Purpose of the tool

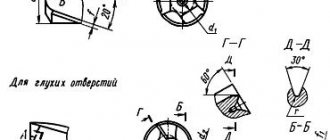

The axis of rotation of the end mill is directed at right angles to the penetration plane. In this case, its main cutting edges are located on the side cylindrical surface, i.e. cutting occurs along the line of their contact with the processing plane. At the end end there are also cutting edges located at an angle to the axis of rotation, which perform an auxiliary function. The cutting surface of such a router is made in the form of spiral or inclined teeth, and the angle of inclination can be 30-45°.

Pedicure discs and replacement files

Can be of different diameters and abrasiveness.

A current replacement for pedicure caps, speeding up the pedicure procedure several times. The discs are made of steel and undergo all stages of tool processing. Disposable files on a self-adhesive base have the same gradation of abrasiveness as pedicure caps. The abrasive of the files, with the exception of Chinese fakes, is made of silicon carbide. The selection of abrasiveness, zones and processing sequence are similar to caps.

Discs, unlike caps, on the contrary, require high speeds. The thinner the abrasive, the higher the rotation speed of the disk should be set and the smaller the angle of the disk to the surface being treated should be.

Not suitable for novice craftsmen, as they are demanding on the accuracy of the work technique. A novice master can accidentally burn a client with unpleasant consequences. For this reason, those interested in this technique should undergo advanced training in working with disks.

Features and Application

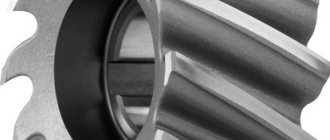

Structurally, metal end mills are divided into two types: all-metal (made of hard alloys) and with inserted cutting elements. The most common are solid carbide end mills. They are characterized by high rigidity, stability of parameters and an optimal ratio of price and technological capabilities. Milling cutters with inserted cutting elements made of special alloys with sputtering are used for special cutting modes, for example, milling on stainless steel, titanium alloys and other complex materials.

The main application of end milling is longitudinal machining of planes parallel to the tool's rotation axis. A typical example of such a technological operation is the milling of linear and contour grooves and grooves, the formation of stepped planes, as well as the selection of straight and shaped recesses of various depths. In this case, for deep surfaces, end mills with a cylindrical or conical shank, extended to the required size, are used. The main types of products processed by end milling are:

- plates with linear and T-shaped grooves;

- stamps and molds;

- flat surfaces and gears with grooves and notches;

- templates, dies, punches;

- shaft with keyways;

- body parts with through windows.

The size ranges of end milling machines are determined by state standards. Products made of high-speed steel with a cylindrical shank have a size range of 3-32 mm and are installed on equipment using chucks and collets. Medium and large diameter tools are available in sizes ranging from 14-63 mm with a cone shank and are used on industrial equipment. Milling cutters for CNC machines have their own size range - 14-50 mm.

Silicone carbide grinders and polishers

Silicone carbide polishers are sometimes also called simply polishers, grinders, or even “Photoshop cutters.” These cutters can rightfully be called safe. Even if you press the rotating sharp nose of the cutter against a nail, the nose will be cut off, not the nail. These attachments are made of dense silicone with inclusions of carbide chips and are designed for final grinding and polishing .

Abrasiveness of SK polishers

Abrasiveness, like that of corundum bits, is not always related to color. Usually there are coarse, medium and fine abrasives; again, you should focus on the description in the store. The most functional are coarse and medium.

- Polishers with a narrowed nose of coarse abrasiveness can be used to clean the pterygium, smooth the eponychium, and polish dry skin to remove small scales.

- You can polish the leather to a Photoshop effect with a medium polisher.

- Larger polishers, with a rounded nose, medium and coarse abrasiveness, are more useful in pedicures for working with parchment skin - they will not thin the thin stratum corneum, but will remove peeling and prolong the effect of perfectly smooth heels.

These nozzles work at low speeds, about 5-7 thousand rpm. They need to be disinfected in solution and sterilized in a dry heater or autoclave.

Special types

In addition to cylindrical end mills, a large range of milling tools is produced, which belong to the same group, but have different shapes and composition of cutting surfaces. This also includes small-sized end mills, which are usually mounted, but with small diameters they are made of all-metal and are classified as end mills.

All special types of end mills are available with both tapered and cylindrical shanks.

The most common types are:

- Keyed. They have two cutting surfaces at the end, which allows cutting in both longitudinal and perpendicular directions. Used for milling keyways on shafts and longitudinal grooves on flat workpieces.

- Angular. Their characteristic feature is inclined cutting edges at the end. Designed for removing rectangular edges (chamfers), processing inclined planes and corner grooves.

- Quarter round concave. Their cutting teeth are shaped like a reverse arc. Used for milling rounded edges.

- For T-shaped and dovetail slots. The cutting part is disk-shaped and has a larger diameter than the shank. Used for milling long slots of the appropriate configuration.

- Copiers with a cylindrical or conical working surface and a rounded end. They are used in the manufacture of stamping tools, molds and various models.

In addition, there are many types of shaped end mills that are capable of forming multi-stage rectangular and round profiles in one pass. This type of milling tool is mainly used in carpentry and plastic processing.

Safe manicure cutters OneyClean

They differ in the length of the working part, shape and number of edges.

Steel cutters without abrasive. They are considered safe for the nail plate if the working technique is followed. Subject to a full tool processing cycle.

They have a specific purpose: opening the pocket under the cuticle, removing glues, cleaning the pterygium. With such a cutter it is impossible to deeply clean the sinus, sand the ridges or cut the cuticle. Such a narrow focus and low functionality makes it of little use for an experienced craftsman.

But it will allow even a beginner to work safely and not leave cuts on the nail plate. It can be useful as a means of instilling confidence in a novice master.

End mill design

In general, an end mill is a monolithic metal cylinder consisting of two parts: a driver (shank) for installation in equipment and a milling part with cutting elements (teeth) arranged in a spiral. Its main geometric parameters are the overall length, the diameter of the cutting part, as well as the diameter, type and length of the shank.

Shanks

In accordance with GOST 53937-2010, end milling machines, depending on their purpose and area of application, can be produced with the following types of shanks of various sizes:

- smooth cylindrical;

- cylindrical with thread;

- cylindrical with several types of flats;

- with Morse cones, complemented by threads and flats;

- with 7:24 cones for manual and automatic tool changing;

- with HSK hollow cone for manual and automatic tool changing.

To secure the end milling cutter into spindles and chucks with other mounting holes, adapter bushings are used. In practice, abbreviations are often used in the designation of shanks, for example, “end mill cutter” means “with a tapered shank,” and “KM2” is a tool with a Morse taper N2.

Download GOST 53937-2010

Cutting part

The design of the cutting part is of two types: all-metal and with inserted cutting elements. The cutting planes and the grooves separating them for removing chips bend around the cylindrical surface in a spiral in the right direction (the tool is also available with left-hand rotation). On their upper part there is either a sharp cutting edge, or closer to its end there are inserted cutting plates. All-metal milling cutters are usually made from high-speed steel. Coated carbide teeth are attached to the end mill body in the following ways:

- soldering;

- eccentrics;

- screws;

- special bolts with a wedge-shaped head.

The number of cutting planes determines how many metal cuts the milling tool makes in one revolution (approach). The most common are one-, two- and three-flute end mills (they are also called “single- (two-, three-, etc.) flute end mills”). High-pass end mills are used for finishing and milling hard and brittle materials.

As mentioned earlier, small end mills belong to the group of end mills. In this type of milling tool, the side cutting surface is supplemented with auxiliary cutting edges located at the end of the cutter.

Grooving, copying and key milling cutters also have additional cutting surfaces.

Ceramic manicure cutters

From left to right: cone, corn, corn, cylinder, rounded cylinder (barrel), bullet.

In fact, they are an analogue of carbide , only they are considered more wear-resistant - their service life is up to 3 years. They are made by baking a special composition. Ceramic cutters heat up less during operation, which provides greater comfort for the client. They do not clog, so they have no restrictions when working with leather or soft gels, such as original shellac or elastic bases. They can also be safely disinfected and sterilized according to all the rules.

One of the disadvantages is their fragility - impacts and falls of such cutters should be avoided, since even a small crack will lead to destruction of the working part. In addition, when removing hard artificial materials, such as gel and acrylic, the ceramics may turn out to be too soft, abrade against the material, and become “bald.”

The shape of ceramic cutters is often similar to TVS cutters, as it is directly related to the intended functions. The abrasiveness marking is the same as for fuel assemblies . The difference is that ceramics with black and green notches have a rough cut, but do not become stronger because of this, so trying to remove even gel build-up can lead to abrasion of the knives. So you can use ceramics to work on hyperkeratosis, but you shouldn’t try to cut acrylic with it.

Which cutters are better: ceramics or TVS

- Firstly, if we compare cutters of approximately the same quality, then ceramics will be more expensive than fuel assemblies. This pays off due to a longer service life.

- Secondly, if you need a cutter for removing artificial surfaces, then ceramics will allow you to quickly remove only soft gels and acrygel. But it will do this atraumatically, without heating up and without “sinking” into the soft base. Choose a red notch for this. If you regularly strengthen your clients’ nails with gel or use hard bases (strong, hard, builder), then it is better to choose a carbide with a blue notch for removing them.

- Thirdly, ceramics are better suited for working on thin and sensitive skin, since they heat up less. If you need to work with thickened and problematic toenails, then choose TVS.

Thus, it will be wise to choose a tool based on your professional tasks and needs.

Classification of end mills

There is no special extended classification for end millers, therefore they are classified according to lists common to milling tools with the addition of their characteristic features. Below are the main sections of the classification used for various types of metal end mills:

By production purpose

In this section, the main feature is the type and shape of the surface being processed. Based on this, the following types of this tool are distinguished:

- general use;

- with end cutting part;

- for keyways (including for slots of segmental keys);

- for figured grooves;

- for shaped flat profiles;

- carbon copies.

By design

GOST obliges manufacturers to produce end mills of two types of lengths: normal and long and determines the ratio of the dimensions of the shank and the cutting part. But in addition to this, there are end mills on the market, both elongated and very short (popularly called “finger”). In addition to the types and length ratios, GOST defines the types of shanks (various types of conical and cylindrical), as well as size ranges of diameters. Most often in industrial production, an end mill with a conical shank is used.

State standards define only general requirements for milling tools. At the same time, global manufacturers offer various innovative designs. An example of these are modular end mills, in which the cutting part is attached to the shank using a high-precision screw connection. Another interesting development is a six-flute overrunning end mill with top and bottom bearings for finishing slots using a template.

According to the shape of the cutting surfaces

To form specific surface profiles of workpieces, in addition to general-purpose tools, a large group of shaped end mills was created. Among them, the main ones are radius and shaped groove milling tools, as well as milling cutters for 2D and 3D processing. The main types of end milling machines, classified according to the shape of the cutting surfaces, are:

- cylindrical;

- end;

- keyed;

- radius end mill;

- radius concave cutter;

- T-shaped cutter;

- cutter for dovetail groove;

- corner end mill;

- Conical and cylindrical end mills with straight and rounded ends.

By the number of cutting edges and direction of rotation

The process of burying a cutting edge into the metal and removing one layer of allowance with it is called “setting in.” The more cutting surfaces a router has, the more passes it makes per revolution. An end milling tool with one cutting surface is single-cut. If there is more than one surface, then the tool is multi-start (single-, double-start cutters, etc.).

In addition, there is an extensive classification of end mills based on the geometry and shape of the cutting surfaces, teeth and edges.

Corundum manicure cutters

From left to right: bullet, truncated cylinder, truncated cones, balls.

They are an artificial porous stone that does not have a convex abrasive. Corundum (emphasis on O, corundum) cutters work due to small cavities on the surface of the stone, which capture particles of skin or material. For this reason, they are often called safe, since you need to try very hard to injure the nail plate with them. Fine grade corundum cutters allow you to sand dry skin to a shine, so it is recommended to use them at the end of a manicure or pedicure as a polisher.

But when working on wet skin, such cutters become more dangerous than diamond cutters - they draw wet skin into their cavities and tear it. At the micro level, of course. After this, you will have to spend a lot of time sanding, so it is better to use them only on normal and dry skin.

These cutters can be disinfected in a solution, like all instruments, but can only be sterilized in an autoclave. In a dry-heat oven, sterilization inside the cavities is not complete.

Abrasiveness of corundum cutters

These attachments for hardware manicure are not marked for abrasiveness, so you should rely on the description. In general they can be green, pink, blue and white. But one manufacturer of white will have a super-fine degree of processing, while another will have a coarse one. Pink corundum cutters are most often described as thin and are the ones chosen for grinding.

Form and function of corundum cutters

They are simultaneously similar to both diamond and fuel assemblies. Corundums never have a very thin and long nose, and large cutters intended for pedicure are not suitable for removing the thickness of the stratum corneum, only for grinding. A novice nail technician can replace some diamond cutters with them at the beginning of his career, in cases where: there is no need to do a deep manicure, the most gentle treatment is required, or there is no confidence in the correctness of the technique.

In addition, the photo shows truncated cone and truncated cylinder cutters. These attachments can be used as additional attachments to lift the cuticle. By pressing the truncated tip into the cuticle at an angle of 90° and using short stitches to describe a semicircle, like the hand of a dial, you can quickly and painlessly prepare the cuticle for the next cut.

Designs of cutters and their influence on the technology of milling operations

Wood cutters for a manual router can have stacked and monolithic designs. In the first case, the design of the tool is a certain set of plates made of high-speed steel, which are attached to the cutter shank by soldering with copper alloys (sometimes, in cheaper sets, tool steel is used instead of a carbide alloy, and alloy structural steel is used as the shank material).

In the second case, the cutter is a monolithic tool, which is made of tool steel. A special type of cutter for a hand router is formed by mounted cutters, which consist of a removable plate, which is then mounted on an adapter shank. Such cutters are the most technologically advanced to use, since when the cutting blade becomes dull on one side, the removable plate can be turned over to the opposite side and continue to use the tool.

When choosing a set of tools in question, pay attention to the following:

- Soldering of typesetting cutters must be done in such a way that the tool does not lose its longitudinal stability during long-term processing, especially if the workpiece is made of hornbeam, pear, oak and other hardwoods;

- When soldering tools, grades PSr40 or PSr37.5, with a high content of silver and copper, should be used as solders. Solders of other brands usually include nickel, which impairs the strength of the connection between the plates and the shank;

- The easiest way to check the thermal strength of a set cutter is by the thermal deformation of the tool during heating of each tooth to a temperature of 200...2500C: the tool after such heat treatment should not allow its longitudinal axis to run out by more than 0.05 mm;

- The stacking cutter should not be made by welding the shank to the working cutting part. Firstly, at the site of the weld, the strength of the metal is always reduced by 15...20%, and, secondly, with sharp impacts (for example, when cutting a cutter into hard wood), chips may appear on the surface of the weld. The use of such a cutter is unacceptable.

It is especially worth highlighting the problem of the hardness of cutters for a hand router. Manufacturers of sets of such tools may be from China. The price of such a tool is noticeably lower, but the quality of the metal from which the equipment is made also decreases. Most often this concerns monolithic cutters. It is impossible to evaluate the steel grade under normal conditions, but the test can be performed at home. To do this, it is best to use a calibrated file, after contact with which there should be no visible marks on the working surface of the cutter. This roughly corresponds to a hardness of 58…62 HRC.

The durability of cutters is determined by the intensity of their use. High-quality stacking cutters with working plates made of high-speed steels have the best durability, while monolithic cutters made from ordinary tool steel have the least durability.

Types

There are several broad categories of face milling and face milling tools, such as center-cutting or non-centring-cutting (whether the router can perform plunge-cutting); and categorization by number of flutes; along the angle of the helix; by material; and coating material. Each category can be divided by specific application and specific geometry.

A very popular helix angle, especially for general cutting of metal materials, is 30°. Finishing end mills typically use a narrower helix with a 45° or 60° helix angle. Straight flute (0° helix angle) end mills are used in specialty applications such as milling plastics or epoxy-glass composites. Straight flute end mills were also historically used for cutting metal until the invention of the helical flute end mill. Carl A. Bergstrom of the Weldon Tool Company in 1918

There are end mills with variable flute helix or pseudo-random helix angle and interrupted flute geometry that help break material into smaller pieces during cutting (improving chip control and reducing the risk of jamming) and reduce tool snagging on large cuts. Some modern designs also include small details such as a chip breaker. Although these end mills are more expensive due to their more complex design and manufacturing process, they can last longer due to less wear and improved performance in high speed machining (HSM) applications.

Increasingly, traditional solid end mills are being replaced by more economical ones. inserted cutting tools (which, although initially more expensive, reduces tool change time and allows worn or broken cutting edges to be easily replaced rather than the entire tool).

End mills are sold in both inch and metric shank and cutting diameters. In the US, the metric is readily available, but is only used in some machine shops and not others; in Canada, due to the country's proximity to the USA, it's the same. In Asia and Europe, metric diameters are standard.

Other manicure attachments

Cleaning Brushes

If the tool is processed correctly, there is no need for them. Only if the tool is clogged with something, for example, undried gel polish, such brushes may be useful to you. When purchasing, choose nylon ones. Do not use metal brushes for cleaning, as... they can damage the abrasive of diamond cutters or scratch other bits.

Felt tips for adding gloss

Can be used in a manicure procedure without a decorative coating to polish the surface of natural nails to a glossy finish. Subject to disinfection, but not sterilization in dry heat.

It’s not entirely clear what and how to sterilize? We have a separate article on how to properly process manicure tools, including cutters, with a detailed description of each stage.

Still have questions? Ask them in the comments!