How to replace soldering acid at home?

Soldering acid is one of the most popular types of fluxes when it comes to using it in complex work, that is, when soldering metals that are difficult to process.

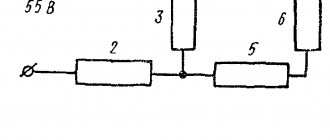

It is characterized by a high degree of aggressiveness, due to which it does an excellent job of removing fatty films, oxides and other types of contaminants from the surface before soldering. In addition, the acid ensures the formation of a protective film that prevents the negative effects of environmental factors on the metal. However, when working with simple connections, especially in cases where thin metal elements are used, it is better to avoid using soldering acid. The danger is that it can simply corrode the metal, so sometimes it is better to look for another flux option.

It is extremely important to pay attention to the concentration of soldering acid, since it can be sold in concentrated and diluted forms. For each specific case there must be a solution of suitable strength so that there are no negative consequences.

The use of excessively concentrated acid for soldering is strictly prohibited. If you do not have a solution of the required concentration on hand, you should take care to bring it to the required parameters, or use another substance that has similar properties.

Content:

- Why does it occur

- Signs

- How it proceeds

- Features of the development of periostitis in children and adults

- What happens if you don't undergo therapy?

- How to remove flux

- How to speed up recovery

- Preventive actions

An inflammatory dental disease that affects the periosteum tissue is called periostitis by dentists.

It is popularly known as flux. It is easy to recognize on your own - a painful abscess forms on the gum, which does not go away for a long time. It is unwise to fight this disease without medical help. When it appears, you should definitely make an appointment at a dental clinic and, during an in-person examination, find out from the doctor how to remove the flux without negative consequences for health.

It is simply impossible to ignore periostitis. It is usually accompanied by acute throbbing pain. Sometimes it can even lead to fever and a sharp decrease in performance. When there is a lot of pus in the “bag”, it bursts. Then the purulent masses flow out, and the symptoms cease to be so bright.

Negative points

- Due to the excessively aggressive environment, it is impossible to work with thin parts.

- Direct contact with human skin can lead to extremely serious consequences, since the acid can corrode not only the skin, but also muscle tissue.

- The acid has an extremely unpleasant odor, and the vapors released when using the substance are extremely harmful to the respiratory system.

What happens if you don't undergo therapy?

It is unacceptable to treat purulent gum lesions as a minor dental disorder. It is very insidious and rarely disappears without a trace on its own. Often, if treatment is refused, the following occurs:

- Abscess. It is a consequence of a long-term presence of a pus-filled sac in the area of the tooth root. The abscess grows and then ruptures.

- Phlegmon. Represents an extended lesion. It usually occurs after a rupture of a purulent sac, if the patient does not comply with the dentist’s instructions, does not rinse the mouth with a special antiseptic solution, or apply anti-inflammatory gels.

- Osteomyelitis of the jaw. It occurs if the gums are not treated for a very long time. The pathological process spreads to the jaw bone, which is very dangerous.

- Inflammation of individual sinuses of the skull. It is also diagnosed with advanced periostitis. The maxillary, frontal and sphenoid sinuses are affected.

It is extremely rare that the disease affects brain tissue. Then the person may even die.

What can soldering acid be replaced with?

There are not many substances that can be considered as an alternative to this acid. Some of them can be prepared at home without any problems, although it is not always possible to obtain the desired properties.

One of the simplest and most accessible substances that can be used instead of soldering acid is an aqueous solution of ordinary aspirin. To obtain it, you just need to take a tablet, crush it to dissolve faster, pour it into a container of water and mix thoroughly until not a single solid particle remains. The use of the resulting solution is similar to other types of flux. The undoubted advantage of such a substance is its absolute harmlessness and safety.

You can also use citric or acetic acid, but they are not as effective as soldering acid. They are sold already in diluted form, so no additional manipulations with them are required.

Another option is concentrated hydrochloric acid. It is one of the main components of the original flux, but can also be used to make soldering acid at home. Due to its high aggressiveness, it allows you to efficiently get rid of a wide variety of types of contaminants and guarantees reliable protection. However, it is hazardous to health and can corrode thin elements, so these aspects should be taken into account when soldering.

Active solder grease has proven itself well, and copes well with contaminants. Also, its undoubted advantage is ease of use and ease of placement on the surface of the product. However, like soldering acid, it is a highly aggressive substance that poses a danger to human health and is not recommended for use with thin metal products.

A worthy alternative to soldering acid is phosphoric acid. It is easy to use, affordable, copes well with oxide, grease and other films and deposits, but is gentle on metals.

If you don’t have the original soldering acid on hand, you can prepare a replacement for it at home. Of course, it will not have such a rich cast, but it will still cope well with the tasks assigned to it.

How it proceeds

The disease progresses through several successive stages:

- Acute serous. Spreads quickly. In just two or three days, a large, painful “bump” forms, with pus inside. The cheek tissues swell.

- Acute purulent. The pain becomes more pronounced, the person feels an unpleasant pulsation. The mucous membrane in the area of the affected unit turns red and swells. Body temperature rises.

- Acute diffuse. The swelling becomes voluminous. It can go under the eye or onto the nose. The patient's appearance changes significantly for the worse.

- Chronic. The painful process fades away and is replaced by a chronic one. The patient may mistakenly think that the problem has disappeared without a trace. In fact, it only calmed down for a while. Periodically, the disease will recur.

The sooner a sick person consults a doctor, the higher his chances of a speedy recovery.

Improvised means for replacing rosin

Any soldering can be successful only if all requirements for the procedure are met. One of the main conditions is to use a multicomponent flux or regular rosin.

There are a sufficient number of ready-made products on sale. Rosin is considered the most affordable and popular. It happens that the material is not at hand, but something needs to be soldered urgently.

We have to figure out what can replace rosin without compromising the result of the work. Fortunately, a large number of special fluxes are produced, and in addition to them, you can use improvised means.

Material requirements

Any flux is designed to remove oxide deposits on metal parts, prevent oxidation during soldering, and improve the distribution of solder mass in the work area.

Rosin copes with the task successfully. The connections are high quality and durable.

When thinking about how to replace rosin at home, you should remember the need to perform all functions with solder.

The replacement must meet a number of the following requirements:

- have a low melting point and low density;

- melts well with a soldering iron;

- do not spread outside the working area;

- effectively dissolve oxides;

- evenly distributed over the surface;

- do not react with metal parts and solder;

- can be easily removed upon completion of work.

Flux decomposition products, together with dissolved oxides, should be easily pushed out of the weld formation zone by the solder melt.

Natural light yellow rosin, similar to a glassy mass, is ideal. Experienced craftsmen suggest what can replace it.

Fat, resin, amber

Animal fat melts well and is distributed on the surface.

Any fat, both food and industrial, will do. Odors during work are unpleasant, but they can be tolerated for some time without ventilation.

Many craftsmen, especially those living surrounded by forests, use ordinary tree resin. It melts easily and spreads well over the surface of the working area.

There are positive reviews about the use of spruce and pine resin. It is collected in ordinary tin cans, crushed as much as possible, and then slowly melted in a water bath.

The melt must be constantly stirred, removing needles and wood particles from it. This material is as close in composition as possible to rosin. Therefore, you can replace it in this way without any problems.

To solder iron, it is recommended to dissolve wood resin in food vinegar. Please note that you cannot use essence or concentrated acetic acid.

Amber is very suitable for use as a flux. The advice is acceptable for residents of regions where amber is mined. For everyone else, it is difficult to replace rosin with amber. The price is too high.

Aspirin and battery electrolyte

Many experts consider the most affordable option to be the use of pharmacy aspirin.

Please note that it will not be possible to replace rosin with effervescent tablets. They contain fillers (sodium compounds) that are not needed for soldering. Therefore, the most common simple aspirin is used.

The tablets should be crushed to a powder and dissolved in water or regular wine-vodka alcohol. You can use cologne as a solvent.

Acetylsalicylic acid dissolves well. Its properties are often sufficient to clean the surface and remove dirt. It can replace rosin without difficulty.

The inconvenience is the need to work under a ventilation hood or in a ventilated place. Solders without rosin with aspirin release sharp-smelling, harmful gases when heated. It is not necessary and impossible to breathe them.

If aspirin is not available, it is recommended to replace rosin with electrolyte from a used salt battery. It is important that it is not alkaline.

Non-standard methods

If there is no rosin nearby for soldering, you can use material for rubbing bows.

It's better cleaned. All properties are saved. The cost of replacement will be significant. Savvy craftsmen who have solders with flux suggest soaking it in alcohol and waiting until the rosin has completely dissolved. It takes a little time.

They say that such an alcoholic extract can successfully replace rosin. The alcohol component will gradually evaporate. The solid component meets the requirements for fluxes.

When working with old equipment, you can replace rosin with residues in places of old soldering. You need to touch the wire and soldering iron there and make a connection. This method is acceptable for extreme situations with not very high requirements for seams.

Acids with stearin

It happens that there is nothing suitable for replacement nearby.

Then any acid except concentrated sulfuric and nitric acid is suitable for removing oxides. To prevent oxidation of the metal, you can thoroughly clean it and the solder, then coat them with stearin. Stearin (paraffin) can be taken from candles.

Before applying a protective layer to the metal, stearin must be melted without overheating. The protective layer will prevent contact with oxygen. Soldering should be carried out under the stearin layer.

Some craftsmen, in order to replace rosin, spread the well-known BF-6 glue onto the cleaned metal surface. In this case, you need to solder while pressing the soldering iron firmly.

The above methods are a “first aid” for a solderer. In unexpected situations, a way out can always be found using simple and accessible means. But still, for the quality of soldering, it is better to use special tools.

Requirements for fluxes

To improve the soldering of parts and the quality of the resulting connection, as well as to clean the surface from oxide film and grease, various fluxes are used. Any flux used in the work must meet the following requirements:

- The melting point should be lower than the melting point of the solder. This is the main condition for high-quality connection of parts.

- Should not react with solder.

- It should ensure good spreading of solder over the surface and wet all workpieces.

- Must remove and destroy all oxide and fatty films.

- Residues should be washed off well from surfaces.

Fluxes are usually divided into active and neutral depending on the presence of acids in their composition.

Acidic compounds actively interact with many soluble oxide films and fats. However, they release toxic substances when evaporated and can damage the circuit board over time if they are not removed. This is due to the fact that the active acid included in these fluxes dissolves various metals well, for example, those that make up radio components and the board itself.

Neutral options often do not have these disadvantages, but soldering is not as good as when using acidic ones.

Flux groups

All existing drugs can be divided according to effectiveness into three groups according to GOST:

- Neutral group . Due to the almost zero activity of the components, these fluxes poorly clean surfaces, and the solders that are used with them must be low-melting. Used when working with copper materials, copper coated with cadmium, silver and tin. This category includes rosin, waxes, tree resins and stearin.

- Slightly corrosive group . It is characterized by dissolution in alcohol, water, various fats and weak acids. One of the required components of each flux in this group is rosin, which provides an anti-corrosion function. During the soldering process it evaporates well, decomposes and burns.

- Strong corrosive group . The components of these fluxes are chlorides, fluorides and strong inorganic acids. Manufactured in paste and solid form, they are capable of destroying persistent oxide films on ferrous and non-ferrous metals.

Is it possible to solder aluminum wire?

Soldering aluminum wires

in the junction box

you can

use a soldering iron or a gas torch. It is more difficult to use a soldering iron due to the inability to accurately heat to the required temperature.

Interesting materials:

Is it possible to drive to the side of the road? Can I join a Zoom meeting without registering? Is it possible to order tobacco by mail? Is it possible to enter a store without gloves? Is it possible to visit relatives in the intensive care unit? Is it possible to marry between cousins? Is it possible to complete higher education as an external student? Is it possible to fill the tank full in summer? Is it possible to fill in the hundredth gasoline? Is it possible to marinate meat and freeze it?

Review of various fluxes for soldering

- Rosin . Rosin is distinguished by the amount of fatty acids in it; the darker it is, the more acids it contains. Although it is an inactive flux, given the presence of acids in the composition, it is better to remove rosin residues from soldering. It is the most popular and accessible material. The disadvantages include the release of a large amount of smoke during soldering and the rapid coating of the soldering iron tip with soot. Solid rosin is difficult to use when soldering, so it tins soldering irons and wires, but to connect radioelements it is better to use liquid rosin in alcohol.

- Soldering acid . The composition of this flux includes strong acids - orthophosphoric or hydrochloric and zinc chloride, which can reach 50% in solution. An affordable and cheap material that corrodes all fatty films and allows you to solder almost any type of metal. But the acid is very toxic, so work should be carried out outside residential premises using personal protective equipment. In addition, it is a good conductor of electricity; even the slightest residue on the connection will corrode the board tracks, so it is better not to use it at all.

- Borax . It is a salt of boric acid and is presented in powder form. To obtain liquid flux, it is mixed with boric acid and water. It works at very high temperatures, so it can be used when working with a hair dryer. Borax is an active flux, so it is necessary to thoroughly wash off any remaining residue.

- Soldering fat . Depending on the composition, it can be either neutral or active. Consists of rosin, petroleum jelly, paraffin, zinc and ammonium chlorides. It works very well when cleaning heavily contaminated surfaces, since the paraffin in the composition draws out all the dirt from the soldering area. It evaporates slowly, leaves almost no soot, but the residue takes a long time to evaporate.

- LTI 120 . The composition is represented by rosin (20%), ethyl alcohol (95%) and auxiliary additives such as triethanolamine (2%) and diethylamine hydrochloride (3−5%). It is low cost and does not conduct electric current, which makes it possible to use this flux for soldering radio components. The kit often comes with a convenient brush, which is easy to apply material to the soldering area. Some disadvantages include rapid evaporation and potential toxicity.

- SKF . Alcohol-rosin flux consists of ethyl alcohol (60−80%) and pine rosin (20−40%). An inactive material that you can make yourself by adding crushed rosin to alcohol. Low smoke, easy to apply. The disadvantage is that it dries quickly due to the evaporation of alcohol, so it should be stored in a tightly closed container.

- Oxidal . Used for cleaning soldering iron tips, as well as soldering heavily oxidized and contaminated copper wires.

How to replace soldering flux

In the absence of flux and the impossibility of acquiring it, you can use some available materials, but you should remember that the quality of soldering will be very low, and the remaining material is often difficult to remove or toxic. However, there are some adequate options you should be aware of.

- Aspirin . Salicylic acid or a solution of aspirin tablets in water can be used for soldering, but its vapors are too toxic, and it is very advisable to work in non-residential areas with good ventilation, and preferably in the open air. It has all the disadvantages of active fluxes and requires mandatory cleaning of the surface after soldering.

- Ammonia , as well as citric or acetic acid, can also be used as a replacement for fluxes, and their concentration does not require additional dilution with water.

- Glycerin may be suitable for soldering radio components on a board, but it has residual resistance and good hygroscopicity, so it must be washed off the board.

It should be remembered that soldering will be of high quality when the flux is selected correctly. There are fluxes that are ideal for every metal, and others may not work as well. In addition, it is highly discouraged to solder boards with active fluxes, especially those containing acids, since if flux residues are not completely removed from the surface of the printed circuit board, the active components will destroy the conductive copper traces.

Parts should be soldered with a soldering iron with a perfectly tinned tip, and when carbon deposits appear, try to clean the tip in oxide, this will allow for very good soldering. Upon completion of work, flux residues from the surface of soldered parts and boards must be removed using a suitable method. The board tracks can be coated with special varnishes, for example, tsaponlak, this will protect them from moisture.

Preventive actions

To reduce the likelihood of periostitis, you need to take care of your teeth and visit the dentist at least once a year. You can't start caries. As soon as a dark spot appears on the surface of the dental crown, it needs to be treated.

After eating, it is advisable to rinse your mouth with warm water. To make hygiene as high as possible, it makes sense to use not only a brush and toothpaste, but also dental floss and irrigators. It is very important to remove tartar every year at the dentist's office.

An important place in the issue of prevention is given to diet. You should eat as much fresh fruits, vegetables, and plant foods as possible. They require more thorough chewing and thus have a positive effect on the ligamentous apparatus that holds the tooth. They also provide natural cleansing of crowns from soft plaque.

If you have any questions about how to remove flux, please contact the doctors at the Line of Smile dental clinic for help. We specialize in the treatment of this disease and know how to quickly rid our patients of it.