Spread the love

Drilling deep holes is a rather complicated operation, especially if you need to drill not one or even ten holes, but hundreds and thousands. The difficulty is that during such an operation it is very easy to break the drill bit.

This article covers the various techniques required, including step drilling, parabolic flute drilling, basic G-code cycles, and so on.

Most CNC machinists know that Peck Drilling, or step drilling, helps when machining deep holes. Some use high-performance geometries, such as parabolic drill bits.

But it turns out that there are a number of known techniques that will help you achieve success when drilling deep holes. I have put together a number of techniques that can help you a lot when drilling deep holes.

Drilling deep holes. Tip from HAAS

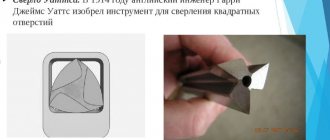

Drills for deep drilling - gun, gun, ejector

A gun drill is a tool that is used to drill through and blind holes of considerable depth. Holes of this type are made in shafts for various purposes, in spindles, as well as in other parts characterized by a significant length. For this purpose, not only gun drills are used, but also, in particular, single-edged and double-edged drills with internal chip removal. Drilling with the help of the latter is characterized by low productivity, but the deep holes made are characterized by high cleanliness, accuracy of geometric parameters and straightness.

Deep drilling process on a turning-milling center

Safety precautions when drilling

When through drilling, regardless of the depth of cut, the following rules must be followed:

- Medium and large workpieces are firmly fixed on the machine table or in fixtures. The immobility of a small product during operation is ensured with the help of hand vises. Under no circumstances should you hold the part with your hands.

- It is prohibited to change or install a tool in a rotating spindle, except in situations where the spindle is equipped with a safe chuck that allows you not to stop the machine to make such a replacement.

- Do not transfer belts from one pulley stage to another if the electric motor is turned on. Such actions are only permissible when the machine is stopped.

- The shavings cannot be brushed off the table with your hands, even with mittens; they cannot simply be blown away. Brushes or hooks are used to clean the work surface.

- Hanging ends on workwear are not allowed. The sleeves are buttoned or rolled up above the elbow. The specialist must tuck the hair under the headdress.

- Processing fragile materials may be accompanied by flying chips, so the worker must protect his face with special glasses.

- When using an electric drill, you must wear rubber gloves, and the body of the tool is grounded.

And one more rule: you cannot be distracted while drilling. You must always be sure that your hands are not under the raised tool, even when the unit is not working.

Features of drilling deep holes

Drilling is called deep if the depth of the hole exceeds five of its diameters. This technological operation is highly complex and labor-intensive, and the main condition for its high-quality implementation is the effective cooling of the tool used, which, as a rule, is carried out under pressure.

In order to perform deep drilling efficiently and accurately, it is very important to ensure the correct direction of the tool at the very beginning of processing. To do this, use a special conductor sleeve or carry out this procedure through a pre-made hole of a smaller diameter.

Due to technical difficulties, deep drilling should be performed using special equipment

A drill used for deep drilling must not be rotated at full speed outside the workpiece itself: this may lead to the cutting part being displaced from the required trajectory. In addition, when drilling deep holes with a long drill, unfavorable conditions are created for removing chips from the processing zone, which can also lead to the tool moving away from the specified direction.

Technologies for drilling holes in metal used in everyday life

In everyday life, three technologies are used for drilling holes in metal. Workpieces and sheets are clamped using clamps and a vice. Most often, ordinary household drills and cylindrical twist drills are used at home.

Conventional drilling

This metal drilling technology is familiar to everyone.

The hole is marked using a hammer and center punch.

The workpiece is clamped in a vice or using a clamp.

A drill of the required diameter is inserted into the drill chuck and clamped.

Drill a through or blind hole.

Photo No. 3: drilling metal at home

Reaming

Metal drilling is a technology aimed at increasing the diameter of a previously made hole. To do this, take drills of large diameters.

At home, holes usually have to be drilled in stages, gradually increasing the diameter of the tools used. This is due to the fact that in many cases the power of a household drill is not enough to drill large diameter holes in thick workpieces. In addition, the step-by-step approach reduces the axial pressure on the drills. This significantly reduces the likelihood of breakdowns.

Image No. 1: the principle of drilling large diameter holes in thick metal at home

Reducing the diameters of the deep parts of the holes

In this drilling technique, a shallow, large-diameter hole is first drilled and then smaller tools are used. The technology looks like this.

Image No. 2: technology for reducing the diameters of holes in metal

Types of deep drill bits

The following can be used as drills for deep drilling:

- spiral drills with a cylindrical shank, the parameters of which are regulated by GOST 886-77 (by design, spiral drills with a cylindrical shank belong to a long series of tools, with the help of which they create holes with a depth exceeding a value equal to 15 diameters);

- rifle, the cutting part of which is completely made of hard alloy;

- rifle, on the cutting part of which carbide plates are fixed by soldering;

- rifle, equipped not only with main, but also with intermediate carbide plates;

- ejector, which are used to perform deep drilling on machines with a horizontal cutting tool;

- cannon type, on the surface of which there is a V-shaped groove designed to remove chips (processing with drills of this type is an outdated method of producing deep holes).

Deep drill bits

You can familiarize yourself with the GOST requirements for long series drills by downloading the document in pdf format from the link below.

Twist drills with a cylindrical shank, produced in accordance with the requirements specified by GOST 886-77, are distinguished by an elongated working part. In accordance with the provisions of the above-mentioned standard from the year 77, such an extended tool can be made entirely of high-speed steel or equipped with cutting inserts made of carbide.

GOST 886 from 1977 also stipulates that cooling of drills of this type can be ensured through not only external, but also internal coolant supply. Twist drills, as indicated by GOST 886-77, can be produced not only with a cylindrical shank, but also with conical shanks. The process of deep drilling itself, carried out using such drills, can be performed either with their periodic removal from the hole being made, which is necessary to remove the formed chips from it, or without performing such a procedure. If we compare spiral drills with gun and cannon drills, then when using the former, drilling productivity increases almost 8 times.

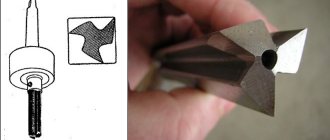

Examples of working heads for gun drills

Gun and gun drills are single-cut tools that can be used to create deep holes with diameters ranging from 0.5–100 mm. Cooling of drills of this type is carried out through a hole made in their internal part, and the chips formed during the processing process are removed using a special groove made on their outer surface. Gun and gun drills equipped with cutting carbide inserts are distinguished by a conical configuration of the working part, which ensures better direction of the tool into the processing area.

Ejector drills are more modern means of deep drilling. Due to the absence of chip grooves on their outer surface, they are characterized by high rigidity.

Operating principle of an ejector drill

How to drill a large diameter hole in metal

This procedure is much more complicated than deep drilling. For small metal thicknesses, this procedure is performed with a special crown, or with ordinary metal drills in several passes.

Crown

It consists of a kit that includes a regular drill that evenly punches a channel in the workpiece and the crown itself of a certain diameter. The working process is carried out at low speeds of the drill, while forced cooling of the cutting edges of the drill and bit is carried out.

Multi-stage drilling

If the part is thick, it is necessary to have a certain supply of drills, the difference in diameter should be within 25% of each other. Work should begin with the thinnest drill. As soon as a through channel is drilled, the drill is replaced with a diameter larger than the previous one. Thus, gradually, the drills are changed to the diameter of the given size.

Step cone drill

This is a set of cone-shaped drills of various diameters located on one common axis. Quite a convenient tool for working with steel sheet metal. The operating principle is practically indistinguishable from conventional drilling.

A step-cone drill is driven into the workpiece until the desired size of the hole being drilled is reached.

Punching holes

The technology of punching holes in metal alloys is quite common. It is used when working with sheet metal. The advantages of the technology are that holes are punched exactly at a given point with a clear diameter and practically without losing a certain amount of time. For this purpose, specialized pressing machines are used.

A hand punch can be used to punch through thin sheet metal . This tool for punching holes in metal is made from a steel pipe pointed at one end. Pipes of various diameters can be used for the punch. To punch a hole, the punch is placed at the marked point, after which several strong blows are applied to it with a hammer. The result is a neatly punched hole.

How to choose the right tool

When choosing drills for deep drilling, you should consider a number of factors:

- diameter and depth of the hole to be made;

- characteristics of the processed material;

- the type of equipment that will be used to perform the processing.

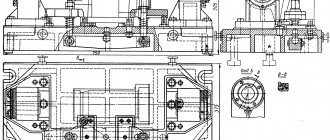

Scheme for calculating drill length when working on a universal machine

It should be borne in mind that the device on which such a drill will be installed must be designed specifically for deep drilling.

Before starting drilling, you should select the optimal speed of rotation and feed of the cutting tool, as well as ensure its effective cooling. For materials that produce long chips when cutting, it is best to use a drill with polished flutes.

Gun drills can be single- or double-sided cutting

Through Drilling Tools

Most often, through drilling is carried out using hand and electric drills, drilling machines, if such a possibility exists. The main element of all the listed devices are drills, which can be of any shape, namely they are:

- spiral (used in most cases);

- screw;

- crowns;

- conical;

- feathers, etc.

Drills, regardless of type, must meet the requirements of GOST standards. There are no markings on tools up to Ø 2 mm; for products up to Ø 3 mm, information about the cross-section and grade of steel is recorded on the shank. For larger diameters, the manufacturer may provide additional information.

To make a hole of a certain size, a drill tenths of a millimeter smaller than the required number is required. The difference between these two sizes depends on the quality of its sharpening - the better the tool is sharpened, the closer the values will be.

Drills come in different lengths and can be short, long or long. When choosing a tool for through drilling, it is important to consider the maximum hardness of the workpiece metal. In addition, the drill shank can be cylindrical or conical, which should not be forgotten when selecting a drill chuck or adapter sleeve.

The implementation of some technological operations and the processing of a number of materials involve special sharpening. The higher the hardness of the metal being processed, the sharper the drill edge should be. Let's say that it is not always possible to drill through thin sheet metal with a conventional twist drill - the latter will have to be replaced with an analogue with a special sharpening. Each type of drill has its own recommendations in accordance with the thickness, hardness of the material being processed, and the type of hole. Since this is a fairly voluminous layer of information, it will not be touched upon in this article.

Before starting work, the workpiece is secured using a vice, stops, jigs, angles, clamps with bolts and other devices. As a result, the safety of the specialist is ensured, and higher quality is achieved.

Technology stages

The process of deep hole drilling itself is performed in the following sequence.

- First of all, a pilot hole is made with an H8 tolerance.

- The tool, rotating at a low frequency, is brought to the surface of the workpiece.

- They include the required rotation speed of the drill and its feed rate, and ensure the supply of coolant to the processing zone.

- The hole is drilled to the required depth without retracting the tool.

- If a very long tool is used for deep drilling, then the first 25 mm of the hole depth is processed at reduced cutting conditions - 75% of the nominal ones.

- After reaching the required drilling depth, the coolant supply to the processing zone is turned off.

- After finishing drilling, the tool is quickly removed from the processing zone and its rotation is stopped.

There are several other deep hole drilling techniques, but the above is the most common one that is used in most cases.

Pre-setting the drilling process

The deeper the hole, the longer the drill. The longer the drill (the greater the distance between the tool tip and the spindle), the greater the influence of runout on the results. In some deep hole applications, the slightest vibration can cause premature tool wear and affect both straightness and surface finish.

However, the need for careful setup does not eliminate the need to spend an inordinate amount of time determining and adjusting runout every time a tool or insert is changed. In particular, in today's manufacturing environment there is no room to climb around work areas to install indicators or to hold pieces of paper in place for tool touches. Most likely, assembling the tools offline with a presetter will save a significant amount of time in any deep drilling operation.

In today's manufacturing environment, there is no room for an operator to work in the work area, to set indicators, or to hold pieces of paper where the tool and part meet.

At one customer's site, three Stealth drills with Allied Machine inserts are installed in the tool shop at the start of each shift. This process takes less than 10 minutes. Setting up three tools on a processing line can take up to 30 minutes, representing 90 minutes of wasted time over three shifts. In a 24/7 production environment, this amounts to nearly 2,200 hours per year (a figure that does not include machine downtime during tool changes). Pre-tuning is probably 5% of the cost of those lost hours.

This drill has an adjustable pin that moves the insert radially to reduce the tolerances common to all indexable tip drills. As a result, dialing no longer requires disassembling and cleaning the tool assembly, adjusting offsets, adding shims to turrets, or relying on experienced machinists trying to find an unorthodox solution. Preset helps reduce setup time by pre-setting the drill bit into the magazine in a holder with minimal runout.

Drilling accessories

Working with metal is a rather labor-intensive process even for experienced professionals. Sometimes you need to hold the drill in strictly one position towards the workpiece for a long time. To make work easier and drill metal efficiently, a right-angle drilling device is used.

There are three types of such devices:

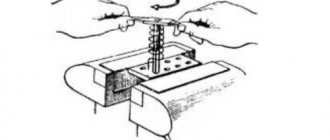

Drill guide

This device is in the form of a box with guide bushings installed inside, which are made of heavy-duty steel that is resistant to drills. The jig can be used for almost all drill diameters up to 20 mm. After installing this device above the center of the intended hole, the drill will no longer move away from its axis

The jig is convenient to use for working with pipes of small diameter, when it is impossible to use a core for marking.

Guide clamp for drill

This mechanism is designed to hold the drill stationary during operation. It consists of two posts, rigidly attached to the sole in the form of a large circle. moves along the racks , There, on the racks, under the drill locking mechanism, there are return springs.

As the drill deepens into the metal, under the force of the master, they compress, but as soon as the force stops, the springs straighten, and the mechanism holding the drill rises along the racks to its original position.

Drill Holder

Essentially, this is a simplified vertical drilling machine, but with minimal functions.

Read also: How to set up a parabolic antenna

It consists of a massive flat sole (platform) and a rigid rod attached to it. The rod is fixed to the platform at a strictly right angle. It also contains a movable carriage with a mount for holding the drill, and a handle for controlling it.

The workpiece is secured to the platform using clamps or a vice. The master lowers the carriage with the drill down by the handle and holds it during the entire drilling process.

Effect of coolant during drilling

Chip formation is the only way to evaluate drill performance during machining. Curved shapes (i.e., "sixes" and "nines") are ideal, while longer, stiffer chips conduct heat away from the cutting zone less efficiently. Color matters too. When the cutting zone overheats, the chips gradually turn gray, black and blue. Discolored chips may indicate the need to reduce heat by slowing the spindle speed, while tough chips may indicate the need to increase the feed rate to the point where the material being cut breaks rather than flakes.

One of the most underestimated factors in any machining process, even after drilling, is the coolant. Given the significant influence of coolant on how chips are formed, adjusting coolant concentration and flow can also help solve problems in optimizing drill performance in the cutting zone.

Water-soluble coolants are the most common because they dissipate heat well. However, semi-synthetic or all-oil formulations may be a better choice to improve lubricity and produce short, segmented chips. Although tools may wear faster and cutting parameters must be less aggressive than using a water-based coolant, an insert coating that improves heat resistance can help compensate for this.

One non-negotiable factor is the use of through-hole coolant. Machines must also provide sufficient coolant pressure. Small drills require significantly more pressure to remove chips because they must operate at higher RPMs to achieve the same surface speed than larger diameter tools. The more pressure, the faster the chips come out of the hole and the faster you can rotate the drill.

Prudence is a virtue

When drilling deep holes, ramping up to full speed and feeds can create safety issues and jeopardize the job. Thus, many of the standard recommendations for universal TA drills can be summed up in one phrase: approach the pilot hole carefully.

Approaching a pre-existing hole carefully helps avoid scarring or damage. This allows the drill bits to interact with the material before you get up to speed. The hole begins to act as a sleeve that keeps the drill centered and ensures quality parts.

Table of contents

Deep hole drills are devices that are used for drilling through and blind holes in shafts, spindles and other parts that are long. They have low productivity and produce completely clean, accurate and straight holes. Drills of this type include gun drills, single-edged drills with internal chip removal and double-edged drills with internal chip removal.

photo:drills for deep drilling

Features of deep drilling

The deep drilling method is used when cutting holes that have a depth of 5xD or more. This method allows the material to be processed with the greatest precision, as well as optimal straightness, which ensures good surface quality. This is a rather complex and time-consuming operation. The main condition for processing with a cutting tool using the deep drilling method is cooling under pressure.

The peculiarity of this method is the need to determine the correct direction when starting the cutting process. This direction passes through a special drill sleeve or into a pre-drilled pilot hole.

The main difficulty is that you cannot freely rotate the cutting tool when deep drilling at full speed outside the part itself. And also, when increasing the length of the drill for deep drilling, unfavorable conditions for the formation of chips are created, which are difficult to remove and remove from the hole during the process. Therefore, it is very important to maintain drill lead when deep drilling.

Types of drills for deep drilling

Drills for deep drilling come in several types:

- A spiral design that has a hole for supplying liquid to the cutting zone.

- A rifle device that has soldered carbide plates.

- A rifle device that has a solid carbide working part.

- Gun mounting with carbide insert and intermediate cutting insert.

- Spindle (feather) devices, which are used for machining holes in machine spindles.

- Cannon devices.

Twist tools are standard twist drills that have an extended working part. They are made from materials such as high-speed cutting parts and carbide. The former have an external coolant supply, and the latter have an internal coolant supply. Drilling with them is carried out through deep drilling, when the tool is removed from the hole in order to remove chips, and without this process. Their productivity is 8 times higher than that of rifle ones.

photo:long spiral drills for metal

Gun and cannon are single-cut cutting tools that are used to produce deep holes of small and large diameters (from 0.5 mm to 100 mm). Coolant is supplied through the device body, chips are discharged through a groove in the structure body. The rifle installation provides better direction of the cutting part; the working part is made conical in the direction from the cutting edge to the rod.

photo: gun drills for metal

The gun tool has a carbide cutting part, a hardened steel stem and a tempered steel shank.

There are also double-sided cutting (ejector and screw) and unilateral cutting of structures (gun and cannon) according to their purpose. And the third type is ring or trepanning heads.

Selecting a drill for deep drilling

Drills for deep drilling have certain selection criteria. Spiral and feather cutting tools are most often used.

The selection criteria are influenced by the presence of certain special equipment, a coolant preparation and supply system, as well as a splash protection system. Drills for deep drilling must be used exclusively on deep drilling machines.

When choosing a design, it is necessary to determine the required diameter, total length of the hole, type of shank and the material being processed. Also pay attention to the feed speed.

- If you are going to drill a hole that is longer than 40d, then you should simultaneously use two drills with a diameter of 10x400 mm and 9.95x800 mm.

- If the depth is 40d, then the structure must have a left-hand rotation direction in order for it to fit into the pilot hole.

- If the material has long chips, choose a tool that has polished flutes.

- When machining aluminum alloy, use single-edge designs that have a 180-degree tip angle.

Process technology

The coolant supply must be under pressure up to 10 MPa. Coolant volume – 20-120 l/min. This indicator depends on the diameter of the processing structure. Diameter processing accuracy is 7-9 grades. The roughness parameter is 2.5-1.25 microns. The possible deviation of the hole is no more than 0.5 mm for each meter of length.

Drilling technology

Drilling holes in metal workpieces or parts is a specific technology for removing thin numerous layers of metal with a drill rotating around its axis. In this case, the main condition for drilling is to keep the drill, fixed in the drill chuck, clearly perpendicular to the workpiece being drilled.

This is especially important when drilling thick metal. If during operation the drill deviates relative to the axis of the hole being drilled, it will simply break. To prevent this from happening, the drill must be firmly fixed. For this purpose, special devices are provided that you can buy at a tool store or make yourself.

Drilling modes

When working with a drill, it is important not only to secure it firmly, but also to choose the optimal mode of its rotation . When processing metal, an important factor remains the number of revolutions made by the drill over a certain period of time and the force that is transmitted to it during this time to ensure penetration into the metal.

For working with metals of different hardness, drills designed for different operating modes are also recommended. The speed of rotation of the drill directly depends on the thickness and hardness of the metal, as well as the diameter of the drill itself. The stronger the material being processed and the larger the diameter of the drill, the slower the drilling mode should be. An indicator of a correctly selected mode is long, spiral-shaped chips.

Core marking, template and jig

You can drill through the metal according to the markings made with a core, use a template or a special jig.

A core is a sharpened metal pin made of heavy-duty steel. With its help, a small recess for the drill is made on the metal part prepared for drilling in the place where it is planned to drill a hole.

To do this, the core is placed with its sharp end at the intended drilling point, after which a strong blow is applied to it with a hammer. The tip of the drill is inserted into the recess left by the core and drilling begins, and at the beginning of work the drill will no longer be able to move away from the marked point.

To mark the center of a cylindrical workpiece, experienced mechanics often use a strip of tin bent at 90 degrees. In this case, one shoulder must correspond to the diameter of the workpiece; it is applied to the workpiece, after which a line is drawn with a pencil along its edge. The operation is carried out 2-3 times, and the point of intersection of the lines will indicate the center of the cylinder, where a core can be used to make a recess for the drill.

The template is made to mark blanks of the same type, on which several points for drilling are marked. It is very convenient when you need to work with several sheet metal parts that are placed in a common stack and secured together with a clamp.

In cases where high accuracy and perpendicularity of the drilled channel is required or the distance between several holes must be strictly maintained, it is recommended to use a jig . Also, a jig will be necessary when working with thin-walled pipes, when it will be impossible to make a hole for the drill using a core.

When deep drilling, special devices are used to firmly fix the drill in a perpendicular position to the workpiece.

Deep drilling

The type of mechanical processing of ferrous metals by cutting holes with rotating mechanisms is called drilling.

There are simple and deep drilling.

In the second case, the depth of the hole must be more than 10 cm, or the depth of more than 5 original diameters (5*d). Using drills, holes of various depths and diameters or multifaceted sections are made.

Processing a workpiece for drilling can be done in several ways:

- The workpiece rotates, while at the same time the longitudinal feed of a non-rotating drilling tool is performed;

- The workpiece does not rotate, it is fixed;

- Simultaneous rotation of the workpiece and tool.

All these methods are widely used in practice. The greatest demand for the deep drilling process is in the following areas: metallurgy, pipe production, oil and gas and aerospace industries, production of heat exchanger plates and boilers, and many others. The most commonly used parts with deep holes are: rotors, shafts, axles, bushings, liners, cylinders, bandages, metal shells and much more.

We perform a full range of metal machining works:

Waterjet cutting

Milling work

Turning works

Locksmith work

Metal drilling tools and equipment

The following basic tools and equipment are used for drilling metals.

Household and industrial drills.

Holders for them, rigidly fixing the tools and allowing them to be fed smoothly and accurately.

Stationary machines for metal drilling (vertical and horizontal types, deep drilling, etc.).

Types of deep drilling

- According to the scheme for removing the material being drilled (chips), a distinction is made between continuous and annular deep drilling. In the first option, the drilled material is removed in the form of chips, in the second, part of the annular plane is removed in the form of a rod, the rest is also in the form of chips;

- According to the cutting method, the following types are distinguished:

- Single rod system (STS system). This method is optimally suited for processing parts in high-performance or mass production. The complexity of the process lies in the fact that it is necessary to use an oil receiver with numerous supply hoses, while the workpiece rotates. The single-rod system is considered the most effective for producing high-quality holes;

- Ejector system. Deep drilling method with average parameters for releasing workpieces. Allows drilling on multifunctional machines (for example, lathes or drills), the system is complemented by a stationary or mobile pumping station. The ejector method is suitable for producing holes d=20-60 mm. and up to 1200 mm deep, not excluding the production of intermittent holes;

- Drilling system with gun or tubular-blade drills with internal supply of lubricant and cooling material. This method is suitable for small enterprises where the technology requires deep holes of small diameter. Single-point drills can be easily integrated into universal machines. The cutter is made of hard alloys and has a V-shaped groove along the entire length of the drill rod, the angle of curvature of which can range from 110 to 1200 degrees. Recommended hole = 35-40 mm, length up to 50*d. With this method, there is no need to carry out operations such as countersinking and reaming.

- Depending on the degree of automation of the drilling process control, deep drilling is distinguished with automatic change of one or more mode parameters (for example, rotation speed, lubricant supply).

Technology for drilling through, blind and other types of holes

- Drilling blind holes.

Similar operations are performed using a sleeve stop on a drill or a measuring ruler fixed on the machine. The drill is brought into contact with the surface of the part, drilled to the depth of the drill cone and the initial position is marked on the ruler using the pointer. Next, the specified drilling depth is added to the resulting indicator. The result is a figure up to which work must be carried out.

There are drilling machines with a stop provided on the measuring ruler - its lower edge is set at the number to which you need to drill. Then the structure is secured with a screw.

VT-metall offers services:

Many units have automatic feed mechanisms with dials; they set the drill stroke to the required depth.

When working with blind holes, it is important to periodically remove the drill from the workpiece, remove the chips and measure the resulting depth using a caliper depth gauge.

- Drilling partial holes or half holes.

If the hole is located at the edge of the workpiece, a plate of similar material is placed against the workpiece and clamped in a vice. Then they make a full hole and remove the excess element.

- Drilling through holes.

For through drilling in a square, it is fixed in a vice, providing a wooden lining. First of all, complete drilling and checking along control circles are carried out. If the drill has slipped, the situation is corrected and work on the hole is completed. Next, the square is moved and installed in the same pattern to make a new hole.

Drilling holes in planes at an angle has its own subtleties, because it is important to avoid breakage and deflection of the tool. Therefore, they begin by preparing a site perpendicular to the axis of the future hole (it is milled or countersunk), wooden inserts or linings are installed between the planes, and then they begin normal drilling.

Working with a cylindrical surface also begins with preparing a site perpendicular to the drilling axis. Be sure to mark the center and then drill a hole, as is done on a plane.

Creating holes in hollow parts differs from other methods of drilling through holes in that it requires plugging the cavity with a wooden plug.

There are two methods to drill shouldered holes:

- They start by preparing a hole with the smallest diameter, which is then drilled out to one or two larger diameters within the depth of each step. Drills are changed in accordance with the number of steps, gradually increasing the diameter.

- Use a drill of the largest diameter, after which they move on to drills of a smaller diameter according to the number of steps.

The described approaches allow you to avoid the drill moving to the side due to good alignment. It is worth mentioning that the second method simplifies measuring the depth of the hole, since the depth gauge rests on its bottom.

To achieve maximum accuracy, make two passes. For the first, use a drill with a diameter 1–3 mm smaller than the diameter of the future hole, protecting the work from the harmful effects of the jumper. Then the hole is drilled to size, it is important that the drill is not dull.

Cleaner holes are obtained by through drilling with low automatic feed with parallel active cooling and constant removal of generated chips.

For small-diameter holes, high-precision machines with appropriate feeds or ultrasonic and electric spark methods are best suited. Whereas large diameters require reaming of the drilled holes. However, you need to understand that you should not drill holes made by casting, stamping and other methods. The fact is that here the center of the hole does not coincide with the axis of the drill, which is why the latter usually leads away strongly.

Liquid supply is a mandatory stage of the technological process, since:

- Effective removal of chips from the cutting zone through outlet channels is ensured;

- The friction force between rubbing parts is reduced;

- The heat that is generated during long-term drilling is removed, thereby ensuring the safety of the drill from burning out;

- Additional processing of the hole is carried out.

As the drilling depth increases, the difficulties in machining the hole increase.

For deep drilling, special tools, equipment and processing methods are used.

Simple drills and drills are not suitable for this, since it will not be possible to achieve drilling accuracy over the entire diameter, a given surface roughness, or straightness of the hole.

An important parameter is also the preservation of the surface of the recess with minimal deviation from roundness.

The use of traditional tools makes the deep drilling process low-productivity, labor-intensive, and in some cases (depending on the depth of the holes) impossible.

In practice, in the mechanical engineering sector, specialized equipment with technical equipment is used, with the additional use of special cutting and other auxiliary tools.

Non-standard devices are often required to perform technological techniques.

Features of deep drilling

When deep drilling, it is very important to follow the main principles of technology. Firstly, the rotation speed of the drilling part of the tool or the optimal cutting speed (feed rate) is selected. Secondly, normal chip crushing must be ensured, as well as complete removal of waste from the channel. An important point when grinding drilling waste is the safety of the cutting part of the tool; there should be no damage to the drill, the formation of burrs or other defects on it. Further, a key factor in high-quality surface treatment of workpieces or parts is the effective and competent supply of cutting fluid.

The drilling process takes place with the obligatory supply of cutting fluid under pressure and at a certain flow rate.

To do this, the system uses pumping equipment - oil pumps or pumps for pumping viscous liquids.

The system capacity is selected in accordance with the fluid flow and the required lubricant supply pressure.

The role of coolant and chip breaking

The biggest obstacle when making deep holes is chips:

- How can I get them out without jamming?

- How to prevent damage to the hole surface?

The choice of tools, drilling method and coolant supply matters.

Certain types of tools have inherent advantages for deep holes. Parabolic flute twist drills change geometry to optimize chip removal from deeper holes. Gun drills and BTA drills are designed for deep hole machining and especially for chip removal.

Coolant is critical for chip removal. The best approach is to apply coolant with as much pressure as possible to the tool tip. The high pressure coolant directly at the tip creates significant force to push the chips up and out of the hole.

The coolant through the spindle delivers pressurized coolant through holes drilled along the length of the drill. This helps remove chips from the bottom of the hole and really makes drilling deep holes easier.

Through-holes for coolant in spindle with twist drill

Peck drilling cycles are chip breaking and chip removal. Each step usually breaks the chip. Long, fibrous shavings cling to everything and are more difficult to remove. Compact chips can be removed more efficiently from deeper holes. The deeper the hole, the more often the twist drill must peck to keep the chips compact.

In addition, the height of the exit from the hole is important. The higher height helps pull chips out of the hole. But this slows down the work as the drill goes deeper, and you also have to be careful not to go all the way out of the hole. An open hole means that chips have reached the very bottom, from where they must be removed a second time.

Deep hole cycles use custom g-code to optimize strategy as the hole gets deeper and deeper.