Connections using electric welding today are widely used in many areas of the national economy: in construction, electrical engineering, automotive industry, shipbuilding, aircraft construction, machine tool industry, etc. To ensure high productivity and efficiency of welding operations, it is necessary to use not only high-quality welding machines, but also reliable components - welding cables, cable connectors. One of the most popular among Russian consumers are welding cables and cable connectors of the Esab brand.

general information

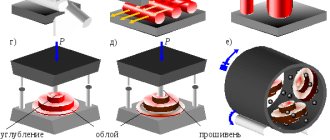

A bayonet connection (aka bayonet connection) is a type of connection, the diagram of which is shown below. This type of connection is made by moving the plug relative to the connector until the plug fits into the groove. To disconnect the two wires from the bayonet mount, you need to turn the plug in the opposite direction.

Bayonet connection diagram

To use such connectors, you need a plug for the welding device and a socket. The plug is often simply called a cable connector or "male", while the female is called panel connectors. Bayonet type cables can be used to connect a cable to a welding machine and to connect two cables to each other.

The bayonet connection is used in many areas. You will find bayonets at a fire station where fire hoses are connected in a similar way. Mounts are also used to connect lenses to the camera body. This mount is somewhat different from the one described above. Because it has a number of additional levers and grooves. But the essence remains the same.

In the welding field, bayonets are used to connect two cables or a cable to a machine for high-frequency current transmission.

Welding cable connector

Cable connectors (cable connectors, bayonet connectors, plugs, quick connectors) are used to easily and quickly connect a cable to a power source or to extend a wire. Special connectors make welding equipment more mobile and significantly expand its capabilities.

The choice of connector depends on the cross-section of the conductor . The most common are connectors with a cross-sectional area of 10...25; 35; 50; 70; 95 and 120 mm2. Since welding cables and COGs of the appropriate mark sizes are the most popular.

You should consider the plug for the welding cable and its structure in more detail. The working part is made of brass, has a square profile, on one side there is a hole for the cable. Another main part is a rubber coupling , which has a conical shape on the cable side. Also included is a copper sleeve .

The wire is first inserted into the coupling from the conical side, then into the sleeve, and then into the brass body. The cord is fixed using a screw, which should be tightened, which will help secure the cord.

To demonstrate this process, we present a video to your attention.

The following types of cable connectors :

- pin ( male , plug for welding cable, insert) installed on the cable;

- in the form of a socket ( “female” ) is also installed on the cable and is a mating part for the plug.

What the welding cable connector of each type looks like is shown in the pictures.

special sockets are installed on it , which experts call differently: panel socket (“chip”, “female”), it is installed on the front panel of the welding machine, and is the mate for the cable plug. There are two types of sockets: for cables with a cross-sectional area of up to 25 mm2, for cables of 35-50 mm2.

design includes the following elements: a brass bushing with internal and external threads, a plastic insulating flange, a fastening ring, a nut, a bolt and two lock washers.

The 35-50 mm2 welding cable plug is more popular, since it can be used to perform work on any equipment, regardless of the manufacturer. There are cable connectors (welding cable plug) on the market from Russian and foreign manufacturers. These products have certificates and are characterized by high quality.

Basic information

I won't hide it. I myself didn’t quite understand what it was and why anyone would even need to buy such a connection for a hose, an 8mm tube, or even for a welding machine or for a Schmitz semi-trailer.

Not exactly the format of our site, but the issue requires consideration. Moreover, the plug according to din 72585 and other similar bayonet connections can be found in ordinary passenger trailers, on MAZ and KAMAZ trucks and semi-trailers.

Therefore, let's start with the simplest. Namely, what it is and what is wrong with standard type fixation. You have already studied the historical information, so in the future it will be easier for you to understand the essence of the issue.

Bayonet connectors are a special type of connection between parts, where there is necessarily a factor of axial movement of one of the connected components relative to the other. In the role of movement, rotations or lateral displacements are used. Bayonet connectors are also called bayonet connectors or bayonet connections.

BRs are widely used in connectors when installing local networks and in other cases when it is necessary to create the strongest possible connection. This fastening method has replaced the usual threaded connection. The new solution turned out to be easier and faster to implement, so it is gradually gaining rapid momentum in popularity.

Design features

Interestingly, the mount can be either two-pin or even 35-pin. Any of them is actively sold in Russia, Ukraine, and is in demand in European countries and beyond.

This is not just an automotive connection method. It is also actively used in electrics, in welding machines, cameras, etc. The wide distribution of the bayonet mount is extremely easy to explain. This is a simple, fast and universal solution.

The following are used as a lock for the bayonet connector:

- special sector grooves;

- electrical contacts;

- mechanical levers.

With their help, such a high-quality, durable and reliable connection is created.

The principle of bayonet fixation has been successfully used to connect cables, including coaxial, and optical connectors.

Historical reference

To begin with, I propose to look into the past and move to France for a while. After all, this is where the concept of a bayonet or bayonet connection came from.

Initially, this was the name given to piercing-type bladed weapons used by the French military. Literally translated, this is a bayonet. It was adjacent to the barrel of the firearm.

This bayonet was invented around the middle of the seventeenth century in the city of Bayonne. Hence the name of the device. Such knives were inserted into gun barrels using a handle. In Russia, the bayonet was better known as a baguinet.

From here the principle of connection was subsequently borrowed. The quick-release connection actually consisted of two components - a bayonet and a receiving socket on the gun. Due to a special shaped slot, the bayonet was inserted into a socket where there was a corresponding protrusion. The part was rotated, as a result of which the protrusion did not allow the bayonet to move.

A simple but very reliable fastening was a success. Now we can observe it in much more peaceful areas of application than weapons.

Specifications

| Name | Current (A) | Cable (mm2) | ø installed |

| ABI-CM 10-25/ABI-IF 10-25 oder ABI-CF 10-25/ABI-IM 10-25 | 125 | to 10 | 20.5mm |

| ABI-CM 10-25/ABI-IF 10-25 oder ABI-CF 10-25/ABI-IM 10-25 | 150 | 10 – 16 | 20.5mm |

| ABI-CM 10-25/ABI-IF 10-25 oder ABI-CF 10-25/ABI-IM 10-25 | 200 | 16 – 25 | 20.5mm |

| ABI-CM 35-50/ABI-IF 35-50 oder ABI-CF 35-50/ABI-IM 35-50 | 250 | 25 – 35 | 30.5mm |

| ABI-CM 35-50/ABI-IF 35-50 oder ABI-CF 35-50/ABI-IM 35-50 | 300 | 35 – 50 | 30.5mm |

| ABI-CM 50-70/ABI-IF 50-70 oder ABI-CF 50-70/ABI-IM 50-70 | 400 | 50 – 70 | 30.5mm |

| ABI-CM 70-95/ABI-IF 70-95 oder ABI-CF 70-95/ABI-IM 70-95 | 500 | 70 – 95 | 30.5mm |

Online order →

Advantages and disadvantages

The advantages of the contact bayonet mechanism are characterized by the following positive factors:

- security;

- reliable and fast articulation;

- high resistance to breakdowns due to the oil-gasoline-resistant and heat-resistant rubber shell, which serves as high protection for installations when using argon arc or plasma welding;

- simple installation, providing optimal fastening with good current transmission;

- suitable for equipment from all manufacturers;

- Can be used in metal or plastic cases;

- Cable performance conditions comply with European standards EN 60974-12.

The latter are designed to support reliable and safe high frequency current connections in the arc welding industry.

However, even the best device has its drawbacks. The mount has two of them:

- High cable price. For resellers it ranges from 80 to 420 rubles. The justification for this cost is reliability and convenience.

- Advertising brochures promise compatibility of the bayonet contact with units from any manufacturer. However, the electrode holder or the welding unit itself may be of an outdated design, where connecting a bayonet mount is impossible. In the latter case, either the failure of a new cable or the purchase of additional adapters is required.

Welding cable terminal

The grounding terminal (ground clamp) is designed to ensure safety during welding work. The following main types of clamps , depending on the type of fixation: “crocodile” (“clothespin”), clamp, centralizer and magnetic mass.

Each type has a whole range of design features, as well as advantages and disadvantages.

The most convenient to use is the last type; magnetic contact can be used when welding any products and structures. Find out more : about the ground clamp of the welding machine here.

Magnetic contact welding cable

The magnetic contact of the welding ground cable is designed for easy and quick connection of the wire to the workpiece. This device provides high quality work. A powerful magnet serves for reliable fastening, while eliminating its welding to the main part. This device must be periodically cleaned of dirt.

More detailed information is presented in the article “Mass Clamp” (see link above).

This article will help you understand what the main devices for welding are.

Tip Installation: Process Principles

Since it is correct to connect a welding cable using lugs, this procedure is most often performed to lengthen and create a convenient shape for the end of the conductive core necessary for connection to the clamp of the device.

To do this, you need to strip and treat the wire with paste, place the tip on the end of the cable and press it until it stops. After this, the product should be crimped using tongs or a matrix press. To increase the mobility of the welding machine, you can extend the wire using different connection technologies. Our specialists recommend using connectors selected according to the cross-section and composition of the core bundle, observing the sequence and rules of the method used. To purchase electrical components, you need to go to the catalog. If difficulties arise with the choice, our manager will provide professional advice.

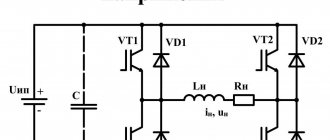

Socket for welding machine 220V

» Articles » Socket for welding machine 220V

An inverter is a technique that significantly loads the wiring. Thoughtless connection can leave you and your neighbors without electricity or lead to more serious consequences. Let's briefly discuss the question of how to properly connect an inverter? Summer is the time for construction work at the dacha, at home, which means there is a need for welding work. Considering the fact that prices for inverters have decreased significantly in recent years (now you can buy an inverter with decent characteristics for only 6,000 rubles), such devices are now available to almost everyone, which means that everyone can cope with the necessary welding work independently, without involving outside help. When starting work, a person who has never worked with an inverter must ask himself the question of how to properly connect the inverter to a 220V network. As a rule, the passport for a welding machine indicates the time of uninterrupted operation, that is, the time intervals for welding and rest are specified, but there is very little information about how to properly connect it to a home outlet. First of all, determine the type of electrical outlet. An inverter operating at a maximum output current of 140A can be easily connected to a 16A outlet. Before connecting, carefully study what wiring and sockets are installed in your home. Older outlets are rated at 10A and usually come with the appropriate wiring. Look at your traffic jams or automatic machines, the presence of bugs. Please note that if an overhead power line is connected to your house, the welding machine can load it so that the voltage drops below 150V, and this will leave both you and your neighbors without light (here you are especially at risk when welding with a transformer). The average length of the inverter network cable is 2 m. You have to use extension cords. Remember that reckless use of extension cords is dangerous. When choosing an extension cord, remember that an extension cord with a wire cross-section of 1.5 square meters. a millimeter is designed for a current of up to 16A, an extension cord with a cross-section of 2.5 is designed for a current of up to 25A. Choose extension cords with a medium cross-section of wire.

In what cases is a connection needed?

Inverters for welding are equipped with short wires, which creates difficulties when performing work at heights and in hard-to-reach places. Connecting welding cables using soldering, welding or installing special connectors expands the capabilities of the equipment and eliminates the need to hold it on the shoulder. When carrying out this task, it must be taken into account that the maximum length should not exceed 30-40 m.

Common connection methods

Before connecting the welding cable using the crimping method, you must purchase aluminum or copper sleeves. You can select products in the catalog. There is a wide range of connectors, components and other electronic components - cables, assemblies, printed circuit boards - of high quality and affordable cost.

Soldering is the second popular method of connecting copper cables. It involves coating the preheated ends of the cores with molten solder. After hardening of the latter, high strength and good electrical conductivity of the product are achieved. This technology is suitable for conductors of small cross-section.

The main advantages of soldering are simplicity and cost-effectiveness. Preparatory activities include:

- getting rid of isolation

- twist,

- cleaning,

- flux treatment.

After soldering, it is necessary to wash off the residues, apply varnish, insulation in the form of tape or shrink film.

Important! The intermediate stage of soldering is twisting the wires. As an independent method, it is prohibited by the regulatory documents of the PUE.

Since welding allows you to connect 2 large-diameter welding cables into a monolithic structure, this method is often used. To connect the wires, a special device VKZ-1, similar to a pistol, is used. The advantages of the method are high contact strength, resistance to mechanical stress, the disadvantages are the need to strip the wire by 10 cm, the difficulty of choosing the current strength, the impossibility of separating the elements.

Arguments:

- Complies with EN 60974-12 standard

- High breakdown strength when used in TIG and plasma welding

- High security

- Fast and confident connection

- Comparable to connectors from other manufacturers

- For installation in metal and plastic housings

- Highest degree of torsion protection thanks to the ABICOR BINZEL square design (see illustration)

What are the types of residential modules for a passenger car?

- the ability to obtain an ideal connection between the current source and its consumer;

- perfect safety of contact between components;

- an elementary joining process, accompanied by the most durable and reliable fixation;

- high-quality current transmission (especially relevant for use in the field of welding equipment);

- compliance with the most stringent international standards and quality requirements.

As you can see, another military invention was continued in civilian peaceful life. But the fact remains a fact. Again, military cunning, there is no other way to call it, turned out to be useful and convenient in everyday life.

I hope you were able to understand with me the issue of the features and purpose of the bayonet connection. In essence, this is a special durable clamp of a special design that allows you to combine different components to ensure reliable and high-quality fixation.

Otherwise, this is a thing for wide use. Bayonet mounts are used everywhere. It is difficult to find an industry where bayonet connectors have not been at least partially used.

Thank you all for your attention! As usual, don’t forget to subscribe, leave comments, ask questions and invite your friends!