(No rating)

Laying a bathroom with tiles is the best option today, and the home craftsman needs to drill tiles to install sockets, shelves, and so on. A circular drill for working with tiles, a spear-shaped drill or ordinary carbide drills are excellent assistants in this matter.

What types of drills are there for tiles and porcelain stoneware? What is the best drill bit to drill into tiles?

Drill bit for working with tiles

How to drill through tiles?

What tasks are most often pursued when drilling ceramic finishes:

- laying water pipes or other communications;

- installation of an electrical outlet;

- hanging shelves, mirrors, hooks and holders;

- heated towel rail insert;

- installation of a clothes dryer.

Before starting drilling, determine the type and quality of the tile. Density, strength, fragility, glaze characteristics and porosity of the tile - all these factors influence the outcome of the drilling process and the choice of tool.

But almost all types of tiles are characterized by one feature - a slippery surface from which the drill will constantly slide. Solving the problem is simple - just cover the working area of the drill with masking tape and get to work.

Another nuance is assessing the density of the tiles. Tap lightly on the facing surface. A dull sound will indicate the absence of voids in the coating - it can be drilled. If the sound is ringing, there are cavities in the tile, which, when drilled, can lead to breaks and chips.

General rules

Under the general name tiles lies a wide range of finishing materials with very different properties. First of all, you should pay attention to the presence of glaze and firing temperature. If the finishing material was fired at a high temperature, 1200˚C or higher, then it has increased strength and will be more difficult to verify. This applies to porcelain stoneware and Metlakh tiles.

In any case, adhere to the following settings:

- The rotation speed of the drill should not exceed 800 rpm. Exceeding this speed has an almost linear effect on the probability of tile breakage;

- Use only special drills;

- Don't try too hard. The pressure on the tool should be even, without jerking or impact;

- “Wet drilling” is preferable to dry drilling, as it avoids local overheating.

- When drilling, be sure to place the tiles on a flat, horizontal surface. The best option is to lay a piece of drywall or plywood.

- Always drill from the front side of the tile. It is easier to center the drill on the reverse side, but when exiting there will almost always be chips in the glaze.

Compliance with the requirements of only these six points guarantees an excellent result by 90%.

What is required for processing?

The best option for working with ceramic tiles would be a corded or cordless screwdriver. Its high rotation speed (800-1000 rpm) allows you to easily handle tile processing. An alternative to a screwdriver is an electric drill, or a manual modification if you have to drill a small hole.

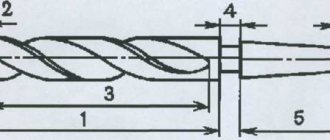

Selecting a drill and auger

When the unit is prepared, all that remains is to choose the type of nozzle aimed at solving certain problems:

- Diamond coated drills. They give the best results for drilling even very hard tiles, but due to their high cost, it makes sense to use them only for a large volume of work.

- Drills with a tip made of pobedit. They work well with soft tiles and medium-hard tiles. It is recommended to drill ceramic tiles on the wall using so-called feather drills - they have a small sharpening angle that does not allow damage to the tile glaze.

- Spear drills. Suitable for laying dowels, they have a low price and an enviable service life.

- Single-sided sharpened carbide drills. These attachments reduce the risk of overheating and make working with very fragile and thin tiles easier.

- Core drills with tungsten carbide coating. Universal components that can easily cope not only with the most durable tiles, but also with marble, brick and porcelain stoneware.

Diamond core drills require periodic cooling with water, and work with them at low speeds - no higher than 500 per minute.

What else can I drill?

If you need to get a hole of a large diameter, a drill with adjustable teeth - the so-called ballerina - will come to the rescue.

The device can drill holes up to 9 cm in diameter, including non-standard shapes for which there are no suitable crowns. But due to the manually moving bracket, the edges of the hole are uneven. Therefore, it is advisable to use a ballerina in cases where the perforation will be covered with something.

Another option for work is a Pobedit concrete drill. Since the tip is not intended for working with tiles, its cutting part is sharpened as sharply as possible, and during the drilling process maximum care is taken so as not to damage the coating.

Cuttings with cutting disc

The tile must be fixed on a soft, thick base, for example, on a wooden block. The reason is that the disc will come out from the back side by 5-7 mm. With this immersion depth, it is possible to trim the edges of the hole more accurately.

The gap between each slot is 3-4 mm.

The cuts are made crosswise. In this case, most of the jumpers will fall off on their own. The protrusions remaining at the edges are broken off with wire cutters or pliers.

The edges do not need to be processed if they will be covered with decorative panels or overlays.

Drilling technique

The purposes of drilling tiles can be very different - from creating a small hole for a screw to drilling an entire circle for a pipe or socket.

Large holes

The best option for creating capacious perforation is to use a ballerina with a tip of the required diameter. It is recommended to first practice on waste tiles in order to “feel” the tool. If a ballerina is not at hand, a hole saw will come to the rescue, which even an owner inexperienced in construction can successfully handle.

Another method of drilling step by step:

- Mark the center of the planned hole and draw a circle of the required diameter.

- Using any tile drill, make several holes along the diameter of the circle, trying to place them close to each other.

- The drilled sectors are carefully pressed, and the remaining pieces are removed with wire cutters.

- The edges are sanded to give the correct shape.

Small holes

Step-by-step instruction:

- Marks are placed on the surface of the ceramic for the hole.

- To prevent the drill from slipping, stick masking tape or lightly chip off the enamel in the center of the future hole.

- Disable the impact mode function on the drill and connect the device to the network.

- Place the drill at an angle of 90° to the tile and start drilling at low speed.

- Gradually the speed is increased, punching the tile to the very base.

- Change the drill to a new one, suitable for the type of wall base (concrete, brick, wood) and continue drilling to the required depth.

The diameter of the second drill should not exceed the size of the first, otherwise the tile will be damaged.

FAQ

Is it possible to use an impact tool (drill, hammer drill) when drilling tiles?

Do not use a hammer when drilling tiles. A quick blow will cause the tile to crack in almost all cases. Make sure you apply even pressure on the drill, and before you know it, you'll have made a hole. Large diameter holes can be made in ceramic tiles using diamond tipped saws.

How can I tell if my tiles are ceramic or porcelain?

The easiest and fastest way to tell ceramic tiles from porcelain tiles is to look at the edge. Ceramic tiles, whether floor or wall tiles, have a glaze on the surface that gives them color and finish. Porcelain tiles can be glazed, but most often they are not.

Is it possible to drill into the grout between the tiles?

When drilling through grout, use a wall anchor. ... For drilling tile and grout, a slow pace works best, so set your drill to 100-200 rpm. Place the drill on the mark and carefully begin drilling. Hold your hand firmly and do not allow the drilling angle to change.

What are carbide tipped drills made of?

Carbide drills are made from tungsten carbide, although they often contain small amounts of other materials, such as cobalt, to reduce their reactivity with iron. Typically, carbide drill bits can be found in one of two forms: carbide tipped or solid.

What are diamond tipped drill bits made of?

These drills contain real diamond powder, pressed into steel using very high pressure. Diamond, being the hardest substance, retains its powerful cutting ability after this process, and drill bits come in different sizes.

How to drill ceramics to install dowels?

A dowel is a fastening device used to create blind holes in surfaces, as well as in cases of hollow walls. On the tile, the dowel will securely hold a mirror, shelf or any other not too bulky accessory.

Distinctive features of drilling

The difficulties in installing dowels are similar to standard drilling into tiles. They consist in increased smoothness of the coating, which can interfere with reliable stop and installation of the drill. In addition to the methods of reducing slip described above (painting tape and removing glaze), you can use a jig.

This device is a wooden or metal plate with holes of different diameters. The size of the hole is selected based on the dimensions of the dowel. They drill very carefully, because at the same time you have to hold both the jig and the screwdriver, and also control the quality of the drilling.

Which drill to choose?

Brick and concrete drills are definitely not suitable for installing dowels - they can destroy and damage the tile cladding. As a result, you will have to re-lay the problem area. Tiers recommend purchasing special drills with a spear-shaped tip for such purposes.

Among the materials, devices made from pobedite remain the most affordable - they are bought more often than others due to their low cost. Ask the seller for a Pobedit drill bit for tiles - it works as accurately as possible.

Operating procedure

Algorithm of actions:

- Secure the tiles from slipping using masking tape or adhesive tape.

- Using a marker or felt-tip pen, mark the center of the hole in the form of a cross.

- Prepare a drill of the selected type and diameter, insert it into a drill or screwdriver.

- Drill the tiles at low speeds, increasing speed as you go.

- When the drill touches the wall, turn off the drill and change the drill to a regular drill (for concrete or brick) of the same diameter.

- Drill the hole to the intended depth, focusing on the length of the dowel.

- Clean the recess from dust and insert the dowel

To prevent the drill from swaying during the drilling process, craftsmen use a special work tripod.

Tile drill bits

Products found: 18

Available from pick-up warehouse

Product type: Drill; Purpose: On tiles, On glass; Brand: No name; Shank type: Cylindrical; Diameter: 6; Length: 75; Packing: 1; Country of origin: Netherlands; Weight: 0.01;

Available from pick-up warehouse

Product type: Drill; Purpose: On tiles, On glass; Brand: Practice; Shank type: Cylindrical; Diameter: 6; Length: 72; Packing: 1; Country of origin: China; Weight: 0.014;

Available from pick-up warehouse

Product type: Drill; Purpose: On tiles, On glass; Brand: KM/Shaft; Shank type: Cylindrical; Diameter: 6; Length: 65; Packing: 1; Country of origin: China; Weight: 0.02;

Available from pick-up warehouse

Product type: Drill; Purpose: On glass, On tiles; Brand: KM/Shaft; Shank type: Cylindrical; Diameter: 8; Length: 70; Packing: 1; Country of origin: China; Weight: 0.04;

Available from pick-up warehouse

Product type: Drill; Purpose: On glass, On tiles; Brand: Bosch; Shank type: Cylindrical; Diameter: 6; Shank diameter: 4.1; Length: 80; Packing: 1; Country of origin: China; Weight: 0.021;

Available from pick-up warehouse

Product type: Drill; Purpose: On tiles, On glass; Brand: Bosch; Shank type: Cylindrical; Diameter: 8; Shank diameter: 5.6; Length: 80; Packing: 1; Country of origin: China; Weight: 0.028;

Available from pick-up warehouse

Product type: Drill; Purpose: On glass, On tiles; Brand: Practice; Shank type: Cylindrical; Diameter: 8; Length: 80; Packing: 1; Country of origin: China; Weight: 0.025;

Available from pick-up warehouse

Product type: Drill; Purpose: On tiles, On glass; Brand: KM/Shaft; Shank type: Cylindrical; Diameter: 10; Length: 120; Packing: 1; Country of origin: China; Weight: 0.05;

Available from pick-up warehouse

Product type: Drill; Purpose: On tiles, On glass; Brand: Practice; Shank type: Cylindrical; Diameter: 10; Length: 90; Packing: 1; Country of origin: China; Weight: 0.042;

Available from pick-up warehouse

Product type: Drill; Purpose: On tiles, On glass; Brand: Bosch; Shank type: Cylindrical; Diameter: 10; Shank diameter: 6.1; Length: 90; Packing: 1; Country of origin: China; Weight: 0.028;

Available from pick-up warehouse

Product type: Drill; Purpose: On tiles, On glass; Brand: Practice; Shank type: Cylindrical; Diameter: 12; Length: 100; Packing: 1; Country of origin: China; Weight: 0.066;

Available from pick-up warehouse

Product type: Drill; Purpose: On tiles, On glass; Brand: Practice; Shank type: Cylindrical; Diameter: 5; Length: 67; Packing: 1; Country of origin: China; Weight: 0.013;

Available from pick-up warehouse

Product type: Drill; Purpose: On glass, On tiles; Brand: Bosch; Shank type: Cylindrical; Diameter: 4; Shank diameter: 3.3; Length: 70; Packing: 1; Country of origin: China; Weight: 0.014;

Available from pick-up warehouse

Product type: Drill; Purpose: On glass, On tiles; Brand: Bosch; Shank type: Cylindrical; Diameter: 12; Shank diameter: 8; Length: 90; Packing: 1; Country of origin: China; Weight: 0.044;

Available from pick-up warehouse

Product type: Drill; Purpose: On glass, On tiles; Brand: Bosch; Shank type: Cylindrical; Diameter: 5; Shank diameter: 4.1; Length: 70; Packing: 1; Country of origin: China; Weight: 0.02;

Available from pick-up warehouse

Product type: Drill; Purpose: On glass, On tiles; Brand: Bosch; Shank type: Cylindrical; Diameter: 14; Shank diameter: 8; Length: 90; Packing: 1; Country of origin: China; Weight: 0.04;

Available from pick-up warehouse

Product type: Drill; Purpose: On glass, On tiles; Brand: Bosch; Shank type: HEX (hex) (1/4 HEX); Diameter: 4-10; Working length: 45; Packing: 5; Weight: 0.793;

Available from pick-up warehouse

Product type: Drill; Purpose: On tiles, On glass; Brand: Bosch; Shank type: Cylindrical; Diameter: 16; Shank diameter: 8; Length: 90; Packing: 1; Country of origin: China; Weight: 0.04;

Useful tips

- You cannot press the tool with great force - the application of force should be moderate so as not to break the tile.

- Drilling tile joints is only permitted if the diameter of the hole does not exceed the width of the joint.

- To work with tiles, choose a drill with smooth speed switching.

- If the tiles are very fragile, use a hand drill, which creates minimal vibration.

- It is convenient to mark the point for drilling using a stationery proofreader. The liquid will make the surface rough and improve the adhesion of the tiles.

- Glass drills are suitable for processing ceramic tiles.

Working with a ballerina

The sequence of actions is similar to the previous point, but to reduce vibration, it is better to reduce the speed to 400 per minute.

IMPORTANT: the drill must be held strictly at an angle of 90˚ . You can determine whether you are maintaining the correct angle at the moment the cutter touches the surface of the tile. If the cutter strikes only along one edge of the circle, then there is an inclination. And an incorrect angle increases vibration.

Please note that the larger the diameter of the hole drilled by the ballerina, the stronger the vibration will be!

How to drill without cracking the material?

You can avoid breaks and cracking of tiles by following several recommendations:

- Do not use an electric drill at speeds above 1000 rpm.

- If you need to drill into ceramics that have not yet been laid on the wall, soak them in a container of water for 60 minutes.

- Before you start drilling, make sure that the hammer function is turned off on the device.

- Practice on an unnecessary piece of tile to choose the optimal operating mode for the screwdriver and the pressure force.

- Do not put the unit in reverse mode.

- When drilling close to the edge, it is better to move the drill bit into the joint, otherwise it will slide off the edge of the tile.

- Start drilling at low speeds and gradually increase speed.

And finally, it is worth mentioning personal protection measures - eye and respiratory safety. During drilling, pieces of glaze and dust fly off the tiles, so do not neglect such basic means as glasses, gloves and a mask.