Connection sizes for plumbing fixtures, taps, ½ and ¾ hoses - how do I know which one I need?

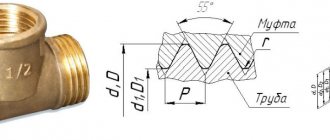

For example, the connecting size of the mixer is ¾.

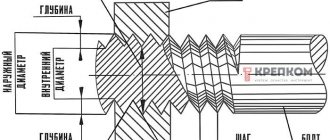

For pipes and other plumbing components, the measurement taken as a basis is from an inch to 25.4 mm. And it’s not so easy to express everything in millimeters. For example, ½ is a 15 mm pipe, and ¾ is 20 mm, an inch is clear 25 mm, an inch and a quarter is 32 mm. All this is along the flow section of the pipe. Even more complexities in carvings. There is a count of the number of threads per inch of length - 12, 14, 16, 18, depending on the diameter.

But there is no need to bother you with these difficulties. On faucets and other fittings it is written: ( 15 ) is ½ inch, (20) is ¾ inch.

For me, like for everyone, it was absolutely not clear what these fractions were in the notation, I had to figure it out.

For our country, sometimes designations of connections such as ½ and ¾ are sometimes not clear to everyone, but here everything depends on experience and general development, since these sizes have long taken root in the country in various areas of production, from plumbing structures to complex devices.

So, in Russia, the metric measure is mainly used in connecting structures, so the most common connection - bolts and nuts, have sizes M6, M8, M10, M12, M14, etc. The letter M indicates that measurements are in the Metric system, and the number indicates the diameter in millimeters.

But in addition to the metric system, which by the way is used in most countries (about 90%), there is also an inch unit of measurement. In Russia, this system is allowed in industry indefinitely.

It is the inch system that is widely used in plumbing, namely in designating connections and measuring the diameter of pipes. The most common designations are ½", ¾", 1″.

½ pipes are installed throughout the house/apartment, ¾ pipes are usually used to the apartment, and 1″ pipes to the house (if it is not large).

But still, let's figure out what exactly these numbers mean.

So, the designation ½ means that the thread size is ½", but in fact the nominal diameter of the pipe in metric measure will be equal to 15 millimeters, the external thread, or rather its outer diameter, is 20.955 millimeters, and the outer diameter of the pipe is 21.3 millimeters, but People commonly refer to ½ pipe as 20 (twenty), i.e. our craftsmen rounded this size to 20.

Now about the designation ¾, this means that the size of the threaded connection on the pipe is ¾", but in fact the nominal diameter of the pipe in metric measure will be equal to 20 millimeters, the external thread, or rather its outer diameter, is 26.441 millimeters, and the outer diameter of the pipe is 26, 8 millimeters.

But absolutely no one needs all these conversions into millimeters, and no one uses them, these numbers do not express either the internal or external diameters of the pipe, the only thing they are tied to is the nominal diameter.

Yes, by the way, ½ and ¾ are not even an inch, and they don’t even translate into an inch, it’s, to put it more clearly, a pipe inch.

Documentation that regulates threaded connections on pipes under the numbers: GOST 3262, GOST 6357.

Types of steel pipes according to their production method

Electric welded (straight seam)For their manufacture, strips or sheet steel are used, which are bent to the required diameter using special equipment, and then the ends are connected by welding. The effect of electric welding guarantees a minimum seam width, which makes it possible to use them for the construction of gas or water pipelines

The metal is in most cases carbon or low alloy. The indicators of finished products are regulated by the following documents: GOST 10704-91, GOST 10705-80 GOST 10706-76. Please note that a pipe manufactured in accordance with standard 10706-26 is distinguished by the maximum strength among its peers - after creating the first connecting seam, it is reinforced with four additional ones (2 inside and 2 outside). The regulatory documentation indicates the diameters of products produced by electric welding. Their size ranges from 10 to 1420 mm.

Spiral weldedThe material for production is steel in rolls

The product is also characterized by the presence of a seam, but unlike the previous production method, it is wider, which means the ability to withstand high internal pressure is lower. Therefore, they are not used for the construction of gas pipeline systems. The specific type of pipes is regulated by GOST number 8696-74.

SeamlessProduction of a specific type involves the deformation of specially prepared steel blanks. The deformation process can be carried out both under the influence of high temperatures and in a cold way (GOST 8732-78, 8731-74 and GOST 8734-75, respectively). The absence of a seam has a positive effect on the strength characteristics - the internal pressure is evenly distributed over the walls (there are no “weak” places). As for diameters, standards control their production with a value of up to 250 mm. When purchasing products with sizes exceeding those indicated, you have to rely only on the integrity of the manufacturer.

Here are a couple more excellent slides of creative advertising for a pipe manufacturer:

About calculating cross-country ability

You can use a simple formula to determine the required internal Ø.

, with which water moves through polypropylene pipes. The parameter value is selected depending on the following conditions:

- For thin ones – 0.7-1.2 m/s

- For fat people - 1.5-2 meters per second.

This difference has its own explanation. The smaller the diameter of the structure, the smaller the ratio between surface and clearance. If the water supply pipe is too thin, the volume of water passing through it is inhibited by the walls.

A lower speed value is used when choosing pipes with a polypropylene base Ø from 10 to 25 millimeters. A larger value is necessary in the case of an indicator equal to 32 millimeters or more.

Video: REHAU pipes, copper, metal-plastic or polypropylene for water supply and heating

Where are squeegees used and installed?

Squeegees are used in water supply systems, heating systems, gas pipelines, they are installed:

- In water supply and heating lines after the valve on the riser. This allows the shut-off valves to be removed from the pipeline in the event of a malfunction for repair or replacement.

- When connecting old-style cast iron pipes to a heating radiator, their use also allows you to clean the pipeline from lime deposits and rust.

- For the supply line when connecting autonomous equipment for heating water - gas boilers, boilers, expansion tanks and plumbing fittings (faucets with a herringbone connector).

- On the pipeline for supplying gas to household and water heating equipment - stoves, boilers.

- Sometimes surges are used in sections of the system to obtain additional outlet, while the coupling is replaced with a tee, and the distance between the pipes is increased.

Conformity between metric and inch sizes

Knowing the dimensions of a steel plumbing system, you can understand what sizes of plastic elements should be used instead of metal ones. To do this, you need to multiply the inch size by 25.4 (1 inch = 25.4 mm). This will give you the inner diameter of the plastic pipe. Then you should select the type of pipe that is closest in value. In this case, you should choose the size in the upward direction. For example, for a 3/4″ size, when converted to mm, we get 19.05 mm. From the table we see that 2 sizes are located closely: 16.6 mm and 21.2 mm. We choose a larger one, that is, a pipe with an outer diameter of 32 mm.

When going to the store, you don’t have to stock up on calipers or a ruler to select the required size of products. Just read the labeling of plastic water pipes. At first glance, the inscription looks like a meaningless collection of letters and numbers, but it is not so. The markings indicate:

- manufacturer (graphic logo);

- product type;

- nominal pressure (alphanumeric designation starting with PN);

- pipe dimensions in mm (outer Ø x wall thickness);

- operating class;

- maximum operating pressure in MPa;

- regulatory document, for example TU or GOST.

To determine the correspondence between metric and inch sizes, you can use the table:

Inch ØMetal-plasticPolypropylenePVC1/21620203/420252512632321 1/43240401 1/2405050

Only the diameter is specified in inches. To indicate the lengths of sections, slopes, center distances, etc., the value in millimeters is used.

Requested dimensions

When laying communications in multi-apartment residential buildings and public buildings, standard pipe sizes are used:

- 1/2″ for wiring inside bathrooms and kitchens;

- 3/4″ and 1″ for heating risers;

- 1¼" and 1½" for water supply risers.

When using metal-plastic:

- 16 mm for wiring;

- 20 and 25 mm for heating;

- 32 and 40 mm for risers.

When choosing polypropylene and PVC:

- 20 mm - water supply;

- 25 and 32 mm - heating;

- 40 and 50 mm - risers.

Larger pipelines are used only for distributing various pipelines in basements, attics and technical rooms.

Thread sizes for pipe threads are always specified in inches. Markings on various fittings, such as taps, couplings, extensions, may indicate dimensions in inches and mm. For example, the inscription on the extension (½" 45) means: thread diameter - ½", length - 45 mm.

Conformity between metric and inch sizes

Knowing the dimensions of a steel plumbing system, you can understand what sizes of plastic elements should be used instead of metal ones. To do this, you need to multiply the inch size by 25.4 (1 inch = 25.4 mm). This will give you the inner diameter of the plastic pipe. Then you should select the type of pipe that is closest in value. In this case, you should choose the size in the upward direction. For example, for a 3/4″ size, when converted to mm, we get 19.05 mm. From the table we see that 2 sizes are located closely: 16.6 mm and 21.2 mm. We choose a larger one, that is, a pipe with an outer diameter of 32 mm.

When going to the store, you don’t have to stock up on calipers or a ruler to select the required size of products. Just read the labeling of plastic water pipes. At first glance, the inscription looks like a meaningless collection of letters and numbers, but it is not so. The markings indicate:

- manufacturer (graphic logo);

- product type;

- nominal pressure (alphanumeric designation starting with PN);

- pipe dimensions in mm (outer Ø x wall thickness);

- operating class;

- maximum operating pressure in MPa;

- regulatory document, for example TU or GOST.

To determine the correspondence between metric and inch sizes, you can use the table:

| Inch Ø | Metal-plastic | Polypropylene | PVC |

| 1/2 | 16 | 20 | 20 |

| 3/4 | 20 | 25 | 25 |

| 1 | 26 | 32 | 32 |

| 1 1/4 | 32 | 40 | 40 |

| 1 1/2 | 40 | 50 | 50 |

Only the diameter is specified in inches. To indicate the lengths of sections, slopes, center distances, etc., the value in millimeters is used.

Requested dimensions

When laying communications in multi-apartment residential buildings and public buildings, standard pipe sizes are used:

- 1/2″ for wiring inside bathrooms and kitchens;

- 3/4″ and 1″ for heating risers;

- 1¼" and 1½" for water supply risers.

When using metal-plastic:

- 16 mm for wiring;

- 20 and 25 mm for heating;

- 32 and 40 mm for risers.

When choosing polypropylene and PVC:

- 20 mm - water supply;

- 25 and 32 mm - heating;

- 40 and 50 mm - risers.

Larger pipelines are used only for distributing various pipelines in basements, attics and technical rooms.

Thread sizes for pipe threads are always specified in inches. Markings on various fittings, such as taps, couplings, extensions, may indicate dimensions in inches and mm. For example, the inscription on the extension (½" 45) means: thread diameter - ½", length - 45 mm.

Classification according to the composition of raw materials: reinforced and others

Three main groups of polymer pipelines are presented, differing in technical characteristics.

- RRV. This type is used for underfloor heating. These polypropylene pipes are used for water supply (for cold water). Characterized by special resistance to impact. The property is achieved by the structure of the polymer, the molecules of which are different in structure and are built according to a certain principle.

- RRN. They are mainly used in industry for sewerage, drainage, cold outdoor water supply, and ventilation systems. They are characterized by impact resistance, and by adding specific additives to the raw material, they acquire antistatic and other required properties. This type is characterized by large sizes of polypropylene pipes. Products with a low melting point, which is why they are not used for heating systems.

- PPR. Most often used in residential construction. Used for heating, water supply, sewerage. They are resistant to temperature fluctuations, the permissible lower limit is -170 degrees, the upper limit is 1400. Products are produced with a diameter of 16 to 110 mm. The molecules of the material have a crystalline structure.

How to install the flow into the system

Steel connecting couplings for installation and installation of water pipelines installed after valves are installed in compliance with the following rules:

- Fittings must have a clearance length between pipes of no more than 5 mm. taking into account the recess of the side with a short thread into the connected equipment or fittings.

- On the side with a thread of at least 20 threads in length, a steel lock nut and a coupling are screwed in succession.

- Flax fiber or thread is wound along the thread

- When installing, flax fiber is wound on the short side, lubricated with a special paste, and the drive pipe is screwed into the outlet pipe of the valve manually, and then pressed with a gas wrench. For convenience, use a second key to hold the valve body with it to avoid turning on the pipeline.

Rice. 5 Steel connecting parts according to GOST 8965-75

- Screw the connecting parts onto the long side: the locknut until it stops and the coupling; flax is wound onto the connected pipe along the thread.

- Drive the long coupling down and screw it onto the pipe, pressing it with a gas wrench.

- Wind flax fiber from the other end of the coupling, coat it with paste and tighten the locknut.

It is necessary to understand that the winding from the other end does not fall under the thread of the coupling, therefore the sealing and sealing of the connection will be carried out by squeezing the fiber with a locknut. Therefore, a larger number of turns of flax fiber should be wound so that the locknut fits the coupling or there is a small gap between them (no more than 1 mm) after strong tightening with a large applied force.