Remote control float level sensors (alarms)

Float level sensors OWEN PDU are devices designed to signal the level of liquids. OWEN PDUs are used as part of systems for monitoring and regulating liquids (water, solutions, light petroleum products and other liquid media, including aggressive ones, with the exception of those corrosive to the sensor material) in various tanks. ARIES remote control units are used to measure both current and limit (maximum or minimum) liquid levels. Float level sensors have general industrial and explosion-proof versions.

OWEN float level sensors are resistant to foam and bubbles and can handle viscous liquids.

To control the level of non-viscous liquids, level sensors with a cylindrical float PDU-1, PDU-2 are produced, for monitoring the level of viscous liquids - with a spherical float PDU-3. According to the installation method, sensors with horizontal and vertical installation are distinguished.

The OWEN company produces single-level, two-level and three-level float sensors; it is also possible to manufacture OWEN PDU sensors with explosion protection of the “intrinsically safe circuit” type 0ExiaIICT4X. Check out the explosion-proof sensors PDU-Ex.

To connect to the automated process control system, OWEN PDU sensors are equipped with a silicone cable AWG 24 with a length of 1 meter to 120 meters, OWEN PDU-N are equipped with an electrical connector standard DIN 43650 A.

Modifications of single-level sensors

| Model | Installation type | Float type | Rod length L, standard version | Maximum rod length L (on request) |

| PDU-1.1 | Horizontal | Cylindrical | 100 mm | 2,500 mm |

| PDU-2.1 | Vertical | Cylindrical | 100 mm | 2,500 mm |

| PDU-3.1 | Vertical | Spherical | 100 mm | 3,000 mm |

When ordering a modification with an extended rod, the length multiplicity is 50 mm.

Modifications of two-level sensors

| Model | Installation type | Float type | Rod length L, maximum (on request) |

| PDU-1.2 | Horizontal | Cylindrical | 2,500 mm |

| PDU-2.2 | Vertical | Cylindrical | 2,500 mm |

| PDU-3.2 | Vertical | Spherical | 3,000 mm |

Two-level sensors are produced to order. When ordering, the multiple of rod length is 50 mm.

Modifications of three-level sensors

| Model | Installation type | Float type | Rod length L, maximum (on request) |

| PDU-3.3 | Vertical | Spherical | 3,000 mm |

Three-level sensors are produced to order. When ordering, the multiple of rod length is 50 mm.

Features of the design and installation of OVEN PDU level sensors

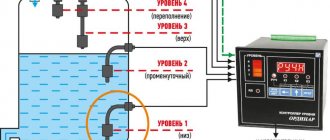

The level sensor has a float that moves along a vertical rod. There is a permanent magnet inside the float, and a reed switch is located in the rod, which is a hollow tube. The reed contact is activated when a magnet approaches. If installing the sensor on top of the container is not possible, then the float level sensor can be mounted in the wall of the container or in the bottom (Fig. 1).

Rice. 1. Options for mounting the level sensor: horizontal (PDU-1.1) and vertical (PDU-2.1, PDU-3.1)

OWEN RC sensors are produced with normally open and normally closed contacts. Options for the OVEN remote control contacts are shown in Fig. 2.

a) Remote control with normally open contact

b) Remote control with normally closed contact

Rice. 2. An increase in the liquid level in the tank causes the float to move upward and the contact of the level sensor to close/open.

Application of level sensors ARIES PDU

OWEN RC sensors can operate at temperatures up to +105 °C in chemically aggressive environments. Sensor material – stainless steel (12X18H10T).

ARIES PDUs are used to control the level of wastewater, chemically aggressive liquids or food products, including viscous liquids. Float sensors can be used to control liquid levels in vehicles, for example, to control the volume of fuel in heavy equipment: trucks, excavators, diesel locomotives. Here, level sensors operate under conditions of strong vibration and disturbance on the surface of the liquid. To eliminate the influence of these factors, the float sensor is placed in a special damper pipe with a diameter slightly larger than the diameter of the float.

It should be remembered that float-type level sensors are not suitable for measuring sticky and drying liquids, liquids with mechanical inclusions, or when the liquid freezes.

Design and principle of operation

The design of measuring devices of this type is determined by the following parameters:

- Functionality, depending on this device, is usually divided into alarms and level meters. The former monitor a specific tank filling point (minimum or maximum), while the latter continuously monitor the level.

- The operating principle can be based on: hydrostatics, electrical conductivity, magnetism, optics, acoustics, etc. Actually, this is the main parameter that determines the scope of application.

- Measuring method (contact or non-contact).

In addition, the design features are determined by the nature of the technological environment. It is one thing to measure the height of drinking water in a tank, another to check the filling of industrial wastewater tanks. In the latter case, appropriate protection is necessary.

Making a water level sensor in a tank with your own hands

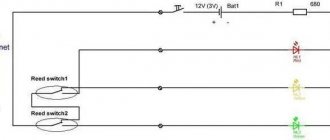

Let's say there is a task to automate the operation of a submersible pump for water supply to a dacha. As a rule, water flows into a storage tank, therefore, we need to make sure that the pump automatically turns off when it is filled. It is not at all necessary to buy a laser or radar level indicator for this purpose; in fact, you don’t need to purchase any. A simple problem requires a simple solution, it is shown in Figure 8.

Water pump control circuit

To solve the problem, you will need a magnetic starter with a 220-volt coil and two reed switches: a minimum level for closing, a maximum level for opening. The pump connection diagram is simple and, importantly, safe. The principle of operation was described above, but let’s repeat it:

- As the water collects, the float with the magnet gradually rises until it reaches the maximum level reed switch.

- The magnetic field opens the reed switch, turning off the starter coil, which leads to de-energization of the engine.

- As the water flows, the float drops until it reaches the minimum mark opposite the lower reed switch, its contacts close, and voltage is supplied to the starter coil, which supplies voltage to the pump. Such a water level sensor in a tank can work for decades, unlike an electronic control system.

Conclusion

So, monitoring the condition of the oil in the engine lubrication system in modern cars is no longer an additional option, but an integral function. An electronic level gauge makes it easier to check the level, temperature, pressure, and in some modifications, the quality of the oil in the crankcase.

The malfunction of this sensor is quite a rare occurrence, but if necessary and desire to tinker around the car, it can be easily changed without the use of additional equipment. The main thing is to make sure that this particular element is faulty.

This video, using a VAZ 2110 as an example, shows where this leveler can be found and how to replace it:

Oil level sensor in the VAZ 2110 engine: what is it, where is it located and how to replace it!

Oil level sensor malfunctions

Damage to the oil level sensor cannot be ignored. If the driver misses the moment when the lubricant level drops to a critical minimum value, the engine will experience oil starvation. In addition to the lubricating effect, engine oil performs the function of removing heat from parts of the unit that are not in contact with the cooling jacket.

If there is not enough lubrication, the load on the motor increases, especially thermal (parts are poorly cooled). This negatively affects their work resource. In real life, reviews from many car owners show that even the minimum level of lubrication may not be critical if you do not run the internal combustion engine at high speeds until the oil is changed or until an additional portion of lubricant is added.

A sensor failure is indicated by a constantly burning oil lamp light on the dashboard. If the alarm does not disappear after topping up or completely changing the oil, the sensor must be replaced. This can also happen when the ECU receives incorrect signals.

In addition to the constantly burning light on the dashboard, the engine icon may light up or the oil can periodically light up and go out suddenly. In this case, the control unit receives incorrect data from the lubricant level sensor. The microprocessor determines this as a serious malfunction, and may even block the operation of the motor.

If the car does not have a dipstick for checking the oil in the engine, then there is no way to determine the breakdown except for diagnostics at a service station. Service center workers connect a car scanner and diagnose all equipment. In addition to this method, in the case of some cars, quick self-diagnosis is possible.

An error code is displayed on the vehicle's on-board computer. In most cases, error P250E indicates a malfunction of such a sensor (but often this refers to in-depth diagnostics, which are carried out by a special auto scanner). Details on how to call up the diagnostic menu on the car’s on-board computer are described in another review .

The oil level sensor stops working for the following reasons:

- A large amount of oil deposits have accumulated on the surface of the scanning device;

- Wiring insulation failure or line break;

- The fuse has blown (the pinout, which is usually indicated on the housing cover, will help you find the corresponding element in the fuse box);

- For VAG models, sensor problems are directly related to a breakdown of the hood switch.

It would seem that this has nothing to do with the hood and the oil level sensor. The manufacturer’s logic (applies to cars coming off the assembly lines of companies owned by the VAG concern ) is as follows. The electronic circuit is looped through the hood switch. When the driver notices that the oil can light on the dashboard, naturally, he will open the hood to add oil or at least check its level.

The activation of this sensor gives a signal to the control unit, saying that the driver has made the necessary changes and went to the service station. Counting on this course of action, the manufacturer programmed the ECU to turn off the alarm signal on the dashboard until the car has driven about 100 kilometers (if the oil has not been added).

Problems with the limit switch are regarded as a breakdown of the oil sensor. For this reason, before installing a new sensor in such machines, you must first check the serviceability of the limit switch. Otherwise, even a working lubrication system sensor will not make the oil can on the dashboard go out.

Level determination of powders and other bulk materials

There are many types of relay switching technologies. So there are many ways to determine the level of powder and other bulk materials. With the release of Proximity Controls TFLS

(Tunable Vibrating Level Switch) and

LTS

(Tilt Switch) Series, Dwyer now offers five different spot level detection technologies for powder and other bulk materials.

These are: diaphragm , vane , tilt , capacitance and vibration .

Types of float level gauges:

Float magnetic level gauges. In the device, the float interacts with a magnet. Any deviation of the float from the magnet is recorded as a change in level.

| ROS-501 float level sensors-relays | SUG-M float liquid level indicators | PMP-052 magnetic float level sensors |

Float magnetostrictive level gauges. A float with a permanent magnet inside moves along a guide rod in which a wire made of magnetostrictive material (waveguide) is stretched. Current pulses are supplied to the waveguide. At the location of the magnet (float), when the magnetic field interacts with the current, pulses of longitudinal deformation arise, which are recorded by a piezoelectric element at the top of the rod. In this case, the pulse travel time is recorded - it is directly proportional to the distance to the surface.

| LLT-MS magnetostrictive float level gauges | VK1700 multichannel level gauges | PMP-201 level-density gauges float magnetostrictive |

Float mechanical level gauges. The float operates a mechanical switch (opens or closes a contact) by direct contact. They work on the principle of communicating vessels.

| DRU-1PM float liquid level sensor-relay | RO-1 liquid level sensors-relays | RU-1 liquid level sensors-relays |

Condition measurement

The oil condition sensor allows for a more rational use of the coolant lubricant resource, since the replacement period is determined not only by the manufacturer’s mileage recommendations, but also by the actual chemical and physical composition of the engine oil.

The device of the condition and oil level sensor of the N57 engine from BMW.

The meter consists of two cylindrical capacitors (6). The outer and inner metal tubes are used as electrodes, between which there is a dielectric - oil. The operating principle is based on a change in the dielectric properties of the oil during aging, which affects the capacitance of the capacitors.

When the level drops, the capacitance of the upper capacitor (5) changes. The temperature is continuously measured using a platinum temperature sensor (9). The change in capacitive characteristics of the capacitors, as well as the signal from the temperature sensor, is converted into a digital signal and sent to the DME unit. Based on the received data, the DME unit calculates oil change intervals.