For reliable and high-quality fastening of 2 or more parts to each other, it is fundamentally important to select the correct dimensions of the fastening elements. This question often causes difficulties, because even the sizes of wrenches are selected taking into account the sizes of the fasteners themselves. Therefore, we will consider all the nuances that are important to consider when choosing the necessary hardware.

The main parameters by which bolts and nuts are selected are the diameter of the product, its thickness and length. But besides them, there is a number of important data, information about which is printed on the hardware. This:

- metric thread (it is designated as M);

- thread pitch (it can be especially small, small, large, especially large, in the latter case the value is not added, denoted as P);

- diameter of the product (designation – D);

- product length (denoted L).

The numbers next to the letter designation of the parameters are data indicated in millimeters. To find out the type, as well as correctly determine the size of, for example, a bolt, you must first find out what type of fastener is needed. Here it is permissible to use domestic GOST, European ISO quality standards or even DIN standards (Germany).

Marking features

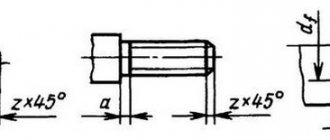

If we are talking about bolts with metric threads , then in the technical documentation such products are designated by markings like MDxPxL , where:

- M – designation of metric thread;

- D – bolt thread diameter indicated in millimeters;

- P – thread pitch expressed in millimeters (it can be large, small or especially small);

- L – product length indicated in millimeters.

Understanding the rules for marking fasteners, you can proceed to determining the dimensions of the product. However, before this, you need to find out by what standards the bolt was manufactured, since, in addition to the Russian GOST, such products can be manufactured according to the ISO or DIN standard.

Stud sizing technology

Studs, like other hardware, are distinguished by the presence of metric threads, therefore they have the corresponding abbreviation MDxPxL. The decoding is also no different from the previous fasteners:

- M - the letter denotes the metric thread of the hardware;

- D - used to indicate diameter;

- P - type of step, indicator in millimeters;

- L - data on the length of the working part of the structure.

The type of measurement is selected in accordance with the appropriate GOST standard, as well as the type of stud. In total, there are 2 large groups for determining the ownership of hardware:

- structures that are used for installation in smooth holes;

- fasteners with an end that screws into a hole.

Essential fastenings: bolts, screws, studs

How is the recharge of fastening elements determined?

Most often, metal parts are specified in the standard for which fastening is carried out.

However, not everyone always has the necessary standard at hand, so since you need to wait until the end of the day, this article will show you how to do it correctly. Also, for this purpose, special tools are needed, such as a centimeter, tape measure or ruler. The most required element for these purposes is a caliper, as it helps to achieve maximum caliper accuracy. While tools alone are not enough, it is also necessary to do the work correctly. In fact, it is not difficult and logical to think that the alignment of the two bolts and screws should go from the head to the end of the rod, knurled with grooves, and the studs from one end to the other. Here are some nuances that you need to be aware of and which we will tell you below.

Significance of Dovzhini Boltіv

As stated above, most of the bolts are driven from the supporting surface of the head to the end of the threaded rod.

The standards that produce such bolts are:

- hex bolts GOST 10602-94, 7805-70, 15589-70, 7798-70;

- hex bolts with a modified head GOST 7796-70, 7808-70, 155591-70;

- adhere to the high standards of GOST 22353-77;

- bolts manufactured according to GOST R 52644-2006 with high value and larger size;

- bolts to mount the guide headrest and hex head GOST 15590-70, 7811-70, 7795-70;

- hex bolts with a modified head, which are used in the openings at the back of the flange GOST 7817-80;

- head bolts of large size, round shape and so-called taste - standard GOST 7801-81;

- The bolts that mount the square headrest and the larger round head are manufactured according to the GOST 7802-81 standard.

All these bolts have one characteristic in common - they smell from the stem and head as they spread over the surface of the joint and do not enter the middle of the opening. Even then, such bolts disappear from the supporting surface. Other types of bolts that, when installed, enter the hole completely and create a smooth surface. In this situation, the completeness of the bolt is covered by the completion of all fastenings - from the head of the head to the edge of the threaded rod.

These types of metal-borne substances are known to be:

- standard GOST 7785-81 - vib with secret head and flavor;

- bolt with square headrest and countersunk head GOST 7786-81;

- tire bolts GOST 7787-81.

The replacement of the foundation bolts, which are produced according to the GOST 24379.1-80 standard, is carried out in the same way - after the replacement of the studs, as well as this main stock.

Rome bolts GOST 4751-73 and jack bolts GOST 3033-79 align from the supporting surface of the ring to the edge of the threaded rod.

Vaznennya dovzhini stilettos

There are three ways to vikorize hairpins:

- stand from one edge of the hairpin to the other, then the entire metalwork. Standards for these studs are DIN 975, DIN 976-1;

- studs for smooth openings (GOST 22042-76, 22043-76) and studs for flanged connections (GOST 9066-75) are also aligned throughout from the end edge of one edge to the end edge of the other;

- the third option allows you to tighten the studs with a screwed end. For such fasteners, the screwed end is not covered; studs are inserted into them, which are prepared according to current standards - GOST 22032-76, 22036-76, 22035-76, 22034-76, 22033-76, 22038-76, 22037-76, 22040 -76, 22039-76, 22041-76.

Celebration of the dove of gwents

By analogy with bolts, the length of the screws extends from the supporting surface to the end chamfer of the threaded rod.

The following standards can be added to such guints:

- screws with a cylindrical head and hexagonal sockets according to GOST 113768-84;

- screws GOST 1491-80 with a cylindrical head;

- screws with a round head, hammered according to the GOST 17473-80 standard.

A number of screws, which have a semi-countersunk head and are manufactured according to the GOST 17474-80 standard, are ancient from the bearing surface of the sphere to the end chamfer of the metal rod, rolled in grooves.

Hardware, countersinked and brought to the GOST 17475-80 standard, disappears throughout the entire element.

The installation screws also remain constant throughout the entire period, since when installing the screws, they always enter the opening. Such fastenings must comply with GOST standards 1476-93, 1478-93, 1479-93, 8878-93, 11074-93, 11075-93.

Wrench sizes

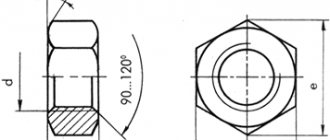

Today, there are universal wrench options that are great for working with different nut diameters. However, cases are different, and the need to select a tool cannot be ruled out. Several options are offered:

- Thread diameter. There is nothing complicated in this case. You can use special devices and tools that allow you to determine the parameters. Or, as an option, look at the information of interest in the technical documentation. Note that if the fastener has a standard thread diameter, then 2 sizes are offered, namely normal and reduced. However, this option is quite rare.

- Head diameter. Depending on the size, the distance of the edges will change: this is what needs to be determined. A ruler is suitable for this. If everything is done correctly, the bolt head will clearly fit into the selected wrench. Of course, it is not always possible to accurately measure a parameter with a ruler, so it would be better to use a caliper.

- Bolt length. The height of the head is not taken into account, only the shaft is considered. If an M16 bolt is required, the thread diameter dimensions should be 16 mm. The marking may also indicate other information: it shows the nominal height of the head, the thread pitch. If you have a car bolt with a pointed tip, then you need to calculate its length taking into account the guide.

Measuring threads with a caliper

Accurate measurements of the thread pitch can be performed using a caliper, thread gauge, or inclinometer. This indicator can be determined by the diameter of the bolt, measuring it with a caliper and comparing the results with the indicators of a special table of metric thread pitches.

The first step is to determine whether the threads are tapering. To do this, place the points of the caliper on either side of the object that needs to be measured. Align it to the outside of the threads at the lower end, away from the head. This is how the width is determined.

The thread pitch of the fastener is determined by dividing the length of the rod by the number of protruding elements. The length is measured with a ruler or caliper if you want to get an accurate result. A ruler is applied to the upper parts of the threaded elements. The recommended length for counting turns is 20 mm.

Next, you need to move the tip so that it touches the threads. The measurement should appear on the screen if the instrument has a display. Otherwise, you will need to rely on the numbers on the sliding part. You should then do the same on the threaded area near the head of the fastener. If the number is higher at the head, then it is a tapered thread.

You can also use a caliper to measure the diameter. If the thread is tapered, measure at the 4th or 5th thread down from the head, i.e. in the middle of the threaded area. If it does not taper, then you can measure anywhere along the thread. When using a caliper, you may notice that there are several places where the arms do not meet closely together, sometimes along the edge of the ruler. There is no need to place what needs to be measured in these spaces.

The numbers should be placed in a standard measurement. Once the pitch value is obtained, you can measure the length of the bolt or screw from under the head and place all the numbers into a standard measurement. It will have the diameter, then the thread pitch and the length. If a metric screw has a diameter of 4 millimeters, a thread pitch of 0.4 mm and a length of 8 mm, then the calculation will be M4 x 0.4 x 8M. For an American screw this could be 1/4" in diameter, 20 TPI and 1" long. The formula will be: 1/4 inch x 20 x 1 inch.

The thread pitch can be determined using a ruler. This is not the most reliable, but accessible method. Use a ruler to measure the length of the desired threaded section. Then the number of threads is counted at this distance. The thread pitch value is calculated by dividing the length of the section by the number of turns.

How to determine the strength class of a part?

To assess the strength characteristics of an old bolt, you need to clean its head of dirt and examine the markings. The strength class of metric parts is indicated by a digital code on the head, while other markings may be found on foreign-made fastener heads. For example, the strength of American SAE fasteners can be identified by radial lines - notches on the head. The greater their number, the higher the strength class of the fastener and the higher the permissible tightening force.

Bolt Strength Comparison Table:

| Inch | Metric | ||||||

| Class (SAE) | Marking | Diameter | Tensile Strength, PSI | Class (ISO) | Marking | Diameter | Tensile strength, PSI (MPa) |

| 2 | 1/4″ – 3/4″ | 74.000 SI | 5.6 | M12 - M24 | 72.500 PSI (500 MPa) | ||

| 7/8″ – 1 1/2″ | 60.000 PSI | ||||||

| 5 | 1/4″ – 1″ | 120.000 PSI | 8.8 | M17 - M36 | 120.350 PSI (830 MPa) | ||

| 1″ – 1 1/2″ | 105.000 PSI | ||||||

| 8 | 1/4″ – 1 1/2″ | 150.000 PSI | 10.9 | M6 - M36 | 150.800 PSI (1040 MPa) | ||

The new bolt should not be inferior in strength to the original. Think twice before replacing high-strength original hardware with a low-cost alternative. A few rubles in savings could cost you an engine rebuild or even your life.

When all the parameters of the hardware are determined, you can easily find it in our online store in the “Inch fasteners” section and place an order.

How to distinguish metric from inch fasteners?

First of all, you need to make sure that your foreign fasteners are inch.

It is difficult to distinguish it from a metric one “by eye” and there is a risk of mistaking, for example, a 5/16″ UNC bolt for M8, which is similar in parameters. A metric thread gauge will help identify inconsistencies - none of its templates will fit an inch thread. In the absence of such an identifier, you can use a more accessible method - try to screw a nut with known parameters onto the rod. If you have to frequently identify threads, we recommend purchasing thread gauges.

In fact, finding the differences between inch and metric fasteners can be even easier. If there are radial lines

– this is “American”, and if there

are numbers on the head

– it is a metric. Lines and numbers are markings of strength. However, it is worth noting that fasteners of strength class from 0 to 2 are not marked at all, so this method is not always acceptable.