This is how an electrode for arc welding burns out.

Do you need to choose electrodes for manual arc welding, but don’t know how to do it correctly? In this article we will teach you how to make the right choice of welding electrodes for welding welding machines.

The demand for welding work is not decreasing these days, which can easily be explained by its availability, affordable cost and good quality of connections. The quality factor of welding directly depends on the correct choice of equipment and consumables, in particular electrodes. To choose the right electrode, you need to understand its markings and have an idea of the characteristics and manufacturers. We will try to figure this out.

Features of cast iron

Unlike steel, cast iron contains a significant amount of carbon - from 2 to 6%, while CO2 is in a free state - in the form of graphite. This determines its unique characteristics - it is extremely hard, but at the same time fragile, has low ductility and viscosity. These properties affect the processing and welding of metal. If the parameters, materials and welding techniques are incorrectly selected, the following risks exist:

- due to the presence of graphite in the metal, cracks may form;

- carbon burns out, which leads to the formation of pores in the weld;

- Refractory oxides are formed, whose melting point is higher than that of cast iron.

In addition, difficulties during welding can be caused by such a property as high fluidity, which prevents the formation of a high-quality seam.

Rapid cooling of gray cast iron after a heating temperature of more than 750°C leads to the transformation of graphite into iron carbide - cementite. The cast iron itself turns from gray to white. Such cast iron cannot be welded.

Welding electrodes and other welding materials

Piece electrodes, welding and flux-cored wire are used as welding materials for electric arc welding.

Piece electrodes

Arc welding electrodes come in two main types: consumable and non-consumable. Consumable electrodes

. Coated consumable electrodes are used very widely; they are the main material for welding work at home.

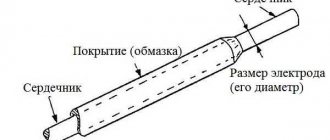

Consumable electrode for welding: 1 - rod, 2 - transition area, 3 - brand of electrode, 4 - coating.

Electrode rods for steel welding are made from low-carbon, alloy or high-alloy welding wire. The standard provides for 77 grades of steel wire used for the production of piece electrodes with a diameter of 1.6 to 6 mm.

The coating of welding electrodes has multiple effects: it forms an atmosphere that protects the metal from oxygen and nitrogen in the air, stabilizes the arc, removes harmful impurities from the molten metal, and alloys it to improve its properties. To perform all these functions, the coating includes many components:

- Slag-forming substances that protect metal from nitrogen and oxygen. They include manganese ore, kaolin, titanium concentrate, chalk, marble, feldspar, dolomite, and quartz sand.

- Deoxidizers that remove oxygen from molten metal. Manganese, silicon, aluminum, and titanium in the form of ferroalloys are used.

- Gas-forming components that create a gaseous environment during the combustion of the coating, protecting the molten metal from oxygen and nitrogen in the air. These are mainly dextrin and wood flour.

- Alloying substances that give the weld metal special properties - strength, heat resistance, wear resistance, increased corrosion resistance. For this, chromium, manganese, titanium, molybdenum, nickel, vanadium and some other substances are used.

- Stabilizing elements that promote ionization of the welding arc - sodium, potassium, calcium.

- Binders that serve to bind the coating components to each other and the entire coating to the electrode rod. The main binder is potassium or sodium liquid glass (silicate glue).

For welding non-ferrous metals and their alloys, along with non-consumable ones, consumable electrodes are used from the corresponding metals and alloys - aluminum, copper, nickel, bronze, brass, etc.

Welding electrodes

Classification and designation of electrodes

. Electrodes used for welding and surfacing are classified according to a wide range of criteria:

- according to its intended purpose (for welding steel, cast iron, non-ferrous metals, surfacing work, etc.);

- according to technological features (for seams of various spatial positions, for welding with deep penetration, etc.);

- by type of coating (acidic, rutile, basic, etc.) and its thickness (thick, thin, medium, extra thick);

- by the chemical composition of the coating and rod;

- on the mechanical properties of the weld metal;

- according to the type and polarity of the current, the value of the rated open-circuit voltage of the power source.

- by quality of workmanship, condition of the coating surface, content of harmful impurities of phosphorus and sulfur.

Each electrode parameter has its own alphabetic or numerical designation in a certain part of the marking. In particular, electrodes for welding carbon and low-alloy structural steels with a temporary tensile strength of up to 60 kgf/mm2 are designated by the letter U

.

Electrodes with a medium-thick rutile coating are marked with the letters C

(medium) and

P

(rutile).

The penultimate number 1

indicates that the electrode can be used to make a seam of any spatial position, and the final number

0

informs that this electrode is used when working with a welding machine that provides direct current.

In accordance with GOST 9466-75, the electrode designation contains information about the type, brand, diameter and other characteristics. The designation of the type of electrodes for welding structural steels includes the letter E

(“electrode for arc welding”) and a figure indicating the minimum temporary tensile strength of the weld metal in kgf/mm2.

If there is a letter A

(for example, E42A, E46A), this means that this type of electrode provides higher plastic properties of the weld metal.

Along with the type, the electrodes also have a brand. One type of electrode may correspond to several brands. For example, electrodes of type E42 correspond to the brands GOSTS-2, TsM-7, ANO-6.

Designation of electrodes according to GOST 9466-75

1 - Type of electrode (E - electrode for arc welding, 46 - strength 460 MPa, A - increased ductility and toughness of the weld metal); 2 — Electrode brand; 3 - Rod diameter; 4 - Purpose of the electrode (U - for welding carbon and low-alloy steels); 5 - Characteristics of coating thickness (D - thick); 6 - Group of indices indicating the characteristics of the weld metal; 7 - Type of coating (B - main); 8 - Spatial position of the seam (1 - for all positions); 9 - Type of current (0 - constant, reverse polarity).

Designation of electrodes according to the international standard EN 499

1 - Electrode for arc welding; 2 - Minimum yield strength (500N/mm2); 3 — Characterizes the temperature at which the minimum value of impact strength is 47 J (about 60 ° C); 4 - Characterizes the chemical composition of the deposited metal (Ni - 2.6-3.8%); 5 — Type of electrode coating (main); 6 - Performance code and type of current (<=105%, constant); 7 - Code of position of seams during welding (all except vertical from top to bottom); 8 — Characterizes the hydrogen content in the deposited metal (10 ml/100g).

Non-consumable electrodes

. Non-consumable electrodes are carbon, graphite and tungsten. The melting point of all these materials exceeds that to which they are heated during welding. This feature determined their name.

Graphite electrodes are made from synthetic pressed graphite, carbon electrodes are made from electrical coal. Graphite electrodes have certain advantages over carbon electrodes. They have higher electrical conductivity, allowing a 2.5-3 times increase in current density, and higher resistance to oxidation at high temperatures. The latter quality allows them to reduce their consumption compared to coal ones.

Graphite electrodes

Copper-plated carbon electrodes

Tungsten non-consumable electrodes are made from pure tungsten or with tungsten additives. Oxides of thorium, yttrium, lanthanum and other substances are used as additives. The presence of a particular additive is indicated by the brand and color of the electrode. The designation EV (WP) means pure tungsten (the end is painted green), EVT (WT) - tungsten with thorium (red), EVI (WY) - with yttrium (dark blue), (WL) - with lanthanum (blue or golden, depending on the lanthanum content), WC - with cerium (gray), WZ - with zirconium (white).

Tungsten electrodes

Using non-consumable electrodes, steel, cast iron, copper, brass, bronze, aluminum and other metals are welded. Welding is most often carried out in a shielding gas environment (argon, helium, nitrogen and their mixtures). It can be carried out both with filler material and without. The latter is used wire, metal rods or strips.

Selection of electrodes for welding steels

The choice of the type of electrode for welding steel depends not only on the brand of the latter, but also on the nature of the connection, the spatial position of the seam, the type of welding current (direct or alternating), ambient temperature during work, etc. Currently, several hundred brands of electrodes are produced for for a variety of purposes.

Electrodes for steels are divided into several groups, depending on the grade of material for which they are intended for welding.

The first group consists of electrodes for welding carbon and low-alloy structural steels containing up to 0.25% carbon and having a tensile strength of up to 490 MPa. Such steels include grades St5ps, St3sp, St0 and others, used for the production of rolled metal, from which most structures are made in everyday life, the strength of which does not have special requirements - gates, fences, etc. For their welding, the following grades of electrodes are used, known to all welders , like ANO-4, ANO-21, MR-3, OZS-41. The popular MP-3 electrode is suitable for welding with both alternating and direct current in all spatial positions of the seam except vertical from top to bottom.

For welding steels with tensile strength from 490 to 590 MPa, electrodes of the E50A, E60 type (grades UONI-13/55, OZS-28, UONI-13/65) are used. These electrodes produce a seam that can withstand greater loads than the previous group of electrodes.

Structural alloy steels of increased and high strength, having a tensile strength of over 590 MPa, must be welded with electrodes NIAT-5, EA-981/15, EA-395/9 (if the product is not subjected to heat treatment after welding) or electrodes OZSh-1, NIAT- 3M, UONI-13/85 - if the welded structure is planned to be subjected to heat treatment in order to ensure equal strength of the seams.

For welding low-alloy and alloy heat-resistant steels operating at temperatures up to 550-600 °C, electrodes of the E-09X1M, E-09MH, E50A types (ANZhR-2, OZS-11, TsU-5 brands) are intended.

Not often, but in everyday life one has to deal with welding heat-resistant and heat-resistant steels intended for operation at temperatures above 550-600 °C. For example, in the manufacture of fireproof grates for a furnace. If you manage to get such steel, you need to cook it with electrodes KTI-7A, OZL-38, TsT-15.

Corrosion-resistant steels that are resistant to corrosion in acidic, alkaline and other aggressive environments, known in everyday life as “stainless steel”, are welded with electrodes of the TsL-11, OZL-7, OZL-22 grades.

Selecting the electrode diameter

. The diameter of the electrode is selected, first of all, taking into account the thickness of the metal being welded. Other working conditions: brand of metal being welded, type of current, mains voltage parameters, forms of edge preparation, etc. - can also put forward their own requirements for the diameter of the electrode, but to a much lesser extent than the thickness of the metal being welded.

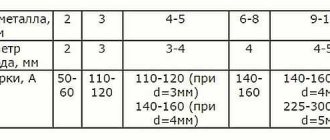

For the initial selection of the electrode, you can use the table below, the values in which correspond to the bottom seam.

| Metal thickness, mm | 2 | 3 | 4-5 | 6-8 | 9-10 |

| Electrode diameter, mm | 2 | 3 | 3-4 | 4 | 4-5 |

When making welds in vertical and overhead positions, electrodes with a diameter of no more than 4 mm are used. If there is a cutting of the edges or it is necessary to fill the gap between the parts, then the root weld can be made with an electrode of a smaller diameter - 2.5-3 mm.

Root welding

Welding wire

Welding wire is produced from various grades of steel, copper, aluminum and other metals.

Steel wire intended for welding, surfacing and production of piece electrodes is manufactured in accordance with GOST 2246-70. The standard provides for 77 grades of steel wire of various chemical compositions - low-carbon, alloyed and high-alloyed. The diameter of the material ranges from 0.3 to 12.0 mm. Wire with a thickness of up to 3 mm is used for semi-automatic hose welding, with a diameter of 1.6-6 mm - for manual welding with stick electrodes, with a diameter of 2-5 mm - for automatic welding. Material of large diameters is used for surfacing work. Depending on the type of coating, the wire can be pure or copper-plated. Copper plating improves the strength and cleanliness of the weld, increases arc stability, and reduces metal spattering.

Letters and numbers are used to designate wire grades. The designation Sv-08GS indicates that this is a welding wire (Sv) containing carbon - 0.8%, manganese (G) - up to 1%, silicon (S) - up to 1%.

Welding wire: stainless, copper-plated, aluminum.

Cored wire

Flux-cored wire (also flux-cored or self-shielding), used for semi-automatic welding, is a metal sheath filled with a special powder.

The latter consists of a mixture of materials (ferroalloys, minerals, ores, chemicals, etc.) that have the same purpose as the coating of piece electrodes - protection of the molten metal from oxygen and nitrogen, alloying and deoxidation of the metal, stabilization of the arc discharge, etc. Configuration options cored wire sheaths

Flux-cored wire allows you to avoid using gas cylinders in semi-automatic welding, but the quality suffers.

When using the content of this site, you need to put active links to this site, visible to users and search robots.

Literature

Electrode grades for cast iron

These features require the selection of special brands of electrodes. They must provide the same concentration of CO2 in the base and filler metal and the same cooling time. Electrodes for cast iron often include copper (copper-nickel, copper-iron electrodes), but they can also be steel, ferro-nickel or nickel. The type of rod coating is basic, less often acidic. Among the most popular grades that are used for welding on cast iron are MNCh-2, OZCh-4, OZCh-6, OZCH-2, OK 92.18, OZZHN-1. Some of them are universal in purpose, allowing you to work with all types of cast iron (except for the white one mentioned above), some have a narrower specialization (more on this below).

| Electrode brand | Cast iron type | Welding direction | Welding type | Properties |

| MNC-2 |

|

|

| Preferred for welding the first layer in joints that require high joint density and surface cleanliness after processing |

| TsCh-4 |

| in the down position |

| For structures made of ductile iron with nodular graphite and gray cast iron with flake graphite, as well as their combinations with steel. |

| OZCH-6 |

|

|

| For manual arc welding and surfacing of thin-walled parts. |

| OZCH-4 |

|

|

| They are preferred when welding the last layers, providing the weld metal with high abrasion resistance and impact strength. |

| OZCH-2 |

|

| cold welding | For welding, surfacing and welding of casting defects when restoring cast iron products. |

| OZZHN-1 |

|

| cold welding | This grade is often used for welding large casting defects and multi-layer surfacing with large volumes of metal. |

| OK 92.18 |

| all provisions | hot welding | They have proven themselves well in the repair of products made from thin parts (welding damage and defects in gearboxes, pump housings, engine blocks, etc.). |

Separation by coverage

The classification of electrodes for manual arc welding allows them to be differentiated according to many characteristics. One of the most common is what kind of coating these consumables have. The coating of electrodes for manual arc welding is often decisive when it is necessary to decide on their purchase.

Types of electrode coatings for manual arc welding have divisions:

- Rutile . This element is titanium dioxide. With this type of coating, metal spattering is reduced, fluidity increases, and a thick layer of slag is formed, which can then be easily separated. However, the risk of formation of defects such as pores is high. It is advisable to use it for connecting parts of small thickness made of low-carbon steel.

- Pulp . In addition to the cellulose itself, the coating contains silicon and magnesium. This coating increases gas formation, which reliably protects the weld pool. The spatterability of the metal is increased. It is convenient to weld vertical seams, but one cannot expect an aesthetic appearance.

- Basics . The main elements are derivatives of calcium and magnesium. This provides high mechanical strength. The weld metal is chemically pure. The big advantage is the ability to weld in any position. Can be used for welding critical structures.

- Sour . They are used only for making horizontal seams. There is a risk of cracks and undercuts. May pose a health hazard to the welder.

Each type has its own designation. Rutile coating is designated by the letter “R”, cellulose by the letter “C”. If the coating is a mixed type of rutile and cellulose, then two letters “RC” are used.

The base coating has the letter “B”, which means base. Acid coating is assigned the letter "A". The letter “P” denotes other coatings. The letter “C” means that we are talking about a special coating, with which it becomes possible to carry out the process under water.

Hot welding of cast iron

Hot welding is welding that requires pre-calcination of the cast iron.

Actually, the “hot” method is the one in which the metal is heated to a temperature of +500... + 600 °C, “semi-hot” - the temperature reaches +300 +400 °C, “warm” - +200 °C. Most often, universal electrodes of the TsCh-4 brand are used for this, as well as OK 92.18 (“warm” method) and OMCh-1. Also in this case, electrode rods of the UONII, ANO brands, carbon and other electrodes are used.

MNC-2

Universal nickel-copper electrodes that allow you to work with any type of cast iron - malleable, gray and high-strength. Products of this brand are specially designed so that welding can be performed without pre-calcination. The core is made of monel metal (mostly nickel, 28.5% copper, iron and manganese are also present) has a special coating. Main purpose: cold welding, surfacing, welding of casting defects. Welding is possible in any spatial position except the ceiling and from top to bottom, and is carried out with direct current of reverse polarity. In addition to versatility of use, there are a number of advantages:

- no need for calcination - minor heating is required only when working with thick products;

- easy ignition, stable arc combustion, high melting rate at a relatively low temperature, easy separation of the slag crust;

- excellent quality of the resulting seam in terms of strength, ductility, corrosion resistance;

- color identity of the base and deposited metal;

- low hardness of the seam, due to which during operation of the structure the risk of cracks in the joint area is minimal.

This brand of cast iron electrodes for electric arc welding is widely used in the repair of worn parts in gears, pumps, gearboxes, excavator buckets and other components and mechanisms. Analogues of the MNC-2 brand according to the international classification are electrodes of the ENiCu-B type.

Important. If multi-layer surfacing is carried out, the bead must be gradually cooled to a temperature of 60 ° C and forged with light blows of a hammer. This reduces the internal stress in the metal structure and reduces the risk of cracks appearing in the heat-affected zone. The length of the welding roller itself is from 30 to 50 mm.

Marking of electrodes for manual arc welding

The ability to read labels is necessary for anyone who deals with technology. Electrodes use alphanumeric names, each part of which indicates certain characteristics. Let's take, for example, the marking E46-ANO-4-F-UD E 43 0(2)-P25. Don’t forget, every self-respecting welder should know the marking of electrodes for manual arc welding!

- E46 . Type. This type of electrode is designed for working with low-alloy and carbon steel. The number 46 here means tensile strength: 46 kg per 1 square millimeter of welding section.

- ANO-4 . This part is a regular trade designation, brand, and does not say anything about the technical characteristics of the product.

- F. _ A symbol that represents the diameter, expressed in millimeters. The diameter itself is indicated somewhere else.

- U. Shows that the electrode can weld low-alloy and carbon steels having a tensile strength not exceeding 451 MPa.

- D. _ Coating thickness. As we found out earlier, this letter means that the coating is thick, up to 80% of the electrode diameter.

- E. _ According to international standards, this letter indicates that the electrode is consumable and has a coating.

- 43. Tensile strength. In this case it is 430 MPa.

- 0. Relative extension. Zero here can be interpreted as an elongation of less than 20%.

- (2). The minimum temperature at which the viscosity of the weld metal is at least 34 Joules per square centimeter. This marking indicates 2 – 0°C.

- R . A type of coating. Here we are dealing with rutile coating.

- 2.Spatial position of the rod. You can weld from any position, with the exception of working along a vertical seam from top to bottom.

- 5. Welding current and connection. In this case, both direct and alternating current of any polarity are allowed for operation at an open circuit voltage of 70V.

For such large markings, it is very difficult to remember the meaning of each of the segments, so it is useful to have reference books on hand that contain the necessary data. It is better, of course, to remember the markings of electrodes for manual arc welding, so as not to waste time working with reference materials.

Recommendations for choosing electrodes

Do not forget about safety precautions; at your leisure, you can read about why you should not watch welding without a welding helmet.

Administration

Knowing the basic characteristics of electrodes, we can navigate their diversity and find exactly what is needed for a specific job. What should you pay attention to when selecting consumables?

- Metal that will be joined by welding. Most often this is structural low-carbon steel, for which domestic grades of electrodes OZS-12 and ANO-4 are suitable. If you need to cook stainless steel, then you should pay attention to the Russian TsL-11 or imported OK 63.34 and OK 61.30.

- Features of the parts to be connected. The choice of coating depends on this. If the surface is clean, then the best coating will be rutile (electrodes brand MP-3), it makes it easy to obtain an electric arc, has a small spread of splashes and is recommended for both beginners and professionals. Cellulose and base coatings are used to create particularly strong joints, but require direct current for welding. An acid coating removes pores from the seam and works against rust, but its fumes are harmful to the health of the welder.

- Thickness of the metal being welded. This determines what electrode diameter to choose and what current to set.

Correlation between electrode and metal characteristics

The ratios of metal thickness, electrode diameter and current supplied from the inverter are usually indicated in special tables. Such a table can usually be found on the box with welding consumables. In general terms, this relationship looks like this:

- with a current strength of up to 50A (home inverters), you can weld metal 1-2 mm thick with electrodes with a diameter of 1-2 mm;

- with 80A you can safely cook workpieces 3 mm thick, and the electrode will also be 3 mm in diameter;

- 100-200A it is permissible to weld metal up to 8 mm with electrodes having a diameter of 4 mm;

- 160-200A (semi-professional transformer) allows you to weld parts 9-12 mm in thickness with 5 mm rods;

- 250-350A (professional devices) and electrodes with a diameter of 8 mm or more weld workpieces with a thickness of more than 16 mm.

OZCH-4

In terms of their properties, these electrodes with a basic coating are almost as universal as the MNCh-2 brand - they can be used to weld any type of cast iron. Electrodes make it possible to obtain a seam with increased wear resistance (which is important if the operation of the product involves constant friction of metal on metal), as well as high manufacturability during cutting and high resistance to impact loads. For welding and surfacing, reverse polarity current is used. Possible spatial positions are lower and vertical. When welding technology, one must comply with the requirements for products of the MNCh-2 brand (cooling and easy forging of the roller), however, unlike MNCh-2, in this case, preliminary calcination for an hour is required at a temperature of 250...280 °C.

Important. OZCH-4 electrodes are most effective when welding the last layers, providing the weld metal with high abrasion resistance and impact strength.

Rating of the best models of welding electrodes

We suggest that you familiarize yourself with the rating of electrodes with rutile coating.

This category includes:

- Esab scel ok 46. Electrodes coated with rutile-cellulose coating. This model is considered one of the best for welding work. Thanks to it, it is possible to quickly ignite the arc, as a result of which a dense seam is formed.

- You can work with such models on welding machines with alternating current. Electrodes do not form a large volume of slag during combustion. When working with rusty metal, additional cleaning from corrosion will be required;

Lincoln electric Omnia

These electrodes belong to an American company. They have been producing quality products for 100 years.

- For the first time they managed to produce an electrode with high-quality coating in 1928.

- Long-term development was not in vain. The company produces the best rutile-cellulose electrodes, which are popular among professional and novice welders.

- The affordable price makes the model in demand among professionals. During the combustion process, a small amount of sparks appears, which can cause inconvenience when installing parts.

- When the electrode melts, a small amount of slag appears. This model can be used on rusty and dirty metal surfaces. Technicians prefer to use omnia to work on the pipeline network;

Special electrodes

This brand is produced in Russia. They are specifically certified to perform welding work on mild steel.

- The main advantage of this model is that it produces an even and light seam. After cooling, a thin crust of slag appears on the surface.

- Rutile electrodes from this manufacturer cope well with climate disasters and temperature changes.

- The surface of the metal seam does not crack or deform. The coating of this model is very sensitive to humidity;

Resanta mr-3

This model of electrodes is considered popular and in demand. However, specialists do not often choose a similar brand for welding work.

The fact is that these products are inferior in all operational characteristics.

- During work, slag pits may appear. During use, a chemical reaction occurs with increased crystallization, resulting in the formation of large amounts of carbon.

- The advantage of this type is the rapid ignition of the arc and the ability to work on electric welding equipment with direct and alternating current.

The main disadvantage is the possible deformation of the seam after it cools.

TsCh-4

Basic coated electrodes designed for both hot and cold welding of ductile, ductile and gray cast irons. The main purpose is welding of defective castings, surfacing when repairing cast iron parts. These are also electrodes for cast iron and stainless steel; they allow high-quality welding of these two alloys with different structures. Often, to obtain a more effective result, they are used only for surfacing the first layers, after which it is performed with other, special electrodes.

What to consider when choosing welding electrodes

Before purchasing an electrode for welding equipment, you must adhere to several simple criteria, which are as follows:

- Product diameter. In this case, it is important to consider the thickness of the metal elements. Don't forget about the power of welding equipment. An electrode with a diameter of 3 mm is considered a universal model;

- Protective covering. The choice of coating directly depends on the purposes for which the consumable will be used. The main function is to protect the metal core inside the electrode. During the heating process, a protective base is formed between the electrode and the iron elements, preventing the release of slag. Some types of electrodes contribute to the appearance of slag pits, which lead to weld deformation;

- Product brand. Most electronic products quickly weld low-carbon and low-alloy steel products. To carry out work on the surface of stainless steel or alloyed metals, you will need to use special types of consumables;

Storage conditions. Different types of protective coating can absorb moisture in different amounts. As a result, the metal seam may become brittle. In addition, difficulties may arise with igniting the arc.

The use of such electrodes is considered unprofitable. Experts recommend storing a pack of welding consumables in a dry place;

Manufacturers. Domestic companies offer a good selection of electronic products. They are capable of producing high-quality seams.

OZCH-2

These are copper electrodes for welding cast iron (copper core) with an acid coating. They have a limited scope of use - they are used only for working with malleable (soft and viscous) and gray cast iron. The scope of work includes cold welding, as well as surfacing and welding of casting defects when restoring cast iron products. The length of the roller that is recommended for welding is small, in the range of 30... 50 mm. The resulting roller must be cooled to 60 °C and then forged with gentle hammer blows. Before welding, the electrode should be calcined for an hour at a temperature of 190-210 degrees. Welding is permissible in the lower and vertical positions with direct current of reverse polarity.

Types of coating

Types of electrode coating are divided into a number of groups, each of which has its own designation. Types of electrode coating are divided into:

- the main one, designated as “B”, is white or beige;

- sour, designated “A”, gray in color;

- cellulose, designated “C”, light gray with a brownish tint;

- rutile, designated “P”, in various colors such as gray, blue, green, reddish.

There are also mixed-type coatings, which is reflected in their designation. So, for example, the combination of letters RC should be deciphered as rutile-cellulose, and “RA”, respectively, as rutile-acid. The letter “P” is a designation for other types of coatings. This gradation is determined by the presence of chemical elements included in the coating. The choice of coating should be made depending on the metals being joined.

Basics

The main coating of the electrodes contains mostly calcium and magnesium carbonates. In order for the slag crust to be diluted, a special element in the form of fluorspar is added to the coating. This somewhat impairs the ability to work when using alternating current, so it is recommended to use electrodes with a basic coating when working with constant current.

The difference between this type of coating is that there is no hydrogen in the resulting gaseous environment, which can lead to the formation of cold-type cracks. When using electrodes with a basic coating, the seam results in increased ductility.

A big advantage is the ability to weld in all positions, however, it should be taken into account that the seam, due to its significant viscosity, will be somewhat convex and not entirely aesthetically pleasing.

Sour

Acid-coated electrodes have a coating containing iron and manganese ores. This contributes to the release of a significant amount of oxygen to the welding site. The result is an increase in temperature and at the same time a decrease in surface tension, which gives it fluidity.

The speed of the welding process increases, but there is a danger of undercuts. Acidic electrodes pose some danger because their coating contains manganese oxides, which are toxic. There are brands of acid coated electrodes, but rutile acid coated electrodes are preferred.

Pulp

According to the name, the main element of this type of coating is cellulose. It also includes organic substances in the form of resins. A special feature is that during combustion in a welded arc a significant amount of shielding gas is formed. In this case, little slag is formed.

Cellulose-coated electrodes have the disadvantage of producing hot metal spatters during welding. In addition, the weld metal has low ductility. This is due to the presence of a considerable amount of hydrogen released during the combustion of organic substances.

Existing brands of cellulose-coated electrodes are characterized by a high speed of the welding process. Their advantages include the ability to weld in all positions, even one in which the electrode moves from top to bottom, which is beyond the capabilities of most electrodes. The disadvantages are large spattering of hot metal, the formation of undercuts on the edges, and the rough surface of the resulting seam.

Rutile

This coating contains an element such as natural rutile concentrate. Additives include feldspar and magnesite. Titanium dioxide guarantees easy arc ignition. There is little splashing.

The electrodes have good technological characteristics. The harmfulness of working with them is less than with other electrodes. Another advantage is that the arc can be ignited without direct contact of the electrode with the surface of the part, since the film formed in the crater acts as a conductor. This is of particular importance when welding is carried out with short stitches.

Electrodes can be used to connect even primed surfaces and the seam will not be inferior in strength and reliability. The arc is stable and it is possible to use any type of current. There are practically no splashes of hot metal. The seam is free from pores.

OZZHN-1

Area of use: exclusively cold welding. A constant current of reverse polarity is used. The types of cast iron to be welded are ductile and gray. Before welding, the electrode must be calcined for an hour at a temperature of 350°C. As is the case with other grades of cast iron, the bead should be forged with light blows of a hammer to relieve internal stress in the weld metal. This grade is often used for welding large casting defects and multi-layer surfacing with large volumes of metal. In the latter case, these electrodes must be combined with MNCh-2 or OZCh-3 (the first and intermediate layers are fused with them).

Characteristics and selection criteria

One of the main parameters of welding electrodes is its coating, or rather its composition:

- Rutile coated conductors. This also includes conductors with mixed rutile-based coating. These are the most popular electrodes, characterized by ease of ignition. Used with alternating and direct current in any position.

- With basic coating. Typically used for DC welding. They provide a plastic seam, but are characterized by difficult ignition and increased sensitivity to humidity.

- With a sour coating. Like products with rutile coating, they are used for inverters, however, work in this case must be done in a well-ventilated area.

- For beginners, electrodes of the OZS-12 type are suitable, while UOSI are more related to professional work.

- Manual arc welding involves the use of a welding inverter. The components for this device must be dry and undamaged. They are selected according to the type of inverter, regarding the technical characteristics of this device.

- The weight of one electrode for each individual brand is different, depending on the materials used. The weight of electrodes in a pack according to the standard should be 3 kg, 5 kg and 8 kg for electrodes with a diameter of 2.5 mm, 3-4 mm, 4 mm, respectively.

OK 92.18

The new name for these electrodes is OK Ni-Cl. They have a base coating with a high graphite content. Designed for welding with minimal heating. They operate on both direct and alternating (at the same time reduced) currents. They have proven themselves well in the repair of products made from thin parts (welding damage and defects in gearboxes, pump housings, engine blocks, etc.). Answering the question of which electrodes are suitable for welding cast iron and steel, we note that along with TsCh-4 these are also suitable.

Other selection options

A few more parameters that determine the choice of electrodes for welding. One of the most important indicators is the polarity of the connection, and accordingly the type of current.

If an inverter is used for welding, then you need to understand that it produces direct current. Therefore, connecting the electrode for welding can be done according to two schemes.

- Polarity is straight. The diagram is as follows: minus is connected to the welding electrode, plus to ground.

- The polarity is reversed. Here it’s the other way around: minus to the mass, plus to the holder.

What are the features of each connection scheme? It all depends on the strength of welding of metals. With direct polarity, the metal parts being welded are subject to high heat. With reverse polarity, the heating temperature is not so high. Therefore, when you need to weld two metal sheets of small thickness, it is better to use reverse polarity, which will provide protection against burn-through. In addition, reverse polarity is used when welding products made from high-alloy steels. They are sensitive to high temperatures.

There are three more indicators that you need to pay attention to.

Welding thickness

The diameter of the electrode must be related to the thickness of the parts being welded. That is, these two parameters are interconnected. Here are some ratios.

| Diameter of welding material, mm | Thickness of welded parts, mm |

| 2,5 | 2 |

| 2,5-3 | 3 |

| 3,2-4 | 4-5 |

| 4-5 | 6-12 |

| 5 | 13 |

It is important to choose an electrode by diameter. The thing is that the higher this indicator, the worse the density of the seam, taking into account the ratios in the table. In addition, incorrect selection leads to instability of the welding arc, deterioration of penetration, and an increase in the width of the seam itself.

Another dependence of the diameter of the welding electrode. In this case, it depends on the current strength.

| Diameter of welding material, mm | Welding current strength, A |

| 2 | 55-65 |

| 2,5 | 65-80 |

| 3 | 70-130 |

| 4 | 130-160 |

| 5 | 180-210 |

| 6 | 210-240 |

It turns out that three parameters: current strength, thickness of the metals being welded and electrode diameters are interconnected. Therefore, when answering the question of which electrodes to choose, it is necessary to take this relationship into account. However, we note that the current strength in each category may differ slightly from those presented in the table. MR electrodes with a diameter of 2 mm can be welded at a current of 40 A. SSSI at 30 A. Therefore, before choosing electrodes, be sure to study their characteristics, which are indicated by the manufacturer on the packaging of the welding material.

Types of metals to be welded

Selecting welding materials for the required metals is not always easy, because by eye you can only determine steel, stainless steel, cast iron or non-ferrous metal. It is clear that in addition to steel structures where the electrodes described above are used, in all other cases special welding products are used: for cast iron, for stainless steel, for aluminum and so on.

As for steel products, there are certain difficulties depending on the definition of the type of steel. But if you figure this out, then the question of how to choose the right electrodes will become easier to answer.

- For welding boiling-type steels, you can use any grade with any coating. These steels include: low-carbon and slightly deoxidized.

- For welding semi-quiet steels, it is better to use electrodes with rutile or basic coating.

- For welding structures made of mild steel, which are subject to high dynamic loads, and which are operated at fairly low sub-zero temperatures, it is better to use grades with a basic coating.

The quality of the weld will also be affected by the stability of the arc. Therefore, the electrode you choose must match the type of current you are using. For welding consumables with a basic coating, only direct current is required; for other types, both direct and alternating current can be used. For electrodes with rutile, cellulose and acid coating, which operate from welding transformers, that is, on alternating current, the arc burns stably. This means the seam is of high quality.

As for the welding direction, cellulose-coated electrodes are welded well in the lower position and vertically. Because these electrodes produce a fairly viscous slag and plus the metal of the wire is transferred to the seam in small drops, which allows you to evenly fill the joint between the metal parts. In this regard, the worst weld seam is formed on electrodes with a basic coating.

When there is a question of welding thick-walled products, the technology determines the multilayer nature of the applied seam. Therefore, such a parameter as good slag separation becomes the main one when choosing electrodes. In this regard, electrodes with basic coating again lose out. Let us also add here that welding products of this type require a certain purity of the metals being welded.

How much do electrodes cost for cast iron?

The main factors that determine the cost of this consumable are the brand and country of origin, the type of electrodes, their brand and coating composition. Traditionally, high-quality European and American analogues are considered more expensive - for example, products from such well-known brands as ASPIK or UTP. Excellent consumer properties when working with cast iron are demonstrated by the German-made UTP 86 FN electrode and also by German Capilla brand products. Russian analogues are cheaper, while the quality of modern domestic products is at a high level.

Features of working with electrodes for manual arc welding

When working, remember that electrodes must meet certain standards:

- ensure minimal splashes during operation;

- create a strong, reliable connection;

- maintain a stable electric arc;

- ensure chemical compatibility with the material being joined;

- create conditions for high-quality sutures;

- maintain resistance to the influence of the external environment;

- do not emit highly toxic gases that can harm the health of the welder;

- The melt should evenly cover the surface of the seam.

Welding polarity

Connecting the electrode also has its own nuances.

- To weld thick materials, use a direct polarity connection, when the electrode is connected to the negative terminal of the inverter, and the part to the positive terminal.

- For thin sheets, it is better to use a reverse polarity scheme, when the electrode is connected to the anode, and the part is connected to the minus.

All this can be attributed to the peculiarities of working with electrodes for manual arc welding. Of course, we must not forget about safety precautions. Before performing manual arc welding, it is necessary to learn the rules of electrical safety, and during work have professional protective equipment:

- welder's mask with special glass;

- protective suit;

- shoes without open lacing or boots;

- fire-resistant gloves or leggings.

Where can I buy electrodes for cast iron?

You should buy such products only from well-known manufacturers and trusted suppliers - this is a guarantee of high factory quality and brand reputation. This is precisely the high quality of cast iron electrodes produced by one of the oldest specialized enterprises in Russia – the Magnitogorsk Electrode Plant.

On our website you can buy products at the manufacturer's price. Depending on the brand, the material is perfect for both welding and restoration surfacing. The products have GOST R and sanitary-epidemiological examination certificates.

Stamps

Brands of electrodes for manual arc welding depend on their purpose. There are a considerable number of them, however, you can choose among them those that are suitable for specific jobs. It is necessary that the brands of electrodes for manual arc welding that attract attention are of high quality and provide a good connection.

There are brands of electrodes that are suitable for welding low-alloy steels with low carbon content. These include ANO, SSSI, OZS, VTSS. Such electrodes are among the most popular types of consumables.

For welding products made of alloy steels, including those with increased strength, grades such as ANP, UONI, OZSh-1 are suitable. For surfacing, it is advisable to choose modifications of OZN and OZSh electrodes.

If you are going to join cast iron products, you should pay attention to the OZCh brand. For aluminum parts, OZA and OZANA are suitable. For copper parts and alloys based on it, it is recommended to choose ANC/OZM and OZB. For nickel and its alloys, an OZL-32 electrode is suitable.

If you want to work with electrodes from foreign manufacturers, you should pay attention to the Japanese consumables KOBELCO LB-52U. When used, the result is a high-quality seam.

Electrodes of the Swedish production ESAB UONII also enjoy deserved recognition. When purchasing electrodes, you need to pay attention to the integrity of the packaging.