill metal correctly, you need to select the desired rotation speed of the drill. The force applied to the drill also plays an important role. It is guided along its axis and ensures the depth of the cutting tool with each revolution. The correctly selected mode is easily determined by the chips. If the effort and speed are not exceeded, then it is long and beautiful.

There are simple rules for correctly selecting a drilling mode. The harder the metal that needs to be processed, the lower the number of revolutions the drill should have. This principle also works when selecting the diameter of the drill. The thicker the drill, the lower the cutting speed.

Dependence of drill rotation speed on its diameter:

- 5 mm – from 1200 to 1500 rpm;

- 10 mm – 700 rpm;

- 15 mm – no more than 400 rpm.

You also need to monitor the force applied to the drill. The deeper the immersion into the metal, the less pressure on the tool is necessary. Ideally, the pressure on the drill should gradually decrease during the drilling process.

Adjusting the speed of a drill Source ytimg.com

See also: Catalog of companies that specialize in the reconstruction and rebuilding of houses

How to choose a drill

Safety

In terms of electrical safety, commercially available power tools belong to class II: double working insulation, use without additional grounding is permissible, i.e. Such a drill can be plugged into a regular, non-European socket through an adapter. At the “iron bazaars” you can find tools of class I (“industrial”), with a grounding terminal on an iron body. It is unsafe to use it in everyday life, and in most cases its chuck fits a drill with a conical shank (Morse taper), which is not suitable for rotary impact drilling. Therefore, do not buy such a drill, even if it is powerful and cheap.

Class I is indicated on the nameplate of the drill, and if there is no designation, the body is partly or completely plastic, and the cord with a Euro plug is a class II tool. Class III - a power tool with an operating voltage of up to 42 V (low voltage) can be identified by the class designation on the nameplate and by a special plug with flat crosswise contacts. It is suitable for home use, but inconvenient: you need a powerful step-down transformer.

For protection against the ingress of foreign objects and water, power tools and equipment are marked with IP (Ingress Protection) signs with 2 numbers after them: 1st - from foreign objects, 2nd - from water. If the protection for any position is zero, the letter X is placed instead of the corresponding number. Thus, an IP32 drill can be used outdoors in good weather; IPХ2 - only inside, IP34 - outside in fog and drizzling rain, and IP68 can work during the Samum in the Sahara and under water.

Fundamentally: the first digit 2 means that the device is protected from penetration of fingers; for example, the plug socket has a degree of protection of IP22. But this does not mean under any circumstances that if the drill chuck with the same degree of protection is grabbed by hand during operation, it will stop on its own. The IP standard does not guarantee foolproof protection.

Cartridge

An ordinary three-jaw chuck is accurate and quite good for rotary drilling. When a rotary impact drill is used, the drill rapidly becomes loose, and the chuck itself loses accuracy and may completely fail: the threaded race of the cam mechanism bursts. For work on hard, brittle materials, the three-jaw chuck is suitable for occasional use or with a diamond working element in rotation-only mode.

In a quick-release chuck (you can tell by its corrugated plastic collar), the drill is clamped by a collet. This type of chuck holds the drill better during impact-rotary drilling, but is the least accurate and is not very suitable for delicate work. Massive drills are equipped with a two-sleeve collet chuck - clamping and loosening are carried out by various rings.

Patron of SDS (Steck-Dreh-Sitzt, nam. "Vstavil-povernul-sitting" Special Direct system Either, osobaâ rovnaâ systems, angle.) Izobreli in the Bosh company. The SDS that works for the machine is completely suitable: a system of figurnyh grooves, SM. . RIS, completely firmly fixes the working body in accordance with the principle of the kitajskoj puzzle; submenu drill delaetsâ only 2 mA legkimi movements.

Unfortunately, SDS is not suitable for mechanics and carpentry: the centering accuracy of the drill is insufficient. An adapter from a three-jaw chuck to an SDS makes no sense: it will become loose from vibration, just like an ordinary drill. Therefore, the SDS drill is incompatible with a conventional drill in terms of the placement of the working body.

Note: SDS fit comes in 3 types: SDS+, SDS Top and SDS Max. SDS Top is used occasionally, as a crotch and generally bad option; SDS+ is designed for one-handed tools weighing up to 5 kg; SDS Max – for a languid two-hander.

Power and speed

When buying a rotary impact drill for general work, you don’t need to skimp on power. A supply of power is needed to create the required torque at low speeds. The external feature of a commutator electric motor with alternating excitation, used in drills, is close to flawless, but the low-power motor at low speeds overheats from the huge current. It is also better to purchase, if not included, a front cap handle.

The highest speed of the drill is also important. A diamond tool is practically “eaten up” at a rotation speed of less than 1600-1700 rpm; its normal operating speed is from 2500 rpm. Carbide tools need more than 1500 rpm. If you come across a drill with a 600-1200 rpm rating, it is a special tool and not suitable for general purpose work.

For precise work on metal, a conventional low-power drill with only rotation is best – 120-200 W. A stand that turns the drill into a tabletop drilling machine will be very useful. And if you also fork out money for a rotary table for the bed, then you can mill small parts with a dental bur.

Mains or battery?

A home craftsman needs a cordless drill in 2 cases:

- If you work on the side, this is your more or less permanent extra income.

- If you have a non-electrified cottage or garage.

In any case, an expensive professional drill with a lithium battery and its charging time of 10-20 minutes is unlikely to pay for itself. This is an option for experts who work a full shift day after day. A regular alkaline battery, charged in 4-8 hours, will suit you. In the latter case, it can be “pumped up” to a hole or two in half an hour.

Section result

All of the above can be boiled down to the following tips:

- Permanent construction work, including metal structures, requires a hammer drill and an impact drill of 350 W or higher.

- Repetitive household work - rotary impact drill from 250 W.

- For precise drilling - additionally a precise drill for rotary drilling at 120-150 W; better - with a bed.

How to make the right hole

To drill a hole in metal, you first need to securely secure the workpiece. If the part has good mass, it is often enough to simply place it on a flat surface. Its own weight will not allow it to “slither” from side to side.

Parts of small dimensions and light mass must be clamped in a vice. If you first mark the future center of the hole according to the applied markings, then this notch will allow you to confidently start when working. The drill installed in it will no longer move to the side.

Through hole

From the lips of some masters you can hear the word “passage”. Because the drill completely penetrates the workpiece in its movement. In fact, this is the easiest operation. But special attention needs to be paid to the final stage.

When leaving the workpiece, the drill can not only damage the surface of the workbench, but also break itself from the impact. To avoid this, you need to do the following. Either place the part above the through hole in the workbench, or place a wooden spacer under it.

Through hole in a metal workpiece Source onarzedziach.pl

Also, a sharp exit from the part creates a hart (burr) on its reverse side. To prevent this from happening, it is necessary to reduce the drill speed at the final stage to the very minimum. This technique will help if you need to make a through hole in the metal, when the part cannot be dismantled and clamped in a vice. That is, drilling occurs at its location.

Blind hole

To ensure that the drill does not go right through the part, but stops at the required depth, two methods are used. A special stop is attached to the drill, positioning it at a given distance from the cutting edge. The device usually has the form of a sleeve.

Or the drill has a movable pin in the chuck area. It is clamped with a screw so that its end creates an emphasis on the workpiece. Not allowing the drill to penetrate deeper than the measured distance.

Drill with stop Source icover.ru

If a machine is used to drill a blind hole in metal, it usually has a ruler. Knowing the required depth, the operator stops the mechanism at the right moment. There are machines in which such an operation is fully automated. And the most serious inconvenience in such work is that it is periodically necessary to remove chips from the hole.

How to properly drill holes in metal

When working with metal, you cannot do without drilling holes. Working with metal is a complex operation. This is due to the fact that metal parts have high strength, for the processing of which special equipment and technologies must be used.

You may need to drill holes in any field and when performing work in the country, at home or in the garage. Even when repairing a car, you have to drill holes in the metal. If you are going to do the work away from the workplace, you will need an electric drill or hammer drill with an adapter chuck for the drill, as well as a core or tap to center the hole.

If you need to make holes in small parts, it is better to use a drill press. On it you will be sure of the correct direction of the drill and the drilling speed.

Which drill to choose for drilling metal

One of the first questions that inexperienced craftsmen ask is which drill to drill into metal? In fact, answering correctly is not so easy. For metal processing, you need to use special drills made of high-speed tool steel. The cutting part in them is made with the addition of titanium nitride.

When choosing drills for drilling metals, the main and running ones are drills made of high-speed tool steel; they can be found in the store by the HSS .

When working with cast iron, stainless steel and other metals that are difficult to machine, you should use carbide drills. Their disadvantage is their very high price, which makes the work expensive.

If you choose drills with one of the best cutting properties, it will be a tool with the addition of cobalt, marked P6M5K5. This is the best value for money.

Is it possible to drill metal with a concrete drill?

There may be an urgent need to make a hole in metal, and only a concrete drill is at hand. On such a drill, the tip is made of pobedite, which makes it possible to drill concrete and brick with a hammer.

You cannot use such a drill to drill a hole in metal. You may lick off the tip of the drill bit, especially if you try to use a large diameter drill bit or drill through thick metal.

To sum it up, you won’t be able to drill through metal with a Pobedit drill.

However, if you sharpen it at the right angle, it is possible to drill into metal.

Power and speed when working with metal

An important factor is the choice of tool, namely a hammer drill, drill or screwdriver, which will be used to make holes in the metal. If you use a drill with a power of up to 700W, you will not be able to make a large hole right away. A hand drill with a power of up to 700W is best used for drilling holes with a diameter of up to 10-13mm.

It is important to choose the correct speed of the drill or screwdriver. After all, at high speeds, your drill will simply burn out. This way you will ruin it.

You need to drill metal at low or medium speeds, not exceeding 500-1000 revolutions.

The larger the diameter of the drill you are working with, the lower the speed you need to choose.

How to drill metal products correctly

One of the most important parameters when drilling a hole is the sharpness of the drill. If you purchased one of the cheapest drills, it may turn out to be dull and made of soft metal, which will not allow you to make even a couple of holes.

How quickly the drill tip will shear and dull depends on the drilling speed, the hardness of the metal, the force applied to the drill, and cooling.

- When drilling large holes, you must first make holes of a smaller diameter. This way the process will be much faster, and the drills will not become dull so quickly.

- To accurately center the hole, you need to use a core punch and punch the center of the hole before drilling.

- To cool the working part of the drill, you need to use machine oil. Simply lower the working part of the drill into a container of oil. Repeat this operation periodically. You can use soapy water for cooling (by reducing friction).

- When drilling deep holes, periodically remove the drill and clear it of chips.

How to drill sheet metal

When working with sheet metal, there should not be any particular difficulties, even when drilling large-diameter holes. The only thing is that you need to place a wooden block under the drilling site, it will help remove the chips. When you feel like you've almost drilled through the metal sheet, reducing the pressure on the drill will also help reduce the likelihood of burrs.

How to make holes in pipes correctly

The main problem when drilling holes in round pipes is the difficulty of perpendicular drilling. This means that the hole from which drilling began does not correspond to the exit hole. To solve this problem, you need to use a drilling machine, or special guides, which you can make yourself or purchase ready-made.

How to drill aluminum

Anyone who has worked with aluminum parts knows that it is a soft metal. The main problem when drilling aluminum is excessive shavings wrapping around the drill bit. Because of this, the drill stops drilling and gets stuck in the metal. To avoid this, you need to remove the drill from the hole more often and remove the chips.

How to drill stainless steel (stainless steel)

Stainless steel is an alloy steel, which is not an easy task to drill. To make drilling comfortable, it is advisable to choose drills with a cobalt tip.

You need to drill stainless steel at minimum speed, namely 100-200 rpm. Such speeds provide the required cutting speed for stainless steel and good quality.

If your tool does not have a rotation speed control, you should press the button periodically for a second or two, which will prevent the drill from accelerating quickly.

If you need to make a hole of a large diameter, you need to use metal crowns, which make it possible to drill only along the outer diameter of the hole.

How to drill large diameter holes

When you need to make large diameter holes in metal, you need to use a tool suitable for this purpose.

- First you need to make a hole of a smaller diameter. You can use several drills, gradually increasing the diameter of the hole. In this way, it will be easier for drills to pass through metal, especially thick metal.

- Using a step drill. Such drills can be called conical drills.

- The use of special crowns for metal. Drilling large diameter holes with hole saws is very easy due to drilling only the outer diameter of the hole. The crown consists of a centering drill, which first drills through the metal in the center and then guides the crown. Drilling with a crown must be done at very low speeds.

One of the best ways is to use metal crowns. The disadvantage of this method is the non-adjustable diameter of the crown (adjustable crowns are also sold, but we do not recommend buying these because of their poor quality). For each hole diameter you need to have different crowns.

How to avoid dulling a metal drill?

While drilling, you can easily burn (blunt) the working part of the drill. This occurs due to high speeds, due to which the drill heats up and melts. This can be avoided by keeping the speed low or lubricating the drill with a cooling lubricant.

If there is no special cooling lubricant for drills, you can use machine oil, which will reduce the friction force.

How to drill with a drill?

To figure out how to properly drill metal with a drill, you need to derive a number of basic rules from which it is not advisable to deviate:

- You will need a drill or screwdriver, a core with a hammer, protective equipment - glasses and a means for cooling the drill (most often machine oil).

- Before starting work, you need to mark the center of the hole

- Wear protective equipment. The chips can easily bounce into your eyes. After which it will be difficult to get out of there without specialized medical care.

- Punch the center of the hole.

- Start drilling at low speed

- Periodically remove the drill from the hole, clearing it of chips and cooling it in oil.

By following the above rules and sequence, you can make holes of any diameter without any problems. When performed, the shelf life of the drill will be maximum due to maintaining low speeds and cooling it in oil.

On a large number of drills, you can install a depth limiter, which allows you to adjust the drilling depth. You may need it when drilling blind holes.

Safety and tips

Before drilling a hole in metal, it is necessary to ensure safety measures. First of all, you need to pay attention to work clothes. It should not contain elements that could get under the rotating parts of the tool.

During operation, chips can fly in different directions. It is necessary to protect your eyes from it by wearing safety glasses. Before drilling itself, check how securely the part is secured in a vice or how tightly it fits to the surface of the workbench.

The drill, approaching the surface of the metal, should already be rotating. This avoids premature dulling. Also, do not stop the drill while removing the drill from the hole. You just need to slow down. Otherwise, the tool will either jam or break.

When the cutting edge penetrates into the metal with great difficulty despite the applied efforts, this indicates that the hardness of the machined surface is much greater than that of the tool. You need to take a drill with a carbide tip. And set the drill to the lowest speed.

How to drill metal with a drill - detailed step-by-step instructions

Concentrate for dilution with water. 5% emulsion - for normal steel and non-ferrous metals, 10% emulsion - for stainless and high-alloy steel, in difficult conditions can be used in a 50/50 ratio, as well as undiluted. More details

- Cutting fluid IVKAT Manufacturer: Vector (Russia) Coolant Ivkat TU 0258-141-05744685-95 is a semi-synthetic water-soluble cutting fluid for metalworking operations. Used to reduce temperature, processing power parameters and wear of cutting tools, dies and rolls. Blade and abrasive processing of cast iron, steel, aluminum and copper alloys. More details

- Spray for drilling Fein Manufacturer: Fein (Germany) Highly effective aerosol Fein for lubrication and cooling of cutting tools. Spray can 300 ml. RUR 1,623 Read more

- Fein paste for drilling and cutting metal Manufacturer: Fein (Germany) Paste in a 300 ml aerosol can, used for cutting and sawing sheet metal. RUR 1,357 Read more

- Lubricating and cooling aerosol Mecutspray Manufacturer: Karnasch (Germany) Coolant - Mecutspray aerosol. Does not contain freon, biodegradable composition - an environmentally friendly product for lubrication and cooling when drilling and cutting ferrous and non-ferrous metals. More details

- Lubricating and cooling soft lubricant Manufacturer: Karnasch (Germany) Universal paste for metalworking. Ideal for use in overhead drilling of non-ferrous metals and all grades of steel. Does not contain chlorine compounds. More details

- Lubricating and cooling wax Manufacturer: Karnasch (Germany) Special wax for non-ferrous metals. Ideal in conditions where splashing is not acceptable or when working overhead. More details

- Pump for supplying coolant Manufacturer: Karnasch (Germany) Capacity for supplying lubricant and cooling fluid Read more

Drill

The following types of drill bits are most commonly used:

- Spiral - are made of tool steel, coated with carbide, with a carbide insert and solid carbide. Used for all types of work on any materials.

- Spade bits can be used to drill wood, MDF and plastic. Allows you to drill holes of huge diameter. They are produced either in one piece or in the form of a set of a shank with a groove and several inserts of various diameters. This set is cheaper than a set of solid nibs, but is the least accurate.

Core bits (crowns) are used for excavating holes in hard brittle materials - stone, concrete and drilling wide holes in chipboard and fiberboard. Available with or without a centering twist drill. The second ones are cheaper, but are only applicable for stone and require strong working abilities.- A circular drill (centre drill, ballerina drill) is used to drill holes of huge diameter in thin, strong but fragile materials with a decorative front surface, such as, for example, tiles or polished decorative stone. The drilling diameter of the circular drill can be easily changed. Rotary impact drilling with a circular drill is unacceptable.

- Diamond drills are thin-walled tubes made of a special alloy coated with diamond. They can be used to drill glass, polished decorative stone, and glazed clay tiles. Roads require careful handling and strict adherence to drilling technology.

Drill sharpening

Self-sharpening of drills is acceptable for twist and feather drills. The first ones are sharpened with a diamond file - they are made of tool steel. Cheap sets can be made from ordinary carbon steel; their feathers can be edited with an ordinary needle file.

Spiral drills are sharpened with an emery wheel (carbide - diamond) using a device - a wedge with an angle of 180 degrees minus half the sharpening angle. So, with a sharpening angle of 120 degrees, the wedge angle is needed at 30 degrees. In the hypotenuse (oblique side) of the wedge, a longitudinal hollow or a blind hole is made, in which the drill is smoothly turned when sharpening. The best sharpening comes from using a small (“velvet”) hand sanding wheel, see fig. below. Different materials require different sharpening angles for the drill bit. In most cases, metal is drilled with drills with a sharpening angle of 116 degrees, concrete and stone - 90 degrees, wood - 60-90 degrees. Precise angles and methods for sharpening different types of drill bits for different materials can be found in reference manuals for materials processing.

About hard alloys

Carbide alloys for drills are made based on boron, tungsten or zirconium compounds. The cheapest ones are based on boron, but such a drill will take concrete with great difficulty and will quickly wear out. Such drills are marked “by stone”. You cannot drill decorative materials with them - the edges of the hole will chip. Tungsten and zirconium compounds differ primarily in their durability: zirconium compounds last longer. They cost more accordingly.