When applying symbols to shut-off valves in the Russian Federation, TsKB standards are used. The Central Bureau has developed documents that contain an exhaustive list of products, with their brief description and numbers of legal acts. A brief description of the valves consists of an alphanumeric code. A total of five elements are used in the designation. How valves are marked and what the symbols used in the description mean, we will consider below.

What does the marking mean?

The term refers to the application of alphanumeric designations to shut-off valves for pipelines, gas and oil pipelines. This also includes graphic symbols of different types of products on hydraulic and pneumatic diagrams.

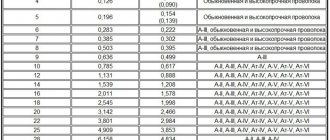

The symbols contain all the key technical parameters necessary for the sale and safe operation of products in various industries. The selection of the necessary reinforcement is done using a table of figures (ST TsKBA 036).

The numbers (1-2) immediately after the letters in the marking indicate the model number (design type). If the description has three numbers, the first of them indicates the type of shut-off valve drive (Table No. 3).

Instrumentation and automation devices in gas pipeline systems

In addition to all of the above, numerous instrumentation and automation devices (instruments and automation) are used in gas pipeline systems.

In addition to gas fittings, instrumentation and control systems are installed on gas pipelines. This allows for constant monitoring of the condition of the equipment and the progress of the technological process. And also quickly identify pre-emergency and emergency situations

The most popular devices used in gas systems are:

- gas alarms;

- equipment for emergency shutdown of incoming gas;

- equipment for measuring the volume of gas passed through;

- electronic regulators of the gas volume passed;

- autonomous power supplies;

- gas valves for automating various processes and optimizing the operation of pipelines;

- gas regulators for regulating the volume of medium passing through some section of the pipeline.

Such devices are high-tech equipment used in a wide variety of conditions.

Types of markings

Manufacturers use a unified scheme for applying numbers and graphic images. This approach allows the end user to quickly understand the range of valves. Types of marking:

- Alphanumeric description of parameters.

- Applying special marks to the product.

- Appropriate color scheme.

- Description of the product according to the table of figures.

Marking signs are applied taking into account the requirements of GOST 4666. Each symbol on the valve body or plate contains specific information.

GOST 4666-2015

The state standard defines the alphanumeric description and status of marking symbols. Types of symbols:

- Required. Can be applied to all types of valves and actuators.

- Additional. Applied to some types of fittings according to the manufacturer's decision. Plus if the application of such information is provided for by the contract or regulations.

- Special. They are applied to the fittings in accordance with the requirements of technical regulations, directives or safety regulations. Special signs are usually placed on a separate plate.

On a note! Additional symbols are mandatory for certain sectors of the national economy. For example, nuclear energy, oil and gas industries.

TsKBA standards

The Central Bureau has developed its own standards - TsKBA 023-2015 and TsKBA 036-2017. The first document defines the rules for the conditional description and registration of a table of figures. The manufacturer cannot establish mass production of locking products of its own design without the permission of the Central Design Bureau. Any other manufacturer can use a figure table registered with the bureau. The only requirement is that the manufacturer must indicate the letter “M”, “M1”, etc. at the end of the table. The new table of figures must be re-registered with the Central Design Bureau.

The second document serves as reference material for describing the valves and drives to them according to design documentation and tables of figures that have been registered with the bureau. The standard includes a complete list of products, with their conditional description and numbers of regulatory acts for the manufacture of products. The document is formatted in tables. They contain:

- mini-description of the product;

- designation according to tables (1, 2, 3);

- nominal pressure (kgf/cm²) and diameter (DN);

- description of products according to design documentation;

- TU or GOST for production and supply;

- drawings for each table.

Rice. 2. Table of figures

Each new model of released fittings is entered into the TsKBA standard 036-2017. In this case, the used table of figures must be indicated. Procedure for obtaining permission:

- The manufacturer submits an application to the bureau for registration of manufactured products. It must contain the technical parameters of the shut-off valves, the document number (TU), on the basis of which the product was manufactured.

- Bureau employees check the package of documents. Sometimes Central Design Bureau employees visit the workshop and inspect the valve production and assembly line.

- Products are registered in the Central Design Bureau directory.

A sample application for registration can be found in ST TsKBA 036-2017.

Where are they used?

There are many areas where such equipment is used. They can be roughly divided into the following subgroups:

- Household sanitary products. This area is rightfully considered one of the most extensive. Such fittings are used in the construction of water supply systems for both apartment and private houses. Installation is also carried out both in heating systems and gas stoves. Often, a manual control type is chosen, since their performance indicators are at the optimal level. They are also very reliable and have their own designation (check valves).

- Fittings that are commonly used in the design of river and sea vessels. This type of product is very specialized; in addition, equipment of this type should weigh little and be characterized by a high level of reliability.

- Pipe shut-off valve type, which is used on an industrial scale. This category includes fountain equipment, systems responsible for transporting radioactive and toxic masses, and the oil industry. Products used in these areas must be characterized by a high level of reliability and an appropriate service life. Resistance to corrosion is required, as is tolerance to sudden temperature and other changes (pressure).

- Fittings intended for general use. This type of fittings can be found in absolutely every area of daily activity of a modern person. This applies to both domestic and commercial use (purpose). So, examples include boiler rooms, water supply systems, gas pipelines and heating systems. All shut-off valves for water supply should also be included in this category.

Graphic symbols

Graphic symbols of different types of fittings on hydraulic diagrams are regulated by GOST 2.785-70. The interstate standard covers all sectors of industry and construction. The exceptions are hydraulic and pneumatic drives, and products of the aviation industry.

On a note! The interstate standard does not regulate the sizes of graphic symbols. The manufacturer has the right to combine symbols based on the type of connection and type of valve control.

Who determines the quantity, type of fittings and location of its installation?

The quantity, type of fittings and installation locations must be selected by the vessel project developer based on specific operating conditions and the requirements of the Rules.

Interesting materials:

How to fix a smelly herring? How to fix overly salted red caviar? How to fix lard that is too salty? How to fix blistering wallpaper? How to correct a statement on the government services website? How did Ivan Ivanovich quarrel with Ivan Nikiforovich? How did Ivan Timofeevich end up in Polesie? How to transfer from Excel to XML? How to get glucose from fructose? How to subtract a positive number from a negative number?

Marking methods

Manufacturers use different methods of applying symbols. Among them:

- Casting.

- Engraving.

- Impact method.

The manufacturer may use other methods of applying symbols to manufactured products. The only condition is a clear image throughout the entire service life of the product.

Requirements for applying symbols are described on the drawing of a separate part or on the assembly drawing of the marked product (clause 4.3.5 of GOST)

Components of the marking

On the valve body there is a mark in the form of the TsKBA system index.

Rice. 3. Marking

| Gate valve model | 30s41nzh Ru16 Du150 | 30ch39r Ru16 Du50 | 30ch6br Ru10 Du100 |

| Housing material | Carbon steel | Gray cast iron | |

| O-ring material | Stainless steel | Rubber | Bronze and brass |

| Digital description of the valve type | 30 | 30 | 30 |

| Letter description of case material | WITH | H | H |

| Letter description of O-ring material | NJ | R | BR |

| Table of figures (sealing material) | 4 | ||

| Valve drive type | Mechanical with spur gear | Manual | Pneumatic |

| Digital description of the drive type | 4 | — | 6 |

| Teak designs | 41 | 39 | 6 |

| Reinforcement diameter | 150 mm | 50 mm | 100 mm |

| Working pressure (kgf/cm²) | 1.6 MPa (16 Bar) | 1.0 MPa (10 Bar) | |

5.3. Pressure gauges

5.3.1. Each vessel and independent cavities with different pressures must be equipped with direct-acting pressure gauges. The pressure gauge is installed on the vessel fitting or pipeline between the vessel and the shut-off valve.

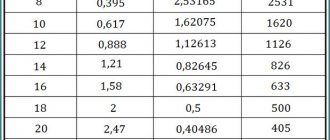

5.3.2. Pressure gauges must have an accuracy class of at least: 2.5 - at a vessel operating pressure of up to 2.5 MPa (25 kgf/cm2), 1.5 - at a vessel operating pressure above 2.5 MPa (25 kgf/cm2).

5.3.3. The pressure gauge must be selected with a scale such that the limit for measuring working pressure is in the second third of the scale.

5.3.4. The owner of the vessel must mark the pressure gauge scale with a red line indicating the operating pressure in the vessel. Instead of the red line, it is allowed to attach a metal plate painted red to the pressure gauge body and tightly adjacent to the glass of the pressure gauge.

5.3.5. The pressure gauge must be installed so that its readings are clearly visible to operating personnel.

5.3.6. The nominal diameter of the body of pressure gauges installed at a height of up to 2 m from the level of the observation platform must be at least 100 mm, at a height of 2 to 3 m - at least 160 mm.

Installation of pressure gauges at a height of more than 3 m from the site level is not permitted.

5.3.7. A three-way valve or a device replacing it must be installed between the pressure gauge and the vessel, allowing periodic checking of the pressure gauge using a control valve.

In necessary cases, the pressure gauge, depending on the operating conditions and the properties of the medium in the vessel, must be equipped with either a siphon tube, or an oil buffer, or other devices that protect it from direct exposure to the medium and temperature and ensure its reliable operation.

5.3.8. On vessels operating under pressure above 2.5 MPa (25 kgf/cm2) or at an ambient temperature above 250 °C, as well as with explosive atmospheres or hazardous substances of the 1st and 2nd hazard classes according to GOST 12.1.007-76 Instead of a three-way valve, it is possible to install a separate fitting with a shut-off valve for connecting a second pressure gauge.

On stationary vessels, if it is possible to check the pressure gauge within the time limits established by the Rules by removing it from the vessel, the installation of a three-way valve or a device replacing it is not necessary.

On mobile vessels, the need to install a three-way valve is determined by the vessel design developer.

5.3.9. Pressure gauges and pipelines connecting them to the vessel must be protected from freezing.

5.3.10. The pressure gauge is not allowed for use in cases where:

- there is no seal or stamp indicating verification;

- the verification period has expired;

- when it is turned off, the arrow does not return to the zero scale reading by an amount exceeding half the permissible error for this device;

- the glass is broken or there is damage that may affect the accuracy of its readings.

5.3.11. Checking of pressure gauges with their sealing or branding must be carried out at least once every 12 months. In addition, at least once every 6 months, the owner of the vessel must carry out an additional check of the working pressure gauges with a control pressure gauge and record the results in the control check log. In the absence of a control pressure gauge, it is allowed to carry out an additional check with a proven working pressure gauge that has the same scale and accuracy class as the pressure gauge being tested.

The procedure and timing for checking the serviceability of pressure gauges by maintenance personnel during the operation of vessels should be determined by the instructions for the operating mode and safe maintenance of vessels, approved by the management of the organization that owns the vessel.

Marking of shut-off valves

Symbols are applied to the valve body in accordance with GOST 4446. They contain:

- Passage diameter. It is indicated in millimeters. Example: in the description the letters and numbers “DN250” or the numbers “250”.

- Nominal pressure. The unit of measurement is “kgf/cm²” or “bar”. Example: the description contains the letters and numbers “PN25”. Pressure can also be indicated in MPa. But then a postscript is made: “PN2.5MPa”.

- Case material. A brief description of the alloy is displayed here. For example, a steel valve is “25L” or “WCB”.

- Manufacturer's logo. The use of an abbreviated name is permitted. Example: CJSC "SibZTA".

- Date of manufacture of fittings. Several application options are allowed. Example: "08/2015", "08/2015" or "August 2015".

- Factory number. Example: "77" or "No. 77". Sometimes manufacturers indicate the number and date of manufacture. The marking looks like this: “04.2015 – 77”, “04.2015 – No. 77” or “77 – 04/15”.

- Direction of rotation of the steering wheel. It is displayed in the form of arrows on the flywheel (← closed or open →).

The manufacturer may also add additional symbols:

- Description of valves according to design documentation.

- GOST or TU, according to which the shut-off valves were produced.

- Data on acceptance of quality control department.

- Standard shutter position.

- Weight of the locking device.

- Climatic performance.

- Gasket type (PON-B, CIS, TRG). The description is applied to the edge of the flange.

On a note! Mandatory symbols are applied to the body of the product being marked. It is also possible to repeat the data on the plate.

The front side displays the product diameter, pressure and body material. On the back there is information about the manufacturer, production number and date, temperature range. If the dimensions of the valve allow, then all data is displayed on its front side.

Separate markings are applied to the electric drives of the valves. Metal plates are used for this. They are attached to the engine housing.

Rice. 4. Label on the electric drive

Main characteristics

Increased demands are placed on products that fall into the category of gas valves, check valves or shut-off valves, since they are constantly in contact with an aggressive working environment that continuously moves inside the installed system. All basic standards and requirements are given in GOST No. 95-44-93. These are exactly what all domestic manufacturers adhere to in the process of manufacturing their own products.

Often, carbon steel is used as the main material, which is characterized as a high-quality material that is resistant to corrosion. Wrought iron, bronze or brass can also be used (in terms of cost, they are more affordable). The tightness of products is checked at the stage of their manufacture, after which, in accordance with existing norms and standards, they will be assigned a certain tightness class.

GOST No. 27-85-70 regulates what designations should be applied to the body of the product. The labeling must contain the following information:

- main material;

- manufacturer;

- diameter;

- pressure;

- direction of movement.

Requirements for product labeling

Letters and numbers on the reinforcement must be applied without tilting. The font size and arrows (casting) are indicated in accordance with Appendix “D” to GOST 4446. If the engraving method is used, then the requirements of GOST 26.008-85 must be taken into account.

When using other methods of marking on reinforcement, you must be guided by the provisions of GOST 2930-62.

Conventional symbols are applied on both sides of the product. The front part is considered to be the right side of the valve body. It determines the direction of flow of liquid, oil or gas. If such data is missing, then the front and back sides of the product are determined in the design documentation (clause 4.2 of GOST 4446).

Some information can be printed on flanges and connecting pipes. For example, on the body flange - 6, on the body-cover connection flange - 4, 8, 10-22.

If the valve diameter is less than 50 mm, then optional symbols can be applied to the tag or information plate.

Preface

Preface

The goals, basic principles and basic procedure for carrying out work on interstate standardization are established by GOST 1.0-2015 “Interstate standardization system. Basic provisions” and GOST 1.2-2015 “Interstate standardization system. Interstate standards, rules, recommendations for interstate standardization. Rules for development, adoption, updating and cancellation” Information about the standard

1 PREPARED BY Closed Joint Stock Company “Research and Production Company “Central Design Bureau of Valve Engineering” (CJSC “NPF “TsKBA”)

2 INTRODUCED by the Interstate Technical Committee for Standardization MTK 259 “Pipeline fittings and bellows”

3 ADOPTED by the Interstate Council for Standardization, Metrology and Certification (Minutes dated November 12, 2015 N 82-P) The following voted for adoption:

| Short name of the country according to MK (ISO 3166) 004-97 | Country code according to MK (ISO 3166) 004-97 | Abbreviated name of the national standardization body |

| Armenia | A.M. | Ministry of Economy of the Republic of Armenia |

| Belarus | BY | State Standard of the Republic of Belarus |

| Kyrgyzstan | KG | Kyrgyzstandard |

| Russia | RU | Rosstandart |

| Tajikistan | T.J. | Tajikstandard |

4 By Order of the Federal Agency for Technical Regulation and Metrology dated May 31, 2016 N 450-st, the interstate standard GOST 4666-2015 was put into effect as a national standard of the Russian Federation on March 1, 2022.

5 This standard has been prepared taking into account the main regulatory provisions of the international standard ISO 5209:1977* “Industrial fittings for general purposes. Marking” (“General purpose industrial valves – Marking”, NEQ) ________________

6 The standard was prepared based on the application of GOST R 52760-2007

7 INSTEAD GOST 4666-75

8 REPUBLICATION. April 2022 Information about changes to this standard is published in the annual information index “National Standards”, and the text of changes and amendments is published in the monthly information index “National Standards”. In case of revision (replacement) or cancellation of this standard, the corresponding notice will be published in the monthly information index “National Standards”. Relevant information, notifications and texts are also posted in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet

What color is applied and why?

Marking is not the only condition in the manufacture and use of valves. The body and lid are painted in a specific color. It depends on the type of metal used in the manufacture of reinforcement (Appendix “E”):

- Malleable and high-strength cast iron – black.

- Carbon steel - grey.

- Alloy steel – blue.

- High-alloy steel, heat-resistant and heat-resistant alloys - blue.

Rice.

5. Painting of valves When painting pipeline fittings for a gas pipeline, you must be guided by GOST R 56001-2014.

When painting valves for main oil pipelines, the requirements of GOST R 55020-2012 must be taken into account.

The manufacturer has the right to change the paint color at the request of the customer. It is also possible to supply unpainted products. However, the body and lid of each product are primed with a special composition.

On a note! The valve markings must not be filled with paint. The applied marks must be distinguishable after all types of processing of the product.

2 Regulatory standards

This standard uses regulatory references to the following interstate standards: GOST 2.310-68 Unified system of design documentation. Applying designations of coatings, thermal and other types of treatment on drawings GOST 2.314-68 Unified system of design documentation. Instructions on the drawings for marking and branding of products GOST 26.008-85 Fonts for inscriptions applied by engraving. Executive dimensions GOST 2171-90 Parts, products, semi-finished products and blanks made of non-ferrous metals and alloys. Brand designation GOST 2930-62 Measuring instruments. Fonts and signs GOST 5632-2014 Alloyed stainless steels and alloys are corrosion-resistant, heat-resistant and heat-resistant. Grades GOST 15150-69 Machines, instruments and other technical products. Versions for different climatic regions. Categories, conditions of operation, storage and transportation in terms of the impact of climatic factors of the external environment GOST 24856-2014 Pipeline fittings. Terms and definitions GOST 26349-84 Pipeline connections and fittings. Nominal pressures. Series GOST 28338-89 (ISO 6708-80) Pipeline connections and fittings. Nominal diameters. Series GOST 31441.1-2011 (EN 13463-1:2001) Non-electrical equipment intended for use in potentially explosive environments. Part 1. General requirements GOST 31441.5-2011 (EN 13463-5:2001) Non-electrical equipment intended for use in potentially explosive environments. Part 5. Protection by structural safety “c” GOST 31901-2013 Pipeline fittings for nuclear power plants. General technical conditions GOST 33259-2015 Flanges of fittings, connecting parts and pipelines for nominal pressure up to PN

250. Design, dimensions and general technical requirements Note - When using this standard, it is advisable to check the validity of the reference standards in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet or using the annual information index “National Standards”, which published as of January 1 of the current year, and according to issues of the monthly information index “National Standards” for the current year. If the reference standard is replaced (changed), then when using this standard you should be guided by the replacing (changed) standard. If the reference standard is canceled without replacement, then the provision in which a reference is made to it is applied in the part that does not affect this reference.