In our article we will show in detail online the tables and dimensions of ball bearings in millimeters according to GOST. These parts are intermediate links between rotating axes and shafts. They also take on radial or longitudinal loads and transfer them to other parts of the mechanism. With their help, rotation, rocking or regular movement with a low coefficient of friction is ensured.

Kinds

They are classified according to the type of force transmission and the design of the supporting elements (balls, rollers, needles and other complex geometric shapes). All units for this purpose are built on the rolling principle.

Ball ones are divided into:

- • radial;

- • self-centering;

- • supporting;

- • radial contact.

Roller:

- • radial and thrust with cylindrical rolling elements;

- • with conical rotating parts.

How to buy articulated heads in Russia

Branded joint heads, the catalog of which is presented on our website, are high-quality products from well-known world brands that meet the highest requirements for quality and efficiency. Our online store offers a profitable option for retail and wholesale purchase of products, the price of which is always affordable. Our offers will certainly interest you, since we receive our goods directly from the manufacturer and provide an official guarantee. The company can also offer professional assistance in choosing products based on consumer requirements. Delivery of bearings from a warehouse in Moscow is carried out to all regions of Russia, as well as to Belarus and Kazakhstan.

Registry:

Let's look at the technical parameters in more detail.

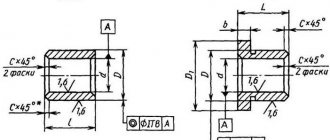

Table of seating dimensions and series of single-row radial ball bearings

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 6003 | 103 | 17 | 35 | 10 | 0,04 | |

| 6004 | 104 | 20 | 42 | 12 | 0,07 | |

| 6005 | 105 | 25 | 47 | 12 | 0,08 | |

| 6006 | 106 | 30 | 55 | 13 | 0,12 | |

| 6007 | 107 | 35 | 62 | 14 | 0,15 | |

| 6008 | 108 | 40 | 68 | 15 | 0,19 | |

| 6009 | 109 | 45 | 75 | 16 | 0,24 | |

| 6010 | 110 | 50 | 80 | 16 | 0,26 | |

| 6011 | 111 | 55 | 90 | 18 | 0,38 | |

| 6012 | 112 | 60 | 95 | 18 | 0,41 | |

| 6013 | 113 | 65 | 100 | 18 | 0,44 | |

| 6014 | 114 | 70 | 110 | 20 | 0,6 | |

| 6015 | 115 | 75 | 115 | 20 | 0,64 | |

| 6016 | 116 | 80 | 125 | 22 | 0,85 | |

| 6017 | 117 | 85 | 130 | 22 | 0,89 | |

| 6018 | 118 | 90 | 140 | 24 | 1,17 | |

| 6019 | 119 | 95 | 145 | 24 | 1,22 | |

| 6020 | 120 | 100 | 150 | 24 | 1,27 | |

| 6021 | 121 | 105 | 160 | 26 | 1,59 | |

| 6022 | 122 | 110 | 170 | 26 | 1,95 |

This type is the most common and is used in mechanisms that have rotating parts: in electric motors, in gearboxes, in belt and chain drives of various sizes, from wristwatches to the power plants of an ocean liner.

The specific markings, table of sizes and numbers of bearings by diameter are the same for all types. They differ in technological features, level of protection and the presence of mounting grooves in the unit.

With one protective washer

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 6003 Z | 60103 | 17 | 35 | 10 | 0,04 | |

| 6004 Z | 60104 | 20 | 42 | 12 | 0,07 | |

| 6005 Z | 60105 | 25 | 47 | 12 | 0,08 | |

| 6006 Z | 60106 | 30 | 55 | 13 | 0,12 | |

| 6007 Z | 60107 | 35 | 62 | 14 | 0,16 | |

| 6008 Z | 60108 | 40 | 68 | 15 | 0,2 | |

| 6009 Z | 60109 | 45 | 75 | 16 | 0,25 | |

| 6010 Z | 60110 | 50 | 80 | 16 | 0,26 | |

| 6011 Z | 60111 | 55 | 90 | 18 | 0,39 | |

| 6012 Z | 60112 | 60 | 95 | 18 | 0,42 | |

| 6013 Z | 60113 | 65 | 100 | 18 | 0,44 | |

| 6014 Z | 60114 | 70 | 110 | 20 | 0,62 | |

| 6015 Z | 60115 | 75 | 115 | 20 | 0,64 |

The parameters and weight of these parts coincide with the data given above. The only difference for ISO is the additional letter z. For example, 6321 Z. According to GOST, the number 60 is placed in front of the number.

With two protective washers

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 6003 ZZ | 80103 | 17 | 35 | 10 | 0,04 | |

| 6004 ZZ | 80104 | 20 | 42 | 12 | 0,07 | |

| 6005 ZZ | 80105 | 25 | 47 | 12 | 0,08 | |

| 6006 ZZ | 80106 | 30 | 55 | 13 | 0,12 | |

| 6007 ZZ | 80107 | 35 | 62 | 14 | 0,16 | |

| 6008 ZZ | 80108 | 40 | 68 | 15 | 0,2 | |

| 6009 ZZ | 8109 | 45 | 75 | 16 | 0,25 | |

| 6010 ZZ | 80110 | 50 | 80 | 16 | 0,26 | |

| 6011 ZZ | 80111 | 55 | 90 | 18 | 0,39 | |

| 6012 ZZ | 80112 | 60 | 95 | 18 | 0,42 | |

| 6013 ZZ | 80113 | 65 | 100 | 18 | 0,44 | |

| 6014 ZZ | 80114 | 70 | 110 | 20 | 0,62 | |

| 6015 ZZ | 80115 | 75 | 115 | 20 | 0,64 | |

| 6016 ZZ | 80116 | 80 | 125 | 22 | 1,86 |

The data for this type of nodes is the same as in the first statement. They only differ in the addition of the symbol ZZ for ISO and for GOST - the additional 80.

With one-sided seal

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 6003RS | 160103 | 17 | 35 | 10 | 0,04 | |

| 6004RS | 160104 | 20 | 42 | 12 | 0,07 | |

| 6005RS | 160105 | 25 | 47 | 12 | 0,08 | |

| 6006RS | 160106 | 30 | 55 | 13 | 0,12 | |

| 6007RS | 160107 | 35 | 62 | 14 | 0,16 | |

| 6008RS | 160108 | 40 | 68 | 15 | 0,2 | |

| 6009RS | 160109 | 45 | 75 | 16 | 0,25 | |

| 6010RS | 160110 | 50 | 80 | 16 | 0,26 | |

| 6011RS | 160111 | 55 | 90 | 18 | 0,39 | |

| 6012RS | 160112 | 60 | 95 | 18 | 0,42 | |

| 6013RS | 160113 | 65 | 100 | 18 | 0,44 | |

| 6014RS | 160114 | 70 | 110 | 20 | 0,62 | |

| 6015RS | 160115 | 75 | 115 | 20 | 0,64 | |

| 6016RS | 160116 | 80 | 125 | 22 | 1,86 | |

| 6017RS | 160113 | 85 | 130 | 22 | 0,89 | |

| 6018RS | 160113 | 90 | 140 | 24 | 1,16 |

The parameters of these nodes coincide with the register above, with the exception of the letters in the ISO marking and the numbers in GOST. Instead of Z, RS is written, and 10 is inserted before the four-digit number.

Double sided

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | D1 mm | a mm | b mm | Weight, kg | Scheme |

| 6003 2RSТ | 750103 | 17 | 35 | 10 | 33,17 | 2,06 | 1,35 | 0,04 | |

| 6004 2RSТ | 750104 | 20 | 42 | 12 | 39,75 | 2,06 | 1,35 | 0,07 | |

| 6005 2RSТ | 750105 | 25 | 47 | 12 | 39,75 | 2,06 | 1,35 | 0,08 | |

| 6006 2RSТ | 750106 | 30 | 55 | 13 | 52,6 | 2,08 | 1,35 | 0,12 | |

| 6007 2RSТ | 750107 | 35 | 62 | 14 | 59,61 | 2,08 | 1,9 | 0,15 | |

| 6008 2RSТ | 750108 | 40 | 68 | 15 | 64,82 | 2,49 | 1,9 | 0,19 | |

| 6009 2RSТ | 750109 | 45 | 75 | 16 | 72,83 | 2,49 | 1,9 | 0,24 | |

| 6010 2RSТ | 750110 | 50 | 80 | 16 | 76,81 | 2,49 | 1,9 | 0,25 | |

| 6011 2RSТ | 750111 | 55 | 90 | 18 | 86,79 | 2,87 | 2,7 | 0,37 | |

| 6012 2RSТ | 750112 | 60 | 95 | 18 | 91,82 | 2,87 | 2,7 | 0,4 |

The data for such parts is analogous to the material given in the previous heading. Only the number 2 is inserted before RS, and 180 is written before the number.

With groove on outer ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | D1 mm | a mm | b mm | Weight, kg | Scheme |

| 6003N | 50103 | 17 | 35 | 10 | 33,17 | 2,06 | 1,35 | 0,04 | |

| 6004 N | 50104 | 20 | 42 | 12 | 39,75 | 2,06 | 1,35 | 0,07 | |

| 6005 N | 50105 | 25 | 47 | 12 | 39,75 | 2,06 | 1,35 | 0,08 | |

| 6006N | 50106 | 30 | 55 | 13 | 52,6 | 2,08 | 1,35 | 0,12 | |

| 6007 N | 50107 | 35 | 62 | 14 | 59,61 | 2,08 | 1,9 | 0,15 | |

| 6008N | 50108 | 40 | 68 | 15 | 64,82 | 2,49 | 1,9 | 0,19 | |

| 6009 N | 50109 | 45 | 75 | 16 | 72,83 | 2,49 | 1,9 | 0,24 | |

| 6010N | 50110 | 50 | 80 | 16 | 76,81 | 2,49 | 1,9 | 0,25 | |

| 6011 N | 50111 | 55 | 90 | 18 | 86,79 | 2,87 | 2,7 | 0,37 | |

| 6012N | 50112 | 60 | 95 | 18 | 91,82 | 2,87 | 2,7 | 0,4 |

The ISO marking says 6003 N, according to GOST 50103.

With groove and one protective washer

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | D1 mm | a mm | b mm | Weight, kg | Scheme |

| 6003 ZN | 150103 | 17 | 35 | 10 | 33,17 | 2,06 | 1,35 | 0,04 | |

| 6004 ZN | 150104 | 20 | 42 | 12 | 39,75 | 2,06 | 1,35 | 0,07 | |

| 6005 ZN | 150105 | 25 | 47 | 12 | 39,75 | 2,06 | 1,35 | 0,08 | |

| 6006 ZN | 150106 | 30 | 55 | 13 | 52,6 | 2,08 | 1,35 | 0,12 | |

| 6007 ZN | 150107 | 35 | 62 | 14 | 59,61 | 2,08 | 1,9 | 0,15 | |

| 6008 ZN | 150108 | 40 | 68 | 15 | 64,82 | 2,49 | 1,9 | 0,19 | |

| 6009 ZN | 150109 | 45 | 75 | 16 | 72,83 | 2,49 | 1,9 | 0,24 | |

| 6010 ZN | 150110 | 50 | 80 | 16 | 76,81 | 2,49 | 1,9 | 0,25 | |

| 6011 ZN | 150111 | 55 | 90 | 18 | 86,79 | 2,87 | 2,7 | 0,37 | |

| 6012 ZN | 150112 | 60 | 95 | 18 | 91,82 | 2,87 | 2,7 | 0,4 | |

| 6013 ZN | 150113 | 65 | 100 | 18 | 96,8 | 2,87 | 2,7 | 0,42 |

Here the designations are as follows: 6003 ZN or 150103.

With groove and two protective washers

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | D1 mm | a mm | b mm | Weight, kg | Scheme |

| 6003 ZZN | 450103 | 17 | 35 | 10 | 33,17 | 2,06 | 1,35 | 0,04 | |

| 6004 ZZN | 450104 | 20 | 42 | 12 | 39,75 | 2,06 | 1,35 | 0,07 | |

| 6005 ZZN | 450105 | 25 | 47 | 12 | 39,75 | 2,06 | 1,35 | 0,08 | |

| 6006 ZZN | 450106 | 30 | 55 | 13 | 52,6 | 2,08 | 1,35 | 0,12 |

ISO – 6003 ZZN, GOST – 450103.

With double seal groove

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 6003 2RS | 180103 | 17 | 35 | 10 | 0,04 | |

| 6004 2RS | 180104 | 20 | 42 | 12 | 0,07 | |

| 6005 2RS | 180105 | 25 | 47 | 12 | 0,08 | |

| 6006 2RS | 180106 | 30 | 55 | 13 | 0,12 | |

| 6007 2RS | 180107 | 35 | 62 | 14 | 0,16 | |

| 6008 2RS | 180108 | 40 | 68 | 15 | 0,2 | |

| 6009 2RS | 18109 | 45 | 75 | 16 | 0,25 | |

| 6010 2RS | 180110 | 50 | 80 | 16 | 0,26 | |

| 6011 2RS | 180111 | 55 | 90 | 18 | 0,39 | |

| 6012 2RS | 180112 | 60 | 95 | 18 | 0,42 | |

| 6013 2RS | 180113 | 65 | 100 | 18 | 0,44 | |

| 6014 2RS | 180114 | 70 | 110 | 20 | 0,62 |

The groove is designated by the letter N, and the seal is designated by RS or 2RS.

Application area

Initially, the design of the rolling apparatus implied the presence of a lubricating device, special safety shields with stuffing box packing, felt or rubber fillers.

The appearance of a ready-to-use mechanism that does not require additional service throughout its entire lifespan has significantly simplified production and reduced maintenance costs. Now all rotation points, if there is no need for constant forced introduction of a sliding solution, are assembled with enclosing bearings.

The operation of such types is provided for by technological features and is used in aggressive conditions, where the equipment is most exposed to non-standard and specific factors:

- • Where evaporation occurs at elevated temperatures, which is caused by humidity.

- • Where fine dust content prevails.

- • Where work is carried out using organic substances (fat, oil).

- • Where the main focus of the industry is directly related to various chemicals.

Most agricultural machinery, motor vehicles, and light industry machines have components that do not require service. Rollers for sports equipment, warehouse equipment (roller or hydraulic trolley), conveyor lines use parts that are prepared for work at the manufacturer. Household and office equipment cannot do without such small-diameter products.

In modern construction tools, such as drills, grinders, screwdrivers, electric and chainsaws, concrete mixers, lawn mowers, vibrating plates, the vast majority of rotating samples are equipped with hidden rolling elements. In a passenger car, this type is used in hubs, a generator, a fan, an air conditioner, a pump, a tension roller, wiper motors, and window regulators.

Angular contact ball bearings

This type provides a reaction in two planes along the axis and perpendicular to it. When using a two-row model, the shaft is fixed in space.

Dimensions in the table of angular contact ball bearings, single-row, one-piece

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 7203B | 66203 | 17 | 40 | 12 | 0,07 | |

| 7204B | 66204 | 20 | 47 | 14 | 0,11 | |

| 7205 B | 166205 | 25 | 52 | 15 | 0,14 | |

| 7206B | 66206 | 30 | 62 | 16 | 0,2 | |

| 7207 B | 66207 | 35 | 62 | 17 | 0,29 | |

| 7208 B | 66208 | 40 | 72 | 18 | 0,37 | |

| 7209 B | 66209 | 45 | 85 | 19 | 0,43 | |

| 7210 B | 66210 | 50 | 90 | 20 | 0,48 | |

| 7211B | 66211 | 55 | 100 | 21 | 0,63 | |

| 7212B | 66212 | 60 | 110 | 22 | 0,81 | |

| 7213B | 66213 | 65 | 120 | 23 | 1 | |

| 7214B | 66214 | 70 | 125 | 24 | 1,1 |

Standard sizes and weights of double-row angular contact ball bearings in the table

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 3203B | 3056203 | 17 | 40 | 17,5 | 0,1 | |

| 3204B | 3056204 | 20 | 47 | 20,6 | 0,17 | |

| 3205B | 3056205 | 25 | 52 | 20,6 | 0,19 | |

| 3206B | 3056206 | 30 | 62 | 23,8 | 0,3 |

Pros and cons of using

The design features of parts directly affect their useful properties and disadvantages. Let's look at them separately.

Rolling

Among the undoubted advantages of this type of device are:

- • Low cost. This factor is especially relevant given that in some complex mechanisms up to several hundred support units can be used simultaneously.

- • Low friction does not lead to serious losses and strong heating. And in general, the supports behave equally well both at the start of operation and in an already established stable operating mode.

- • A wide variety does not exclude the interchangeability of parts, and easy installation allows you to make repairs quickly and efficiently.

- • For normal operation, virtually no lubricants are needed.

- • Overall, much less care and attention is required to the parts in which these products are installed.

On the downside, rolling devices are quite susceptible to shock and vibration loads due to their rigid design. This precludes their use in some machines. In terms of their dimensions, the products that provide rocking are large, and the work takes place in quite a lot of noise.

Slip

Among the advantages of use are:

- • Small size.

- • The design can be either detachable or prefabricated.

- • Performance in high-speed mechanisms is significantly better than that of other devices.

- • They are resistant to shock waves and vibrations, which increases the possibility of operation.

- • Works in the most adverse environmental conditions.

Among the disadvantages are:

- • The need for constant monitoring of the lubricant level, since without it the technical characteristics deteriorate significantly.

- • During start-up, large losses occur.

- • Efficiency is lower than in rolling bearings.

- • Expensive raw materials are used for production, which increases the overall price.

- • Components are produced unevenly, which complicates the maintenance of the entire machine as a whole.

You can search for a bearing by size online, but many other key parameters will still have to be determined additionally. With the right choice, you can ensure stable operation of the machine and reduce the need for maintenance. Sometimes it is better to seek help from professionals who will answer your questions and advise which option to choose.

Thrust ball

This series of parts is designated by two types.

Single

| ISO marking | Analogue GOST | d mm | d1 mm | D mm | D1 mm | T mm | Weight, kg | Scheme |

| 51104 | 8104 | 20 | 35 | 35 | 20,2 | 10 | 0,04 | |

| 51105 | 8105 | 25 | 42 | 42 | 25,2 | 11 | 0,06 | |

| 51106 | 8106 | 30 | 47 | 47 | 30,2 | 11 | 0,07 | |

| 51107 | 8107 | 35 | 52 | 52 | 35,3 | 12 | 0,08 | |

| 51108 | 8108 | 40 | 60 | 60 | 40,2 | 13 | 0,12 | |

| 51109 | 8109 | 45 | 65 | 65 | 45,2 | 14 | 0,15 | |

| 51110 | 8110 | 50 | 70 | 70 | 50,2 | 14 | 0,16 | |

| 51111 | 8111 | 55 | 78 | 78 | 55,2 | 16 | 0,24 | |

| 51112 | 8112 | 60 | 85 | 85 | 60,2 | 17 | 0,29 | |

| 51113 | 8113 | 65 | 90 | 90 | 65,2 | 18 | 0,34 | |

| 51114 | 8114 | 70 | 95 | 95 | 70,2 | 18 | 0,36 | |

| 51115 | 8115 | 75 | 100 | 100 | 75,2 | 19 | 0,42 |

There are no English letters in the ISO marking, and numbers begin with 511. According to the state standard, four-digit numbers with a prefix of 81.

With backing ring

| ISO marking | Analogue GOST | d mm | D mm | d1 mm | D2 mm | D3 mm | C1 mm | R mm | S mm | T mm | Weight, kg | Scheme |

| 53203+U203 | 18203 | 17 | 35 | 35 | 38 | 26 | 4,00 | 32 | 16 | 15 | 0,071 | |

| 53204+U204 | 18204 | 20 | 40 | 40 | 42 | 30 | 5,00 | 36 | 18 | 17 | 0,102 | |

| 53205+U205 | 18205 | 25 | 47 | 47 | 50 | 36 | 5,50 | 40 | 19 | 19 | 0,155 | |

| 53206+U206 | 18206 | 30 | 52 | 52 | 55 | 42 | 5,50 | 45 | 22 | 20 | 0,182 | |

| 53207+U207 | 18207 | 35 | 62 | 62 | 65 | 48 | 7,00 | 50 | 24 | 22 | 0,279 | |

| 53208+U208 | 18208 | 40 | 68 | 68 | 72 | 55 | 7,00 | 56 | 28,5 | 23 | 0,35 | |

| 53209+U209 | 18209 | 45 | 73 | 73 | 78 | 60 | 7,50 | 56 | 26 | 24 | 0,388 | |

| 53210+U210 | 18210 | 50 | 78 | 78 | 82 | 62 | 7,50 | 64 | 32,5 | 26 | 0,464 | |

| 53211+U211 | 18211 | 55 | 90 | 90 | 95 | 72 | 9,00 | 72 | 35 | 30 | 0,752 | |

| 53212+U212 | 18212 | 60 | 95 | 95 | 100 | 78 | 9,00 | 72 | 32,5 | 31 | 0,817 | |

| 53213+U213 | 18213 | 65 | 100 | 100 | 105 | 82 | 9,00 | 80 | 40 | 32 | 0,912 | |

| 53214+U214 | 18214 | 70 | 105 | 105 | 110 | 88 | 9,00 | 80 | 38 | 32 | 0,967 | |

| 53215+U215 | 18215 | 75 | 110 | 110 | 115 | 92 | 9,50 | 90 | 49 | 32 | 1,018 |

Double row thrust ball bearings

| ISO marking | Analogue GOST | d mm | d1 mm | D mm | D1 mm | T mm | S mm | Weight, kg | Scheme |

| 29428 | 9039428 | 140 | 257 | 280 | 198 | 85 | 86 | 24,1 | |

| 29436 | 9039436 | 180 | 342 | 360 | 250 | 109 | 110 | 52,6 | |

| 29452 | 9039452 | 260 | 460 | 480 | 346 | 132 | 154 | 107,8 | |

| 29488 | 9039488 | 440 | 745 | 780 | 576 | 206 | 260 | 413 |

Cylindrical roller bearings

These parts compare favorably with ball parts due to the increased load on the axle. The contact area of the roller is much wider than that of a spherical bearing. Some modifications allow longitudinal displacement along the axis.

We will show tables that can be used to determine the size by bearing number:

Without flanges on the outer ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| N 1007 | 2107 | 35 | 62 | 14 | 0,18 | |

| N 1008 | 2108 | 40 | 68 | 15 | 0,22 | |

| N 1009 | 2109 | 45 | 75 | 16 | 0,29 | |

| N 1110 | 2110 | 50 | 80 | 16 | 0,31 |

With single breasted inner ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| NJ 1034 | 42134 | 170 | 260 | 42 | 8,2 | |

| NJ 1036 | 42136 | 180 | 280 | 46 | 10,1 |

With one built-in and one free flange on the inner ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| NUP 305 | 92305 | 25 | 62 | 17 | 0,24 | |

| NUP 306 | 92306 | 30 | 72 | 19 | 0,36 | |

| NUP 307 | 92307 | 35 | 80 | 21 | 0,48 |

Sealed bearings on one side

160000 – with one seal, d - nominal diameter of the inner ring hole;

D – nominal diameter of the outer cylindrical surface of the outer ring; B is the nominal width of the bearing. These single-row bearings are designated according to GOST 8882-75 (ST SEV 3793-82)

Additionally designated: ball bearings with metal rings (non-contact seal), closed on one side (additional designation Z) and bearings with metal-rubber seals (contact seal), closed on one side (additional designation RS).

Tapered roller bearings

They have the same advantages as cylindrical ones: high load, the ability to disassemble. In addition, they allow you to adjust the gap between the rolling surfaces after working. These include the following types.

Single row

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width T in mm | Weight in kg | Scheme |

| 30204 | 7204 | 20 | 47 | 15,25 | 0,12 | |

| 30205 | 7205 | 25 | 52 | 16,25 | 0,15 | |

| 30206 | 7206 | 30 | 62 | 17,25 | 0,24 |

With a large cone angle

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width T in mm | Weight in kg | Scheme |

| — | 27305 | 25 | 62 | 18,25 | 0,26 | |

| — | 27306 | 30 | 72 | 20,75 | 0,39 | |

| — | 27307 | 35 | 80 | 12,75 | 0,52 |

Double row

| ISO marking | Analogue GOST | Inner diameter mm | Outer diameter mm | Width T in mm | Width B in mm | Weight in kg | Scheme |

| — | 9716 | 340 | 520 | 180 | 135 | 118 | |

| — | 9717 | 360 | 540 | 185 | 140 | 132 | |

| — | 9718 | 380 | 560 | 189 | 141 | 169 |

Four-row

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width T in mm | Width B in mm | Weight in kg | Scheme |

| — | 2077140 | 200 | 310 | 275 | 10 | 75,8 | |

| — | 2077144 | 220 | 340 | 305 | 10 | 10,4 | |

| — | 2077148 | 240 | 360 | 310 | 10 | 108,7 |

Selection of bearings according to parameters

The technical characteristics of the products are not limited to the listed values. The choice is influenced by many other data:

- • The maximum magnitude of the load by its nature and direction. Some parts can only handle radial and axial pressure, while others can handle mixed loads successfully.

- • Number of maintained revolutions per minute. The best performance here is characteristic of nodal rolling bearings.

- • Accuracy class, on which the rotation of the device, and hence the overall operation of the structure, depends.

- • Type of lubricant used (liquid, gas, etc.).

- • The moment of fatigue, that is, the maximum service life of the product.

- • Noise and vibration levels.

- • The actual dimensions, which have already been discussed earlier.

It is also important to take into account the operating conditions of the bearing, including temperature conditions, the ability to use it in water and other features. It can be difficult for the average person to decide on a specific type of support, and the selection form on the Internet is very limited and does not take into account most of the listed parameters. So it can be difficult to do without additional consultation from specialists, especially if the product is purchased to operate an expensive machine.

Spherical roller bearings

They combine the ability to withstand high loads and have a deviation in the axes of landing and rotation. They are also called self-centering.

Double-row with sides on the inner ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 22208 | 3508 | 40 | 80 | 23 | 0,58 | |

| 22209 | 3509 | 45 | 85 | 23 | 0,6 | |

| 22210 | 3510 | 50 | 90 | 23 | 0,65 |

With beadless inner ring

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 22208 | 53508 | 40 | 80 | 23 | 0,58 | |

| 22209 | 53509 | 45 | 85 | 23 | 0,6 | |

| 22210 | 53510 | 50 | 90 | 23 | 0,65 |

Spherical double-row with sides on the inner ring with a landing cone 1:12

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 22208 CCK | 153508 | 40 | 80 | 23 | 0,58 | |

| 22209 CCK | 153509 | 45 | 85 | 23 | 0,6 | |

| 22210 CCK | 153510 | 50 | 90 | 23 | 0,65 | |

| 22211 CCK | 153511 | 55 | 100 | 25 | 0,88 | |

| 22212 CCK | 153512 | 60 | 110 | 28 | 1,2 |

Spherical double-row with sides on the inner ring with a cone 1:30

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 24024 K30 | 4113124 | 120 | 180 | 60 | 5,4 | |

| 24026 K30 | 4113126 | 130 | 200 | 69 | 7,95 | |

| 24028 K30 | 4113128 | 140 | 210 | 69 | 8,45 | |

| 24030 K30 | 4113130 | 150 | 225 | 75 | 10,5 |

Spherical double-row with a beadless ring with a hole with a taper of 1:30

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 24024 CCK30 | 4153124 | 120 | 180 | 60 | 5,4 | |

| 24026 CCK30 | 4153126 | 130 | 200 | 69 | 7,95 | |

| 24028 CCK30 | 4153128 | 140 | 210 | 69 | 8,45 | |

| 24030 CCK30 | 4153130 | 150 | 225 | 75 | 10,5 |

Flatbed with inner ring with seat cone 1:12

| ISO marking | Analogue GOST | Inner diameter d mm | Outer diameter D mm | Width in mm | Weight in kg | Scheme |

| 22208 CCK | 153508 | 40 | 80 | 23 | 0,58 | |

| 22209 CCK | 153509 | 45 | 85 | 23 | 0,6 | |

| 22210 CCK | 153510 | 50 | 90 | 23 | 0,65 | |

| 22211 CCK | 153511 | 55 | 100 | 25 | 0,88 |

Thrust spherical single row

| ISO marking | Analogue GOST | d mm | d 1 mm | D mm | D 1 mm | T mm | S mm | Weight in kg | Scheme |

| 29428 | 9039428 | 140 | 257 | 280 | 198 | 85 | 86 | 24,1 | |

| 29436 | 9039436 | 180 | 342 | 360 | 255 | 109 | 110 | 52,6 | |

| 29452 | 9039452 | 260 | 460 | 480 | 346 | 132 | 154 | 107,8 |

Sliding: performance characteristics, advantages and disadvantages

Their design is different from rolling because in fact the two main parts (rings) do not roll on rollers, but slide against each other. The result is an increased area of friction, which consequently makes this force much greater. This is the main disadvantage that is attached to the product. If there is not enough lubricant, the metal will heat up, which can lead to failure.

Let's consider the advantages and disadvantages of the product.

Pros:

- At high rotation speeds they are very reliable, so they are used for turbines, aircraft construction and other important areas. This is ensured by the fact that the rolling body (ball) cannot jump out of the system at high speeds. In fact, this is a very primitive design, and the simpler it is, the fewer malfunctions can occur.

- The large area of the contacting surface leads to the fact that vibrations have little effect on it. This is also ensured by a dense layer of oil. This layer makes any shocks and vibration interference virtually unnoticeable.

- Small radial dimensions.

- It fits perfectly with the crankshaft, attaches to its journal and transmits torque.

There are also disadvantages:

- It loses in the classification of bearings by type of friction, because the mechanism rubs a lot, especially during start-up or low speeds. The metal heats up, its qualities are lost, and it may begin to crack or wear off.

- Wear is higher than that of the rolling unit, replacement is required more often.

- To function, the lubricant must be constantly replenished. This can be either automatic or manual.

Performance characteristics and structure

The inner sleeve, that is, a ring of smaller diameter, is usually created from a material with anti-friction properties. They have a low coefficient of friction, which partially eliminates the problem of all sliding mechanisms. The body is made of steel. It fits tightly onto the bushing. The small gap between them is intended to allow lubricant to flow there. The system assumes automatic feeding. The layer of this liquid is determined depending on pressure, temperature and actual flow.

Based on the type of sliding bearings and their application, the degree of friction can be determined:

- dry;

- borderline;

- hydrodynamic;

- gas-dynamic.

The first ones are most susceptible to rapid wear. It should also be taken into account that during a number of actions, for example, when starting or turning off, during slow rotation, all products belong to the second type, that is, they are at their maximum capabilities.

The durability of the unit is affected not only by operating conditions, but also by the nature of the lubricant used. Its functions are as follows:

- cooling, because when moving, heat is generated, and if there is excess heat, all nearby metal parts can be damaged;

- removal of friction force;

- protection of the part from external influences - not only dust particles and other contaminants, but also moisture can have a negative impact;

- rust prevention.

Another classification is based on the types of thrust sliding bearings based on the lubricant used. It can be dry, classic wet, gas or plastic. The most innovative development is the use of porous metal. This material has pores. It is as if impregnated with a dry substance, which changes its state of aggregation when heated. From the first movements, when the structure heats up, liquid begins to ooze out of small holes in the metal casing or in the bushing. After work, cooling occurs, and at the same time the lubricant returns to a powdery state.

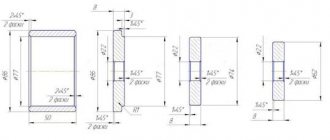

Let's look at the product image:

But the proposed structure with a powder that changes its properties when heated is rather an exception to the rule. This is a difficult device that requires the use of expensive materials. Two other subspecies are considered classics. Types of plain bearings and their purpose, application, depending on the supply of lubricant:

- hydrostatic - it is necessary to maintain the liquid level from the outside, the mechanism receives a request for a low amount of liquid, this is implemented by other structures;

- hydrodynamic - more modern and original, their distinctive feature is that they themselves control the pressure as they rotate, when it becomes lower than it should be, the pump automatically fires, the container supplied from the outside begins to compress, transferring the required amount of lubricant.

And the last classification is the definition of design features. The body can rotate around different bushings. Bearings can be:

- Spherical. The sphere inside has significant deviations from the plane, so skew during movement is allowed. But the effectiveness will be confirmed only at low speeds. If you are tall, you definitely need strong support.

- Persistent. They only support axial loads.

- Linear. This type of bearing is installed in fans and other systems where classic circular rotation is required.

Now let's look at less general product classifications.

Plain bearings

This unit does not have rolling elements. Its characteristics are as follows: the inner and outer cages are made along the same radius. Therefore, the axis, relative to the mandrel, has several degrees of freedom. Most often they are used in articulated joints.

Plain bearings with a hole and grooves for lubrication in the inner ring with a single-break ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10 EC | ESHSP 10 | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 EC | ESHSP 12 | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15 EC | ESHSP 15 | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 EC | ESHSP 17 | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

With double-break outer ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 20 EXC | ShSL 20 | 20 | 35 | 16 | 12 | 9 | 24 | 29 | 0,07 | |

| GEH 20 EXC | 2ShSL 20 | 20 | 47 | 26 | 15 | 22 | 23 | 35 | 0,19 | |

| GE 25 EXC | ShSL 25 | 25 | 42 | 20 | 16 | 7 | 29 | 35 | 0,12 | |

| GEH 25 EXC | 2ShSL 25 | 25 | 52 | 28 | 15 | 22 | 28 | 40 | 0,26 |

With holes and grooves in the inner ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10 C | ESH 10 | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 C | ShS 12 | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15 C | ESH 15 | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 C | ESH 17 | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

With grooves on inner and outer rings

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10 S | ESH 10K | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 S | ShS 12K | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15 S | ESH 15K | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 S | ESH 17K | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

Without holes and grooves with single break ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10 E | ESR 10 | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 E | ShP 12 | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15 E | ESR 15 | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 E | ESR 17 | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

With holes and grooves on outer and inner rings with single break ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10ES | ESHSP 10 | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 ES | ShSP 12 | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15ES | ESHP 15 | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 ES | ESHSP 17 | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

With double-break outer ring

| Alternative ISO markings | Analogue GOST | d mm | D mm | B mm | C mm | Rotation angle deg | d1 mm | d2 mm | Weight in kg | Scheme |

| GE 10 EXS | ESHSL 10 | 10 | 19 | 9 | 6 | 12 | 13 | 16 | 0,01 | |

| GE 12 EXS | ShSL 12 | 12 | 22 | 10 | 7 | 10 | 18 | 10 | 0,02 | |

| GE 15 EXS | ESHSL 15 | 15 | 26 | 12 | 9 | 8 | 18 | 22 | 0,04 | |

| GE 17 EXS | ESHL 17 | 17 | 30 | 14 | 10 | 10 | 20 | 25 | 0,05 |

Below we provide tables of closed sizes of rolling and sliding ball bearings.

Bearings are sealed on both sides

180000 – with two seals;

d - nominal diameter of the hole of the inner ring; D – nominal diameter of the outer cylindrical surface of the outer ring; B is the nominal width of the bearing. Designation according to GOST 8882-75 (ST SEV 3793-82)

Additionally designated: ball bearings with metal rings (non-contact seal) closed on both sides (additional designation 2Z) and bearings with metal-rubber seals (contact seal) (additional designation 2RS).

Compared to sealed bearings on one side, this type of bearing is more versatile and can be installed in places where there is a possibility of contamination on either side.

Needle Bearing Size Chart

| International designation | Russian designation (GOST) | Dimensions (mm) | Load capacity (kN) | Weight (kg) | ||||

| d | Fw | D | B | Dynamic | Static | |||

| NK 32/20 | 524706 | 32 | 32 | 42 | 20 | 23,3 | 40,5 | 0,068 |

| RNA 49/28 | 42549/28 | 32 | 32 | 45 | 17 | 25,1 | 36,5 | 0,073 |

| RNA 69/28 | 62549/28 | 32 | 32 | 45 | 30 | 39,6 | 65,5 | 0,14 |

Plain bearings

| International designation | Russian designation (GOST) | Dimensions (mm) | Load capacity (kN) | Weight (kg) | ||||

| d | Fw | D | B | Dynamic | Static | |||

| RNA 4010V | 4024110 | 62 | 62 | 80 | 30 | 59,6 | 153 | 0,44 |

| RNA 4911 | 4254911 | 63 | 63 | 80 | 25 | 57,2 | 106 | 0,26 |

| RNA 6911 | 6254911 | 63 | 63 | 80 | 45 | 89,7 | 190 | 0,47 |

Thrust-radial roller

| International designation | GOST | Dimensions (mm) | Weight (g) | ||||

| d | D | de | De | Bx | |||

| AXK 2035 | 999904 | 20 | 35 | 22 | 34 | 2 | 5 |

| AXK 2542 | 999905 | 25 | 42 | 29 | 41 | 2 | 7 |

| AXK 3047 | 219806 | 30 | 47 | 34 | 46 | 2 | 8 |

Table fields

They display the names of the main parameters and their geometric dimensions.

ISO marking

It is standard for most countries of the world, which indicates the number and design features.

GOST

It is a Russian analogue and performs the same functions.

Node internal diameter

It is measured in millimeters (mm) and is designated by the English letter d.

Outside diameter

Denoted as D.

Width

Measured in mm and identified by a capital B.

Weight

The measure is in kilograms (kg).

Scheme

Explains the basic structure.

Manufacturers

The popularity of units is growing, so all manufacturers in the world are trying to master the production of such products. Models from Japanese brands NTN and NSK, German LFD, FBJ from China, and many other countries come to our market.

Russian EPK and GPP are represented by:

- • Moscow numbered 1 and 2.

- • Saratov Plant for No. 3.

- • Samara instrument making plants.

- • Tomsk OJSC “Roltom” – 5.

- • Yekaterinburg Gas Processing Plant 6.

In total, there are 28 large enterprises in Russia that produce such products. Active construction began in the thirties of the last century. During the Second World War they were evacuated with all their equipment beyond the Urals. After the Victory, they began to develop the industry in these northern regions, where to this day they successfully work for the benefit of the national economy.

The biography is very extensive, gas processing plants are located not only in Siberia, but also located in Rostov-on-Don, Kursk, Penza, Vologda, Samara, in the Kurgan and Volgograd regions. In addition, enterprises in post-Soviet countries such as Kazakhstan, the Republic of Belarus, and Ukraine do not stop operating. Trade and production sells a wide range of rolling units designed for manual hydraulic trolleys and stackers. We have given detailed recommendations on how to open, disassemble and replace the grease in a closed bearing and why this should be done.

Product sizing

In everyday life or production, these parameters are measured with certain tools: calipers, micrometers, bore gauges.

External Diameter Measurement

Manufacturing parameters are maintained quite accurately. Therefore, you should not trust the readings of a caliper. If it shows a non-standard value, then the real data will be the closest indicators indicated in the register.

How to measure the inner diameter of a product

Construction stores sell a special device called a bore gauge. But it is better to take the closest number from the classic report card as the true value.

Advantages

The advantages include:

- • Products delivered from the factory are immediately ready for use.

- • Long service life.

- • Can be used in conditions of heavy dust and precipitation.

- • The sliding zone is permanently sealed and therefore no leakage of safety material occurs.

- • Short-term use with complete immersion in water is acceptable. In this case, the fluid is removed without consequences for the node.

- The temperature regime of its use will depend on what kind of lubricant to fill a closed bearing with. For example, if you use “Ciatim”, then heating more than 100 degrees will not lead to leakage and increased wear.