Steel water and gas pipes are the most popular rolled metal product for wide application. In addition to being used for laying communications in accordance with the name, they successfully perform the functions of heating devices. Smooth and ribbed registers of various configurations are made from VGP pipes, which are not inferior to modern radiators in terms of heat transfer efficiency. They are perfect for transporting coolant in systems with natural circulation, while simultaneously participating in space heating.

When installing steel water and gas pipes for heating, it is very important to know their main characteristics. First of all, these include weight and heat transfer coefficient. By carefully performing preliminary calculations, you will protect yourself from unexpected difficulties during installation and ensure the desired effect during operation.

Calculation of registers from smooth pipes

Steel heating registers are easy to make with your own hands.

The cost of such a heating system will depend on who will cook them. If you own the welding technique yourself, the option is the most low-budget; if the welder needs to be paid, there will not be much difference in cost with inexpensive aluminum ones. In this case, the registers will occupy larger areas than standard heating devices: due to the small surface of contact with air, their efficiency is low. They increase heat transfer by installing a more powerful pump, but there are speed restrictions due to possible noise in the system. Read about how to select the pump power here.

Diameters, as mentioned, range from 32 mm to 100-150 mm. Large pipe sizes lead to an increase in system volume. When starting and accelerating the system, this is a minus - it will take quite some time until the coolant heats up. When working, a large volume is rather a plus: milder conditions for the boiler. On the other hand, with a large amount of coolant, it is difficult to regulate the temperature.

Table of heat transfer of steel pipes of different diameters for different operating conditions of the system (click on the picture to enlarge its size)

The distance between two pipes in the register should not be small: this reduces heat transfer. Therefore, they are located at a distance of no less than 1.5 radii. The number of rows and register length depend on the required power, as well as the diameter of the selected pipes. In the general case (for central Russia, for rooms with average thermal insulation and a ceiling height of 3 m), it can be calculated by the heat transfer of a meter of steel pipe. These values are given in the table. Using it you can find the size and number of registers by area of the room.

Heat transfer of one meter of steel pipes of different diameters - to calculate the heating register by area

To calculate the heat losses of a room, there are averaged data on the thermal power of a linear meter of steel pipe. You can use them for standard conditions. If the system operates at other temperatures, adjustments may need to be made up or down.

If these tables did not help you, you can calculate the register using the formula.

Formula for calculating registers made of steel pipes

By substituting the appropriate values, you will find the heat transfer of one pipe under your conditions. The heat transfer of all subsequent ones (second or more) will be slightly less. The found value must be multiplied by 0.9. So you will calculate and be able to make a register from smooth pipes with your own hands.

Heated towel rails

In old houses, heated towel rails made of steel pipes are very common, because in most cases they were laid out by the project, and almost until the end of the last century they were threaded into the system.

Not so long ago, they began to use circular inserts in elevator units, which ensure a stable hot temperature of the device.

Since the heating circuits in heated towel rails were constantly subject to temperature changes - they either heated up or cooled down - it was difficult for the threaded connections to withstand this regime, so they periodically began to leak.

Somewhat later, when the heating of these devices became stable thanks to the insertion into heating risers, the problem of leaks became less pressing. At the same time, the dimensions of the coil have become much smaller, resulting in a reduction in the heat transfer area of the steel pipe. However, such a heated towel rail remained warm not only while using hot water, but constantly.

Reduced heat transfer.

In order to save energy, it becomes important to reduce the heat transfer of pipes in those sections of communications that are not used for their intended purpose, for example, when moving from one building to another or in an unheated room.

There are many options for using thermal insulation materials for this. Manufacturers offer a fairly wide range to choose from, ranging from cheap fiberglass to more expensive types of polystyrene foam. You can purchase pipes with insulating elements already built into them.

To summarize, we conclude that the use of such calculations helps to significantly save money and avoid many technical obstacles when designing water and heat supply systems.

Actually, you are a desperate person if you decide to undertake such an event. The heat transfer of a pipe, of course, can be calculated and there are a great many works on the theoretical calculation of the heat transfer of various pipes.

Let's start with the fact that if you decided to heat your house with your own hands, then you are a stubborn and purposeful person. Accordingly, a heating project has already been drawn up, pipes have been selected: either metal-plastic heating pipes or steel heating pipes. Heating radiators have also already been looked at in the store.

But, before acquiring all this, that is, at the design stage, it is necessary to make a conditional relative calculation. After all, the heat transfer of heating pipes, calculated in the project, is the key to warm winters for your family. There is no room for error here.

Methods for calculating heat transfer from heating pipes

Why is the emphasis usually placed on calculating the heat transfer of heating pipes? The fact is that for commercially manufactured heating radiators, all these calculations have been made and are given in the instructions for use of the products. Based on them, you can easily calculate the required number of radiators depending on the parameters of your home: volume, coolant temperature, etc.

Tables.

This is the quintessence of all the necessary parameters collected in one place. Today the Internet contains a great many tables and reference books for online calculations of heat transfer from pipes. In them you will learn what is the heat transfer of a steel pipe or cast iron pipe, the heat transfer of a polymer or copper pipe.

All that is needed when using these tables is to know the initial parameters of your pipe: material, wall thickness, internal diameter, etc. And, accordingly, enter into the search the query “Table of heat transfer coefficients of pipes.”

This section on determining the heat transfer of pipes also includes the use of manual reference books on heat transfer of materials. Although they are becoming more and more difficult to find, all information has migrated to the Internet.

Formulas.

The heat transfer of a steel pipe is calculated according to the formula

Qtr=1.163*Str*k*(Twater - Air)*(1-efficiency of pipe insulation), W where Str is the surface area of the pipe, and k is the heat transfer coefficient from water to air.

The heat transfer of a metal-plastic pipe is calculated using a different formula.

Where is the temperature on the inner surface of the pipeline, °C; t

c is the temperature on the outer surface of the pipeline, °C;

Q—

heat flow, W;

l

—pipe length, m;

t

—coolant temperature, °C;

t

inc—air temperature, °C;

a n is the external heat transfer coefficient, W/m 2 K; d

n - outer diameter of the pipe, mm;

l—thermal conductivity coefficient, W/m K; d

in

-

internal diameter of the pipe, mm; a int - internal heat transfer coefficient, W/m 2 K;

You understand perfectly well that calculating the thermal conductivity of heating pipes is a relative value. The formulas include the average parameters of certain indicators, which may, and do, differ from those that actually exist.

For example, as a result of the experiments, it was found that the heat transfer of a polypropylene pipe located horizontally is slightly lower than that of steel pipes of the same internal diameter, by 7-8%. It is internal, since polymer pipes have a slightly thicker wall thickness.

Many factors influence the final figures obtained in tables and formulas, which is why the footnote “approximate heat transfer” is always included. After all, the formulas do not take into account, for example, heat loss through the building envelope made of different materials. There are corresponding tables of amendments for this purpose.

However, by using one of the methods for determining the heat output of heating pipes, you will have a general idea of what kind of heating pipes and radiators you need for your home.

Good luck to you, builders of your warm present and future.

Determination of heat transfer

To correctly select the size of registers for space heating in accordance with heat loss, it is necessary to know the heat transfer value of a 1 meter long pipe. This value depends on the diameter used and the temperature difference between the coolant and the environment. The temperature difference is determined by the formula:

∆t= 0.5·(t1 + t2) – tк,

where t1 and t2 are the temperatures at the inlet and outlet of the boiler, respectively;

tk – temperature in the heated room.

The heat transfer table for 1 m of steel pipe will help you quickly determine the approximate value of the amount of heat received from the register. Despite the fact that the result is very approximate, this method is the most convenient and does not require complex calculations.

For reference: 1 BTU/hour · ft2 ·oF = 5.678 W/m2K = 4.882 kcal/hour · m2 ·oC.

The table shows what the heat transfer of steel pipes in an air environment will be at certain temperature changes. For intermediate temperature differences, calculations are performed by interpolation.

To more accurately determine the amount of heat produced by a steel pipe, you should use the classic formula:

Q=K ·F · ∆t,

where: Q – heat transfer, W;

K – heat transfer coefficient, W/(m2 0С);

F – surface area, m2;

∆t – temperature difference, 0С.

The principle of determining ∆t was described above, and the value of F is found using a simple geometric formula for the surface of a cylinder: F = π d l,

where π = 3.14, and d and l are the diameter and length of the pipe, respectively, m.

When calculating a section 1 m long, the formula takes the form Q = 3.14·K·d·∆t.

Note: when determining the heat transfer of a single pipe, it is enough to substitute the reference value of the heat transfer coefficient for steel when transferring heat from water to air, which is 11.3 W/(m2 0C). For a heating device, the K value depends not only on the material from which the pipes are made, but also on their diameter and the number of threads, since they influence each other.

The average values of heat transfer coefficients for the most popular types of heating devices are shown in the table.

Important! When substituting values into formulas, you must carefully monitor the units of measurement. All quantities must have dimensions that are consistent with each other

Thus, the heat transfer coefficient found in kcal/(hour m2 0С) must be converted to W/(m2 0С), taking into account that 1 kcal/hour = 1.163 W.

Of course, the heat transfer table for steel pipes allows you to get results faster than calculations using formulas, but if accuracy is important, you will have to tinker a little.

To determine the required register size, the required thermal output must be divided by the heat output of 1 meter, rounded up to the nearest whole number. As a guide, you can take the average data for an insulated room up to 3 m high: 1 m of register with a diameter of 60 mm is capable of heating 1 m2 of room.

Note: As can be seen from the table, the K coefficient for steel pipes can vary from 8 to 12.5 kcal/(hour m2 0C). Increasing the diameters and number of threads leads to a decrease in the efficiency of heat transfer. In this regard, to increase the heat transfer of the register, preference should be given to increasing the length of the elements.

It is also necessary to take into account that large pipes require an increased volume of water in the system, which creates additional load on the boiler. The recommended distance between the threads is equal to the diameter of the pipes plus another 50 mm.

If the system is filled not with water, but with a non-freezing liquid, then this significantly affects the heat transfer of the register and requires an increase in its size after additional calculations. This is especially true when using devices with heating elements and oil as a coolant.

Steel pipeline is a fairly strong, durable product with good heat dissipation. Registers made of smooth pipes can have various configurations, are very easy to maintain and do not require periodic washing. This allows them to successfully compete with lightweight bimetallic and aluminum heating devices, as well as with traditional “indestructible” cast iron radiators.

Water and gas pipes are widely used in external heating networks when laid open due to their high rigidity and wear resistance. The feasibility of using steel pipes for space heating is determined by operating conditions, financial capabilities and aesthetic taste of the owners. The use of registers is most justified in production and technical premises, but in other cases they have their advantages.

Author (Site Expert): Irina Chernetskaya

We calculate the return for 1 m of product

It is easy to calculate the heat transfer of 1 m of pipe made of steel. We have a formula, all we have to do is substitute the values.

Q = 0.047*10*60 = 28 W.

- K = 0.047, heat transfer coefficient;

- F = 10 m2, pipe area;

- dT = 60° C, temperature difference.

It's worth remembering

Do you want to make a heating system correctly? You should not select pipes by eye. Heat transfer calculations will help optimize construction costs. In this case, you can get a good heating system that will last for many years.

The thermal conductivity of steel is quite high - this is a law of physics, and one cannot argue with it. But you can turn this property of metal to your advantage. It is this heat transfer that allows steel to be used in the production of various devices for heating rooms.

Numbers and formulas

Both of these categories - the calculation of heating devices and the calculation of heat losses along the way to them - come down to one thing: we need to know how much heat a steel pipe gives off at a given temperature of the water in it and the air outside. An additional condition is the presence or absence of thermal insulation.

The entire calculation of heat transfer of steel pipes looks like this : Q=K*F*dT, where:

Q is the heat transfer of the pipe in kilocalories;

K is the thermal conductivity coefficient of a steel pipe, which depends, in addition to the material, on the diameter of the pipe, the temperature difference between the coolant and air and the number of threads of the heating device;

F is the surface area of the pipe or pipes;

dT is the temperature difference, which is equal to half the sum of the temperatures at the pipe inlet and outlet minus the temperature inside the room.

The coefficient varies from 8 to 12.5 depending on:

- Pipe diameter;

- The number of pipe threads in the register (in the case of a heating device);

- Temperature pressure.

In the case of a thermally insulated pipe, the result is multiplied by the efficiency of thermal insulation, that is, by the percentage of heat that it transmits into the surrounding space.

So, let’s take a register of three threads from a weave pipe one meter long. We take the temperature in the room to be 20 C; When passing through the register, the temperature of the coolant drops from 81 to 79 C.

Remember how the surface of a cylinder is calculated? S=2 πrh, circumference by height. In this case, the area of the jumpers and ends can be safely neglected.

The total area of each register pipe will be equal to 2*3.1415*0.05*1=0.31415 m2. There are three such pipes; their total area will be slightly less than a square meter.

Next: dT in our case is equal to (79+81)/2-20=60. The coefficient K for a three-pipe register with a pipe diameter of 100 mm and a temperature difference of 60 C is taken equal to 9.0. So: Q=9*1*60.

Our register will leave only 540 kilocalories of heat in the room.

Heat transfer of heating registers (download calculator)

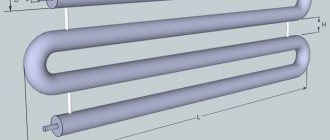

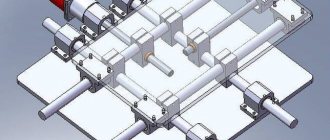

A heating register of four smooth pipes and a flow diagram of the coolant are shown in the figure below.

We turn on the computer, MS Office and start the calculation in Excel.

Initial data:

There is not a lot of initial data, they are clear and simple.

1.

Pipe diameter

D

in mm is entered

to cell D3: 108,0

2.

the length of the register (one pipe)

L

in m

to cell D4: 1,250

3.

the number of pipes in register

N

in pieces

to cell D5: 4

4.

the water temperature at the “supply”

tп

in °C

to cell D6: 85

5.

the water temperature at the “return”

in

°C

to cell D7: 60

6.

the room air temperature

tb

in °C

to cell D8: 18

7.

Select the type of outer surface of the pipes from the drop-down list

in merged cells C9D9E9: “In theoretical calculation”

8.

the Stefan-Boltzmann constant

C0

in W/(m2*K4)

to cell D10: 0,00000005669

9.

the value of free fall acceleration

g

in m/s2

to cell D11: 9,80665

By changing the initial data, you can simulate any “temperature situation” for any standard size of the heating register!

The heat transfer of just a single horizontal pipe can also be easily calculated using this program! To do this, it is enough to indicate the number of pipes in the heating register equal to one (N=1).

Calculation results:

10.

The degree of emissivity of the radiating surfaces of pipes

ε

is automatically determined by the selected type of outer surface

in cell D13: =INDEX(H5:H31,G2) =0,810

In the database, located on the same sheet with the calculation program, 27 types of external surfaces of pipes and their degree of emissivity are presented for selection. (See the download file at the end of the article.)

11.

the average temperature of the pipe walls

tst

in °C

in cell D14: =(D6+D7)/2 =72,5

tst=(tp+to)/2

12.

temperature difference

dt

in °C

in cell D15: =D14-D8 =54,5

dt=tst— tv

13.

The coefficient of volumetric expansion of air

β

in 1/K is determined

in cell D16: =1/(D8+273) =0,003436

β=1/(tв+273)

14.

the kinematic viscosity of air

ν

in m2/s

in cell D17: =0.0000000001192*D8^2+0.000000086895*D8+0.000013306 =0,00001491

ν=0.0000000001192*tв2+0.000000086895*tв+0.000013306

15.

Prandtl criterion

Pr

is determined

in cell D18: =0.00000073*D8^2-0.00028085*D8+0.70934 =0,7045

Pr=0.00000073*tv2-0.00028085*tv +0.70934

16.

Calculate the thermal conductivity coefficient of air

λ

in cell D19: =-0.000000022042*D8^2+0.0000793717*D8+0.0243834 =0,02580

λ

=-0,000000022042*

tв2+0.0000793717*tв+0.0243834

17.

A

pipes in m2 is determined

in cell D20: =PI()*D3/1000*D4*D5 =1,6965

A=π*(D/1000)*L*N

18.

The heat flux of radiation from the surfaces of the pipes of the heating register

Q and

in W is calculated

in cell D21: =D10*D13*D20*((D14+273)^4- (D8+273)^4)*0.93^(D5-1) =444

Qi =C0*ε *A*((tst +273)4— (tv +273)4)*0.93(N-1)

19.

the heat transfer coefficient for radiation

αi

in W/(m2*K)

in cell D22: =D21/(D15*D20) =4,8

αi=Qi/(dt*A)

20.

Grashof criterion

Gr

is calculated

in cell D23: =D11*D16*(D3/1000)^3*D15/D17^2 =10410000

Gr=g*β*(D/1000)3*dt/ν2

21.

We find the Nusselt criterion

Nu

in cell D24: =0.5*(D23*D18)^0.25 =26,0194

Nu=0.5*(Gr*Pr)0.25

22.

the convective component of the heat flow

Qк

in W

in cell D25: =D26*D20*D15 =462

Qк=αк*A*dt

23.

And the heat transfer coefficient during convection

αk

in W/(m2*K) is determined accordingly

in cell D26: =D24*D19/(D3/1000)*0.93^(D5-1) =5,0

αк=Nu*λ/(D/1000)*0.93(N-1)

24.

the total heat flow power of the heating register

Q

in W and Kcal/hour, respectively

in cell D27: =(D21+D25)/1000 =0,906

Q=(Qi+Qk)/1000

and in cell D28: =D27*0.85985 =0,779

Q'=Q*0.85985

25.

the heat transfer coefficient from the surfaces of the heating register to the air

α

in W/(m2*K) and Kcal/(hour*m2*K) respectively

in cell D29: =D22+D26 =9,8

α=αi+αk

and in cell D30: =D29*0.85985 =8,4

α'=α*0.85985

This completes the calculation in Excel. Heat transfer from the heating register from the pipes has been found!

The calculations have been repeatedly confirmed by practice!

Making a heating battery from a profile pipe

A heating radiator is a device that can be manufactured not only by industrial companies, but also by home owners, including those new to this business. True, the latter will have to spend a lot of time. The easiest way is to make a battery from a profile pipe with a square or rectangular cross-section. This is because it does not spin and is easy to lock into place, allowing you to concentrate on all your welding and metal cutting work.

The design of a heating radiator made from a profile pipe is as follows:

- 3 horizontal pipes;

- 4 vertical jumpers;

- 6 plugs;

- couplings with internal threads welded to the ends of the upper and lower pipes.

Vertical bridges are placed at the ends of the pipes and allow water to flow from the top pipe to the bottom pipe.

How to install

There are two installation options: hang it on the wall or put it on a stand. The choice depends on the dimensions and weight of the resulting structure, as well as on the type of walls.

Quite often they do a combined installation: they weld racks, which are then attached to the wall. Even very massive registers can be installed in this way. This installation option also provides a high level of security.

Each such heating device must have an air vent at the top point. It is needed to bleed air from the system.

Types of heating systems and the principle of adjusting radiators

Handle with valve

In order to correctly adjust the temperature of radiators, you need to know the general structure of the heating system and the layout of the coolant pipes.

In the case of individual heating, adjustment is easier when:

- The system is powered by a powerful boiler.

- Each battery is equipped with a three-way valve.

- Forced pumping of coolant has been installed.

At the stage of installation of individual heating, it is necessary to take into account the minimum number of bends in the system. This is necessary in order to reduce heat loss and not reduce the pressure of the coolant supplied to the radiators.

For uniform heating and rational use of heat, a valve is mounted on each battery. With it, you can reduce the water supply or disconnect it from the general heating system in an unused room.

- In the central heating system of multi-storey buildings, equipped with a vertical supply of coolant through a pipeline from top to bottom, it is impossible to adjust the radiators. In this situation, the upper floors open the windows due to the heat, and the rooms on the lower floors are cold, since the radiators there are barely warm.

- A more advanced one-pipe network. Here, the coolant is supplied to each battery and then returned to the central riser. Therefore, there is no noticeable temperature difference in the apartments on the upper and lower floors of these buildings. In this case, the supply pipe of each radiator is equipped with a control valve.

- A two-pipe system, where two risers are mounted, ensures the supply of coolant to the heating radiator and back. To increase or decrease the coolant flow, each battery is equipped with a separate valve with a manual or automatic thermostat.

Simple ways to increase heat transfer from radiators

We improve air circulation. The batteries transfer heat to the air, which, when heated, rises, and then, when cooled, falls down. This is how air circulates, and the room becomes as warm as the heat transfer of the battery and the air flow speed allow. Therefore, in order to increase the temperature inside the room, first of all, you need to ensure good air circulation. To do this, you should free up the space around the battery as much as possible: remove the protective screen, raise the curtains, move the furniture, and so on.

We accelerate air circulation using a fan. The faster the air moves, the more thermal energy it can take from the battery. On the coldest days, you can turn on the fan, directing it to the center of the radiator to cover as much area as possible. To ensure the autonomy of such a system and ensure its quiet operation, computer fans can be placed. They are quiet, low-power, and when placed directly under the battery, they do not disrupt the natural direction of air movement in the room. The fans will allow you to raise the temperature in the room by 3-10 degrees, and their low consumption makes it possible to blow on the battery all winter long without significantly damaging your wallet. Calculate for yourself: the power of ordinary fans is about 40 Watts, computer fans – no more than 5. Total consumption: 40 * 24 (hours) * 30 (days) = 29 Kilowatts = about 95 rubles per month. In the case of computers, it’s even less – about 23 rubles/month. when connecting 2 at once.

We install a heat-reflecting screen. Heat from the radiator emanates in all directions, and in order not to heat the walls, but to direct thermal energy into the room, you need to install a heat-reflecting screen behind the radiator. For these purposes, you can use foil-isolon (foam base with foil on one side), gluing it to the cleaned wall behind the battery with any suitable means (tile adhesive, universal glue 88, silicone, etc.). Ideally, the area of the heat-reflecting screen should be larger than the area of the battery.

If the battery is cold you need to bleed the air. To do this, you need to unscrew the regular or “Mayevsky” tap at the battery.

It will not be superfluous to keep a container or towel under the valve, because as soon as the air comes out, water will flow in a thin stream. Once this happens, the valve can be closed. The procedure should be repeated for each battery in the house.

Basic heating register calculation

If the level of heat transfer of a purchased battery can be found out from its passport, then in the case of homemade heaters you have to calculate everything yourself. Otherwise, it will not be possible to heat the room effectively and evenly.

Calculating the required radiator power to heat a room

For calculations, they use formulas that may be simple, but require certain mathematical skills. Another option is online calculators, of which there are now more than enough on the Internet. Strictly speaking, the topic is quite extensive and deserves a separate article, so we will use simple calculation methods

In any case, this issue should be given close attention, otherwise your family will complain that the radiators do not heat well and the room is cold

A simplified method for calculating the required thermal energy is to calculate the heating area and then multiply by 100. Why is this so? Because for comfortable living per square meter you need 100 W of heat. To be more precise in the calculations, let’s take into account the number of window openings and walls:

- A room with one window and one external wall – 100 W per 1 m² of area.

- A room with one window and two external walls - 120 W per 1 m².

- A room with two windows and two external walls - 130 W per 1 m².

Simple calculation of the thermal power of a radiator made of steel pipes

Knowing what to strive for, all that remains is to choose the design of the heating device that would satisfy your needs. How to do this?

There is an elementary solution - use a table. It already calculates the heat transfer rates of rolled pipes. The values take into account the temperature regime, in which the supply temperature of the coolant is +90℃, and the return temperature is +20℃.

So, the table below allows you to find out the thermal power of one linear meter of register pipe per square meter of heated area.

| External section of the pipe, mm | Heated room area, m² |

| 25 | 0,5 |

| 32 | 0,57 |

| 42 | 0,69 |

| 57 | 0,94 |

| 76 | 1,19 |

| 89 | 1,37 |

| 108 | 1,66 |

| 133 | 2,0 |

| 159 | 2,43 |

What other quantities do you need to know?

So, we have decided on the option - all that remains is to draw up a drawing. At this stage, such a parameter as the distance from section to section – h – is often forgotten.

When assembling a coil-type radiator from steel pipes, this value is determined by the dimensions of the bends used

Here it is worth paying attention to the value of F - this is the so-called outlet height. Without a doubt, the intersection distance here will be expressed by the formula:

h = 2F-D

If you decide to assemble a simple sectional radiator, then the gap between the pipes can be set independently, but with one condition:

H = D+50 mm

The same principle applies when working with rolled profiles, only instead of the diameter the height of the square or rectangular profile is used. Of course, the design features of the device are taken into account.

How to calculate the required diameter of heating pipes

When calculating the diameter of a pipe for heating a living space, one more important parameter should be taken into account. This is the thermal load. In accordance with the standards, comfortable living conditions in a room with a ceiling height of 2.5 m provide 0.1 kW of thermal power per 1 m2 of its area. Therefore, you can very easily calculate how much heat is required to heat, for example, a room of 20 m2:

20 * 0.1 = 2.0 (kW).

In accordance with the table, the diameter of the pipes that can provide comfortable heat is selected. In our example, according to the table presented, in order to always keep the room warm, pipes with an internal diameter of 1/2 inch are quite suitable.

Thermal load and coolant flow for heating pipes of various diameters

Estimated indicators

To calculate the power of heating equipment, as well as to find out the scale of heat loss during transportation of the coolant, it will be necessary to remove heat from the pipe at certain temperatures of the liquid inside it and the air outside. The thermal insulation layer serves as an additional parameter.

The formula for calculating the heat transfer of a steel pipe looks like this:

Q=K×F×dT, in which:

Q – the desired result of heat transfer from a steel pipe in kilocalories;

K – thermal conductivity coefficient. It depends on the pipe material, its cross-section, the number of heating circuits, as well as the temperature difference between the outside air and the coolant;

F is the total surface area of a pipe or several pipes in the device;

dT – temperature pressure, that is, ½ the total temperature of the liquid at the inlet and outlet of the pipe minus the air temperature in the room.

If the pipes are additionally wrapped in a layer of thermal insulation, then its efficiency in percentage terms (the amount of heat passed through it) is multiplied by the resulting heat transfer rate.

For example, let’s calculate the heat transfer of a register made of three pipes with a cross-section of 100 mm and a length of 1 m. The temperature in the room is 20 ℃, and the coolant, when passing through the pipe, cools from 81 to 79 ℃.

According to the formula S=2pirh we calculate the surface area of the cylinder:

S= 2×3.1415×0.05×1=0.31415 m2. If there are three pipes, then their total area will be 0.31415 × 3 = 0.94245 m 2.

Indicator dT = (79+81):2-20 = 60.

The value of K for a register of three pipes with a temperature head of 60 and a cross-section of 1 meter is taken equal to 9. Therefore, Q = 9 × 1 × 60 = 540. That is, the heat transfer of the register will be equal to 540 kcal.

Thus, we examined the concepts of heat transfer, as well as ways to minimize the heat loss of a steel pipe for certain cases. There is nothing very complicated about this. The main thing is to approach the issue responsibly.

Heat transfer is the heat exchange between two media separated by a surface. Its intensity is characterized using a coefficient. When installing a heating main, the problem of energy saving must be taken into account. Therefore, old heating mains are replaced with new ones, which use pipes equipped with thermal insulation, which reduces heat loss by almost 80%.

In everyday life, the need to determine the heat transfer coefficient arises in two situations:

- if you need to calculate heating devices;

- if you need to evaluate heat loss in the pipeline.

In both the first and second cases, it is necessary to determine how much heat the steel pipe for the heating main gives off to the space, if the temperature of the coolant and the temperature of the medium are known. An additional parameter is the absence or presence of thermal insulation.

Why is the heat transfer coefficient determined?

When setting up a heating system where metal pipes are used as channels for supplying coolant and heating elements, the heat transfer rate is one of the parameters necessary when creating a project in which you need to take into account:

- optimal sizes and number of heating devices;

- boiler equipment power;

- possible heat loss during coolant transportation;

- size of pipe structures.

The heat transfer coefficient is a value obtained as a result of calculations that characterizes the intensity of heat exchange between the pipeline and the environment. The average thermal conductivity of steel channels is determined as 74 W/meter multiplied by K - the heat transfer coefficient.

More accurate calculations should also take into account such indicators as:

- surface area involved in heat exchange;

- pipe shape;

- type and color of coating;

- properties of the thermal insulation material used in the heating system;

- climatic conditions;

- speed and temperature of the carrier.

Registers

The simplest design of heating radiators is registers. These are medium- or large-diameter pipes welded at the ends, single or connected in sections by jumper tubes. They can be seen in entrances, at industrial facilities or in private houses with individual heating.

Steel pipelines are considered traditional for the installation of water supply, sewerage and underground gas supply systems

To increase their thermal power, they use a method of increasing the area - thin metal plates are welded. This improves the heat transfer of the battery by almost one and a half times. Compact radiators, the closest relatives of cast iron accordion batteries, have approximately the same heat transfer. Although they are, of course, far from panel bimetallic devices.

To ensure maximum heat transfer from heating radiators, a simple and inexpensive convection method is used. This method involves hanging the device correctly. It is installed as close to the floor as possible, where cold air accumulates, but the gaps necessary for circulation are left, including near the wall itself.

With this installation, the battery sections come into contact with a medium that has the lowest possible temperature under the given conditions, that is, the thermal pressure increases. And the air heated by the registers, thanks to the gaps left, rises freely, and the room is heated faster.

An excellent method is to increase the heat transfer surface area. They do this in different ways:

- By increasing the total length of the heating pipes by forming them into U-shaped registers.

- With fins - strictly speaking, this method increases not specifically the thermal conductivity of the steel pipe, but of the entire radiator, but the power increases by 50%.

- Increasing the number of sections.

Black surfaces have the best heat transfer, but not every interior will fit such a dark battery, which is why this method has not found application. Registers traditionally continue to be painted white.

Types of registers

The most common type is registers made of smooth pipes, and most often electric-welded steel ones. Diameters - from 32 mm to 100 mm, sometimes up to 150 mm. They are made of two types - serpentine and register. Moreover, register ones can have two types of connection: thread and column. A thread is when the jumpers through which coolant flows from one pipe to another are installed either on the right or on the left. It turns out that the coolant sequentially runs around all the pipes, that is, the connection is sequential. With a column connection, all horizontal sections are connected to each other at both ends. In this case, the movement of the coolant is parallel.

Types of registers made of smooth pipes

Any type of registers can be used for any type of system: with one-pipe and two-pipe wiring, with vertical and horizontal supply type. With any system, greater heat transfer will occur when the supply is connected to the upper pipe.

When used in systems with natural circulation, it is necessary to maintain a slight slope towards the movement of the coolant of the order of 0.5 cm per meter of pipe. Such a small slope is explained by the large diameter (low hydraulic resistance).

This is a serpentine heating register

These products are made not only from round, but also from square pipes. They are practically no different, only they are more difficult to work with, and the hydraulic resistance is a little higher. But the advantages of this design include more compact dimensions with the same volume of coolant.

Square tube registers

There are also registers made of pipes with fins. In this case, the area of contact between the metal and the air increases, and heat transfer increases. In fact, builders still install just such heating devices in some budget new buildings: the well-known “pipe with fins.” Although they don’t look the best, they warm rooms well.

A register with plates will have a much higher heat transfer

If you insert a heating element into any register, you can get a combined heating device. It can be separate, not connected to the system, or used as an additional heat source. If the radiator is insulated with heating only from the heating element, it is necessary to install an expansion tank at the top point (10% of the total coolant volume). When heated by a domestic boiler, the expansion tank is usually built into the structure. If it is not there (often happens in solid fuel boilers), then in this case it is necessary to install an expansion tank. If the material for the registers is steel, then the tank needs a closed type.

Possible installation errors

In order to avoid any technical difficulties after installation, it is necessary to provide for common errors that are often made during operation. So, if you install batteries less than 7 centimeters from the floor surface, then in the future we will be faced with the difficulty of not only cleaning underneath them, but also with heat exchange in the room. On the contrary, if you install the batteries higher than 15 centimeters, then, most likely, significant temperature changes will occur.

In addition, heat transfer may deteriorate if the radiator is installed close to the wall. Also, do not forget that you should not cover homemade pipe heating radiators with decorative grilles - this will lead to a decrease in their power.

Replacing batteries

If radiators need to be replaced, then it is advisable to start work in the warm season. The fact is that the heating is turned off during this period, so dismantling/installation can be carried out without any difficulties. Often, replacement is required if the equipment wears out or, alternatively, if it is necessary to reduce the number of sections. By the way, we prepare not only the batteries for replacement, but also the wall surfaces located behind them.

Note! We putty, level and paint the walls before installation, since after installation, as noted above, this will not be possible. Video - Replacing radiators

Video - Replacing radiators

Comparison of types of heating batteries - looking for the best

Previously, we reviewed and compared different types of heating radiators, thereby identifying their positive and negative sides; in addition to this article, we advise you to read this information

How to improve heat transfer performance

If your home is cool, before looking for ways to increase the heat transfer of the pipe, eliminate possible problems that impede heat transfer, in particular, make sure that there are no:

- air jams;

- blockages and scale;

- insufficient air exchange due to furniture, decoration or decorative boxes;

- multi-layer paint and varnish coating;

- external contamination of heating devices.

If, after eliminating the obstacles, the problem still remains relevant, study the issue of how to increase the heat transfer of the heating pipe. You can do this in several ways:

- Improve air convection. To do this, it is enough to free up space near the heating elements. Active air circulation will significantly increase heat transfer.

- Installation of a convector system for forced air circulation and homemade finning of pipes.

- Arrangement of screens that reflect thermal energy into the room. A sheet of foil or foil insulation attached to the wall behind the radiator helps reduce heat loss.

- Insertion of additional registers into the heating system.

- Painting pipes dark.

All these methods, to one degree or another, help improve the heating system and increase its efficiency.

Increased heat transfer.

To effectively increase the radiated heat rate, there are many ways:

- installation of a convector;

- painting pipes with black paint;

- register setting;

- additional battery sections.

The convector is a curved pipe with metal plates. You can make it yourself or buy a more modern analogue in the store.

The use of matte black paint to paint the surface of the coolant also gives a good result. Aesthetically, it doesn’t look very attractive, but when it comes to comfort, you have to choose.

Another inexpensive and fairly popular design is a register. These are several wide pipes connected to each other with welded sections. These also include heated towel rails, radiators, main lines and even an ordinary steel pipe fixed around the entire perimeter of the room.

We make a calculation

The formula by which heat transfer is calculated is as follows:

Q = K*F*dT, where

- K – thermal conductivity coefficient of steel;

- Q – heat transfer coefficient, W;

- F is the area of the pipe section for which the calculation is being made, m 2 dT is the value of the temperature pressure (the sum of the primary and final temperatures taking into account room temperature), ° C.

The thermal conductivity coefficient K is selected taking into account the area of the product. Its size also depends on the number of threads laid in the premises. On average, the coefficient is in the range of 8-12.5.

dT is also called temperature difference. To calculate the parameter, you need to add the temperature that was at the outlet of the boiler with the temperature that was recorded at the entrance to the boiler. The resulting value is multiplied by 0.5 (or divided by 2). The room temperature is subtracted from this value.

dT = (0.5*(T 1 + T 2)) - T to

If the steel pipe is insulated, then the resulting value is multiplied by the efficiency of the insulating material. It reflects the percentage of heat that was given off during the passage of the coolant.

How to optimize the heat transfer of a steel pipe?

During the design process, specialists are faced with the question of how to reduce or increase the heat transfer of 1 m of steel pipe. To increase, you need to change the infrared radiation upward. This is done with paint. Red color increases heat transfer. It is better if the paint is matte.

Calculation

Another approach is to install fins. It is mounted outside. This will increase the heat transfer area.

In what cases does it need to be reduced? The need arises when optimizing a pipeline section located outside a residential area. Then experts recommend insulating the area - isolating it from the external environment. This is done using polystyrene foam, special shells that are made from special foamed polyethylene. Mineral wool is also often used.

Heat loss through pipes

In a city apartment, everything is simple: the risers, the supply lines to the heating devices, and the devices themselves are located in a heated room. What's the point of worrying about how much heat the riser dissipates if it serves the same purpose - heating?

However, already in the entrances of apartment buildings, in basements and in some warehouses, the situation is radically different. You need to heat one room and supply coolant to it through another. Hence the attempts to minimize the heat transfer of the pipes through which hot water enters the batteries.

Thermal insulation

The most obvious way to reduce the heat transfer of a steel pipe is to insulate the pipe. Twenty years ago there were two ways to do this: recommended by regulatory documentation (insulation with glass wool wrapped with non-flammable fabric; even earlier, external insulation was generally made solid using gypsum or cement mortar) and realistic: pipes were simply wrapped in rags.

Now there are a lot of quite adequate ways to limit heat loss: here are foam linings on pipes, and split shells made of foamed polyethylene, and mineral wool.

These materials are actively used in the construction of new houses; However, in the housing and communal services system, the limited budget, politely speaking, leads to the fact that pipes in basements are still simply wrapped with piss... um, torn rags.

Welcome to the twenty-first century

Heat loss through pipes

In apartment conditions, there is no particular point in calculating the heat transfer of a stainless pipe, because in this case all the heat given off by the riser and heating circuits will be dissipated inside, heating the room.

But if it is necessary to efficiently heat basement or warehouse facilities, and the coolant must be supplied to them from another place, then in this case, calculating the heat transfer of the pipe will be more than advisable so that you can figure out how much heat is lost along the way. Then you can try to look for ways to reduce heat loss from hot water pipes.

Using cross-linked polyethylene for heated floors

Metal-plastic is very convenient as a material for a pipeline that will be hidden under your floor and will have to warm the feet of you and your family. Metal-plastic is multi-layered, so it is not susceptible or minimally susceptible to corrosion, lasts more than fifty years, the pipes have a large footage (from 50 to 500 meters), in addition, they have low linear elongation when heated.

Connections can be detachable, conditionally detachable and permanent. Detachable fittings include threaded and collet fittings; for conditionally detachable ones - compression ones, and for non-detachable ones - press fittings. Of course, it is necessary to buy both the pipes themselves and fittings only from reliable and trusted manufacturers.

Metal-plastic floor pipes have many advantages, but they also have some disadvantages. These disadvantages can be very significant if you are not warned about them in advance.

So, firstly, due to the different expansion coefficients of the polymer and aluminum, spontaneous expansion may occur and/or the pipes may crack (a phenomenon that professionals call pipe delamination will occur). Secondly, if you use threaded fittings for installation, then scale may form on their inside. Therefore, it is better to use exclusively press fittings (of course, when possible).

Despite a number of significant disadvantages, today metal-plastic pipes for floor heating are the best and most used option for those who value comfort, long service life of the product, as well as their own safety and the safety of their family. They have good thermal conductivity and have multiple advantages.

What are there

Heating registers are made of different materials and have different shapes. Each has pros and cons.

What are they made from?

If we talk about materials, the most common is steel, or rather electric-welded steel pipes. Steel does not have the best heat transfer, but this is compensated by its low price, ease of processing, availability and a large selection of standard sizes.

It is very rare to find pipes made of stainless steel - for decent power a large number of pipes are required, and you have an idea how much stainless steel products cost. If they did, it was probably a long time ago. They also use galvanized steel, but it is more difficult to work with - you won’t be able to cook it.

- Requires neutral and clean coolant, free of solid particles

- the presence of other metals and alloys in the system is undesirable, except for compatible ones - bronze, brass, nickel, chromium, therefore all fittings and fittings will need to be made from these materials;

- Careful grounding is mandatory - without it, in the presence of water, electrochemical corrosion processes begin;

- the softness of the material requires protection - covers are needed, etc.

There are registers made of cast iron. But they are too bulky. In addition, they have a very large mass; no less massive racks need to be made for them. Plus, cast iron is fragile - one blow and it can crack. It turns out that this type of registers also needs protective covers, and they reduce heat transfer and increase cost. Moreover, installing them is complex and hard work. The advantages include high reliability and chemical neutrality: this alloy does not care what coolant it works with.

In general, copper and cast iron are not easy. So it turns out that the optimal choice is steel registers.