Load grippers | 01/11/2020

Eye bolts are a type of rigging fasteners designed to perform various tasks of lifting and moving loads. The technical requirements and range of these domestically produced products are regulated by GOST 4751-73. Products almost similar in size are also produced abroad according to DIN 580.

MAIN PARAMETERS AND DIMENSIONS

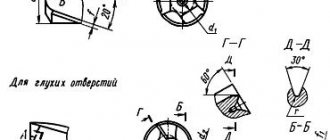

1.1. The design and main dimensions of the eye bolts must correspond to those indicated in the drawing and table. 1.

Table 1

Dimensions in mm

| Thread symbol d | Applicability | D1 | d2 | d3 | d4 | b | h | h1 | l | l 1, no less | r | r1 | Weight 1 piece, kg |

| M8 | 36 | 20 | 8 | 20 | 10 | 12 | 6 | 18 | 12 | 2 | 4 | 0,05 | |

| M10 | 45 | 25 | 10 | 25 | 12 | 16 | 8 | 21 | 15 | 0,12 | |||

| M12 | 54 | 30 | 12 | 30 | 14 | 18 | 10 | 25 | 19 | 6 | 0,19 | ||

| M16 | 63 | 35 | 14 | 36 | 16 | 20 | 12 | 32 | 25 | 0,31 | |||

| M20 | 72 | 40 | 16 | 40 | 19 | 24 | 14 | 38 | 29 | 3 | 8 | 0,50 | |

| M24 | 90 | 50 | 20 | 50 | 24 | 29 | 16 | 45 | 35 | 12 | 0,87 | ||

| M30 | 108 | 60 | 24 | 63 | 28 | 37 | 18 | 55 | 44 | 15 | 1,58 | ||

| M36 | 126 | 70 | 28 | 75 | 32 | 43 | 22 | 63 | 51 | 4 | 18 | 2,43 | |

| M42 | 144 | 80 | 32 | 85 | 38 | 50 | 25 | 72 | 58 | 20 | 3,72 | ||

| M48 | 162 | 90 | 36 | 95 | 42 | 52 | 30 | 82 | 68 | 22 | 5,54 | ||

| M56 | 180 | 100 | 40 | 105 | 48 | 60 | 34 | 95 | 78 | 5 | 25 | 8,09 | |

| M64 | 198 | 110 | 44 | 115 | 52 | 65 | 40 | 110 | 93 | 10,95 | |||

| М72×6 | 234 | 130 | 52 | 135 | 62 | 75 | 45 | 115 | 98 | 35 | 18,54 | ||

| M80×6 | 270 | 150 | 60 | 160 | 70 | 88 | 50 | 125 | 108 | 25,40 | |||

| M100×6 | 324 | 180 | 72 | 190 | 85 | 105 | 60 | 150 | 133 | 40 | 43,82 |

An example of a symbol for an eyebolt with M8 thread without coating:

Eye bolt M8 GOST 4751-73

The same, with fine thread M100×6, with coating 01 (zinc with chromating), thickness 9 microns:

Eye bolt M100×6.019 GOST 4751-73

(Changed edition, Amendment No. 1, 2).

1.2. The lifting capacity of the eye bolts must correspond to those indicated in the table. 2.

table 2

| Thread symbol | Load capacity per 1 eye bolt, kg, + | ||

| when directing the slings | |||

| along the vertical axis of the eye bolt | at an angle of 45º from the vertical axis of the eye bolt | ||

| in the plane of the ring | with deviation from the plane of the ring | ||

| M8 | 120 | 80 | 40 |

| M10 | 200 | 125 | 65 |

| M12 | 300 | 175 | 90 |

| M16 | 550 | 250 | 125 |

| M20 | 850 | 325 | 150 |

| M24 | 1250 | 500 | 250 |

| M30 | 2000 | 700 | 350 |

| M36 | 3000 | 1000 | 500 |

| M42 | 4000 | 1300 | 650 |

| M48 | 5000 | 1650 | 800 |

| M56 | 6200 | 2000 | 1000 |

| M64 | 7500 | 2500 | 1250 |

| М72×6 | 10000 | 3500 | 1750 |

| M80×6 | 14000 | 4500 | 2250 |

| M100×b | 20000 | 6500 | 3250 |

Notes:

1. When lifting a load, the direction of the slings at an angle from the vertical axis of the eyebolt of more than 45° is not allowed.

2. To install in the same plane the rings of two eyebolts screwed in until they stop, it is allowed to use flat washers with a thickness of:

- up to 1 mm - for eye bolts with M8-M12 thread;

- no more than half the thread pitch - for eye bolts with threads over M12.

1.3. The design and dimensions of the sockets for eye bolts are given in the Appendix.

Proper handling of fasteners for successful work

Before work, it is important to pay attention to the quality of fasteners. Like any device, they must be not only durable, but also safe. They are used with large loads, so you need to follow some simple rules tested by professionals. Before use, it is necessary to evaluate the quality of the fasteners; you should not use worn or damaged ring bolts. Also, do not use devices that are bent or with deformed eyes.

It is important that the holes and threads are clean before use. Bolts that have been altered, shortened or otherwise modified must not be used. In addition to inspection, certain rules must also be observed when performing installation work. When using elements, the permissible working load must not be exceeded (usually this can be checked in special tables that are included in the package). Conventional bolts and nuts should not be used when lateral loads are required. For lateral loads, only ring bolts with either nuts or supports should be used.

It is important to use these devices at permissible working loads: usually, if the angle to the vertical is about 90 degrees, then the permissible load can be 30 percent in line, and at an inclination of 90 degrees, the permissible working load should not exceed 25 percent. Such bolts should not be shortened when attaching to weights, and before fastening, the holes must be drilled correctly to match the prepared fasteners, or washers must be used. It is important to screw in not only the bolts themselves, but also the nuts until they stop.

Even if the fasteners are attached in accordance with all the rules and checked for quality, the following safety rules must still be observed when moving the load: you cannot stand under the load while working, but you must lift it evenly, without jerking, it is important to control the lifting in such work. Ring bolts must be loaded in the plane of the eye; this should not be done at an angle. If double or more branched slings are used when working with them, it is important that the load is calculated taking into account the angle of inclination of the sling. Of course, this is a science not for the everyday level, but for large construction projects or logistics centers, where the loads are heavier and the responsibility is greater.

- Author: Mikhail Malofeev

(1 vote, average: 5 out of 5) Share with your friends!

TECHNICAL REQUIREMENTS

2.1. Eye bolts must be made of steel grade 20 or 25 (subgroup a) according to GOST 1050-88 by stamping. Production by forging is allowed.

Compliance of the material with the prescribed grades must be confirmed by a certificate from the metal manufacturer.

(Changed edition, Amendment No. 1).

2.2. (Deleted, Amendment No. 1).

2.3. Technical requirements for stamped forgings in accordance with GOST 7505-89, accuracy class - II, degree of complexity - C3.

Note. When producing eye bolts by free forging in backing dies, it is allowed to increase the plus tolerances by 2 times.

(Changed edition, Rev.

№ 1).

2.4. A flat on the inner circumference of the ring is allowed, resulting from deburring, provided that the size is maintained within the tolerances of clause 2.3.

2.5. Welding or sealing of defects is not allowed.

2.6. Eye bolts after stamping or forging must be normalized and free of scale.

2.7. The hardness of normalized eye bolts must correspond to that indicated in the table. 3.

Table 3

| steel grade | Hardness of HB eye bolts with thread size | |

| from M8 to M64 | from M72×6 to M100×6 | |

| 20 | 105-149 | 95-121 |

| 25 | 134-187 | 105-149 |

One repeated heat treatment is allowed.

2.8. Center holes are not allowed on the eyebolt ring.

2.9. Cuts on the machined part of the shank are not allowed.

2.10. Thread - according to GOST 24705 with a tolerance range of 8g according to GOST 16093.

Dimensions of chamfers and thread runs - according to GOST 10549-80. The amount of thread run-out for the angle of the tool intake is 20°.

Note. When applying the coating, the specified dimensions and roughness must be ensured.

2.11. The thread should not have broken threads, burrs or dents.

2.12. Thread axis perpendicularity tolerance d

at a length of 100 mm relative to the reference plane of the ring:

0.10 mm - for eye bolts with threads from M8 to M16;

0.05 mm - for eye bolts with threads from M20 to M100×6.

2.13. Thread axis symmetry tolerance d

relative to the general planes of symmetry of the eye bolt:

T 1 mm - for eye bolts with threads from M8 to M12;

T 2 mm - for eye bolts with threads from M16 to M48;

T 4 mm - for eye bolts with threads from M56 to M100×6.

2.12 — 2.13. (Changed edition, Rev.

№ 2).

2.14. Eyebolts must withstand a strength test with a load equal to twice the rated load capacity.

The permissible deviation of this load is ±5%.

2.15. Eye bolts can be manufactured with a coating. Types and symbols of coatings - according to GOST 1759.0-87.

Technical requirements for coatings and surface quality of eye bolts before coating are in accordance with GOST 9.301-86.

(Changed edition, Amendment No. 1).

Scope of application and features

Thanks to its very simple design , the eyebolt product is widely used in various industries.

The equipment is considered universal, it can be used for several technological operations: This mount is mounted on various types of equipment, the load-carrying capacity of the device depends on the angle of inclination of the bolt. If we take into account the standard size of the product and the angle of the rope relative to the axis, its load capacity will be in the range of 30–20,000 kg. Do not lift the load if the angle of deviation from the vertical exceeds 45 degrees.

Professionals recommend lifting the load relative to the plane of the bolt axis. This type of fastening is considered the most reliable and safe.

The current GOST classifies bolts according to several basic parameters:

- Thread diameter.

- Ring size.

- Type of fastening: rigid, movable.

When the ring rotates freely on the rod, we speak of a movable joint. Sometimes a hook is installed instead of a ring. It makes it easier to grasp the load, as well as its subsequent retention.

Eye bolts are manufactured in full accordance with GOST 4751–73. It sets specific requirements for the following details:

- Availability of a certificate.

- Load capacity.

- Hardness - 105-149 HB.

- No scale.

Fixture production method

Typically, products are made by ordinary stamping. Sometimes eye bolts are forged. Soldering of such equipment is strictly prohibited. Steel bolts made from ST 25 must have a hardness of 105-149 HB.

When testing the strength of a part, a load is given that is several times greater than that established by GOST. The appearance of cracks and elongations is not allowed. There are no dents, burrs or damaged threads allowed on the surface of the thread.

The factory that produces bolts is required to subject them to strict quality control. Any batch must be subjected to testing; the characteristics obtained must correspond to those specified in the standard.

The bolt shackle is marked with several symbols:

- Thread parameters.

- Trademark of the enterprise.

Finished products are packed in wooden boxes. Thick paper is placed on the bottom. Only one batch with the same parameters is placed in each box. The weight of such packaging should not exceed 60 kg. An accompanying sheet is included in the box, which states:

- The name of detail.

- Quantity.

- Test result.

- Quality.

Each package must be marked. According to safety requirements, if bolts are used on marine vessels, then before use all parts are checked for corrosion and possible defects.

If the surface of a part is covered with corrosion, this can cause very serious negative consequences. After all, ships have to lift and transport heavy loads. Therefore, a lot depends on the reliability of the bolt.

Types of equipment for lifting loads

Today, eye fastenings are used for the manufacture of non-standard systems and mechanisms that allow for the rapid transportation of goods.

The high demand for custom products, especially in building construction, has forced manufacturers to develop custom bolt types. Currently, you can purchase a product equipped with a swivel. This hinge prevents any rotation of the part. The device is used for loading:

- Small, light parts.

- Weights with extended rings.

- Non-standard containers.

There are also special devices for working with heavy non-standard structures. Every innovative system must be manufactured in accordance with the current standard. No exceptions are allowed. These structures are designed to transport and lift very important heavy loads, so it is very dangerous to use untested parts.

ACCEPTANCE RULES

3.1. The manufacturer must conduct acceptance tests of eye bolts. During acceptance tests, eye bolts are checked:

before machining

— for compliance with the requirements of clause 1.1 in terms of dimensions obtained by stamping or forging and clauses. 2.3, 2.4: in the case of production by open forging in backing dies - each eye bolt; in the case of production by volumetric stamping - 5% of the batch, but not less than 5 pieces;

— for compliance with the requirements of paragraphs. 2.5 and 2.6 each eye bolt;

— for compliance with the requirements of clause 2.7 10% of the lot, but not less than 5 pieces; after machining:

— for compliance with the requirements of clause 1.1 (dimensions l, l

1 and

hl

and

d

) pp. 2.8 - 2.14 each eye bolt;

— for compliance with the requirements of clause 2.15 — according to GOST 9.301-86.

Note. The batch consists of eye bolts of the same size, made of steel of the same grade, and heat treated together.

(Changed edition, Rev.

№ 1).

3.2. If unsatisfactory test results of eye bolts are obtained according to at least one of the indicators, repeated tests are carried out on a double number of samples; taken from the same party, in full. The results of repeated tests are final and apply to the entire batch.

(Introduced additionally, Amendment No. 2).

Reliability

As for the level of reliability of these tools, almost every tool related to eye bolts has increased resistance to excess and additional loads, which is determined by their technological features, material and production stages. By the way, when purchasing, pay attention to the certificate of a particular device. On the Russian market, all instruments of this type must comply with GOST number 4751. Everything else is either a fake or counterfeit.

Thus, eye bolts are one of the most reliable and practical devices that are used when transporting cargo of various curb weights.

TEST METHODS

4.1. Compliance with the requirements of clause 2.3 is checked by external inspection without the use of magnifying devices.

Magnifiers up to three times magnification can be used.

(Changed edition, Amendment No. 2).

4.2. Hardness (clause 2.7) is determined according to GOST 9012-59 on the generatrix of the supporting part of the ring.

4.3. The threads (clause 2.10) are checked with maximum gauges.

4.4. The deviation from the perpendicularity of the axis of the threaded shank to the supporting surface of the ring (clause 2.12) is checked with an angle template or feeler gauge along the clearance between the supporting surface of the ring and the end surface of the control gauge.

4.5. Compliance of eye bolts with the requirements of clause 2.4 is checked by a tensile test with holding under load for 10 minutes.

The load must be applied along the axis of the eyebolt rod.

The application of the load should be smooth, without jerking.

After removing the load, there should be no residual deformation, cracks or tears in the eye bolts.

The absence of residual deformations is determined by checking the dimensions along the axis of the eye bolts before and after testing.

The absence of cracks and tears is checked by external inspection using a magnifying glass with at least four times magnification.

4.6. The thickness of the coating layer (clause 2.15) is checked on the eyebolt ring. Methods for checking the quality and thickness of the coating are in accordance with GOST 9.302-88.

4.7. (Deleted, Amendment No. 2).

Scope of application and features

Thanks to its very simple design , the eyebolt product is widely used in various industries. The equipment is considered universal; it can be used for several technological operations:

This mount is mounted on various types of equipment; the load-carrying capacity of the device depends on the angle of inclination of the bolt. If we take into account the standard size of the product and the angle of the rope relative to the axis, its load capacity will be in the range of 30–20,000 kg. Do not lift the load if the angle of deviation from the vertical exceeds 45 degrees.

Professionals recommend lifting the load relative to the plane of the bolt axis. This type of fastening is considered the most reliable and safe.

The current GOST classifies bolts according to several basic parameters:

- Thread diameter.

- Ring size.

- Type of fastening: rigid, movable.

When the ring rotates freely on the rod, we speak of a movable joint. Sometimes a hook is installed instead of a ring. It makes it easier to grasp the load, as well as its subsequent retention.

Eye bolts are manufactured in full accordance with GOST 4751–73. It sets specific requirements for the following details:

- Availability of a certificate.

- Load capacity.

- Hardness - 105-149 HB.

- No scale.

APPENDIX (Recommended) EYE BOLTS SOCKETS

1. The design and dimensions of sockets for eye bolts in products made of ferrous metals must correspond to those indicated in the drawing and table.

mm

| Thread symbol d | d 1 | h | l , no less | Thread symbol d | d 1 | h | l , no less |

| M8 | 13 | 5 | 19 | M42 | 52 | 14 | 74 |

| M10 | 15 | 6 | 22 | M48 | 60 | 84 | |

| M12 | 17 | 26 | M56 | 68 | 17 | 97 | |

| M16 | 22 | 7 | 33 | M64 | 75 | 112 | |

| M20 | 28 | 9 | 39 | М72×6 | 85 | 117 | |

| M24 | 32 | 10 | 47 | M80×6 | 95 | 127 | |

| M30 | 38 | 11 | 57 | M100×6 | 115 | 152 | |

| M36 | 45 | 12 | 65 |

(Changed edition, Rev.

№ 2, 4).

2. Thread - according to GOST 24705 with a tolerance range of 7N according to GOST 16093.

The thread should not have broken threads.

3. Perpendicularity tolerance of thread axis d

at a length of 100 mm relative to the supporting surface of the socket:

0.2 mm - for eye bolts with threads from M8 to M16;

0.1 mm - for eye bolts with threads from M20 to M100×6.

(Changed edition, Amendment No. 2, 3).

4. Sockets for eye bolts must be clean, without holes or undercuts.

5. The size of the supporting flat surface of the socket, having a roughness designation of Ra 12.5 microns, must be no less than the diameter of the supporting surface of the eye bolt.

(Changed edition, Rev.

№ 1, 4).

Types of steel eye fastenings

In addition to their intended purpose, fastenings of a special design are also used in the formation of a non-standard lifting system. Such products are eye bolts with a hinge (swivel), which prevents the rotation of a load with longitudinal rings or rods when lifting heavy, oversized and light objects.

Any innovative design is manufactured according to the conditions of the state standard, ensuring the safety of personnel and the integrity of the cargo. TU and GOST differ from manufacturer to country, but the main indicator of product reliability is considered to be compliance with the “International Standard DIN 580”, adapted to the interstate GOST 4751−73. All products must have alphanumeric markings and the manufacturer's trademark on the headband (M8, M16, etc.).

The technical characteristics of bolts are determined by the manufacturing method:

- Stamping

- Forging.

The finished product is fired at high temperature.

The following method is used for marking:

- Stampings

- Impact application.

Each batch of products is equipped with a Certificate of Conformity with the manufacturer’s logo, batch number, number of fasteners, and the result of the examination. Products should be packaged in layers, with oiled paper between layers.

INFORMATION DATA*

1. APPROVED AND ENTERED INTO EFFECT by Resolution of the State Committee of Standards of the Council of Ministers of the USSR dated May 10, 1973 No. 1169

2. The inspection period is 1993, frequency is 5 years.

3. INSTEAD GOST 4751-67

4. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Item number |

| GOST 9.014-78 | 5.6 |

| GOST 9.301-86 | 2.15, 3.1 |

| GOST 9.302-88 | 4.6 |

| GOST 515-77 | 5.3 |

| GOST 1050-88 | 2.1 |

| GOST 1759.0-87 | 2.15 |

| GOST 2991-85 | 5.3 |

| GOST 7505-89 | 2.3 |

| GOST 9012-59 | 4.2 |

| GOST 10549-80 | 2.10 |

| GOST 14192-96 | 5.8 |

| GOST 15150-69 | Introductory part |

| GOST 16093-81 | 2, application |

| GOST 24705-81 | 2, application |

5. Tested in 1988. The validity period was removed by Decree of the USSR State Standard of December 16, 1988 No. 4162

6. REISSUE (June 1998) with Amendments No. 1, 2, 3, 4, approved in May 1979, January 1983, December 1988, August 1990 (IUS 7-79, 5-83 , 3-89, 11-90)

Reprint (as of April 2008)

* See notes from FSUE STANDARDINFORM (p. 8).