Types of drilling on lathes

Conventionally, there are three types of process of drilling holes on a lathe according to the degree of human intervention:

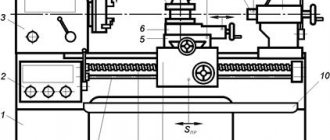

- Manual. This method involves feeding the cutting tool into the cutting zone using a tailstock flywheel driven by human muscle power.

- Mechanical. With this method of processing holes, the drill is fed using a mechanical feed coming from the caliper carriage to the tailstock through a special device. Not all lathes have such devices and, accordingly, the ability to carry out mechanical drilling.

- Using CNC. Full automation of product processing is possible on CNC machines. On a CNC lathe, you can make holes using various methods and tools without human intervention.

Types of procedure and cooling

There are several main types of drilling: making cylindrical holes, multifaceted or oval, as well as drilling existing cylindrical holes to increase their diameter.

The main problem that arises in the process of drilling metal is the strong heating of the consumable element, that is, the drill, as well as the work site. The temperature of the material can reach 100 degrees Celsius or more. If it reaches certain values, then combustion or melting may occur

It is important to note here that many steels that are used to make drills lose their hardness when heated, due to which friction will only increase, so the element, unfortunately, will wear out faster

In order to combat this disadvantage, various cooling agents are used. Most often, when vertical drilling on a machine, it is possible to organize the supply of coolant directly to the work site. If it is carried out using hand-held instruments, then after a certain period of time it is necessary to interrupt the process and dip the drill into the liquid.

The process of drilling and reaming holes on lathes

To create new holes in a workpiece or change the size of old ones, the following types of operations must be performed on a lathe:

- Align the tailstock so that the quill axis coincides with the spindle axis.

- Secure the workpiece in the headstock chuck so that it protrudes beyond the level of the jaws as little as possible.

- Install the cutting tool in the tailstock quill. If you have to change it frequently, it is better to use a quick-change chuck and a set of special bushings. This will help to significantly reduce the time required to change tools. When using a quick-change chuck, all drills, countersinks, reamers, etc. must have shanks with the same Morse taper number. At the beginning of drilling, the quill should be pulled out from the tailstock to the shortest possible distance.

- The first work operation is preparing the end of the workpiece. It should be smooth. This is done by trimming the end with a cutter.

- Make a small recess at the end of the part. This operation will help you drill exactly at the rotation point of the workpiece. This recess is made with a persistent cutter or a short drill.

- Drill using the tailstock flywheel. Feed the tool smoothly. Periodically move it out of the cutting zone to free it from chips. Cool the cutting zone using a special emulsion.

- When through-cutting, you need to reduce the feed speed at the exit from the workpiece so as not to damage it when the load on the cutting edges increases sharply.

- To increase the diameter of the holes, you need to: install a drill of a larger diameter and drill; apply a countersink - carry out countersinking; use a boring cutter to make boring.

- To reduce roughness, reaming is used (the process is reaming).

- To work with edges, use a countersink (the process is countersinking).

[Show slideshow]

When processing cast iron, small chips are formed, which, during liquid cooling, clog the channels for its removal. Therefore, the emulsion cannot be used in such cases.

Video of drilling a hex hole on a lathe

All of the above processes can be performed not only in a labor-intensive manual way, but also by taking advantage of the possibility of connecting a mechanical feed to the tailstock or using CNC. If the cutting processes are carried out using CNC lathes, then the entire tool is attached at the very beginning of the preparatory process in special devices that change automatically in a certain sequence.

Boring

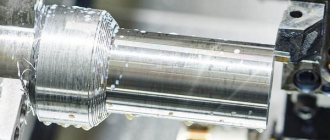

If the diameter of the hole exceeds the diameter of standard drills or countersinks, then the hole is bored. Boring is also used when machining holes with uneven allowance or with a non-linear generatrix.

Depending on the purpose, turning boring cutters are distinguished for processing through and deep holes. For turning boring rod cutters, the cantilever part is made round, and the rod for fastening the cutters is square; With such cutters you can bore holes with a diameter of 30.65 mm. To increase vibration resistance, the cutting edge of the cutters is made along the axis of the rod.

On turret lathes, round boring cutters are used, which are mounted in special mandrel holders (Fig. 4.30).

The shape of the front surface and all angles of the boring cutters (except for the back one) are taken to be the same as those of the cutters used for external turning. The cutting angles of boring cutters can be changed by setting the cutting edge of the cutters relative to the longitudinal axis of the part (above or below the axis).

When boring, the cutter is in more difficult conditions than during external longitudinal turning, since the conditions for chip removal, coolant supply and heat removal worsen.

A boring cutter, compared to a turning cutter, has a smaller cross-sectional area of the holder and a larger overhang, which causes the cutter to be pressed out and contributes to the occurrence of vibrations; Therefore, when boring, as a rule, smaller chips are removed and the cutting speed is reduced.

When rough boring steel, the cutting depth is up to 3 mm; longitudinal feed - 0.08. 0.2 mm/rev; cutting speed is about 25 m/min for high-speed steel cutters and 50.100 m/min for carbide cutters.

When finishing boring, the cutting depth does not exceed 1 mm, the longitudinal feed is 0.05. 0.1 mm/rev, cutting speed - 40.80 m/min for high-speed steel cutters and 150.200 m/min for carbide cutters.

Sources:

https://www.inmet16.ru/sverlenie-otverstij/ https://moy-instrument.ru/instrumenty/tehnologiya-obrabotki-otverstij-na-tokarnyh-stankah.html

Deep Hole Machining

In case of making deep holes, it is necessary to perform all preparatory operations in the same sequence as usual:

- Setting the alignment of the tailstock and spindle.

- Securing the workpiece.

- Preparation and installation of cutting tools.

- Trimming the workpiece.

- Making a recess at the end of the workpiece.

In this case, you need to adhere to several recommendations:

- Deep drilling should be started with a short tool to a depth equal to the diameter of the drill, and then changed to the main one. This will help prevent the main drill from deviating from the desired direction.

- At the beginning of cutting, to increase the rigidity of a long drill, it is supported from the side with the back side of the cutter fixed in the tool holder.

Deep drilling causes significant thermal and mechanical loads on the cutting tool due to the larger area of rubbing surfaces. Therefore, it is necessary to pay more attention to cooling and timely removal of chips from the cutting zone.

Features of CNC machines

When working on lathes, CNC (computer numerical control) can be used. This only provides advantages when producing large quantities of products. Since debugging and setting up such machines takes a lot of time, it requires the creation of special programs and the presence of a qualified operator-setter.

Advantages of using CNC machines:

- Freeing the operator (turner) from any calculations.

- The accuracy of parts processing increases.

- The human factor is minimized.

- Increased labor safety.

- Increased labor productivity.

- Possibility of working around the clock and seven days a week.

- Reduces unit production costs.

Countersinking

With the help of countersinking, performed using a special cutting tool, the following tasks related to the processing of holes produced by casting, stamping, forging or through other technological operations are solved:

- bringing the shape and geometric parameters of the existing hole into accordance with the required values;

- increasing the accuracy of the parameters of a pre-drilled hole up to the eighth grade;

- processing of cylindrical holes to reduce the degree of roughness of their internal surface, which, when using such a technological operation, can reach a value of Ra 1.25.

When countersinking, less cutting force is applied than when drilling, and the hole is more accurate in shape and size

If it is necessary to subject a hole of small diameter to such processing, it can be performed on tabletop drilling machines. Countersinking of large diameter holes, as well as processing of deep holes, is carried out using stationary equipment installed on a special foundation.

Manual drilling equipment is not used for countersinking, since its technical characteristics do not provide the required accuracy and surface roughness of the hole being machined. Varieties of countersinking are technological operations such as counterbore and countersinking, which use various tools to process holes.

Conical countersinks for metal

Experts give the following recommendations for those who plan to perform countersinking.

- Countersinking should be carried out during the same installation of the part on the machine in which the hole was drilled, and only the type of tool used changes from the processing parameters.

- In cases where an unprocessed hole in body-type parts is subjected to countersinking, it is necessary to control the reliability of their fixation on the machine table.

- When choosing the amount of allowance for countersinking, you need to focus on special tables.

- The modes in which countersinking is performed must be the same as when drilling.

- When countersinking, the same occupational health and safety rules must be observed as when drilling on plumbing equipment.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

How to properly drill holes in metal

When working with metal, you cannot do without drilling holes. Working with metal is a complex operation. This is due to the fact that metal parts have high strength, for the processing of which special equipment and technologies must be used.

You may need to drill holes in any field and when performing work in the country, at home or in the garage. Even when repairing a car, you have to drill holes in the metal. If you are going to do the work away from the workplace, you will need an electric drill or hammer drill with an adapter chuck for the drill, as well as a core or tap to center the hole.

If you need to make holes in small parts, it is better to use a drill press. On it you will be sure of the correct direction of the drill and the drilling speed.

Which drill to choose for drilling metal

One of the first questions that inexperienced craftsmen ask is which drill to drill into metal? In fact, answering correctly is not so easy. For metal processing, you need to use special drills made of high-speed tool steel. The cutting part in them is made with the addition of titanium nitride.

When choosing drills for drilling metals, the main and running ones are drills made of high-speed tool steel; they can be found in the store by the HSS .

When working with cast iron, stainless steel and other metals that are difficult to machine, you should use carbide drills. Their disadvantage is their very high price, which makes the work expensive.

If you choose drills with one of the best cutting properties, it will be a tool with the addition of cobalt, marked P6M5K5. This is the best value for money.

Is it possible to drill metal with a concrete drill?

There may be an urgent need to make a hole in metal, and only a concrete drill is at hand. On such a drill, the tip is made of pobedite, which makes it possible to drill concrete and brick with a hammer.

You cannot use such a drill to drill a hole in metal. You may lick off the tip of the drill bit, especially if you try to use a large diameter drill bit or drill through thick metal.

To sum it up, you won’t be able to drill through metal with a Pobedit drill.

However, if you sharpen it at the right angle, it is possible to drill into metal.

Power and speed when working with metal

An important factor is the choice of tool, namely a hammer drill, drill or screwdriver, which will be used to make holes in the metal. If you use a drill with a power of up to 700W, you will not be able to make a large hole right away. A hand drill with a power of up to 700W is best used for drilling holes with a diameter of up to 10-13mm.

It is important to choose the correct speed of the drill or screwdriver. After all, at high speeds, your drill will simply burn out. This way you will ruin it.

You need to drill metal at low or medium speeds, not exceeding 500-1000 revolutions.

The larger the diameter of the drill you are working with, the lower the speed you need to choose.

How to drill metal products correctly

One of the most important parameters when drilling a hole is the sharpness of the drill. If you purchased one of the cheapest drills, it may turn out to be dull and made of soft metal, which will not allow you to make even a couple of holes.

How quickly the drill tip will shear and dull depends on the drilling speed, the hardness of the metal, the force applied to the drill, and cooling.

- When drilling large holes, you must first make holes of a smaller diameter. This way the process will be much faster, and the drills will not become dull so quickly.

- To accurately center the hole, you need to use a core punch and punch the center of the hole before drilling.

- To cool the working part of the drill, you need to use machine oil. Simply lower the working part of the drill into a container of oil. Repeat this operation periodically. You can use soapy water for cooling (by reducing friction).

- When drilling deep holes, periodically remove the drill and clear it of chips.

How to drill sheet metal

When working with sheet metal, there should not be any particular difficulties, even when drilling large-diameter holes. The only thing is that you need to place a wooden block under the drilling site, it will help remove the chips. When you feel like you've almost drilled through the metal sheet, reducing the pressure on the drill will also help reduce the likelihood of burrs.

How to make holes in pipes correctly

The main problem when drilling holes in round pipes is the difficulty of perpendicular drilling. This means that the hole from which drilling began does not correspond to the exit hole. To solve this problem, you need to use a drilling machine, or special guides, which you can make yourself or purchase ready-made.

How to drill aluminum

Anyone who has worked with aluminum parts knows that it is a soft metal. The main problem when drilling aluminum is excessive shavings wrapping around the drill bit. Because of this, the drill stops drilling and gets stuck in the metal. To avoid this, you need to remove the drill from the hole more often and remove the chips.

How to drill stainless steel (stainless steel)

Stainless steel is an alloy steel, which is not an easy task to drill. To make drilling comfortable, it is advisable to choose drills with a cobalt tip.

You need to drill stainless steel at minimum speed, namely 100-200 rpm. Such speeds provide the required cutting speed for stainless steel and good quality.

If your tool does not have a rotation speed control, you should press the button periodically for a second or two, which will prevent the drill from accelerating quickly.

If you need to make a hole of a large diameter, you need to use metal crowns, which make it possible to drill only along the outer diameter of the hole.

How to drill large diameter holes

When you need to make large diameter holes in metal, you need to use a tool suitable for this purpose.

- First you need to make a hole of a smaller diameter. You can use several drills, gradually increasing the diameter of the hole. In this way, it will be easier for drills to pass through metal, especially thick metal.

- Using a step drill. Such drills can be called conical drills.

- The use of special crowns for metal. Drilling large diameter holes with hole saws is very easy due to drilling only the outer diameter of the hole. The crown consists of a centering drill, which first drills through the metal in the center and then guides the crown. Drilling with a crown must be done at very low speeds.

One of the best ways is to use metal crowns. The disadvantage of this method is the non-adjustable diameter of the crown (adjustable crowns are also sold, but we do not recommend buying these because of their poor quality). For each hole diameter you need to have different crowns.

How to avoid dulling a metal drill?

While drilling, you can easily burn (blunt) the working part of the drill. This occurs due to high speeds, due to which the drill heats up and melts. This can be avoided by keeping the speed low or lubricating the drill with a cooling lubricant.

If there is no special cooling lubricant for drills, you can use machine oil, which will reduce the friction force.

How to drill with a drill?

To figure out how to properly drill metal with a drill, you need to derive a number of basic rules from which it is not advisable to deviate:

- You will need a drill or screwdriver, a core with a hammer, protective equipment - glasses and a means for cooling the drill (most often machine oil).

- Before starting work, you need to mark the center of the hole

- Wear protective equipment. The chips can easily bounce into your eyes. After which it will be difficult to get out of there without specialized medical care.

- Punch the center of the hole.

- Start drilling at low speed

- Periodically remove the drill from the hole, clearing it of chips and cooling it in oil.

By following the above rules and sequence, you can make holes of any diameter without any problems. When performed, the shelf life of the drill will be maximum due to maintaining low speeds and cooling it in oil.

On a large number of drills, you can install a depth limiter, which allows you to adjust the drilling depth. You may need it when drilling blind holes.

| [td]» Articles » Professionally about metalworking » Drilling machines |

We recommend purchasing:

Installations for automatic welding of longitudinal seams of shells - in stock!

High performance, convenience, ease of operation and reliability in operation.

Welding screens and protective curtains are in stock!

Radiation protection when welding and cutting. Big choice. Delivery throughout Russia!

Depending on the required quality and number of workpieces to be processed, holes are drilled using markings or a jig. During the work process, the following basic rules must be observed:

- when drilling through holes in workpieces, it is necessary to pay attention to the method of securing them; if the workpiece is mounted on a table, then you need to place it on a support to ensure free exit for the drill after processing is completed;

- the drill should be brought to the workpiece only after turning on the spindle rotation so that when it touches the surface of the workpiece, the load on it is small, otherwise the cutting edges of the drill may be damaged;

- Do not stop spindle rotation while the drill is in the hole being machined. First you need to remove the drill, and then stop rotating the spindle or stop the machine, otherwise the drill may be damaged;

- if a grinding noise or vibrations occur during drilling resulting from jamming, misalignment or wear of the drill, you should immediately remove it from the workpiece and then stop the machine;

- When drilling deep holes (l>5d, where l is the depth of the hole, mm; d is the diameter of the hole, mm), it is necessary to periodically remove the drill from the hole being machined to remove chips, as well as to lubricate the drill. This significantly reduces the likelihood of drill breakage and premature dulling;

- a hole with a diameter of more than 25 mm in solid metal is recommended to be drilled in two transitions (with reaming or countersinking);

- drilling should be performed only according to the modes specified in the technological maps or in the tables of reference books, as well as according to the recommendations of the foreman (technologist);

- When drilling holes in workpieces made of steel or viscous materials, it is imperative to use coolant to protect the cutting tool from premature wear and increased cutting conditions.

Drilling by marking is used in single and small-scale production, when the manufacture of jigs is not economically justified due to the small number of processed parts. In this case, the driller receives marked blanks with control circles marked on them and the center of the future hole (Fig. 6.21, a). In some cases, the marking is made by a driller.

Drilling according to the markings is carried out in two stages: first, preliminary drilling, and then final. Pre-drilling is carried out with manual feed, drilling a small hole (0.25d). After this, the spindle and drill are retracted, the chips are removed, and the alignment of the circle of the overdrilled hole with the marking circle is checked.

If the preliminary hole is drilled correctly (Fig. 6.21, b), drilling should be continued and completed, and if the hole has gone to the side (Fig. 6.

21, c), then make the appropriate adjustment: cut two or three grooves 2 with a narrow chisel (crossmeisel) on the side of the center where you want to move the drill (Fig. 6.21, d).

The grooves guide the drill to the location designated by the center punch. After correcting the offset, continue drilling to the end.

Drilling on the jig

To guide the cutting tool and fix the workpiece according to the requirements of the technological process, various jigs are used.

Constant mounting bases of the device and jig bushings that provide direction to the drill increase the accuracy of processing.

When drilling along a jig, the driller performs several simple techniques (installs the jig, the workpiece and removes them, turns the spindle feed on and off).

Drilling through and blind holes. There are mainly two types of holes in workpieces: through holes, passing through the entire thickness of the part, and blind holes, drilled only to a certain depth.

The process of drilling through holes is different from the process of drilling blind holes. When drilling through holes, when the drill comes out of the hole, the resistance of the workpiece material decreases abruptly. If you do not reduce the feed speed of the drill at this time, it may become jammed and break.

This happens especially often when drilling holes in thin workpieces, through intermittent holes and holes located at right angles to one another. Therefore, drilling a through hole is carried out with a high mechanical feed speed of the spindle.

At the end of drilling, you need to turn off the feed speed and drill the hole manually at a speed lower than mechanical.

When drilling with manual tool feed, the feed speed before the drill leaves the hole should also be reduced somewhat, drilling should be done smoothly.

There are three main methods of drilling blind holes.

If the machine on which a blind hole is drilled has any device for automatically turning off the spindle feed speed when the drill reaches a given depth (reading rulers, dials, hard stops, automatic stops, etc.), then when setting up to perform this operation it is necessary to adjust to the specified drilling depth.

If the machine does not have such devices, then to determine the achieved drilling depth, you can use a special chuck (Fig. 6.22, a) with an adjustable stop.

The thrust sleeve 2 of the chuck can be moved and installed relative to the body 1 with the drill at a given processing depth.

The machine spindle moves down until the end of the bushing 2 stops at the end of the jig bushing 3 (when drilling along the jig) or into the surface of the workpiece. This chuck ensures hole depth accuracy within 0.1...0.5 mm.

If greater accuracy of drilling depth is not required and there is no specified chuck, then you can use a stop in the form of a sleeve attached to the drill (Fig. 6.22, b), or mark the depth of the hole on the drill with chalk. In the latter case, the spindle is fed until the drill goes deep into the workpiece to the mark.

The drilling depth of a blind hole is periodically checked with a depth gauge, but this method requires additional time, since you have to remove the drill from the hole, remove the chips and, after measuring, reinsert it into the hole.

Hassle-free drilling

During work, you can use a small section nozzle, as well as a used grinding wheel for an angle grinder. It is important to remember that it should have a smaller diameter than the hole being created.

Before carrying out work, a circle for the hole is marked on the workpiece, and the second circle will be smaller than the first by a distance equal to the diameter of the drill used. After this, 2 holes are marked in opposite places of the circle. It is necessary to retreat 3 mm from them and mark the places for drilling. Thus, drilling occurs along the entire drawn circle. If additional work is necessary, some areas will have to be processed with a chisel. This will create jagged edges that will then need to be filed down. It is important to ensure that during work the circumference does not increase, i.e. do not expand the planned diameter.

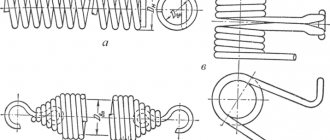

Cone drill

The described types of drills are made from tool steel. The shanks of such products can be hexagonal or cylindrical. The cutting edge removes all burrs, so the edge is smooth. The end of the drill head has a sharpened point that allows pre-drilling of the material.

Using these products you can:

- create cuts with a diameter of up to 30 mm;

- forget about jagged edges;

- carry out boring of various diameters without changing the nozzle.

Thanks to step drills, you can create cuts of various diameters in sheet steel up to 4 mm thick. Unlike a simple cone drill, when using such products, the drilled diameter is fixed.

The disadvantages include:

- the need to use tools with low speeds and high torque;

- sensitivity even to small distortions.

Despite these disadvantages, this attachment allows you to conveniently work with metal plates, quickly drilling circles of the required diameter.

Metal crown

Metal processing is a complex process, so such work is usually carried out using specialized equipment. To carry out work at home, you can use core drills.

Such products allow you to make the edges round and centered. In this case, a standard drill is used for drilling. The products consist of several parts:

- crown;

- centering attachment;

- product shank;

- screws that are necessary for fastening.

When using a core drill, the speed of work increases up to 10 times. Another advantage is the ability to accurately drill in the range from 1.2 to 15 cm.

In this case, there is no need to perform alignment during drilling. It is also worth noting that such drills have higher wear resistance compared to twist drills.

Before starting work, a centering drill is installed in the center of the circle, after which drilling is carried out. After this, the drill is retracted and the work is carried out with a crown.

Features of large diameter holes

This procedure is more complex than deep drilling. Cutting work is carried out either using a crown or using a cone drill. Crowns for metal are similar to products for concrete and drywall. The only difference is the material used to create the cutting edge.

Drilling can also be carried out with standard products in several stages. To do this, first use a nozzle of small diameter. Then a larger tool is selected.

The most convenient way is to use cone drills. Such devices allow you to drill a large hole in one go. To do this, the tool is simply recessed into the material.

Read also: The best works of wood carvers