How to Drill Through Wood with a Hacksaw

And even if they have already thought about many circular saws, chainsaws and jigsaws, there should still be a wooden saw in the wizard's arsenal.

How to choose a hacksaw, what to look for and which brand to choose, and even a little history. all this awaits you below. Historical reference

Thanks to archaeologists, we know enough about pollen. The first documented records of hand dust date back to ancient Egypt and date back to around 3000 BC. there is only one mystery as they used dust. Even the murals inside the pyramids vary, with some showing carpenter's saws, others dismantling stone-cutting saws, and others showing torture with a hand saw.

Hacksaws of that time were made of copper, and with the advent of iron they became much stronger. Although shark teeth have been found on some islands in Indonesia. If you upgrade them a little (bigger the handle and add teeth) you'll have a great melee weapon.

By the way, every nation is trying to answer the authorship. For example, in China, someone named Lu Bun is believed to have invented the hacksaw. But the Greeks believe Ovid: the poet wrote that the invention of the hacksaw was the work of Daedalus' nephew named Talos.

How to choose a hacksaw for wood

Each hacksaw has its own characteristics that determine its use. When choosing this tool for yourself, you must decide in advance what operations it will be used for. For example, to cut cross-sections of grain or lengthwise, cut tree branches or floorboard dust, cut chipboard, or make just the beginning of the cut and then continue with another tool.

- Canvas length. This is a very important indicator, and to prove this, we will look at a small example. Let's say you need to cut a cross section that is 200,000mm wide and you have a blade with a blade length of 350cm at hand. At first glance, it may seem that there should be no problem, since the length of the blade exceeds the length of the material. However, the cut is made in a back-and-forth motion, and at this length the saw blade does not completely leave the cut. The hacksaw will quickly clog, and you will complain about poor sharpening or the “wrong” material.

It can be seen that with a length of 40 cm, only about 30 cm of the canvas will work. The shape of the handle interferes.

- Number of teeth and their size. The smaller the tooth with a hacksaw, the cleaner the cut. But there is also a drawback: cutting with a hacksaw along the teeth will take more time. However, this cannot be completely considered a disadvantage, since such hacksaws are usually used for small workpieces. The abbreviation TPI (Theeth Per Inch) is used to define the number of teeth on a hacksaw. Literal translation: the number of teeth per inch, that is, the number next to the abbreviation TPI means the number of teeth located one after the other over a length of 2.54 cm. The larger the teeth, the fewer inches, the faster and rougher the cut. With TPI 7 there should be 7 teeth. Yes, all together.

- Tooth shape. Classic shape. triangular. But with the development of technology, other forms began to be used. In particular, the trapezoidal shape has become especially common. Sharpening a saw if it has such teeth is very problematic, and not every master can do it. Trapezoidal teeth are hardened with hacksaws.

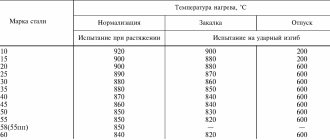

- Steel and hardening. The grade of steel affects the sharpness and, therefore, the cleanliness of the cut and the duration of the operation. And it also depends on the grade of steel, whether you can sharpen the hacksaw for wood, consult a specialist, or throw it away and buy a new tool. Hardened teeth from a hacksaw are very difficult to grind on your own and, as a rule, do not even sharpen them. Disassembling the blade or sharpening it is not a problem.

- Lever arm. Seems simple: the handle looks like a pen, but it should be comfortable. When examining externally, take a hacksaw if you are ready to work with it. Consider whether you will be comfortable holding the hacksaw and keep in mind that you are just holding it now and there will be some tension on your hand, fingers and arm in general. The number of calluses depends on the comfort of the handle, and you always want to keep them free. The rubber handle is much better than the plastic one.

- Goal of the work. A hacksaw for wood can be transverse, longitudinal (along the grain) or combined. If you buy a single copy of a hacksaw and for infrequent work, it is better to have a combined version. If you consider yourself a craftsman, the answer is obvious: a small hacksaw. The markings on the canvas will tell you everything.

- Price. Like most tools, the quality of a hacksaw is determined by its cost. If you don't know how to choose, start insisting on price. the more expensive the better. Naturally, if we are talking about a brand, and not a Chinese fake. An expensive hacksaw will last longer and you will need to sharpen it less often or without sharpening. This is a cheap but high quality hacksaw. Such a rarity.

- Possibility of measuring angle. This is not a very important indicator, but it is worth remembering. Typically, using a handsaw, you can quickly mark out 90° and 45° angles. Of course, this is not the best way to measure accurately, but the error (if any) is small. The accuracy is not so great, but for rough markings it will do.

Video: How to Drill with a Hacksaw in Wood

Instead of a conclusion

How to choose a hacksaw for wood is already familiar. All you need to do is take care of the instrument after purchase. You should clean the saw blade after each operation and store it in a dry place. Also try to protect it from metal: check the workpieces for the absence of nails or wires, and do not hit metal objects (for example, when laying a tool). No matter how you feel about the saw, it works. ask any master.

Use of lubricants

Drilling into hot steel creates significant friction. This is why it is recommended to buy and use different oils. Among the features of this processing method, we note the following points:

- Let's start with the fact that the drilling zone is being processed. A small amount of oil is applied to the surface where the hole will be.

- Oil is added to the cutting edge. A small amount of the substance is required to machine hardened steel, but it must be added from time to time as the tool is rotated.

- During operation, it is recommended to take breaks to cool the cutting surface and the surface being processed.

Special steel oil lubrication

This is because oil can reduce the temperature of the cutting edge.

Category: “We work with metal”

Of course, you need to drill steel until it’s hot. And if you come across a hardened workpiece (especially a thick one), release it, drill holes with a regular drill and harden it again, if necessary. But this option is not always possible and justified; sometimes non-standard situations arise in which it is necessary to drill (perforate) steel that is already very hardened.

Well, for example, the blade of a knife broke, or you decided to make a knife from a piece of a saw. It’s a pity to throw away such valuable material; skilled people usually give such things a second life.

Yes, it’s not technologically advanced, but folk craftsmen have come up with many different ways to drill hardened steel, or how to make holes in it. To do this with less effort, you need to proceed from the capabilities and materials that you have, and also depending on what purposes. Maybe, instead of a hole, you will be satisfied with just a slot with a grinder, into which you can put a screw and secure the part. To make the slot smaller, you need to make it on both sides, and use a trimming disc of the smallest diameter, i.e. almost erased.

Before drilling, you need to thoroughly examine the steel to see how hard (crumb) it is, and from there choose methods. If, after all, the steel bends even a little and then breaks (this can be determined by the broken end or by running it with a file), then it can be drilled with an ordinary concrete drill with pobedit tips. True, the drill must be sharp. It is also very advisable to change (correct) the sharpening of the drill, the angle, like a metal drill, then the drilling process will go much faster.

If there is no machine for sharpening saw blades

Precisely maintain the required sharpening angles while holding the weight of the saw in your hands. The task is impossible even for a person with a unique eye and enviable stiffness of hands. The most reasonable thing in this case. to create a simple sharpening device that allows you to fix the saw in a certain position relative to the circle.

The simplest of these tools is a grinding stand, the surface of which is at the same level as the axis of the grinding wheel. By placing the saw blade on it, you can ensure that the front and back planes of the tooth are perpendicular to the saw blade. And if the upper surface of the stand is made mobile. fixing one side hinged and the other. Relying on a couple of bolts that can be screwed in and out. then it can be installed at any angle, making it possible to sharpen an inclined tooth on the front and rear planes.

True, in this case one of the main problems remains unresolved. Extracting the same front and back corners. This problem can be solved by fixing the center of the saw in relation to the abrasive wheel in the desired position. One way to implement this. Make a groove on the surface of the mandrel support on which the saw is mounted. By moving the frame with the wheel in the groove, it will be possible to maintain the required tooth cutting angle. But to sharpen circular saws of different diameters or sharpening angles, it must be possible to either move the motor or the support, and with it the groove. Another way to ensure the desired sharpening angle is simpler and install stops on the step that fix the disc in the desired position. At the end of the article there is a video demonstrating this adaptation.

Post Views: 2

How to drill high-speed steel grade P6M5 or HSS according to the European designation? For example, we made a knife from a blade from a mechanical saw, and we need to drill holes in it with a diameter of 5-6 mm for pins to install and secure the handle pads. The same operation may be needed to drill a hacksaw blade for metal from 1Х6ВФ steel, from which you can make some useful products. A piece of blade from a mechanical saw made of 9HF steel is suitable not only for making knives, but, for example, also non-standard keychains.

Wood saw - select tooth size

Even if you already have a hacksaw on your farm, it is quite possible that it will not be suitable for your purposes, so sooner or later you may need to go for a new saw. When choosing this tool, knowledge about its structure and features will be useful. If the saw has straight teeth, it will be easiest for it to cut wood crosswise; to cut wood along the grain, you will need a tool with inclined teeth. In accordance with their inclination, the hacksaw will be transverse or longitudinal. If you craft often, you'll need both options.

A hacksaw with large teeth cuts the fastest, but you won't get a straight edge with it. For working in the garden or quickly cutting rough boards, this saw is quite suitable for you. For a cleaner cut edge, a tool with a fine tooth is used, but working with such a hacksaw is slower - it is more difficult to remove sawdust from the cut.

For cutting coarse-grained wood across the grain, a saw with large teeth is best; for general sawing needs, choose a medium tooth, and if you need precise work, choose a hacksaw with a fine tooth.

A carpenter's saw with a very fine tooth is used by professional carpenters; it is unlikely to be useful on the farm. There is also a mechanical hacksaw - this is a small machine with a mechanically movable blade, these are used in factories for sawing metal pipes and other metal elements; in a home workshop it will be replaced by a hacksaw for metal.

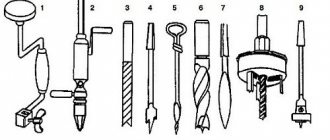

Necessary tools and samples

All of the considered and other grades of high-speed steels are drilled using spear-shaped (feather) drills for tiles, having different designs. For example, shanks are made round or hexagonal, which is not of fundamental importance for the main work - drilling. They are freely sold in almost all construction stores or outlets selling all kinds of tools. What is very important, drills of this type and purpose are attractive because they are inexpensive. Also, for drilling high-speed steels, you will need cutters of various shapes and designs. With their help, the accuracy, cleanliness, shape and required diameter of the drilled hole are ensured. We have to drill the following samples:

- a piece from a frame saw made of 9HF steel.

- blade from a hacksaw for metal made of steel grade 1Х6ВФ.

- Mechanical saw blade made of HSS steel.

Tempered saw - what is characteristic of such a hacksaw?

The steel from which the tool blade is made must be elastic and durable. Curvature of the blade when jammed, rapid dulling of the teeth indicate low quality steel. To maintain the sharpness of the tool for as long as possible, without compromising the elasticity of the blade, manufacturers resort to a small trick - they harden only the teeth. In this case, they acquire a blue-black color, which makes it very easy to distinguish a hardened instrument from a regular one. Such saws are especially convenient for cutting artificial materials such as plywood, plastic, and plaster. However, it must be protected from getting on nails, otherwise, if such teeth are damaged, it will no longer be possible to restore their former sharpness.

How to sharpen a hacksaw for wood - step by step diagram

Step 1: Align the teeth in height

To determine which tooth is lagging in height, take a smaller file and run it along the top of the teeth. Untouched tips will show us defects in the saw. In this case, all other teeth must be filed with a file to the lowest level. To avoid injuring your hands, you can cut out a nest for a file in a piece of wood, secure it in it, and then safely straighten the teeth.

Step 2: Saw the canvas

Check the teeth for their relationship to each other. Short elements make cutting difficult, especially after several sharpenings. In this case, cuts are made in the blade itself, which lengthen the teeth. We clamp the tool blade in a vice, setting the teeth at the same level as the edges of the vice to prevent the cut from being too deep. You will need a hacksaw for metal - use it to cut the blade to the desired tooth height. The saw will work best if the width of the teeth is one and a half times smaller than their height.

Step 3: Spread the teeth

It's time to start setting up the saw. If you do the cutting with ordinary pliers, then you will never be able to achieve a uniform, precise spreading to the sides - as a result, the saw will begin to tear the wood, creating a lot of waste and creating a sloppy cut. Therefore, prepare in advance a simple tool that you can make yourself - cut a groove in a strip of thin metal into which a tooth can easily fit, and drill several holes in it to secure the limiter. The limiter can be cut with metal scissors, giving it the angle required for wiring. We attach the limiter to the bar and test it in practice, increasing or decreasing the bend angle if necessary. Using such a tool, the wiring will be exactly the same. It does not need to be done often, once every two or three sharpenings. Obviously, the teeth need to be moved in different directions, taking turns. When setting, you should not go too far with the distance at which the top of each clove is bent - too small a distance will not do anything, too much will complicate the cutting process and turn a large amount of material into sawdust.

Useful Drilling Techniques

You can use different techniques to work with hardened steel. The most common technologies are characterized by the following features:

- Surface treatment with acid. This technology is characterized by long-term use, since it takes a lot of time to reduce the surface hardness. For digestion, you can use sulfuric, perchloric or other acid. The procedure involves creating balls that will contain the substance used in the cutting area. After prolonged irradiation, the metal becomes softer and can be drilled using the usual option.

- To achieve this goal, you can use a welding machine. When exposed to high temperatures, the metal becomes softer, which greatly simplifies the procedure.

- The most commonly used special drills. There are commercially available options that can be used to process hardened steel. Their production uses metal with high wear resistance and high temperature. However, the complexity of manufacturing and some other points determine that the cost of a special tool is quite high.

Additionally, a hammer is often purchased to achieve this purpose. Using it, you can make a small hole, which will make further drilling easier.

Do-it-yourself powerful electric hacksaw for wood [LIFE HACK]

An angle grinder is a universal tool. It’s hard to imagine almost any metal work without it. However, its scope is not limited to this - not a day goes by without a new purpose being invented for it.

How to make a hacksaw from a grinder is the topic of today’s article.

What is required for production

Grinder reciprocating saw

To make a power saw you will need:

- wood hacksaw

- small piece of 1.5 inch pipe

- bearing – internal diameter about 22 mm

- metal sheet 2 mm

- M8 nut

- M6 bolts and nuts

- reinforced M14 washers

You will also need:

- welding inverter

- Bulgarian

- vice

- drill press or drill

Drilling nuances

The technology under consideration has a large number of features that must be taken into account. Hot metal drilling is carried out taking into account the following points:

- Before carrying out work, you must pay attention to the hardness of the surface. This option is used to select the most suitable drill bit. Hardness can be determined using various technologies.

- During drilling, a large amount of heat is generated. This is why the cutting edge wears out quickly. In this regard, in many cases, coolant is supplied to the cutting zone.

- When cutting heavy materials, it is necessary to sharpen the cutting edge from time to time. For this, a conventional grinding machine or a special tool is used. Only a diamond-coated wheel is suitable as an abrasive.

Steel drilling tool

There are many ways to cut hot steel. Some of them greatly simplify processing. Only by taking into account all the nuances can the quality of the hole be improved.

Making an electric hacksaw

Homemade electric hacksaw from a grinder

When working with an angle grinder, torque is used. For a hacksaw, we need translational movements. We will transform the rotation using an eccentric.

Step No. 1 - making an eccentric

This stage will not cause any difficulties.

We install a reinforced washer on the angle grinder spindle and place a bearing on top of it.

The center of rotation of the bearing will be shifted using a bolt. We mark the excess.

Having sawed off the bolt, we place its shortened rod inside the bearing.

Place a second reinforced washer on top and tighten it with an M8 nut;

The eccentric is ready. You can move on to the next stage.

Step No. 2 - make a blank for attaching the nozzle

We will make it from a steel pipe.

We trim the edge of the pipe using sandpaper.

We measure the distance to the lower level of the bearing.

We draw with a caliper.

Duplicate the markings with a marker.

We cut according to the markings with a grinder.

Step No. 3 - making the fastening

Nozzle mount

At this stage, the pipe blank will need to be cut in half.

We measure the length of the seat for attaching the nozzle.

Using a compass, we draw transverse markings.

We outline it with a marker and make markings for the cut, which is needed to fix the mount on the grinder.

We make a cut on the marking, incl. transverse.

We weld two bolts onto the fixing propylene ring to secure the fastening.

We put the mount on the grinder and fix it.

Step No. 4 - making a body for the hacksaw

The body will consist of 2 steel plates. Their dimensions are arbitrary, but should not be less than 2 diameters of the bearing used.

We find their center and mark it.

We check the outer diameter of the bearing and use a caliper to divide it in half.

From the center of the plates we make control points using a bar, apply a bearing and outline it.

We drill holes on a drilling machine.

Holes in the plates can be cut out. To do this, use a drill with small drills and a chisel. The geometry is adjusted with a round file.

Step No. 5 - preparing the hacksaw blade

Preparing woodworking material

Marking is carried out in arbitrary sizes.

Remove the handle from the wood saw.

We determine the place of contact of the hacksaw blade with the bearing. Mark the center.

Using a compass, we make the initial markings for the bearing - 3-4 points from the center.

We attach the bearing and outline it with a marker.

We form a hole according to the markings.

The resulting hole must be flared along the vertical level of the saw blade.

The hole needs to be shaped into an oval. The dimensions of its diameters are approximately 1 to 1.3. To accurately determine the shape of the hole, you need to try on the canvas in place.

Step No. 6 - assembling the saw body

We form a bolted connection on the nozzle body

At this stage, you need to weld the cuffs (fastening) to one of the metal plates and form holes for fastening.

We fix the workpiece in a vice, apply fasteners and weld it to the plate. The welded bolts to the ring should be on top.

Mark 4 holes for bolt fastening in each plate.

Let's move on to the next stage.

Step No. 7 - install the hacksaw blade

Installation of wood blade

According to the body plates, we make markings in the hacksaw blade.

Sawing requires a stroke of the hacksaw blade, so the holes need to be bored along the saw by 1-1.5 cm, this must be done while maintaining symmetry.

We periodically check that the holes for the stroke are sufficient by turning the eccentric.

Step #8 - final assembly

After making sure that the rotation of the eccentric is stable, you can finally assemble the attachment for the grinder. This is done using two nuts for each hole.

For appearance, the product can be painted. Before assembly, the internal parts of the plate must be thickly lubricated with lithol.

Material and properties of carbide teeth

In domestic saws, sintered tungsten-cobalt alloys of grades (6, 15, etc., the pattern means the percentage of cobalt) are used as the material for cutting inserts. At 6 the hardness is 88.5 HRA, at 15. 86 HRA. Foreign manufacturers use their own alloys. Hard alloys consist mainly of tungsten carbide cemented with cobalt. The characteristics of the alloy depend not only on its chemical composition, but also on the grain size of the carbide phase. The smaller the grain, the higher the hardness and strength of the alloy.

Carbide plates are attached to the disc using high-temperature soldering. Silver solders (PSr-40, PSr-45) are used as soldering material in the best case, and in the worst case. copper-zinc solders (L-63, MNMC-68-4-2).