It is possible to prepare oil or water-soluble coolant with your own hands at home. To do this, you need a little free time and a simple set of components.

Do-it-yourself coolant is potentially dangerous to your equipment and health! We are not responsible for negative consequences. Using the recommendations from this article, you act at your own peril and risk!

The popularity of cutting fluids (coolants) is explained by their wide spectrum of action. They extend the service life of the machine by cooling the cutting tool, improve the quality of processing, increase speed and productivity, and make operations safer and more comfortable. Buying a ready-made liquid is not always the easiest or most obvious way to get these benefits. Sometimes it’s easier to prepare coolant for machines with your own hands.

Does homemade coolant have a right to life? You can replace expensive components with more affordable ones, but you cannot guarantee that the liquid obtained at home will “work” correctly.

How to make oil-based coolant

It’s easy to make coolant yourself, especially if it contains mineral oils. To prepare the base you will need oil, water and a surfactant.

The simplest recipe looks like this: mix 200 ml of surfactant (liquid soap will do), purified vegetable oil, kerosene and soda ash. Add 50 ml of laundry bleach, 25 ml of concentrated dishwashing detergent. Bring the resulting volume to 10 liters using plain water, and then heat to 90 °C, stirring constantly. The output will be do-it-yourself coolant for a lathe. Before use, dilute it in a ratio of one to three.

In some recipes you can see industrial oil - replace it with motor oil, the result will be the same. For example, another popular recipe involves preparing a mixture of industrial (motor) oil, water and a surfactant, which again can be any detergent or liquid soap.

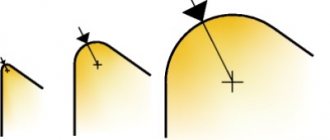

Characteristics of the tape web

In general, low cutting speeds and high feed pressures are required to cut hard or hardened metals, and a significant amount of high coolant pressure is also required. On the other hand, cutting easy-to-cut metals allows you to work at high cutting speeds and low feed pressure and requires a higher degree of cooling supply. The cutting fluid absorbs and dissipates heat through evaporation during the cutting process. As heat builds up during the cutting process, a blade with a larger cross-section will become hotter much more slowly than a blade with a smaller cross-section. Free-flow synthetic coolant is more efficient than oil coolant and is more suitable for cutting large cross-sectional workpieces.

How to prepare water-based coolant

The composition of coolant for do-it-yourself machines can be different. Along with oil-based ones, water-soluble lubricating fluids are popular. They have a simple composition, and preparation consists of dissolving the main components in warm water. The composition of such coolant may include:

| Main component | Auxiliary Component |

| Soda Ash | – |

| Soda Ash | Sodium nitrite |

| Trisodium phosphate | – |

| Trisodium phosphate | Sodium nitrite |

| Potassium soap | Trisodium phosphate + sodium nitrite |

| Potassium soap | Soda Ash |

An aqueous solution with soda and sodium nitrite is often used. This mixture prevents corrosion on metal workpieces. If the composition includes trisodium phosphate, the coolant is suitable for turning workpieces.

If you make coolant yourself, the composition may change. But the safety rules for their preparation must remain unchanged. Use personal protective equipment, and carry out work in a non-residential area: workshop, garage, etc.

Semi-synthetics

This coolant has a synthetic base, but also contains oil (5 to 30%) and water. A “hybrid” of both soluble and synthetic fluids, it can be used in a wide range of applications and is suitable, for example, for machining large cross-sections of cast iron.

Advantages include versatility, good microbiological control, corrosion control, cooling and lubrication. There are other benefits too, these include ease of maintenance and long service life. On the other hand, water hardness can affect stability and cause foaming.

How to replace coolant

Cooling lubricants are not unique in composition and principle of action. If you have a small amount of work to do, you can get by with the closest home-made analogues with similar characteristics.

Let's say you need to prepare coolant for aluminum with your own hands. At home or in the garage, you can get by with kerosene or turpentine, but this will not be the best solution for many reasons (the main ones are a strong unpleasant odor and toxicity). Ethyl and isopropyl alcohol are good alternatives. They do not require a high degree of purification, but you need to monitor their water content. If its mass fraction exceeds 0.1, you risk causing corrosion on the metal surfaces of the cutting or grinding tool.

Rules of application

To effectively use coolant, it is recommended to follow some rules:

- It is recommended to select a flow rate of at least 10-15 l/min;

- the liquid is directed to the area with maximum heat generation;

- coolant supply begins from the moment turning begins, otherwise sudden cooling of an overheated tool will lead to the formation of cracks;

- when working with difficult-to-cut material, the liquid is supplied in a thin stream from the back side of the cutter;

- lubricants used for equipment must be compatible with coolant;

- before carrying out work on the machine, the liquid concentration is monitored;

- the coolant concentrate is stored indoors with good ventilation at a temperature of 50 to 400 ° C; the substance must not be frozen and containers with galvanic coating inside must not be used.

Coolant is not used for working with brittle materials that produce small chips in order to avoid premature wear of the machines.

Cutting fluids have a positive effect on process performance, as well as protection of turning equipment and products from overheating and deformation.

Each type of coolant has certain parameters and characteristics that must be taken into account when used.

Which is better: homemade or factory coolant?

Many people wonder how to make coolant for a machine with their own hands. But at the same time they think little about the consequences. Experts say that the best option is to purchase a ready-made cooling lubricant.

Homemade products have many disadvantages:

- it is difficult to achieve stable fluid characteristics;

- alternative components do not always perform the stated functions;

- there is a high probability of damage to the coolant due to the development of fungus or rotting of individual components during storage.

If you prepare the liquid and coolant pump with your own hands, you will have to come into contact with chemically active components that can be dangerous to the skin and mucous membranes, and inhale toxic fumes. The result may be dizziness, nausea and other signs of poisoning, which should promptly consult a doctor. Therefore, it is better not to experiment, but to immediately purchase ready-made concentrated coolant for specific tasks.

Characteristics of Band Saw Machine

Some bandsaws are equipped with a coolant system that sucks and drains the coolant back into the coolant tank. As a general rule, a non-coolant bandsaw should only be used for cutting easy-to-cut materials such as mild steel and aluminum. An oil mist system can also be installed on a vertical or horizontal band saw to provide lubrication to reduce frictional heat. However, the fogging system does not provide evaporative cooling of the blade or workpiece, therefore, the cutting speed must be reduced by 15%-20%. Dry parting without coolant requires half the normally recommended cutting speed.

Coolant - do-it-yourself video

You can see how to make coolant for a machine yourself in this video. Its author needed a simple set of ingredients for the work: 72% laundry soap, waste oil, warm water. Tools include a convenient knife for grinding soap, two separate containers for mixing and heating the items listed above, plus an electric stove. We invite you to familiarize yourself with the preparation process:

If you prefer to use high-quality products with a predictable effect in your work, we recommend purchasing coolant for a lathe from a trusted manufacturer at Loc-Line. We will offer the optimal cutting fluid for your operating conditions, and advise on its use and replacement. For detailed information, call number 8 in St. Petersburg or write by e-mail

Soluble oils

It is the most popular type of coolant and is used in light to heavy duty applications involving both non-ferrous and ferrous metals. It contains a mixture of water and oil that combines the lubricity of cutting oils with the cooling power and economy of water.

Benefits include good lubrication, improved cooling ability and good rust protection. It also resists mixing with grease and guide oils.

Disadvantages include increased maintenance costs, susceptibility to rust, bacterial growth, oil contamination and evaporation losses.

Belt cooling methods

The most effective method of using coolant for the operation - high-performance cutting of metal on a band saw machine - is a coolant supply system flowing from above through guide tubes on the side where the band blade enters the workpiece being cut and on the side where the band blade leaves it. Using this coolant method effectively reduces frictional heat and provides maximum lubrication as the blade passes through the guides over the workpiece being cut. This ensures that coolant is effectively supplied to the cutting zone. For small bandsaws that are not equipped with a coolant tank, a small and relatively inexpensive oil mist system can pay for itself in a short period of time. The design of the belt blade often results in high coolant loss when using the guide tube coolant method. The angle of supply of the guide tube and the small thickness of the channel can only cover a blade of small cross-section, thus, little heat is removed from the cutting zone. Consequently, an oil mist system is usually more effective in providing reduction of frictional heat from the belt. It is also very important that both sides of the tape should be lubricated evenly. If one side of the belt is not sufficiently lubricated, the belt will usually pull toward the more lubricated side.

Solving cooling problems on a band saw

The use of coolant is so important that it cannot be overemphasized. High-quality coolant is one of the most important factors for efficient cutting and increasing the life of your band saw. Usually there are no problems with the use of coolant, but if problems do arise, then the tips below can help correct them. Rust on the band saw or its working parts. The ratio of water to coolant concentrate may be too high. You need to check the emulsion ratio of the coolant with a refractometer and mix it to the correct ratio recommended by the coolant manufacturer. Keep in mind that contaminants (unwanted impurities) in the coolant, microscopic organisms and fine metal dust (or shavings) can accelerate the development of rust in the coolant. It is necessary to clean the entire coolant system and fill in a new emulsion. Foaming coolant. Coolant emulsions with a high content of coolant concentrate may have a tendency to foam. You need to check the ratio of the coolant emulsion with a refractometer and mix it to the correct ratio. Fine metal dust (or shavings) in the coolant tank can take away the antifoam properties of the coolant emulsion. Clearing the coolant system of these chips may help. Air entering through a loose hose or passing through fittings can cause foaming, as can a coolant tank emulsion level that is below the pump's demand level. All coolant hoses and the coolant emulsion level in the coolant tank should be checked. Bad odor or surface foam in the coolant tank is usually caused by contaminants, such as band saw oil leaks, that allow microorganisms to grow in the coolant emulsion heated during the cutting operation or warm shop floor temperature. A low coolant concentration ratio will contribute to this problem. All oil leaks must be checked and repaired. It is necessary to clean the entire coolant system and fill in a new emulsion. Reduced performance of the band saw. The investigation of this problem should begin with a complete mechanical inspection of the belt and its guides. If they are in good condition, then you need to check the coolant emulsion ratio and whether there are fine metal shavings at the bottom of the coolant tank. It can be circulated and fed into the cutting zone, significantly dulling the blade, causing a rough or wavy surface on the workpiece being cut. It is necessary to clean the entire coolant system and fill in a new emulsion. Hot shavings or blue shavings. It is necessary to check that the coolant emulsion ratio is not too high (there is not too much water). This can be seen by visually examining the coolant jet for the presence of a sufficient amount of coolant concentrate in the cutting zone. If after all the above problems still exist, then they are probably no longer related to the coolant emulsion. Instead, they were most likely caused by incorrect blade selection, cutting speed or cutting feed.

| You can order any of your materials at our production Contacts: , , , |

Additional technical information can be read in the “Articles” section.

Application of coolant

Coolant affects the reliability and duration of continuous operation of the grinding machine. It wets cutting and processed surfaces and also reduces heat generation. The quality of processing increases, and the tool becomes less dull and fails less often.

Additionally, the coolant performs other functions:

- effectively removes abrasive particles from the treatment area;

- cleans the pores of the wheel from dust particles and chips;

- keeps the circle in working condition longer;

- extends the intervals between wheel adjustments;

- improves ergonomics in the workplace.

Thanks to coolant, you can work with harder wheels, which expands your capabilities for processing hard materials.

Emulsion of metalworking machines

One of the lubricant-cooling technological agents (LCTS) or in other words cutting-lubricating liquids (CLF) is an emulsion for metal processing. The use of COTS (coolant fluid) is necessary to increase the efficiency of metalworking equipment and improve the quality of the processed surface.

Cutting fluids are used to facilitate blade and abrasive processing of metals - common and labor-intensive technological operations in mechanical engineering. Blade machining processes differ in speed (up to 80 m/sec), temperature in the working area (up to 1700 degrees) and pressure (up to 4000 MPa).

The functional purpose of the cutting fluid (coolant) in metal blade processing is to increase the wear resistance of the cutting tool, reduce the friction force and power consumption of the machine, remove waste from the working area, and protect against corrosion.

To perform these functions, the coolant must have:

- good lubricating properties

- cooling properties

- cleaning properties

The conditions for using coolant differ from the conditions under which lubricants operate in friction units (bearings, shafts, etc.). In the local area where processing occurs, high temperatures arise as a result of frictional forces. Friction surfaces under such conditions have high chemical activity. In the working area, under the influence of temperature, the cutting fluid is destroyed. Its components come into contact with the chips and the cutting surface of the cutter, forming durable lubricating films. In addition, the coolant ingredients make the surface layer of the workpiece less durable than the underlying layers of metal, facilitating the formation of chips.

The deformation of the metal is accompanied by its heating. The higher the strength of the metal and the cutting speed, the greater the heat transfer in the processing zone. The cutting edge can heat up to 800 degrees, which leads to deformation of the tool and deterioration in the quality of the machined surface. When using coolant, due to heat removal, the temperature decreases by 100-150 degrees, which improves the mechanical characteristics of the work. The temperature of the rubbing surfaces decreases.

The cleaning effect of coolant is to remove chips and tool particles from the working area, which is especially important during grinding and honing, as the quality of processing improves.

In addition to the basic requirements, the coolant must meet the following requirements:

- non-corrosive

- have a long validity period

- do not have bacterial infection

- don't be toxic

- don't foam

- do not destroy the rubber seals of the equipment

- do not destroy the paint and varnish coating of the equipment

- be fire and explosion proof

Classification of lubricants and cooling agents used for metal-cutting equipment:

- Mineral oils; vegetable oils; kerosene; mineral oils activated with surfactant additives and chemically active substances; vegetable oils and fats;

- aqueous solutions of electrolytes;

- aqueous solutions of surfactants;

- emulsols and pastes;

- activated emulsions.

When choosing coolant, we focus on the following processing parameters:

- cutting speed and depth

- surface quality requirements

- liquid supply method

The operating principle of metalworking machines is to deform metal workpieces in a given mode. As a result of friction between the working surface of the tool and the surface being processed, heating of the contacting parts occurs. Thermal stresses arise that destroy the cutting edge of the tool (drills, cutters, etc.), as well as disrupt the physical and chemical properties of the surface of the treated area.

The dispersed system (emulsion) is designed to reduce the friction force and lower the temperature in the contact zone. The emulsion used for metalworking is water in which mineral oils are dissolved. To ensure that the solution does not separate, emulsifiers are added to its composition. These water-soluble compounds make it possible to create stable lyophilic mixtures that have a cooling and lubricating effect.

The composition of the coolant may also include other additives and additives: bactericidal, anti-corrosion, extreme pressure. Bactericidal resistance is especially important, since the shelf life of the solution after its preparation is limited. An unpleasant odor and separation means that the metalworking emulsion has become unusable.

To obtain a stable colloidal liquid, the petrochemical industry produces a concentrated emulsol mixture, which includes petroleum oils (up to 85%), surfactants, emulsifiers and other additives (alcohol, bactericidal, anti-corrosion agents). The percentage of concentrate in water ranges from 1 to 5%.

The advantage of this type of cutting fluid is:

- high thermal conductivity

- low fire hazard

- low toxicity

The main disadvantages are insufficient cooling, low efficiency at high processing modes, and the requirement for frequent replacement.

Commercially available imported cooling lubricants are pastes, sprays, and concentrated solutions.

Area of application: drilling, turning, cutting ferrous metals, grinding, honing, turning.

What are the high-quality cutting fluids for grinding?

Recently, the market for consumables for special equipment has offered many types of coolant for grinding carbide and polymers. However, their quality and, accordingly, the completeness of functions differ. The products for processing operations from the German brand Zeller+Gmelin are recognized as one of the best in the world.

The company has developed a line of grinding lubricants called Zubora. These are synthetic coolants that are suitable for even the most demanding equipment. The reputation of Zeller+Gmelin, which the company has won over years of impeccable work, and its recognition throughout the world speaks volumes about the quality of the products presented.

The brand was awarded prestigious awards and awards “TOP 100” and “Bosch Supplier Award”. This is one of the largest enterprises in Germany. The quality of the coolants that the company produces is achieved thanks to a high level of control at each stage of production, as well as improved formulas of finished products. A team of technologists constantly studies the needs of the market and creates cutting fluids that are ahead of the high demands of modern production.

The production of lubricants takes place exclusively in a single plant in Germany. This allows us to fully comply with production technology and supply cutting fluids of identically high quality to any country.

Coolant supply system on a band saw machine

Clean new coolant, a clean coolant tank and clean coolant guide tubes will maximize the effectiveness of any coolant. It is best to check the band saw's coolant tank daily to ensure that the coolant level is not lower than the pump level and that the coupling ratio is correct. Metal shavings or oil leakage from the working parts of the band saw machine deteriorate the coolant. Stop all hydraulic leaks, wash the entire system with a quality detergent, and then refill the coolant tank with properly mixed new coolant. It is necessary to replace the coolant on a regular basis depending on the volume of cutting, at least twice a year. It is also very important to regularly remove chips from the coolant tank, especially cleaning it of small (almost microscopic) metal chips, because during the operation of cutting metal on a band saw machine, it passes through the coolant system, reducing the durability of the band blade (dulling its cutting edge) , as well as generally negatively affecting and prematurely wearing out guides, wheels and other metal parts of the band saw machine.

Features of the impact on machines and workpieces

In general, coolant solves three problems: cools, lubricates and removes small particles (chips). But in reality there are many more problems. For example, here are the consequences of efficient cooling:

- the wear process of the cutting tool is reduced;

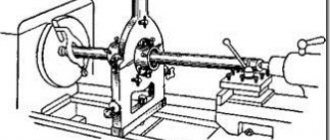

- the accuracy of work on a lathe increases;

- the number of technological processes is reduced;

- the quality of processed parts improves;

- Risks for the employee are reduced, and their workplace becomes more comfortable.

Coolant for a lathe is not an essential component of metalworking, but without it it is impossible to obtain high-quality products and rationally plan tool maintenance costs.

Additives in coolant for machine tools

Additives are an important component of metalworking coolants. Having a very small concentration, they can significantly improve the quality and efficiency of working with metal.

Additives for various purposes perform several important functions:

- Increases the resistance of metals to corrosion

- Anti-wear by reducing wear on tool working surfaces

- do not allow scuff marks to form on the surface of the metal workpiece during processing,

- Prevents the formation of foam, which reduces the quality of the coolant, and the appearance of oil mist, which is harmful to the skin and respiratory organs of working personnel

How to supply lubricant to the cutting area

The following methods are popular in modern production:

- high pressure supply. Several nozzles are used simultaneously, from which liquid comes out under pressure using a jet-pressure method;

- free flow delivery. In this case, it is sent directly to the metalworking zone. The liquid enters through the axial hole in the equipment and is distributed to the peripheral areas due to the centrifugal force that arises due to the rotation of the tool;

- feeding directly to the cutting or grinding site. This method is used only for those liquids that have pronounced lubricating properties. Feeding begins a few minutes before starting work on the milling machine;

- feeding by contact method. The coolant is directed directly to the cutting part of the tool or to the workpiece.

It must be taken into account that small particles of chips and dust in the workplace settle on the nozzles from which the liquid is supplied and reduce its efficiency. The system becomes clogged and ceases to perform its functions, and at the same time the quality of metal processing decreases. To prevent this from happening, the coolant must be filtered regularly. Otherwise, a favorable environment appears for the development of microorganisms that cause rotting, corrosion damage occurs, an unpleasant odor is possible, etc.

Emulsion coolant for band saw machine

The correct balance of oiliness and cooling of the coolant is very important to achieve optimal performance of the band saw blade and the entire band saw machine. This balance can be achieved by maintaining the correct ratio from the start or by periodically adding concentrated coolant. The ratio is indicated by the manufacturer depending on the type of coolant. For example, if the original emulsion ratio recommendation is 10 to 1, then this means that the manufacturer recommends 10 parts water to 1 part coolant concentrate for optimal performance. Never pour coolant concentrate directly into the band saw coolant tank. You must first mix the coolant concentrate with water in a clean container, and then pour it into the clean coolant tank of the band saw. Since the water in the coolant tank evaporates through heat transfer, the coolant tank must be refilled. The replenish emulsion requires a lower ratio than the initial compound because the coolant concentrate does not evaporate as quickly as water. To maintain maximum efficiency, coolant concentration should be measured periodically using a Brix refractometer. The ideal location to take a sample is the tip of the coolant guide tube. By comparing the current value of the ratio of the emulsion coolant to the previous ones, it is possible to determine the ratio for replenishment. Never add water or coolant concentrate directly to the coolant tank. Mix at least three parts water to one part coolant concentrate and mix well before pouring into the coolant tank.

Types of coolant for metal forming processes

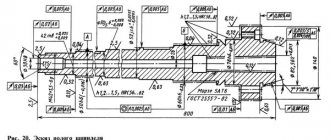

Due to the significant specific forces, as well as the speeds of relative sliding of the workpiece material along the tool, grades for use in technological processes must have a significantly higher viscosity. In addition, at significant degrees of deformation, chemical-mechanical surface reactions begin on the contact surfaces, contributing to the deterioration of friction conditions. This reduces tool life, particularly when machining soft metals such as aluminum. It is unacceptable to use partially waste substances when processing aluminum. Therefore, the characteristic features of these compositions for Russian conditions are:

- Quite high viscosity. In practice, it varies from 45 - 50 cSt for coolants based on mineral oils of type I20 (GOST 20799-88), to 75 - 80 cSt for coolants with sulfur compounds and animal fats (a typical representative is Ukrinol GOST 9.085-88);

- Resistant to high temperature delamination or fracture. The composition necessarily contains sulfur additives and anionic emulsifiers. The most commonly used brands include ethanolamines and alkyl sulfates with additives in accordance with GOST 10534-88. In waste products, the concentration of such components decreases sharply;

- Water-based graphite types, including an additive based on an oil suspension of fine-flaked graphite. Produced in accordance with GOST 5962-88.

A special group is represented by substances used in the processing of aluminum and its alloys. Aluminum is characterized by intense adhesion to the contact surfaces of the equipment, so it should be ensured not so much a decrease in temperature as a high cleanliness of the final surface of the product.

For example, when rolling aluminum sheets, the following are used:

- Products based on 5 - 10% lubricant 59c (GOST 5702-85);

- Emulsols based on synthetic fatty acids with the addition of triethanolamines (GOST 8622-85);

- Substances containing high molecular weight synthetic alcohols: for example, ethylene glycol GOST 10136-97 or glycerin GOST 6823-97.

Quite a lot of coolant systems designed for working with aluminum are produced according to the specifications of Russia and other CIS countries. The viscosity of such compositions for processing aluminum is usually assumed to be minimal.