Welding work, like any other production activity, requires the presence and observance of certain rules so that the welding process is as productive as possible and the welded joints are of high quality. In Russia and some countries of the former USSR, such rules are established by documents SNiP (building codes and regulations), GOST (state standard), ENiR (uniform norms and prices), SP (code of rules) and others.

When starting a job for the first time, novice welders are often faced with ignorance of SNiPs and GOSTs, and this is not surprising. After all, the welder is faced with the task of studying and understanding dozens of regulatory documents written in an official business style, and this takes a lot of time. We decided to help you and, based on the rules used in construction and welding, we have compiled a list of the most important standards that you should know before starting work. We will teach you how to calculate the welding time per 1 m of seam and calculate how many meters per day you need to weld, we will tell you how to carry out quality control of welded joints and what are the requirements for welded structures.

Welding standards

First, let's figure out why standards are needed at all and what they are. First of all, standards regulate the quality and speed of work. The standards are also influenced by the welding method, the functionality of the welding equipment used in welding, and the qualifications of the welder. After all, an experienced master can do twice as much work per shift as a novice worker. The welder’s workplace is also taken into account, and special attention is paid to its organization.

Modern standards regulate the time that a welder must spend on his work, the amount of work performed (for example, the number of welded metal products per shift), the consumption of electricity and materials (electrodes, welding equipment, etc.). Let's take a closer look at each of the standards.

Time standards

In most countries of the former USSR, there are so-called uniform time standards for making 1 m of seam. They are usually specified in regulatory documents. But, despite this, each welder must be able to independently calculate welding time, since this is one of the most important indicators of his productivity. The time standard consists of how many minutes the welder must spend on the immediate welding process, and how many minutes he must spend on preparatory and/or other production operations. In general, there are three production operations that make up the norm:

- Basic production operation. This includes the procurement of materials for welding and metal, its processing and preparation for welding. This also includes the welding process itself.

- Auxiliary production operation. This includes quality control of welded joints and seams, as well as transportation of the finished part to the next workshop.

- Additional time. It is also regulated and given specifically so that the welder can carry out maintenance of the welding process 1 and put the part into storage, if necessary, between the main and auxiliary operations.

Also note that before calculating the welding time, you need to take into account other processes that take even a few seconds during operation. Such processes include setting up the welding machine, the time spent igniting and burning the arc when welding special types of metals, time spent changing rods, applying flux or cleaning the seam, and the like. Also, do not forget to take into account that the welder needs time to care for the workplace and to rest (for this you need to subtract about 20% of the time received).

We wrote above that the qualifications of the welder, as well as his experience, are also taken into account. This is usually calculated using a special coefficient. During the calculations, we obtain a figure that is the equivalent of a qualification. Simply put, each qualification is assigned a number, which is then used in calculations.

The calculation can be done in different ways, but the most common is work units. One work unit is equal to one welded product. The higher the qualification, the more units the welder must perform per shift. If the volume of work is too large and does not allow calculation in units, then the time required to complete 1 m of seam is calculated in minutes. As you can see, the time standard includes many operations that should be taken into account when calculating. We'll talk about how to make the calculation later, but for now let's look at the rest of the rules.

Production rate

Output rate is essentially just the amount of work you complete in a certain amount of time. As we said above, the norm can be expressed in the number of products or in meters of weld that you managed to weld in an hour or per shift. The production norm can be simply one of the components of the time norm, or it can exist as an independent rule.

To make it clearer, we will give a simple example. Let’s say a welder needs to weld 24 meters of seam per shift. We calculate everything: the time that needs to be spent setting up the equipment, preparing the metal, igniting the arc, the welding process, and so on, plus we don’t forget to add time for rest. In total, for a welder of average qualification the norm will be 3 meters of seam in 1 hour. Accordingly, per day (assuming an 8-hour working day) the welder must make 24 meters of seam.

Electricity consumption standards

Another equally important rule that should not be forgotten. It is necessary to calculate the cost of welding work and the finished product. Often, consumption is calculated in kilowatt-hours that the welder spent on his work. Readings are taken from the meter.

Component consumption rate

As you understand, during welding you consume not only electricity and time, but also components: electrodes, gas, flux, wire, etc. This also includes the natural wear and tear of equipment used in welding. Not only equipment is subject to wear, but also specific elements required for special types of welding. For example, contact jaws, roller guides, contact plates and much more. All this needs to be taken into account. By the way, in this article we described in some detail how to calculate the consumption of welding wire. Be sure to read it.

In this case, the degree of wear can depend on many factors, for example, on the material from which the components are made, on the metal that you are welding, and even on the mode set in the welding machine. It is important to consider all these factors, since they also affect the cost of your work and the finished product. As you understand, standardization of welding work is simply necessary in a production environment.

Now that we have dealt with the standards, let's move on directly to calculating the time we need to spend on welding and see what standards modern construction documents offer us.

Safety rules according to SNIP

Labor safety of welding work in construction in SNiP is specified in Part 1, which contains general requirements. The list containing the scope of application also indicates the manufacture of structures and products. The document states that before welding can begin, the work manager is obliged to check compliance with the requirements specified in the regulatory document.

The safety requirements for welding metal structures are specified in the regulatory document SNiP III-18-75. It lists the following requirements:

- steel structures must be welded using a high-performance mechanized method;

- when welding, it is necessary to be guided by the requirements of the approved technological process;

- when welding, a stable mode is required;

- the manager must have a certificate indicating that he has the right to carry out work related to welding;

- manual, semi-automatic and automatic welding must be carried out by performers with a suitable category;

- Before assembly, it is necessary to clean the metal surface in the area of operations and the surrounding area;

- when performing multilayer welding, it is necessary to clean each previous layer before applying the next one;

- should be cleaned from dirt, rust, deposits, slag and metal splashes;

- moisture should be removed from condensation;

- during semi-automatic and automatic welding, during a break in work, before resuming the process, it is necessary to clean the end of the weld;

- the place where welding is carried out should not be exposed to drafts, wind, or precipitation;

- At sub-zero temperatures, heating devices should be located near the welder’s workplace, in particular for warming hands.

Welding metal structures according to SNiP will ensure that a welded joint of the required quality and reliability is obtained.

Calculation of time spent on welding

Time standards for welding work are established for a reason, you could understand this after reading the last section. As you remember, our productivity indicator is either the number of products that you welded or the meters of welds that you welded.

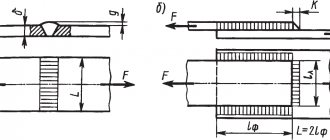

Below is a table in which you can see the uniform time standards for one-sided welding of butt joints without beveled edges. These standards are taken from ENiR (Collection E22, section “Welding work”). You can also find standards in SNiP for welding. The standard time for welding may differ depending on many factors: from the type of seam to, again, the qualifications of the craftsman. Now let's get down to direct calculations, since every master must know this and apply it in practice.

Calculations

To calculate the time for making 1 meter of seam with an electric arc, formulas are used. The most universal formula is as follows:

t0 is fundamental time, usually measured in hours and sometimes in minutes.

L is the length of the seam, usually 1 m of seam is measured in meters or centimeters.

F is the cross-sectional area of the seam, measured in square centimeters.

7.85 is an example of the density of the deposited metal, taken in grams per cubic centimeter, you must substitute your density value.

I is the value of the welding current, measured in amperes.

Kn is the deposition factor.

To calculate how much time a welder spends on work per day, simply multiply the resulting figure by the number of working hours.

If you need to calculate the time spent on gas welding, then use the following formula:

S is the thickness of the metal being welded, indicated in millimeters.

K is a coefficient, it depends on the type of metal used in welding (for low-carbon steel this coefficient is 4-5; for alloy steel, cast iron, brass and bronze - 6, for copper - 3, and for aluminum and its alloys - 4 ).

It would also be useful to remember the formula for calculating the time spent on oxygen cutting:

L is the cutting length, indicated in millimeters.

v is the cutting speed, denoted by mm in mi.

How to organize your workplace

In order for a welder to fulfill all the norms assigned to him per day, he needs to properly organize his workplace. Agree, sitting on an uncomfortable chair or with an incorrect desktop height is difficult to meet the norm. Our goal is to maximize labor productivity. Usually at work there are so-called NOT plans (scientific organization of labor). They describe in detail what kind of workplace you are entitled to. In the picture below you can see a workplace that complies with the rules.

In addition to physical comfort, the workplace must comply with safety regulations. Also, the welder should have easy access to all the necessary tools so as not to waste time looking for an electrode or a new part.

The need to follow the rules

Regardless of the type of equipment used, the welder and other people present at the work site are affected by negative factors.

The need to comply with the rules is explained by the possibility of the following traumatic situations:

- sparks getting on the welder’s clothes;

- burning shoes made of fusible materials;

- injury to the skin of the face and organs of vision by hot metal vapors;

- ignition of materials located on the site due to the spread of sparks;

- burns from particles falling on the skin;

- high-intensity electric shock;

- falling of poorly fixed parts of metal structures.

Quality control of welding work

We're done with the standards, now let's talk about what the welder should do after welding. First of all, he must carry out quality control of welding work. In large industries this is done by individuals, but in most factories this responsibility is assigned to a welder. The topic of quality control is quite extensive, so let’s look at it in more detail.

Control of welding work can be divided into three stages:

- Welder qualification check

- Quality control of welded parts

- Visual and mechanical quality control of welded joints

Let's take a closer look at each stage.

Qualification check

Before allowing a welder to work, you need to check the compliance of his skills and assigned qualifications. Each welder must present documents with a welding permit and make a test weld on a sample of the part given to him. During the test, you need to use the same electrodes and the same metals as during the main work. The samples are then sent for examination and examined. If the welder’s work complies with the standards, then the master is allowed to weld.

Quality control of welded parts

Before work, you need to check the quality of the parts that need to be welded. Parts must have appropriate documents and be made of certified metal. Before welding, the parts must be carefully inspected to find out if there are any defects. In general, the quality of parts is also regulated by standards. You can study them separately by reading SNiPs and GOSTs.

Visual and mechanical quality control of welded joints

This is the final stage, which is carried out after welding. First you need to clean the seam from slag and particles of splashed metal. Then you need to inspect the seam. Ideally, the seam should have a fine-scale structure, and the transition from seam to metal should be smooth. The height of the seam should not exceed 3 millimeters, ideally 1 millimeter.

If welding rules are not followed, defects will form almost immediately, so a visual inspection can help identify 50% of problems before the part is subjected to more serious testing. During visual inspection, cracks, excessive porosity of the joint, excessive slagging, and unwelded seams can be detected.

After a visual inspection, the seam must be subjected to mechanical tests. With their help, the tensile strength of the connection is determined. If deficiencies are found, additional inspection is carried out to confirm the presence of defects. If, after a second check, the negative result is confirmed, the welder will be removed from work and sent to advanced training courses.

Mechanical testing can reveal additional defects that are not visible during visual inspection. This may be lack of penetration of the root of the seam, lack of lateral penetration, burn-through or internal cracks. If the welding seam is long, then cutting out the defective area is allowed.

Ultrasonic testing of welded joints

Ultrasound can be used to check the quality of welds. The principle of operation is simple: the device generates ultrasonic waves with a frequency of up to 20 thousand Hz, which easily penetrate the pores of the seam and begin to be reflected from internal cracks and or voids, if any. The sound wave is straight, but if there is a defect in its path, it becomes bent.

Such work is usually entrusted not to a welder, but to a special operator who records all defects on the device monitor and records the test results in detail. In general, this is one of the most popular ways to detect defects hidden from view.

We have listed the most popular methods of quality control. Of course, there are other methods, but the ones listed above have long proven themselves to be the most effective. Especially in large-scale production environments. After quality control of welding work has been carried out, the results must be recorded in a journal and on a drawing.

What can be used as a return wire for electric welding?

As a return wire connecting the product being welded to the welding current source, flexible wires can be used, as well as, where possible, steel bars of any profile of sufficient cross-section. The return wire must be insulated in the same way as that connected to the electrical holder. The use of metal building structures of buildings, communications and non-welded technological equipment as a return wire of the grounding network is prohibited.

The individual elements used as the return wire are carefully connected to each other (by welding or using bolts, clamps or clamps). In arc welding installations, if necessary (for example, when making circular seams), it is possible to connect the return wire to the product being welded using a sliding contact.

Requirements for welds

It is also advisable for the welder to know the requirements for welds of metal structures. This will contribute to proper quality control and adequate assessment of your work.

Requirements for the mechanical properties of a welded joint

Welding metal structures or welding pipelines implies the absolute strength and reliability of the welds. This can only be achieved if the requirements for the mechanical properties of the joints are fully met. Based on GOSTs and rules, we have identified the following basic properties of the seam that must be observed in order to obtain a high-quality connection:

- The relative elongation of the weld metal should not be less than 15-16%.

- Impact strength must be at a high level. To find out this parameter, you need to conduct a test: check the reaction of the seam at the average daily temperature, and the test must be carried out for a week at the lowest temperature in your region. The minimum value of impact strength is 29 J/sq.cm.

- The tensile strength of the weld should be similar to that of the metal used for welding. A lower resistance value is not allowed.

- The hardness of the metal should be 350 HV for welded structural elements belonging to group 1, and 400 HV for welded elements of all other structures. These rules are regulated by SNiP II-23.

Weld quality requirements

When welding metal structures, it is extremely important to pay attention to the quality of the seam itself. Previously, we talked about how the quality control of welding joints is carried out, now we will talk about the classification of seams based on their quality. So, seams come in three categories:

- First category. Best quality. This category may include any type of seams that have special requirements for durability and reliability. Seams of the first category must withstand enormous loads and ensure reliable connection of complex metal structures, including industrial ones. Seams of the first category are used to weld metal frames of buildings and the hull of ships. Also in the first category are seams designed for long-term use in harsh climatic conditions. For example, in the Far North.

- Second category. Medium quality. This is the most common category and includes any type of tear-resistant seam. In general, most compounds can be classified into this category. A striking example is the seams used to weld car bodies. Such seams can withstand relatively large loads, but are not designed for use in harsh conditions.

- Third category. Below the average. Seams of this category are not necessarily the worst in quality, but they definitely cannot be applied to critical structures. But you can weld auxiliary metal structures, saving time and effort.

Other requirements for welded joints

Requirements for welded structures and seams can be very diverse, and in addition to those indicated above, there are a number of features that are worth knowing before starting work. Within the scope of this article, we will not be able to describe all the features, since the welding process has many nuances. We recommend that you familiarize yourself with SNiPs on the topic that interests you. There you can find all the necessary information about the location of the welding joint, its recommended length and thickness for each type of structure and metal. Think of norms not as a set of rules, but as a convenient cheat sheet for work.

Necessary skin and eye protection

When starting work, the welder must use the following accessories to prevent injury:

- Work suit. Special clothing is issued by the enterprise. It is sewn from fire-resistant fabrics - tarpaulin, suede, split leather. Suits made of synthetic fabrics are prohibited. In winter, they wear cloth clothes.

- Mittens or gloves. Suede products are of the highest quality. The tarpaulin burns quickly, so you will have to change the mittens often.

- Shoes made from different materials. Most often, enterprises provide employees with tarpaulin boots or boots with rubberized soles. Shoes should not have nails that increase the risk of electric shock.

- Welding mask. It is not advisable to use self-made shields. Even a small gap in the mask can cause damage to the organs of vision.

Increased demands are placed on industrial safety equipment for welding.

Technical conditions for the manufacture of welding structures

Technical standardization is extremely important; it regulates the entire welding process. The final result at an assembly and welding plant of any scale depends on the correct organization of work. Technical specifications for the manufacture of a welded structure are, in fact, a set of documents that you can read and find out all the information about a particular part. These documents describe all stages of the welding process: from preparation to transportation. The classic package of documents consists of drawings of the finished product, technical specifications and a production program (it can be approximate). Let's take a closer look at this.

Let's start with the drawings. Not a single more or less professional welding can do without them, since it is impossible to accurately determine “by eye” where the seams should be. This is especially true for particularly critical metal structures, which can cause harm to humans if welded incorrectly and subsequent destruction.

The drawings usually contain information about what metal is used in the manufacture of the product, what features it has, what size and thickness of the metal is used, what types of welds are used in welding, etc. The drawing is submitted to the chief engineer for verification, and work begins only after approval. If the engineer finds inaccuracies, the welder (or a separate designer) needs to make a new, corrected drawing. Now let's talk about technical conditions, as a separate component of the package of documents. GOST No. 15001-69 says that technical conditions should be selected in accordance with the drawings, expected operating conditions of the product and accumulated experience. In simple words, the technical specifications describe where and under what conditions the part will be used, whether it will cause harm, etc.

The technical specifications also indicate the operating features of the structure or part. For example, the product may not be intended for use at sub-zero temperatures or under increased mechanical loads. All this information must be indicated in the technical conditions in order to avoid problems. So there are several types of designs: especially responsible, responsible and all others. Based on the type, the corresponding conditions are prescribed.

And the last act included in the documentation package is the release program. As we indicated earlier, it may be approximate. This indicates the number of products that need to be produced within a certain period. This information is needed not for accounting of manufactured products, but as a basis for using a particular set of welding equipment and proof of the economic feasibility of using such a set in work.

The production process consists of many stages and it is extremely important to follow their sequence and not deviate from generally accepted norms. This will help produce products quickly, efficiently and inexpensively.

Filling rules

The welding permit is printed on regular A4 sheets. They must be clean, as parts of the form may move to the reverse side, this is acceptable. In this case, the sheets must be fastened together; there is no need to number the pages.

The work order itself is issued in two copies, one of which is handed over to the shift supervisor, and the second remains with the authorized person for filing with the case.

You can fill out the form manually or electronically. This way you can avoid the risk of blots, grammatical errors and unreadable handwriting. The welding permit must be filled out only with a good writing, non-smearing pen. A pencil, marker and other office supplies will not be useful.

Errors, blots and dirt on the document will cause it to be reissued. You cannot correct anything, especially with a proofreader, otherwise the form may be declared invalid. This is another advantage of filling out a document electronically, where errors can be corrected at any time before it is printed.

Important!

The work permit must be filled out in duplicate, either manually with a pen or electronically, without any marks!

Design rules

The responsibility for drawing up a special document on permission to perform hot work lies with the person appointed by the order responsible for fire safety measures for the enterprise or its structural unit. Through its local regulations, the company can independently establish a list of employees who can issue such orders. An exception is for organizations that are subject to special rules (for example, machine-building plants), where approvals are made by the head of a unit (shop, department, etc.).

If the organization acts as a contractor, then the permit document must be issued by an authorized person of this organization with the approval of the hot work with the fire safety services of the customer company. An appropriate note must be made on the permit form.

It is important that a separate permit is issued for each type of hot work and for each work shift.

All issued orders are subject to recording in the appropriate registration log.

How many joints should a welder weld per day?

Assessing the effectiveness of a welder’s production activities and calculating his remuneration is carried out taking into account the time standards for welding work.

The time indicator depends on several factors: the qualifications of the performer, the group of material being welded, the type of seam joint, working conditions, equipment.

When assessing the rate of time spent, all types of activities of the welder should be taken into account. The work can be roughly divided into several stages:

- The main procedures include procurement, pre-processing, assembly, welding itself and final finishing necessary to obtain a complete product;

- auxiliary operations consist of monitoring the condition of the received product and delivering it to the intended place;

- Additional time is required to maintain welding and organize conditions for proper storage of materials and devices.

Time standards for carrying out the main set of welding work take into account the time spent on preparing all the necessary materials and parts; bringing equipment and auxiliaries into working condition.

An important factor for calculating time standards is the period during which the work zone is initiated. An example would be arc burning time.

The main types of welding work are accompanied by mandatory auxiliary activities. You need to change the electrode, carefully inspect the seam, and prepare the edge if necessary.

All main and auxiliary procedures constitute operational welding time. It is impossible to postpone them without compromising the result.

Quantitative calculation of the rate of time spent determines the welding speed, which should ensure a high-quality seam. To a predominant extent, it depends on two values: the thickness of the product and the weld seam. You need to work so that the liquid melt does not overfill the working bath, does not form sagging, and smoothly passes to the main part of the parts.

Exceeding or decreasing the speed leads to a sharp deterioration in the quality of work, changing the welding time. At optimal speed, the seam is deep enough, but not very wide.

This guarantees compliance with quality standards. For manual arc welding, the best results are usually obtained by welding work carried out at a speed of 30-40 m/hour.

Standard values may vary depending on the specifics of the material. With semi-automatic welding, speeds are often higher. This is understandable and explainable by the specifics of the equipment used.

A welder, in accordance with his qualifications, has to work with a variety of materials. This significantly affects the standard welding time.

It is customary to distinguish several main groups, differing in the content of chemical components and purpose. For example, group M01 includes structural steel alloys with a carbon and low-alloy composition. The yield strength of these materials does not exceed 360 MP.

As the value of the number in the marking increases, the characteristics of the alloys improve. Thus, class M07 includes reinforcing steels intended for the manufacture of reinforced concrete structures. When calculating time standards for welding work, the quality of materials is of fundamental importance.

When making calculations, a number of standard indicators are used that take into account the specifics of welding, the qualifications of the performer, the characteristics of the chemical composition and shape of the parts. In its simplified form, the formula is a fraction.

The numerator contains the length of the seam joint, the denominator is the normalized speed for a given production situation. The resulting value must be multiplied by a factor of 0.35, thus obtaining the time standard for visually assessing the quality of the seam.

To take into account the duration of stripping a seam, you need to multiply its length by a factor of 0.6. The total indicator displays the total amount of time for the main part of the welding work.

Preparation requires 5% of the time from the obtained value. We calculate this indicator and add it to the previous number. After that, you should take into account the need for the worker to rest, which should be at least 10% of the time spent on welding.

The total indicator is the standard time spent on carrying out specific welding work on the object in question.

It should be taken into account that the standard indicator of the speed of welding work is significantly influenced by the size of the cross-sectional area of the part, the current strength, and the quantitative characteristics of the electrodes and melt in the working area.

Calculation of time standards for welding work can only be carried out by experienced specialists in the field of labor standards with knowledge in this industry.

Welder is a prestigious profession. They get paid better than many others, because a high-quality welder is worth his weight in gold. But knowing how to cook using conventional methods is not a difficult task.

As practice shows, after several attempts, even the most ordinary person can somehow weld one metal workpiece to another.

That’s why people learn this profession, that’s why there is such a thing as the ranks of welders.

Before moving on to analyzing the categories of welders, it is necessary to understand the categories.

How to fill out the fields

In the document, the specific names of the columns are clearly and clearly given on the title page; it is difficult to make a mistake here. So, a well-executed document may contain:

- The name of the company that performs the task.

- At what facility the welding work is performed, its address and name.

- Full name and position of the employee who performs the work and enters data on its completion in the journal (this paragraph provides a place for a signature).

- The name of the company that developed the design documentation for the work. There may be a dash in this paragraph if project activities were not carried out, and the employee acted according to ready-made diagrams and drawings.

- Project code.

- Who manufactured the connected structures.

- Full name of the representative of the customer of the welding work performed with the title and signature of the technical supervision officer.

- Dating: beginning and end of journaling.

Important point! Even if two teams of welders from different organizations are working on a construction site at once, they keep separate logs of welding work. And vice versa. When moving to another facility, one organization is required to start a new journal.

After the title page, the financially responsible person should fill out a table with data on the engineering and technical personnel who were involved in welding work. These are mainly engineers and chief engineers. It was these employees who found it necessary to connect metal elements in a specific place and in exactly this way.

The list may consist of one or several lines, it depends on the number of employees involved in the design and development of technical specifications. In any case, it is necessary to record information about employees as completely as possible, indicating their full name, education, category, specialization and position.

Two separate columns are dedicated to the start and end dates of work at the described facility. If a trial takes place, then using these data it will be possible to identify those responsible for the incident.

This table must contain information whether the engineer responsible for the correct execution of welding work has a certification mark for this type of construction activity.

In her absence, the manager does not have the right to allow this specialist to monitor the performance of welding work.

After the table with data about engineers, there is data about the welders themselves, who are responsible for the quality of the work done and certify this with their signatures in the last column. In addition to it, the second table on personnel includes information about:

- FULL NAME.

- Qualification level of the employee.

- The number of the personal mark (it is placed on each welded joint made responsibly).

- Welder's certificate (validity period, number, in what spatial position he has the right to weld seams).

- The quality of welding of the provided test samples (satisfactory or unsatisfactory).

The welder's mark is a blank consisting of two lines of numbers 5 mm and 3 mm high, with or without a frame. It helps to determine which employee welded a particular joint. This is especially true for pressure vessels and other metal compounds, on which people’s lives may directly depend.