Grinding technologies are used in the machine and machine-tool industries, jewelry, optics, and construction. They are technological operations for processing materials with abrasives. They are used for finishing surfaces of flat, cylindrical, end, internal and external parts and products made of hard materials, as well as restoration of cutting ability and configuration. The goal of the process is to obtain a surface with the required roughness and cleanliness. Grinding of parts is a type of cutting operations, with the help of which the dimensions of the part are adjusted to the required value indicated in the design drawings. To process materials for various purposes by grinding, a large number of abrasives, tools and equipment are used. The quality of work depends on the correct choice of grinding technology method and the necessary components. By grinding, accuracy classes 1 and 2 and surface cleanliness classes 6–10 are achieved.

Metal grinding

The processing of metal and various alloys using an abrasive material is usually called grinding. This technology allows you to change the roughness and other parameters of the outer or inner cylindrical, as well as flat surface. Metal grinding can be carried out using various special equipment. When considering the features of such mechanical processing, you need to pay attention to the following points:

- The grinding process is the final stage of processing, which is carried out to obtain a certain roughness.

- This technology is not used to change sizes over a large range.

- Using modern equipment, the surface can be brought to the required roughness after heat treatment of the metal.

When carrying out the operation in question, a fairly large number of features are taken into account:

- Wheel speed is a parameter that depends on the outer diameter of the abrasive and the capabilities of the machine.

- Speed of movement of the part.

- Depth of cut.

- Possibility of cross feeding.

It is worth noting that today such technology is gradually being replaced by fine turning of metal at high speeds and minimal feed.

The influence of speed on processing quality

The grinding speed is usually called the rotation speed of the grinding wheel. Measured in m/s. The productivity of the process increases with its increase. The grinding speed is selected taking into account the diameter of the wheel, the material of the workpiece and the grinding wheel, the type of grinding, and the design of the machine. Usually they try to select a circle of the largest diameter permissible for installation on a specific machine model, and select the required number of spindle revolutions from the table indicated in the passport data. High speed leads to vibration, which affects the quality of grinding and will also cause wheel wear. To avoid negative consequences resulting from overheating, in some cases special cutting fluids (coolants) are used.

In the video you can see how the gear grinding process is carried out on a CNC machine:

We ask those who have dealt with grinding to share their experience and in the comments to the text tell us about the nuances of working on machines and manually.

Main types of grinding

Grinding of parts can take place using a variety of technologies. The most widespread are the following:

- Circular grinding of metal.

- Changes in the roughness of internal surfaces.

- Gear grinding.

- Centerless technology.

- Sanding flat surfaces.

In addition, classification can be carried out according to the type of material used during processing. To automate the process and reduce labor costs, specialized machines are used. There are also models with a built-in CNC unit, which automates the process and ensures high quality of the resulting surface.

Cylindrical external grinding

Metal grinding when using this technology involves the use of special equipment. Among the features of cylindrical grinding, we note the following points:

- An abrasive wheel is used as a consumable. It rotates around its axis.

- Simultaneously with the circle, the workpiece rotates in the opposite direction. Due to this, the efficiency of the operation is significantly increased.

- Longitudinal and transverse feeds can be carried out, due to which the depth of penetration of the tool changes and processing is ensured along the entire length.

Principle of cylindrical grinding

Cylindrical external grinding

This technology is often used for grinding cylindrical workpieces. This is due to the fact that when the grinding wheel comes into contact with a cylindrical workpiece, the entire surface is processed at the moment of rotation.

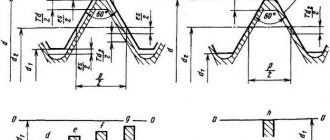

Gear grinding

Gears are part of a wide variety of mechanisms. The complexity of the shape of the working part determines that special grinding equipment has to be used. Among the features of this technology, we note the following points:

- The profile of the ring gear is processed.

- The circle changes to the size of the tooth involute.

- Special machines are suitable for working with gears.

Gear grinding

Often the tooth surface is hardened, which makes the machining process significantly more complicated.

Content

- 1 Process

- 2 Equipment 2.1 Types of surface grinding machines 2.1.1 Horizontal spindle (peripheral) surface grinding machines

- 2.1.2 Vertical spindle (grinding) machines

- 2.1.3 Disc sanders and double disc sanders.[3]

- 6.1 Bibliography

Centerless grinding

This technology is characterized by the fact that the workpiece is not fixed in the centers. In this case, grinding of metal parts takes place by applying rotation to only two grinding wheels, between which the workpiece is placed. In the central part there is a knife made of stainless steel. It eliminates the possibility that the product will fail due to displacement or become slightly jammed.

The use of such equipment can significantly speed up the grinding process. This is due to the fact that two abrasive wheels are used at once. There are simply a huge number of machines on sale that operate on the principle of centerless grinding.

Centerless grinding

Wear, durability and wheel dressing

During the grinding process, the cutting properties of the wheel change. Abrasive grains become dull, partially split, and crumble; the pores between the grains become clogged with grinding waste (the wheel becomes “greasy”); the surface of the circle loses its original shape. As a result, the cutting force and temperature increase; processing accuracy decreases and the likelihood of burns increases. However, when the dull grains are broken out, new, sharpened grains are exposed on the surface of the wheel, i.e., the wheel partially sharpens itself. In this sense, the role of the binder (the substance that fixes the grains) and the “hardness” of the circle is very important. If the grain is weakly secured, they break out faster, the wheel sharpens itself better, but the working surface of the wheel quickly loses its shape, which is convenient for rough grinding. If the grains are excessively fixed, the wheel quickly loses its cutting properties, but the working surface is well preserved, which is convenient for fine grinding.

To restore the geometry of the wheel and its cutting properties, the wheel is edited. A diamond or abrasive tool is used to remove part of the working surface of the circle. The thickness of the removed layer usually does not exceed 0.01–0.03 mm.

The geometric durability of a grinding wheel is the time (number of processed workpieces) of continuous operation, after which editing is necessary in order to restore the geometric parameters of the working surface. Geometric resistance is usually prescribed for finishing grinding, for grinding shaped or conical surfaces. The physical durability of a grinding wheel is the time (number of processed workpieces) of continuous work, after which dressing is necessary in order to restore the cutting properties of the working surface. Physical resistance is usually specified for rough grinding.

Sanding flat surfaces

Flat body blanks made of various metals are often processed. The operation to change the surface roughness is characterized by the following features:

- The workpiece is placed on a special table, which ensures reliable fastening. Fixation can be mechanical or magnetic.

- The main rotation is transmitted to the abrasive wheel, reciprocating the workpiece or tool.

Sanding flat surfaces

By selecting a wheel with the most suitable profile, it is possible to process the most complex shapes. During operation, coolant can be supplied to the contact area between the tool and the workpiece.

Process

Surface grinding is the most common grinding operation. It is a finishing process in which a rotating abrasive wheel is used to smooth the flat surface of metallic or non-metallic materials to give them a more refined appearance, removing oxide layer and contaminants from the surfaces of the machined parts. This will also allow you to obtain the desired surface for functional purposes.

A surface grinder consists of an abrasive wheel, a clamping device known as a chuck, and a reciprocating or rotary table. The chuck holds the material in place during processing. This can be done in two ways: ferromagnetic parts are held in place using a magnetic clamp, while non-ferromagnetic and non-metallic parts are held in place using vacuum or mechanical means. A machine vice (made of ferromagnetic steel or cast iron), placed on a magnetic chuck, can be used to hold non-ferromagnetic parts if only a magnetic chuck is available.

Factors to consider in surface grinding are the material of the grinding wheel and the material of the workpiece.

Typical workpiece materials include cast iron and mild steel. These two materials do not clog the grinding wheel during processing. Other materials include aluminum, stainless steel, brass and some plastics. When grinding at high temperatures, the material tends to weaken and is more prone to corrosion. This may also result in loss of magnetism in materials where applicable.

The grinding wheel is not limited to a cylindrical shape and can have many options that can be useful in conveying different geometries to the object being processed. The operator can straighten straight wheels to create custom geometries. When sanding the surface of an object, keep in mind that the shape of the circle will be transferred to the material of the object as an inverted image.

Sparks

is a term used when looking up precision values and literally means "until the sparks go out (no more)." It consists of passing the workpiece under the wheel without changing the depth of cut more than once, and as a rule, many times. This ensures that any discrepancies in the machine or workpiece are corrected.

Processing parts before grinding

As previously noted, sanding is the finishing step. Before it is carried out:

- Rough turning of metal. Due to this operation, the workpieces are given the required shape and dimensions, taking into account the allowance.

- Finish turning is carried out to give the required dimensions.

- Milling is another technological operation that involves mechanical removal of metal. Most often, housing parts and gears are milled.

- Heat treatment. In order to significantly increase the surface hardness and strength of the product, hardening is carried out. The fragility of the structure can be reduced by tempering and annealing. In some cases, thermochemical treatment is carried out, which involves introducing certain chemicals into the surface layer.

Processing parts before grinding

When developing processing modes, allowance for all technological operations is taken into account.

Characteristics and marking of abrasive tools

In most cases, when grinding metal, an abrasive tool is used. It is represented by a combination of a large number of grains, which are interconnected by a special lubricant. The circle is characterized by the following properties:

- Form. The working part may vary depending on what type of surface will be processed.

- Dimensions. The abrasive wheel is also selected by size depending on the dimensions of the surface being treated.

- Type of material used in manufacturing. The crumb can be made from crumbs of different hardness. Diamond chips are characterized by greater resistance to abrasion.

- Grain size. For fine grinding of metal, a wheel with the smallest grain size is selected. However, as the grit size decreases, the required time to complete processing increases.

- Surface hardness. This parameter is one of the main ones, indicated during labeling.

- Mounting hole size. It is taken into account when selecting a wheel for the characteristics of the machine.

The production of abrasive materials is carried out in accordance with established standards and technical conditions.

Circle markings are used to indicate the type of material used in manufacturing. Electrocorundum is artificial corundum based on aluminum oxide. There are several varieties of circles available for sale:

- Normal 14A and 15A, 16A.

- White 22A, 23A and 24A.

- Chrome 32A and 33A.

- Spherocorundum ES.

Silicon carbide can also be used. There are two types of stamps on sale: black and green. Boron carbide is marked with the letters KB. Recently, the most popular options are made from synthetic diamond; they are marked ACP and ASO, ARV and ARC.

Abrasive materials