Various European standards include more than 150 wrought aluminum alloys. However, only 17 of them are used in the construction of buildings according to Eurocode 9 [1]. An important condition for choosing these alloys is their level of corrosion resistance under various operating conditions of buildings with a minimum of maintenance. The following overview of the main types of aluminum corrosion provides an understanding of why some aluminum alloys can be used in construction and others cannot.

See more Construction aluminum alloys

Aluminum and its reaction with water

Aluminum was first produced only at the beginning of the 19th century. This was done by physicist Hans Oersted. He conducted his experiment with potassium amalgam, aluminum chloride and mercury.

By the way, the name of this silvery material comes from the Latin word “alum”, because it is from them that this element is mined.

Alum [Wikimedia]

Alum is a natural metal-based mineral that combines sulfuric acid salts in its composition.

Previously, aluminum was considered a precious metal and was worth an order of magnitude more expensive than gold. This was explained by the fact that the metal was quite difficult to separate from impurities. So only rich and influential people could afford aluminum jewelry.

Japanese aluminum decoration [Wikimedia]

But in 1886, Charles Hall came up with a method for extracting aluminum on an industrial scale, which dramatically reduced the cost of this metal and made it possible to use it in metallurgical production. The industrial method involved the electrolysis of molten cryolite in which aluminum oxide was dissolved.

Aluminum is a very popular metal, because many things that people use in everyday life are made from it.

Application of aluminum

Due to its malleability and lightness, as well as its resistance to corrosion, aluminum is a valuable metal in modern industry. Aluminum is not only used to make kitchenware; it is widely used in automobile and aircraft construction.

Aluminum is also one of the most inexpensive and economical materials, as it can be used endlessly by melting down unwanted aluminum items, such as cans.

Aluminum cans

Aluminum metal is safe, but its compounds can be toxic to humans and animals (especially aluminum chloride, acetate and sulfate).

Physical properties of aluminum

Aluminum is a fairly light, silver-colored metal that can form alloys with most metals, especially copper, magnesium and silicon. It is also very plastic; it can easily be turned into a thin plate or foil. The melting point of aluminum = 660 °C and the boiling point is 2470 °C.

Chemical properties of aluminum

At room temperature, the metal is coated with a durable film of aluminum oxide Al₂O₃, which protects it from corrosion.

Aluminum practically does not react with oxidizing agents due to the oxide film that protects it. However, it can be easily destroyed so that the metal exhibits active restorative properties. The aluminum oxide film can be destroyed with a solution or melt of alkalis, acids, or with the help of mercury chloride.

Due to its reducing properties, aluminum has found application in industry for the production of other metals. This process is called aluminothermy. This feature of aluminum is its interaction with oxides of other metals.

Aluminothermic reaction involving iron (III) oxide [Wikimedia]

For example, consider the reaction with chromium oxide:

Cr₂O₃ + Al = Al₂O₃ + Cr.

Aluminum reacts well with simple substances. For example, with halogens (except fluorine), aluminum can form aluminum iodide, chloride, or bromide:

2Al + 3Cl₂ → 2AlCl₃

With other non-metals such as fluorine, sulfur, nitrogen, carbon, etc. aluminum can only react when heated.

Silver metal also reacts with complex chemicals. For example, with alkalis it forms aluminates, that is, complex compounds that are actively used in the paper and textile industries. Moreover, it reacts as aluminum hydroxide

Al(OH)₃ + NaOH = Na[Al(OH)₄]),

and metallic aluminum or aluminum oxide:

2Al + 2NaOH + 6Н₂О = 2Na[Al(OH)₄] + ЗН₂.

Al₂O₃ + 2NaOH + 3H₂O = 2Na[Al(OH)₄]

Aluminum reacts quite calmly with aggressive acids (for example, sulfuric and hydrochloric acids), without ignition.

If you dip a piece of metal into hydrochloric acid, the reaction will be slow—at first the oxide film will dissolve—but then it will speed up. Aluminum dissolves in hydrochloric acid, releasing hydrogen. The reaction results in aluminum chloride:

Al₂O₃ + 6HCl = 2AlCl₃ + 3H₂O

2Al + 6HCl → 2AlCl₃ + 3H₂.

Aluminum chloride [Wikimedia]

Here you will find interesting experiments to study the chemical properties of metals.

Reaction of aluminum with water

If you put aluminum shavings in ordinary water, nothing will happen because the aluminum is protected by an oxide film that prevents this metal from reacting.

Only by removing the protective film with mercury chloride can you get the result. To do this, the metal must be soaked in a solution of mercuric chloride for two minutes, and then rinsed well. The result is an amalgam, an alloy of mercury and aluminum:

3HgCI₂ + 2Al = 2AlCI₃ + 3Hg

Moreover, it does not stick to the metal surface. Now, by immersing the purified metal in water, you can observe a slow reaction, which is accompanied by the release of hydrogen and the formation of aluminum hydroxide:

2Al + 6H₂O = 2Al(OH)₃ + 3H₂.

Source: https://melscience.com/ru/articles/alyuminij-i-ego-reakciya-s-vodoj/

Cleaning features, general recommendations

Heating of aluminum cookware occurs evenly and does not require much time. After some time, carbon deposits begin to appear on aluminum cookware and traces of oxide become noticeable. Most often, they try to clean aluminum using dishwashing detergent, but it can only remove external dirt and grease.

Dishes made from this material should only be washed cold, since they can easily be damaged when hot. If a hot metal is immersed in cold water, it will become deformed, and therefore you should try to avoid such a failure.

You should not try to clean burnt food immediately using iron sponges and other objects. To make the task easier, you just need to pour warm water and wait about half an hour. During this time, the food will get wet and can be removed using a regular dishwashing sponge.

It is not recommended to wash aluminum cookware in the dishwasher, since the dishwasher uses hot water during the washing process, which can damage the material. To avoid deformation, it is recommended to wash aluminum cookware by hand with warm water.

You should not use strong acids in the process, as they will not be able to restore the shine of the dishes, and may harm them. It is also not recommended to clean it with metal sponges, which leave scratches on the dishes.

Ways to combat aluminum corrosion

Aluminum is a metal widely used in industry and everyday life. Aluminum does not oxidize in air. Its inertness is due to the thin oxide film that protects it. However, under the influence of certain environmental factors, this metal is still subject to destructive processes, and corrosion of aluminum is not such a rare phenomenon.

Types of corrosion

Aluminum oxidizes quickly in the atmosphere, but to a shallow depth. This is prevented by a protective oxide film. Oxidation accelerates above the melting point of aluminum. If the integrity of the oxide film is compromised, aluminum begins to corrode. The reasons for the thinning of its protective layer can be various factors, from exposure to acids, alkalis and ending with mechanical damage.

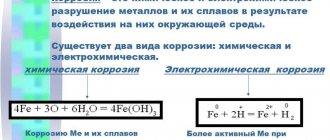

Aluminum corrosion is the self-destruction of metal under the influence of the environment. According to the flow mechanism, they are distinguished:

- Chemical corrosion - occurs in a gas environment without the participation of water.

- Electrochemical corrosion – occurs in humid environments.

- Gas destruction - but accompanies heating and hot processing of aluminum. As a result of the interaction of oxygen with metals, a dense oxide film appears. This is why aluminum does not rust, like all non-ferrous metals.

On video: electrochemical corrosion of metals and methods of protection.

Causes of aluminum corrosion

The corrosion resistance of aluminum depends on several factors:

- purity - the presence of impurities in the metal;

- exposure environment - aluminum can be equally susceptible to destruction in clean rural air and in industrially polluted areas;

- temperature.

In many cases, low-concentration acids can dissolve aluminum. The natural oxide film does not protect against corrosion.

Powerful destroyers are fluorine, potassium, sodium. Aluminum and its alloys corrode when exposed to chemical compounds of bromine and chlorine, lime and cement solutions.

Corrosion of aluminum and its alloys occurs in water, air, carbon and sulfur oxides, and salt solutions. Sea water leads to accelerated destruction. Aluminum is considered an active metal, but it also has good corrosion properties.

There are two main factors that influence the intensity of the corrosion process:

- degree of aggressiveness of the acting environment - humidity, pollution, smoke;

- chemical structure.

Friction rotary welding

Friction rotary welding is a solid state joining process that works by rotating one part relative to another while subjected to an axial compressive force. Friction between the surfaces produces heat, causing the interface material to plasticize. The compressive force displaces the plasticized material from the interface, promoting metallurgical bonding mechanisms. Without entering a liquid state, friction welds remain much cooler during processing.

In addition, welding aluminum, fast friction, preventing the weld from being exposed to high temperatures for a long time. Consequently, friction welding is used commercially to join a range of dissimilar materials as the formation of intermetallic compounds is greatly reduced.

Despite the advantages of friction welding in reducing intermetallic formation between aluminum alloys and steels, care must still be taken in the selection of parameters.

Main types of aluminum corrosion

Aluminum and, to varying degrees, its alloys are highly resistant to corrosion even without any special protective coating.

Natural oxide coating

The natural surface of aluminum, which is created during the manufacturing of an aluminum product, such as extrusion, rolling or casting, has high resistance to corrosion in most types of environments. This occurs because a fresh aluminum surface spontaneously and instantly forms a thin but very effective oxide layer that prevents further oxidation of the metal.

This oxide film is impermeable and, unlike the oxide films of other metals, such as iron, is very firmly “attached” to the base metal. In case of any mechanical damage, this film is instantly restored and healed.

The natural oxide layer is the main reason for aluminum's good resistance to corrosion. This coating is resistant in environments with acidity - pH value - from 4 to 9.

Three main types of aluminum corrosion

The most common types of aluminum corrosion are:

- galvanic (contact) corrosion;

- pitting (pitting) corrosion;

- crevice corrosion.

Stress corrosion, which leads to cracking, is a more specific type of corrosion. It occurs primarily in high-strength aluminum alloys, such as AlZnMg alloys, when they are subjected to prolonged tensile stress in the presence of a corrosive environment. This type of corrosion does not usually occur in 6xxx series alloys, i.e. AlMgSi alloys.

Galvanic corrosion of aluminum

Galvanic corrosion can occur when two different metals are in direct contact and an electrolytic bridge has formed between them. The less noble metal in this combination becomes the anode and corrodes. The more noble metal becomes the cathode and is protected from corrosion.

In most combinations with other metals, aluminum is the less noble metal. Aluminum is therefore at higher risk of galvanic corrosion than other building materials. However, this risk is less than is generally believed.

Necessary conditions: contact and moisture

Galvanic corrosion of aluminum occurs only when simultaneously:

- there is contact with a more noble metal (or other electrical conductor with a higher chemical potential than aluminum, such as graphite;

- between two metals there is an electrolyte with good conductivity, most often water with dissolved salts.

Galvanic corrosion does not occur in a dry air atmosphere, such as inside a normal living space. There is no big risk of galvanic corrosion and a clean rural atmosphere. However, the risk of galvanic corrosion must always be taken into account in atmospheres with high chloride content, for example in areas near seas and oceans.

Aluminum and galvanized steel

There may be problems with galvanic corrosion when pairing aluminum with galvanized steel. The zinc coating on galvanized steel will initially protect the aluminum from corrosion.

However, this protection decreases when the surface of the steel begins to be exposed as the zinc is consumed. Hot-dip galvanizing of steel produces a thicker zinc coating than electrochemical galvanizing and provides longer-lasting protection for aluminum.

Therefore, in aggressive atmospheres in contact with aluminum, only hot-dip galvanized steel is used.

Electrical insulation

Where different metals are used in contact, galvanic corrosion can be avoided by electrically isolating one metal from the other. An example of such a solution for a bolted connection between an aluminum and steel sheet is shown in Figure 1.

Electrolyte may form between the bolt head and the surface of the aluminum, but the electrically insulating washer will not allow galvanic electric current to flow and corrosion will not occur.

On the other hand, there is no possibility of moisture ingress in the contact between aluminum and steel sheets, electrolyte is not formed and corrosion does not occur.

Battery principle

Galvanic corrosion works like a battery, which consists of two electrodes:

- cathode where the reduction reaction occurs

- anode where the oxidation reaction occurs.

These two electrodes are immersed in a conductive liquid called an electrolyte. An electrolyte is usually a dilute acid solution, such as sulfuric acid, or a saline solution, such as copper sulfate. These two electrodes are connected externally by an electrical circuit that allows electrons to circulate. Inside a liquid, electric current is transmitted by the movement of ions. The liquid thus provides an ionic electrical connection (Figure 9).

Figure 9 – Principle of a galvanic cell [3]

Figure 1 shows a cell in which the electrolyte is a sulfuric acid solution. Sulfuric acid is completely dissociated in water (since it is a strong acid) by forming H+ ions, which determine the acidity of the medium. The following electrochemical reaction occurs [3]:

- The zinc anode is oxidized:

Zn → Zn2+ + 2e−

H+ protons are reduced at the copper cathode:

2Н+ + 2e− → Н2

The complete reaction looks like:

Zn + H2O → Zn(OH)2 + H2

This cell produces electricity by consuming zinc, which is released as zinc hydroxide Zn(OH)2.

For the cell to operate, three conditions must be met simultaneously:

- two different metals that form two electrodes;

- presence of electrolyte;

- continuity of the entire electrical chain.

If any of these conditions are not met, for example if the electrical contact is broken, then the cell will not produce electricity and oxidation at the anode will not occur (nor reduction at the cathode).

Corrosion of aluminum and methods of its protection

Aluminum and its alloys are characterized by excellent resistance to various types of damage. However, despite this, corrosion of aluminum is not such a rare phenomenon. Various forms of corrosion represent the main cause of deterioration of these materials. To combat destructive processes, it is imperative to understand the factors that cause their occurrence.

Aluminum corrosion is a reaction that takes place between the metal and its environment. This process can be of either natural or chemical origin. The most common form of metal destruction is the appearance of rusting processes on its surface.

A special feature of all types of metals is their ability to react with water and the environment. The only difference for each type of metal is the intensity of this process. For example, for noble metals such as gold, the rate of such a reaction will not be too fast, but iron, including aluminum, will react to influences of this nature quite quickly.

Two factors can be distinguished that have a direct impact on the intensity of the corrosion process. One of them can be called the degree of aggressiveness of the environment, and the second is the metallurgical or chemical structure. The atmosphere that surrounds us is always characterized by a certain level of humidity. In addition, it is characterized by a certain level of pollution and waste.

If we consider that the properties of the atmosphere are often determined by the region and the degree of industrialization, today we can distinguish:

- rural areas (low pollution and average humidity);

- coastal areas (moderate pollution and high humidity);

- urban area (average level of humidity and average level of decay products of liquid fuel, sulfur and carbon oxides);

- industrial and industrial areas (large amounts of sulfur, carbon oxides and acids, as well as average humidity levels)

For most cases, inorganic acids, even at low concentrations, will be able to dissolve aluminum. And even a natural aluminum oxide film cannot provide sufficient protection against the occurrence of corrosive processes.

The most powerful solvents are fluorine, potassium and sodium. In addition, aluminum is characterized by rather low resistance to chlorine and bromine compounds. Lime and cement mortars are very aggressive to various aluminum metal alloys.

There are several types of corrosion of aluminum and its alloys:

- Superficial. This type of destruction occurs most often and is the least harmful. It is easiest to notice on the surface. This makes it possible to use safety precautions in a timely manner. Surface damage is very common on anodized profiles for construction.

- Local. Such damage appears in the form of shapes, depressions and spots. This type of corrosion can be of the surface or intercrystalline type. Destructions of this nature are especially dangerous because they are quite difficult to detect. Such corrosion very often destroys hard-to-reach parts of structures and assemblies.

- Thread-like or filigree. This type of aluminum failure often appears under organic-type coatings, as well as at the boundary surfaces of processing. Filament-like corrosion occurs at weakened areas of damaged organic coating or at the edges of holes;

Quite often, the natural anti-corrosion abilities of aluminum and its alloys are not enough to protect against destruction. And a long period of operation of products made from these metals will necessarily require the use of additional protection methods. The most common methods of protecting metals from corrosion include:

- anodizing oxidation (research by German specialists shows that this type of protection is used by 15% of the total production of building profiles in the world);

- coating of metal surfaces with powder compositions;

- protection against contact with other metals

Anodizing

Anodized coating is a coating that creates a durable aluminum oxide film on the surface of aluminum that is resistant to aggressive environments. This treatment makes it possible to create a layer of film on the surface of the metal that simply does not allow aluminum to come into contact with the external environment and protects it from oxidation processes.

Properties

Let's study the characteristics of aluminum. The described metal melts at a temperature of 659 degrees Celsius. The density of the substance is 2.69*103 kg/cm3. Aluminum belongs to the group of active metals. Resistance to corrosion processes depends on a number of factors:

- Purity of the alloy. For the production of various equipment, metal is taken that is distinguished by its purity. It should not contain various impurities. Aluminum grades AI1 and AB2 are widely used.

- Environment in which aluminum is located.

- What is the concentration of impurities in the environment surrounding aluminum.

- Temperature.

- The pH of the environment has a great influence. You need to know that aluminum oxide can form when the pH is in the range between 3 and 9. In an environment where an oxide film immediately appears on the surface of an aluminum sheet, corrosion processes will not develop.

Aluminum corrosion

Aluminum corrosion is the destruction of metal under the influence of the environment.

For the reaction Al3+ +3e → Al, the standard electrode potential of aluminum is -1.66 V.

The melting point of aluminum is 660 °C.

The density of aluminum is 2.6989 g/cm3 (under normal conditions).

Aluminum, although an active metal, has fairly good corrosion properties. This can be explained by the ability to passivate in many aggressive environments.

The corrosion resistance of aluminum depends on many factors: the purity of the metal, the corrosive environment, the concentration of aggressive impurities in the environment, temperature, etc. The pH of solutions has a strong influence. Aluminum oxide forms on the metal surface only in the pH range from 3 to 9!

The corrosion resistance of Al is greatly influenced by its purity. For the manufacture of chemical units and equipment, only high-purity metal (without impurities), for example, AB1 and AB2 aluminum, is used.

Corrosion of aluminum is not observed only in those environments where a protective oxide film is formed on the surface of the metal.

When heated, aluminum can react with some non-metals:

2Al + N2 → 2AlN – interaction of aluminum and nitrogen with the formation of aluminum nitride;

4Al + 3С → Al4С3 – reaction of interaction of aluminum with carbon with the formation of aluminum carbide;

2Al + 3S → Al2S3 – interaction of aluminum and sulfur with the formation of aluminum sulfide.

Corrosion of aluminum in air (atmospheric corrosion of aluminum)

Aluminum, when interacting with air, becomes passive. When pure metal comes into contact with air, a thin protective film of aluminum oxide instantly appears on the aluminum surface. Further, film growth slows down. The formula of aluminum oxide is Al2O3 or Al2O3•H2O.

The reaction of aluminum with oxygen:

4Al + 3O2 → 2Al2O3.

The thickness of this oxide film ranges from 5 to 100 nm (depending on operating conditions). Aluminum oxide has good adhesion to the surface and satisfies the condition of continuity of oxide films. When stored in a warehouse, the thickness of aluminum oxide on the metal surface is about 0.01 - 0.02 microns. When interacting with dry oxygen – 0.02 – 0.04 microns. When heat treating aluminum, the thickness of the oxide film can reach 0.1 microns.

Aluminum is quite resistant both in clean rural air and in an industrial atmosphere (containing sulfur vapor, hydrogen sulfide, ammonia gas, dry hydrogen chloride, etc.). Because sulfur compounds do not have any effect on the corrosion of aluminum in gas environments - it is used for the manufacture of sour crude oil processing plants and rubber vulcanization devices.

Corrosion of aluminum in water

Aluminum corrosion is almost not observed when interacting with clean, fresh, distilled water. Increasing the temperature to 180 °C does not have any special effect. Hot water vapor also has no effect on aluminum corrosion. If you add a little alkali to water, even at room temperature, the corrosion rate of aluminum in such an environment will increase slightly.

The interaction of pure aluminum (not covered with an oxide film) with water can be described using the reaction equation:

2Al + 6H2O = 2Al(OH)3 + 3H2↑.

When interacting with sea water, pure aluminum begins to corrode, because... sensitive to dissolved salts. To use aluminum in seawater, a small amount of magnesium and silicon is added to its composition. The corrosion resistance of aluminum and its alloys when exposed to sea water is significantly reduced if the metal contains copper.

Corrosion of aluminum in acids

As the purity of aluminum increases, its resistance to acids increases.

Corrosion of aluminum in sulfuric acid

Sulfuric acid (has oxidizing properties) in medium concentrations is very dangerous for aluminum and its alloys. The reaction with dilute sulfuric acid is described by the equation:

2Al + 3H2SO4(dil) → Al2(SO4)3 + 3H2↑.

Concentrated cold sulfuric acid has no effect. And when heated, aluminum corrodes:

2Al + 6H2SO4(conc) → Al2(SO4)3 + 3SO2↑ + 6H2O.

In this case, a soluble salt is formed - aluminum sulfate.

Al is stable in oleum (fuming sulfuric acid) at temperatures up to 200 °C. Due to this, it is used for the production of chlorosulfonic acid (HSO3Cl) and oleum.

Corrosion of aluminum in hydrochloric acid

Aluminum or its alloys quickly dissolve in hydrochloric acid (especially when the temperature rises). Corrosion equation:

2Al + 6HCl → 2AlCl3 + 3H2↑.

Solutions of hydrobromic (HBr) and hydrofluoric (HF) acids act similarly.

Corrosion of aluminum in nitric acid

A concentrated solution of nitric acid has high oxidizing properties. Aluminum in nitric acid at normal temperatures is extremely resistant (resistance is higher than that of stainless steel 12Х18Н9). It is even used to produce concentrated nitric acid by direct synthesis.

When heated, corrosion of aluminum in nitric acid proceeds according to the reaction:

Al + 6HNO3(conc) → Al(NO3)3 + 3NO2↑ + 3H2O.

Corrosion of aluminum in acetic acid

Aluminum is quite resistant to acetic acid of any concentration, but only if the temperature does not exceed 65 °C. It is used to produce formaldehyde and acetic acid. At higher temperatures, aluminum dissolves (with the exception of acid concentrations of 98 - 99.8%).

Aluminum is stable in bromic and weak solutions of chromic (up to 10%), phosphoric (up to 1%) acids at room temperature.

Citric, butyric, malic, tartaric, propionic acids, wine, and fruit juices have a weak effect on aluminum and its alloys.

Oxalic, formic, and organochlorine acids destroy metal.

The corrosion resistance of aluminum is greatly influenced by vapor and liquid mercury. After a short contact, the metal and its alloys intensively corrode, forming amalgams.

Remove carbon deposits

Cleaning oxides and carbon deposits is also quite simple. This will require funds and products that many people have in their homes. Moreover, such cleaning does not take much time and does not require serious effort.

- Aluminum is clarified using brine from cucumbers, fermented milk products such as milk and kefir. It is necessary to pour the available product into the dishes that need to be cleaned for half a day. Most often they leave it overnight so that you can simply wash the dishes in the morning. If you need to clean some objects from carbon deposits, they can be placed at the bottom of the container that was filled. Cleansing occurs thanks to the acids found in these products.

- A sour apple will help clear carbon deposits and remove oxidation. The fruit needs to be cut in half and rubbed onto the desired surface until shiny. The acid will corrode all dirt, and therefore, after rinsing with water, the item will shine.

- Contaminants can be removed using a saline solution. You need to take salt and water in equal proportions, and the first ingredient should be completely dissolved. Using a sponge, you need to apply the solution to the item that requires cleaning, leave it in this state for a while, and then rinse thoroughly with water.