Angle grinder (grinder) AEG 451403 WS 8-115. Photo 220Volt

There are many models of grinders with different technical characteristics . One of the determining factors for the purpose of a power tool is the diameter of the working disk. This parameter is the basis for classifying grinders according to weight and dimensions. One of the groups represents standard sizes related to small angle grinders. Information about this group is in this article.

What is the name of

Actually, the technically correct name for an angle grinder is an angle grinder . Angular because the axis of the working spindle is at right angles to the axis of rotation of the electric motor.

Angle grinder (grinder) EINHELL TE-AG 125 CE. Photo 220Volt

“Bulgarian” is the most common colloquial name for an angle grinder. It came into circulation during the existence of the USSR with the advent of the first samples produced in Bulgaria (hence the name “Bulgarian”). The grinder also has other informal names such as:

- “Fortuna” - after the name of the first models of Bulgarian manufacturers;

- “Turbine” - similar to the sound when working with a functioning aircraft turbine;

- “Flexi” is a common alternative to the name grinder in Europe, derived from the name “Flex” of the first European models, which served as the prototype of an angle grinder.

Micro, mini and small: disk size/diameter, power, how many watts and other characteristics

BOSCH GWS 12-76 V-EC cordless angle grinder (grinder). Photo 220Volt

In practice, manufacturers and trading companies unofficially use the classification of grinders according to the size of the attachments used in their work. Classic angle grinders are divided into small, medium and large. The closest thing to small angle grinders in terms of technical parameters are micro and mini power tools, which have the following values.

- Micro. The disc size of this power tool does not exceed 50 mm. Most often used in precision jewelry and dental practice. The power of a micro angle grinder does not exceed 500 W. In design, most modifications are made without a reduction gear, which distinguishes micro angle grinders with increased working spindle speeds (50 thousand rpm - 70 thousand rpm).

- Mini. These angle grinders are functionally practically no different from the classic versions, the only difference is the compactness of the design. The power of mini-angle grinders is from 0.5 kW to 0.8 kW, the spindle speed reaches 20,000 rpm.

- Small ones. The diameter of the cutting disc on such angle grinders is 115 and 125 mm. Of all the classic versions, grinders have the maximum rotation speed of the working disk - about 12,000 rpm. The optimal power for performing work with small angle grinders ranges from 0.8 kW to 1.3 kW.

Why you can’t install a large disk 150 mm or more

Theoretically, on a small grinder designed to work with a maximum size disc, for example, 125 mm. You can remove the protective cover and install a disk with a diameter of 150 mm. Actually, this very action is already a gross violation of safety regulations , leaving parts of the human body unprotected from sparks and fragments.

Important: there are restrictions on the linear speed of the disk; it should not exceed 80 m/s. A disk with a diameter of 150 mm or more, placed on an angle grinder with a maximum allowable size of 125 mm for safe operation, will have a linear speed of more than 80 m/s, which will entail a sharp increase in vibration and destruction of the attachment.

Features of a small angle grinder and scope of application

If an angle grinder is a necessary tool in your home, then you should choose it wisely. And only the right choice will allow you to appreciate the capabilities of this tool.

When choosing a particular model, you need to take into account certain characteristics and nuances, in particular, the scope of application.

Like large tools , small grinders are classified according to the following criteria:

- engine power;

- spindle rotation speed;

- weight;

- dimensions;

- ergonomics.

The key difference between a mini grinder and a large tool is its dimensions . It is comparable in size to several electric toothbrushes. But despite its size, the tool is equipped with all the necessary components: grinding wheels and additional accessories that help expand the functionality of the machine.

Another advantage of the machine is its versatility of use , as well as the ability to solve high-precision tasks (which can also be called “jewelry” work). In addition, it will be possible to easily process areas with a small area, which is very good when other tools are powerless.

In terms of their general functions, mini-versions of grinders are practically no different from large models. During operation, you do not have to exert much effort; you can hold your hands freely, since the device is quite light. Accordingly, you do not have to choose the optimal position in your hand to create the required force at the point of work.

Another advantage of small machines is that they can be used without additional handles or protective covers . This will make working with the tool more comfortable. But this does not mean that the requirements of safety regulations do not need to be observed: regardless of its size, an angle grinder can become a source of injury to a person.

Purpose: on wood, metal and more

Small grinders with a circle of 115 mm. due to the small working surface of the cutting wheel (about 25 mm) and its wear during operation, they are ineffective for cutting workpieces. To a greater extent, such grinders enjoy priority when performing grinding work. Depending on the type of attachments, they can be used to grind a wide range of different materials (metal, glass, wood, porcelain and others).

Angle grinder (grinder) VORTEX USHM-125/900. Photo 220Volt

Angle grinder with a 125 mm wheel. solve a much wider range of problems. Possibility of cutting workpieces with a thickness of about 35 mm. make them indispensable for performing work in domestic conditions. The retail chain has a wide variety of attachments of this size, thereby increasing the number of tasks in relation to various materials that can be solved by a small angle grinder with a 125 mm circle.

Mini and micro grinders

By and large, a manual cutting machine has no right to be called a mini-grinder. So, to work with it, one strong male hand is required to cover the full circumference of the body. In some cases, you will need the help of a second hand. But the name stuck. For domestic needs, electrical machines are used, and in some places, pneumatic machines. Based on their functionality, they are divided into micro- and mini-grinders.

The micro angle grinder is held in the hand similar to a ballpoint pen. The cutting or grinding disc has a diameter of no more than five centimeters. These tools have found their application, for example, among dentists and jewelers. Read about the features of the wood grinding disc here.

Mini-grinders have received a wide range of applications due to their capabilities. Average power, convenient disk sizes, and adjustable handles allow you to use them when cutting sheet metal and rolled products of various shapes up to 8 mm thick, cutting down trees or branches, processing pressed wood or fiber panels, and cleaning cut corners. And this is not the full range of capabilities of this practical tool. With certain skills, shaped cutting and artistic processing of metal or other material surfaces is possible.

Advantages, reviews

The main advantages of small grinders are as follows:

- Light weight allows a small angle grinder to perform any work without strain: at heights, holding the angle grinder suspended with one hand, being in an awkward position, performing other similar actions.

- Compactness in size helps to carry out work in hard-to-reach places where it is impossible to carry out work with angle grinders of medium and large dimensions.

- It will not be difficult for the user to make an accurate cut or create the most effective pressure during grinding

Angle grinder (grinder) Kolner KAG 125/1000 V. Photo 220Volt

There are a lot of reviews on the Internet from users of small grinders. They highlight the above advantages . Among the models that deserve good reviews are those in which the small size of the wheel interacts with the increased power of the electric motor of a small angle grinder.

Battery and other types of manual angle grinders

Depending on the power source, the following types of manual angle grinders are distinguished.

- Electric, the most productive of all types. The disadvantage is the mandatory presence of an electrical network.

- Rechargeable , have an autonomous power source, which increases the possibilities of their use; there is no need for the presence of an electrical network. Battery life increases with the use of brushless (instead of brushed) electric motors, which consume less energy.

Cordless angle grinder Metabo W18 LTX 125 + 3.5 Ah LiHD + charger ASC 55 T0333. Photo VseInstruments.ru

- Small pneumatic angle grinders are used for performing minor repair and installation work in the field, where there is only a mobile compressor.

Angle grinder design

It should be understood that the use of an industrial or mini-grinder is advisable for large-sized products with extended lines of cutting and processing of material, when other cutting tools such as a hacksaw or mechanized scissors are not applicable. Thus, using an angle grinder without fixing it in a machine does not provide accurate cutting parameters, and manual cutting increases the impact of vibration and the human factor on both labor safety and the quality of work.

According to their motor drives and technical characteristics, disc cutting tools are divided into:

- electrical (220 and 380 volts);

- pneumatic (3−10 atmospheres);

- rechargeable (a wearable battery included in the handle with external charging from the mains);

- gasoline (internal combustion engine as the power body of the product).

Design features:

permissible maximum diameter of a cutting (flat type) or grinding (disc type) wheel;- engine power;

- parameters of engine power supplies or battery capacity;

- degree of electrical safety and level of protection against disk destruction;

- protection system against power overload and sudden power outage;

- vibration suppression system;

- principle of fastening and fixing the disk.

The size and frequency of rotation of the disk is determined by the power of the angle grinder. For these parameters, the range of values is the most extensive:

- cutting disc, from 115 to 500 mm;

- cutting, grinding, roughing disc, including cylinder, cutter, up to 115 mm.

For a specific diameter, a corresponding disk thickness is set, varying from 1 to 8 mm. Moreover, steel disks have radial cuts to compensate for their thermal expansion.

With speed control, soft start and other functions

Equipping small grinders with additional functionality increases the range of work performed by the same power tool.

Small grinders have high spindle speeds with a working tool. mechanisms with a speed controller on them . In this option, it will be possible to perform high-quality grinding work, cut off low-melting materials, for example, plastic, which are produced at lower speeds, set using the rotation speed controller.

To a lesser extent, small angle grinders require a “soft start” installation , which is effective for high-power angle grinders.

Bulgarian Interskol 125/700. Photo 220Volt

There are many additional options that make working with an angle grinder easier (restart blocking, automatic balancing, protection against overload and dust formation inside the angle grinder body, as well as many others). Providing additional options should not become an end in itself. This leads to an increase in the cost of power tools. You should select only those that are necessary for specific operating conditions.

The main purpose of the tool

During the Soviet years, the most popular scientific journal was Science and Life. The reason for this was the sections “Crossword with fragments” and “Little tricks” . The last section was filled with letters from readers who were ready to share their experience of inventing in non-standard solutions to everyday problems, among which electricity issues occupied a significant share.

In those years, electric cutting machines were not widely sold, and therefore no mention of grinders can be found in “Little Tricks”. After all, the industrial grinders, or “fortunes,” that already existed then, powered by compressed air, were not used in an apartment or garage. In addition, their design flaw in the form of a heavy pneumatic hose and the presence of a compressor with a receiver nullified the possibility of using it in everyday life.

But now the choice of cutting tools is widest, and its areas of application meet all the needs of modern builders. The main purposes of the grinder:

- trimming various parts or structures;

- removal of part of the material in the body of the product structure, gating;

- stripping unprepared surfaces of parts and assemblies before further work with them, including deburring after cutting;

- surface grinding using special wheels, including dulling of sharp edges;

- tool sharpening (using diamond wheels, cutters, etc.).

Popular brands

Manufacturers well-known on the power tool market produce almost any standard size of grinders. Below are examples of some models of small grinders from popular brands among users.

BOSCH GWS 18-125 V-LI

powered model . On one charge it provides maximum cutting performance among other grinders with similar parameters. The special 4-pole design of the electric motor ensures its reliability and long service life. Lightweight, weighing about 2.3 kg, ensures comfortable work with the tool in an overhead position.

Cordless angle grinder Bosch GWS 18-125 V-LI 0.601.93A.30B. Photo VseInstruments.ru

Metabo WEV 10-125 Quick

The power of the model best matches the loads experienced by 125 mm. work tool. Equipped with speed control with stabilization function under variable load. The design includes a quick-release nut for changing attachments .

Angle grinder (grinder) METABO WEV 10-125 Quick 600388000 (in box). Photo 220Volt

AEG WS 13-125 XE

A powerful and at the same time compact model weighing about 2.4 kg. Can be used with one hand. Equipped with a soft start system and speed control from 2800 rpm to 11500 rpm. The absence of vibration during operation, the presence of a quick-release nut, and the simple design of fixing the protective housing (lever system) are additional advantages of this model.

Angle grinder AEG WS13-125XE. Photo VseInstruments.ru

DeWALT DCG414N

Model with battery power supply. According to user reviews, it is distinguished by the power required for operation and reliability. The convenient location of the power button provides additional comfort during operation.

Hitachi G12SR4

The power of the 730 W model is sufficient to work in a 115 mm circle. Equipped with a high-quality dust protection system.

Sparky M850E HD

Small grinder with speed control (3000 rpm - 10000 rpm). a magnesium alloy gearbox in the design of the gearbox reduces the weight of the grinder to 1.7 kg. To increase operating comfort, the package includes an anti-vibration handle.

Angle grinder Sparky M 850E HD. Photo VseInstruments.ru

Bison USHM-115-800 M3

An inexpensive small model (circle diameter 115 mm), light weight (2.4 kg) made in China from a Russian company.

Whirlwind angle grinder 115/650

Despite the low power of the model (650 W), it is quite useful for household and garage work.

Makita 9562 CVH

The 1.2 kW model cuts almost any material with a thickness corresponding to a 125 mm circle. during operation . The model has excellent protection from dirt and dust - you can effectively operate this angle grinder in dusty conditions.

Angle grinder (grinder) MAKITA 9562 CVH. Photo 220Volt

HAMMER USM 1200E

A universal-use model with variable speed control and high power (1200 W) ensuring stable operation of a circle with a diameter of 125 mm.

Interskol angle grinder 125/750

One of the lightest models of small grinders weighing only 1.75 kg. Used when working in hard-to-reach places, it is possible to work confidently with one hand.

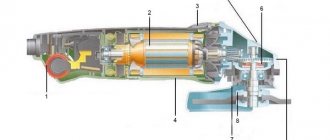

Device

The cutting discs of a small angle grinder are the main working element of the design. The products differ not only in their basic dimensional characteristics. They still have to match the processing material. For example, to process thin metal sheets, disks of a minimum size are needed.

These can be used to cut metal pipes, which are often located in places with difficult access. Designs that do not require connection to an electrical network are convenient for operation. Especially for these purposes, angle grinders are equipped with an autonomous energy source. This can be a lithium-ion or cadmium battery.

The absence of an electrical cable adds convenience to use. Possible size for angle grinder wheels is 125 mm. Cutting, abrasive, and diamond options can be combined with mini-sized tools. Thanks to this diversity, angle grinders successfully replace many types of hand tools. The design and components of all grinders are the same. The difference lies in the complementary components that perform different functions. Main details:

- starter;

- rotor;

- electric brushes.

Other devices of the unit:

- a clutch that prevents kickback if the wheels become stuck;

- speed controller;

- engine start button;

- engine overload protection system;

- a button that locks the gear in the gearbox, necessary during the process of removing or replacing wheels;

- attachment of the grinding wheel.

In addition to plastic housings, products can be equipped with modern reinforced polymer options. The electric motor can receive energy from both batteries and the household network. The machine has a single-stage bevel gearbox with variable speed control. It is usually made of aluminum or magnesium alloy. The tool can be used to process wood, ceramic tiles, concrete or metal substrates. Some angle grinders are still provided with a protective casing. It protects against sparks and chips flying off during work.

How to choose for home and other purposes

Angle grinder AEG 451410 WS13-125XE in operation. Photo 220Volt

The main approach when choosing an angle grinder is that it is selected for specific types of work. The scope of application depends on the following characteristics of the angle grinder.

- First of all, when choosing, you should pay attention to the maximum size of the cutting tool working in tandem with the grinder. If its use is limited to cutting profiles, sheet metal, kitchen ceramic tiles, cleaning rusty surfaces and solving other household and garage problems, then a small grinder will be the best option. To cut thick-walled pipes, channels, beams, concrete structures and other similar work, you should use a grinder of medium and large categories.

- Power. This parameter is directly related to the size of the nozzle. When performing complex long-term work, professional grinders with a large circle size and high power are used. For working in hard-to-reach places, lightweight compact small angle grinders with low power ratings are suitable.

- When choosing cordless angle grinders, the main criterion will be the battery capacity. The higher the capacity, the longer the operating time before recharging. For short-term work, it is enough to use small cordless angle grinders with small batteries and minimal capacity.

- The use of pneumatic angle grinders is associated with the speed of supply of compressed air and, accordingly, with the power of the compressor. For small grinders, an air pressure of about 6 atm and a flow rate of about 100 l/min are sufficient for operation. Large pneumatic machines are effective at delivering up to 540 l/min.

Disk selection rules

When choosing a grinding machine, be sure to take into account that the conditions for replacing discs are created as optimal as possible. Some cutting models often come with wrenches. And some contain special nuts, with which you can easily replace the disk.

As for the disks themselves, when choosing, you need to decide on the purposes of their use. Key parameters are:

- thickness;

- diameter.

The smallest grinding machines have discs with a diameter of 125 mm, and the largest - 250 mm, respectively. But keep in mind that these indicators are not the limits for a particular tool, since larger discs can be used on professional tools.

You need to pay attention to the diameter of the disk because it determines the thickness of the workpiece. As well as the maximum cutting depth

If you need a tool for cutting metal products, it is better to use cutting discs. The thickness of household models is 1−1.2 mm. Industrial models can have a value of up to 2.5 mm.

The correct size disc is designed to create optimal conditions for the craftsman, since it will not need to apply much pressure to the angle grinder. As a result, the cut will be neat and done without difficulty. If you need a tool for curly carving on thin metal, then the discs should be of the minimum size or take old, used ones.

Some craftsmen believe that it is better to use diamond blades for cutting metal, but this is not true. If such a disk is used for metal, it can get stuck in it, and then it will be problematic to use it for its intended purpose.

Rating of top models with battery and more, characteristics

There is information on the Internet that, from a huge range of various modifications of grinders, based on expert opinions, contains data on the best, in their opinion, models. It is quite subjective, but you can use it as a starting point when choosing an angle grinder for purchase. According to experts at the TechnoPro store, the following are worth attention among small Bulgarians in 2022.

BOSCH GWS 18-125 S. Power 900 W, circle diameter 125 mm. Weight 1.8 kg, lightweight, can be held with one hand. Low noise level during operation, vibration is practically not felt. The spindle speed is 11,000 rpm, adjustable for high-quality grinding work. It is well suited not only for home work, but also with the appropriate equipment, for example, with a wall chaser attachment, for professionals.

Angle grinder (grinder) BISON UShM-125-950 M3. Photo 220Volt

BISON USHM-125-950 MZ. Unlike the BOSCH model, it has an inexpensive price and a fairly high power of 950 W for the category of small angle grinders. Increased requirements for dust protection guarantee high reliability during operation. Rotation speed 11000 rpm.

Which is better, good options to choose from

Each of the angle grinder models is designed to perform a specific type of work. This is where the classification of angle grinders comes from: household, semi-professional, professional. Therefore, the concept of “the best grinder” is not global. According to a user survey, the following were recognized as the best small angle grinders with a 125 mm circle in 2022:

- BOSCH GWS 9-125 S;

- Metabo WEV 850-125;

- Makita 9565HZ;

- DeWALT DWE4119.

Angle grinder (grinder) BOSCH GWS 9-125 S. Photo 220Volt

Criteria for choosing a good grinder

When compiling the rating, the following performance characteristics are taken into account:

- Typical disk size.

- Electric power.

- Engine speed.

Before purchasing a tool, it is also important to consider its ergonomic features.

Appearance of the grinder

Disc diameter

The diameter of the disk is a key indicator that determines the type of work to be done.

Note! The seat size for most types of circles has a standard value of 22.2 mm.

When choosing this parameter, we take into account the pattern according to which, as the diameter of the working circle increases, its rotation speed increases and the developed power increases. The extreme values of diameters are from 115 to 230 mm.

When choosing the optimal option, they are guided by specific samples of grinders that work with discs of the following sizes:

- 115 mm blade (due to its small size, it is used exclusively for sanding).

- The 125 mm disc is optimal for home work (except when you plan to cut thick parts).

- The 150 mm size is in less demand, however, it is a good option when you need a model that is medium in size and power. It is used both for grinding and cutting metals.

Discs of different sizes

The maximum standard size (230 mm) is in demand when carrying out repair work on large elements of objects under construction.

Power

With an increase in the power of the electric motor of the angle grinder, the force developed on the working axis of the tool increases, which allows you to work with more durable materials.

Important! Along with the increase in this indicator, the mass of the grinding unit increases, which is important when working with it for a long time.

The industry has mastered the production of grinding machines with motors with operating power ranging from 0.5 to 3 kW. Products with motor powers varying in the range from 0.8 to 1.2 kW are suitable for home and garden use. Samples with values exceeding these numbers will be more difficult to hold in your hands when using, and, in addition, they will consume more electricity.

In the case where large-scale construction is planned, accompanied by the assembly of formwork and cutting of steel bars, for example, you will have to use a more powerful tool (up to 1.5 kW).

Speed

In products of this type, the maximum speed of rotation of the drive shaft (otherwise known as the operating speed) ranges from 2.5 to 12 thousand rpm. The optimal operating range is from 3 to 6 thousand rpm.

Additional Information! Manufacturers of angle grinders set this parameter at the design stage, linking it with the rated power of the engine.

Professional-grade angle machines have a built-in mechanism that allows you to adjust the speed, which is very important in conditions where you often have to change the disc. This option significantly simplifies the handling of the tool at high rotation speeds (more than 10 thousand revolutions per minute).

Number of handles

Not only the ease of handling, but also the safety of working with it depends on the number of holders or handles on the tool body. The presence of one handle is typical for lightweight models of grinders of any class. This is because such a tool can be held with one hand.

Two-handled tool

Grinders with an additional handle are more massive models, the handling of which requires considerable physical strength and a comfortable grip. If the handles have a special rubberized coating and are also equipped with a vibration damping mechanism, it will be much easier to work with it.

Additional features

High-quality samples of grinders provide a number of functions that simplify working with them and the durability of the tool. Some of these options are given below:

- The so-called “soft start”.

- Blocking brushes during power outages.

- Automatic disk balancing.

- Fixation of switching on.

- Possibility of electronic adjustment of rotation speed.

To increase the reliability of grinding machines, they are provided with protection of internal mechanisms from dust, as well as a special socket for a vacuum cleaner.

Do it yourself

A small grinder with 115 or 125 mm circles. can be made from an ordinary hand drill . It should immediately be noted that the disadvantages of the homemade product are the low rotation speed of the wheel, which impairs the productivity and quality of the cut. However, in case of an emergency, you can use a small grinder from a drill to saw off some small part.

How to disassemble an angle grinder, gearbox, angle grinder head, disassembly process

If the angle grinder has malfunctions that affect stability in operation, it should be diagnosed to identify their causes. To do this, the power tool must be disassembled; you can do this yourself. The disassembly process (separation of the plastic housing from the gearbox) is shown in the following video.

After checking the functionality of the gearbox mechanics, if necessary, it is disassembled and repaired, as shown in the video.

How to change bearings

Wear of the bearing units of the angle grinder leads to increased backlash, which contributes to the failure of the entire angle grinder as a whole. Therefore, a preventive inspection of the angle grinder is required for the presence of play and, if necessary, replacing them as shown in the video.